Spindle Definition In Machine . Spindle is a very important part of a cnc machining center. In machine tool spindle design, choosing the right type of spindle is key to achieving the best performance for your specific application. The shaft at the center of a machine tool’s rotating axis applies the torque, speed, and accuracy required for. Spindles rotate on the axis which receives input on movement from the cnc controller. Let’s dive into the four main types of spindles:. Typically, there is a shaft that holds the tool together, a motor, and a taper used to. In cnc machining, the spindle is the heart of the machine. Let’s dive into what makes these. A spindle is a rotating component that is used to hold and rotate a workpiece or tool in a machine. It’s what turns your tool or workpiece, making all the cutting, drilling, and milling possible. A cnc spindle is the backbone of cnc machines. It is commonly used in manufacturing processes such as milling, drilling, and turning.

from mavink.com

In machine tool spindle design, choosing the right type of spindle is key to achieving the best performance for your specific application. Typically, there is a shaft that holds the tool together, a motor, and a taper used to. A spindle is a rotating component that is used to hold and rotate a workpiece or tool in a machine. It’s what turns your tool or workpiece, making all the cutting, drilling, and milling possible. Let’s dive into what makes these. The shaft at the center of a machine tool’s rotating axis applies the torque, speed, and accuracy required for. It is commonly used in manufacturing processes such as milling, drilling, and turning. Spindles rotate on the axis which receives input on movement from the cnc controller. A cnc spindle is the backbone of cnc machines. In cnc machining, the spindle is the heart of the machine.

Lathe Spindle Types

Spindle Definition In Machine A cnc spindle is the backbone of cnc machines. A cnc spindle is the backbone of cnc machines. In machine tool spindle design, choosing the right type of spindle is key to achieving the best performance for your specific application. It is commonly used in manufacturing processes such as milling, drilling, and turning. In cnc machining, the spindle is the heart of the machine. Let’s dive into the four main types of spindles:. Let’s dive into what makes these. A spindle is a rotating component that is used to hold and rotate a workpiece or tool in a machine. Spindle is a very important part of a cnc machining center. Typically, there is a shaft that holds the tool together, a motor, and a taper used to. The shaft at the center of a machine tool’s rotating axis applies the torque, speed, and accuracy required for. It’s what turns your tool or workpiece, making all the cutting, drilling, and milling possible. Spindles rotate on the axis which receives input on movement from the cnc controller.

From www.stylecnc.com

A Practical Guide To CNC Router Spindles Spindle Definition In Machine The shaft at the center of a machine tool’s rotating axis applies the torque, speed, and accuracy required for. A spindle is a rotating component that is used to hold and rotate a workpiece or tool in a machine. Spindle is a very important part of a cnc machining center. Spindles rotate on the axis which receives input on movement. Spindle Definition In Machine.

From www.visumatic.com

MultiSpindle Components Visumatic Industrial Products Spindle Definition In Machine Spindle is a very important part of a cnc machining center. Let’s dive into the four main types of spindles:. Spindles rotate on the axis which receives input on movement from the cnc controller. The shaft at the center of a machine tool’s rotating axis applies the torque, speed, and accuracy required for. It is commonly used in manufacturing processes. Spindle Definition In Machine.

From www.smartlathe.com

Overview of Electric Builtin Spindles Used in CNC Lathe Tools Spindle Definition In Machine Let’s dive into the four main types of spindles:. It’s what turns your tool or workpiece, making all the cutting, drilling, and milling possible. It is commonly used in manufacturing processes such as milling, drilling, and turning. In cnc machining, the spindle is the heart of the machine. Typically, there is a shaft that holds the tool together, a motor,. Spindle Definition In Machine.

From www.researchgate.net

Structure of aerostatic spindle (a) machine tool, (b) spindle, and (c Spindle Definition In Machine The shaft at the center of a machine tool’s rotating axis applies the torque, speed, and accuracy required for. Typically, there is a shaft that holds the tool together, a motor, and a taper used to. Let’s dive into the four main types of spindles:. Spindle is a very important part of a cnc machining center. In cnc machining, the. Spindle Definition In Machine.

From www.youtube.com

What is a CNC Spindle? As the Spindle Turns YouTube Spindle Definition In Machine Typically, there is a shaft that holds the tool together, a motor, and a taper used to. In machine tool spindle design, choosing the right type of spindle is key to achieving the best performance for your specific application. It’s what turns your tool or workpiece, making all the cutting, drilling, and milling possible. The shaft at the center of. Spindle Definition In Machine.

From www.cncsupport.co.uk

SCM Prisma 5 Axis CNC Machine Spindle Repair Machinery service and Spindle Definition In Machine It is commonly used in manufacturing processes such as milling, drilling, and turning. A cnc spindle is the backbone of cnc machines. In machine tool spindle design, choosing the right type of spindle is key to achieving the best performance for your specific application. It’s what turns your tool or workpiece, making all the cutting, drilling, and milling possible. Spindles. Spindle Definition In Machine.

From www.sandvik.coromant.com

How to a choose spindle Spindle Definition In Machine A cnc spindle is the backbone of cnc machines. A spindle is a rotating component that is used to hold and rotate a workpiece or tool in a machine. Typically, there is a shaft that holds the tool together, a motor, and a taper used to. The shaft at the center of a machine tool’s rotating axis applies the torque,. Spindle Definition In Machine.

From www.millscnc.co.uk

TwoSpindle Machining Centres Mills CNC Spindle Definition In Machine Typically, there is a shaft that holds the tool together, a motor, and a taper used to. Spindles rotate on the axis which receives input on movement from the cnc controller. It is commonly used in manufacturing processes such as milling, drilling, and turning. In cnc machining, the spindle is the heart of the machine. A spindle is a rotating. Spindle Definition In Machine.

From www.colonialtool.com

Belt Driven Spindle Machine Spindle Colonial Tool Spindle Definition In Machine Let’s dive into what makes these. It is commonly used in manufacturing processes such as milling, drilling, and turning. In cnc machining, the spindle is the heart of the machine. The shaft at the center of a machine tool’s rotating axis applies the torque, speed, and accuracy required for. Let’s dive into the four main types of spindles:. A spindle. Spindle Definition In Machine.

From www.ctemag.com

The ins and outs of machine tool spindle maintenance Cutting Tool Spindle Definition In Machine In cnc machining, the spindle is the heart of the machine. Spindle is a very important part of a cnc machining center. Spindles rotate on the axis which receives input on movement from the cnc controller. A spindle is a rotating component that is used to hold and rotate a workpiece or tool in a machine. Let’s dive into the. Spindle Definition In Machine.

From www.colonialtool.com

Machine Tool Spindles Colonial Tool Spindle Definition In Machine It’s what turns your tool or workpiece, making all the cutting, drilling, and milling possible. Spindles rotate on the axis which receives input on movement from the cnc controller. A cnc spindle is the backbone of cnc machines. In machine tool spindle design, choosing the right type of spindle is key to achieving the best performance for your specific application.. Spindle Definition In Machine.

From www.youtube.com

TwinSpindle Machining at Absolute Machine Tools YouTube Spindle Definition In Machine Spindle is a very important part of a cnc machining center. Typically, there is a shaft that holds the tool together, a motor, and a taper used to. A cnc spindle is the backbone of cnc machines. It is commonly used in manufacturing processes such as milling, drilling, and turning. Let’s dive into what makes these. In machine tool spindle. Spindle Definition In Machine.

From www.machinistguides.com

CNC Spindle Controls Explained [M03, M04, M05 and More Spindle Definition In Machine Spindle is a very important part of a cnc machining center. Spindles rotate on the axis which receives input on movement from the cnc controller. Let’s dive into the four main types of spindles:. It is commonly used in manufacturing processes such as milling, drilling, and turning. A cnc spindle is the backbone of cnc machines. The shaft at the. Spindle Definition In Machine.

From boringresearch.com

Spindle Square & Tramming Tool Boring Research LLC Spindle Definition In Machine It is commonly used in manufacturing processes such as milling, drilling, and turning. Typically, there is a shaft that holds the tool together, a motor, and a taper used to. A cnc spindle is the backbone of cnc machines. Let’s dive into what makes these. In machine tool spindle design, choosing the right type of spindle is key to achieving. Spindle Definition In Machine.

From www.smartlathe.com

Overview of Electric Builtin Spindles Used in CNC Lathe Tools Spindle Definition In Machine Let’s dive into the four main types of spindles:. It is commonly used in manufacturing processes such as milling, drilling, and turning. In cnc machining, the spindle is the heart of the machine. A cnc spindle is the backbone of cnc machines. It’s what turns your tool or workpiece, making all the cutting, drilling, and milling possible. Spindle is a. Spindle Definition In Machine.

From www.youtube.com

Spindle assembly YouTube Spindle Definition In Machine The shaft at the center of a machine tool’s rotating axis applies the torque, speed, and accuracy required for. Spindles rotate on the axis which receives input on movement from the cnc controller. Typically, there is a shaft that holds the tool together, a motor, and a taper used to. A cnc spindle is the backbone of cnc machines. In. Spindle Definition In Machine.

From www.researchgate.net

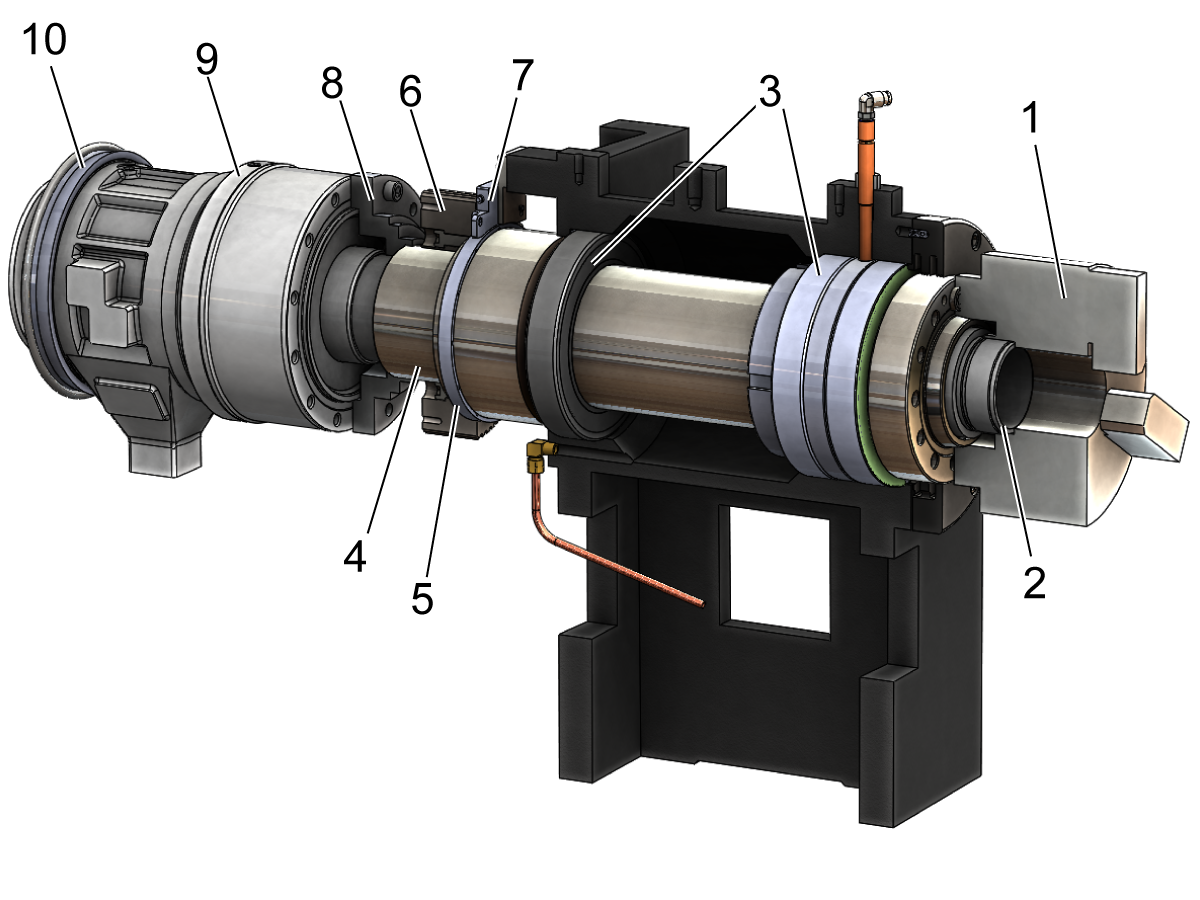

The motorized spindle system Download Scientific Diagram Spindle Definition In Machine Spindle is a very important part of a cnc machining center. The shaft at the center of a machine tool’s rotating axis applies the torque, speed, and accuracy required for. In cnc machining, the spindle is the heart of the machine. A spindle is a rotating component that is used to hold and rotate a workpiece or tool in a. Spindle Definition In Machine.

From asaphardwoodfloors.blogspot.com

Spindle Spindle Cnc Axis Chronos Scm Machine Routech Machinery Spindle Definition In Machine In cnc machining, the spindle is the heart of the machine. It’s what turns your tool or workpiece, making all the cutting, drilling, and milling possible. Spindles rotate on the axis which receives input on movement from the cnc controller. Spindle is a very important part of a cnc machining center. Let’s dive into the four main types of spindles:.. Spindle Definition In Machine.

From www.semanticscholar.org

Design and development of a lathe spindle Semantic Scholar Spindle Definition In Machine A spindle is a rotating component that is used to hold and rotate a workpiece or tool in a machine. In cnc machining, the spindle is the heart of the machine. Spindles rotate on the axis which receives input on movement from the cnc controller. The shaft at the center of a machine tool’s rotating axis applies the torque, speed,. Spindle Definition In Machine.

From encyclopedia.pub

HighSpeed Motorized Spindles of CNC Machine Tools Encyclopedia MDPI Spindle Definition In Machine In cnc machining, the spindle is the heart of the machine. Let’s dive into what makes these. A cnc spindle is the backbone of cnc machines. It’s what turns your tool or workpiece, making all the cutting, drilling, and milling possible. In machine tool spindle design, choosing the right type of spindle is key to achieving the best performance for. Spindle Definition In Machine.

From www.muller-england.co.uk

Repeatability in MultiSpindle Machining The Benefits Muller England Spindle Definition In Machine In machine tool spindle design, choosing the right type of spindle is key to achieving the best performance for your specific application. The shaft at the center of a machine tool’s rotating axis applies the torque, speed, and accuracy required for. Spindle is a very important part of a cnc machining center. Typically, there is a shaft that holds the. Spindle Definition In Machine.

From textileapex.blogspot.com

What is ring spindle? Essential qualities of a spindle Inverter Spindle Definition In Machine It’s what turns your tool or workpiece, making all the cutting, drilling, and milling possible. In machine tool spindle design, choosing the right type of spindle is key to achieving the best performance for your specific application. A spindle is a rotating component that is used to hold and rotate a workpiece or tool in a machine. Spindles rotate on. Spindle Definition In Machine.

From www.metramh.com

Multi Spindle Automatic Lathe New Times! CNC Machines Multi Spindle Definition In Machine Let’s dive into the four main types of spindles:. Typically, there is a shaft that holds the tool together, a motor, and a taper used to. Spindles rotate on the axis which receives input on movement from the cnc controller. It’s what turns your tool or workpiece, making all the cutting, drilling, and milling possible. A cnc spindle is the. Spindle Definition In Machine.

From www.benztooling.com

BENZ multispindle heads for multiple machining operations Spindle Definition In Machine Let’s dive into the four main types of spindles:. A cnc spindle is the backbone of cnc machines. It is commonly used in manufacturing processes such as milling, drilling, and turning. In machine tool spindle design, choosing the right type of spindle is key to achieving the best performance for your specific application. It’s what turns your tool or workpiece,. Spindle Definition In Machine.

From www.colonialtool.com

Machine Tool Spindles Colonial Tool Spindle Definition In Machine In cnc machining, the spindle is the heart of the machine. Let’s dive into what makes these. Typically, there is a shaft that holds the tool together, a motor, and a taper used to. Let’s dive into the four main types of spindles:. Spindle is a very important part of a cnc machining center. It’s what turns your tool or. Spindle Definition In Machine.

From www.colonialtool.com

Machine Spindle Design Spindle Design Colonial Tool Spindle Definition In Machine In cnc machining, the spindle is the heart of the machine. A spindle is a rotating component that is used to hold and rotate a workpiece or tool in a machine. Spindles rotate on the axis which receives input on movement from the cnc controller. The shaft at the center of a machine tool’s rotating axis applies the torque, speed,. Spindle Definition In Machine.

From ksp-group.ir

Khavaran Sanat Pasargad Spindle Definition In Machine In cnc machining, the spindle is the heart of the machine. In machine tool spindle design, choosing the right type of spindle is key to achieving the best performance for your specific application. It is commonly used in manufacturing processes such as milling, drilling, and turning. Let’s dive into what makes these. Let’s dive into the four main types of. Spindle Definition In Machine.

From www.youtube.com

Machine Definition Setting up Max Spindle RPMs YouTube Spindle Definition In Machine In cnc machining, the spindle is the heart of the machine. A spindle is a rotating component that is used to hold and rotate a workpiece or tool in a machine. Spindles rotate on the axis which receives input on movement from the cnc controller. Let’s dive into what makes these. It’s what turns your tool or workpiece, making all. Spindle Definition In Machine.

From mziprecision.com

Getting to Know Your Machine Tool Spindle MZI Precision Spindle Definition In Machine The shaft at the center of a machine tool’s rotating axis applies the torque, speed, and accuracy required for. Typically, there is a shaft that holds the tool together, a motor, and a taper used to. It is commonly used in manufacturing processes such as milling, drilling, and turning. Spindle is a very important part of a cnc machining center.. Spindle Definition In Machine.

From www.colonialtool.com

Machine Spindle Design Spindle Design Colonial Tool Spindle Definition In Machine In machine tool spindle design, choosing the right type of spindle is key to achieving the best performance for your specific application. The shaft at the center of a machine tool’s rotating axis applies the torque, speed, and accuracy required for. It’s what turns your tool or workpiece, making all the cutting, drilling, and milling possible. Typically, there is a. Spindle Definition In Machine.

From www.schuette.de

MultiSpindle Machines Schütte Spindle Definition In Machine In machine tool spindle design, choosing the right type of spindle is key to achieving the best performance for your specific application. Typically, there is a shaft that holds the tool together, a motor, and a taper used to. A cnc spindle is the backbone of cnc machines. Let’s dive into what makes these. Spindle is a very important part. Spindle Definition In Machine.

From mavink.com

Lathe Spindle Types Spindle Definition In Machine Spindles rotate on the axis which receives input on movement from the cnc controller. It is commonly used in manufacturing processes such as milling, drilling, and turning. A cnc spindle is the backbone of cnc machines. Spindle is a very important part of a cnc machining center. Let’s dive into the four main types of spindles:. Typically, there is a. Spindle Definition In Machine.

From exobashxu.blob.core.windows.net

Spindle Def Definition at Lucy blog Spindle Definition In Machine A spindle is a rotating component that is used to hold and rotate a workpiece or tool in a machine. Spindle is a very important part of a cnc machining center. It is commonly used in manufacturing processes such as milling, drilling, and turning. The shaft at the center of a machine tool’s rotating axis applies the torque, speed, and. Spindle Definition In Machine.

From spindlerepair.com

Spindles for Metalworking Spindles for Metal Fabrication Spindle Definition In Machine The shaft at the center of a machine tool’s rotating axis applies the torque, speed, and accuracy required for. In machine tool spindle design, choosing the right type of spindle is key to achieving the best performance for your specific application. It is commonly used in manufacturing processes such as milling, drilling, and turning. Spindles rotate on the axis which. Spindle Definition In Machine.

From www.youtube.com

HomeMade Lathe Part 1 spindle forces explained static, dynamic (radial Spindle Definition In Machine A spindle is a rotating component that is used to hold and rotate a workpiece or tool in a machine. Spindles rotate on the axis which receives input on movement from the cnc controller. In cnc machining, the spindle is the heart of the machine. The shaft at the center of a machine tool’s rotating axis applies the torque, speed,. Spindle Definition In Machine.