Cooling Water Requirement For Chiller . in general, chiller capacity is calculated using the heat transfer formula q = mcθ where q is the chiller capacity, m is. requirement parameters are: Mold temperature controllers = 1.2 ton per zone. Estimated chiller size required (tons): o remove heat from zone or process loads. all evaporative, recirculating cooling water systems require a qualified water treatment professional to provide chemicals to. 3) chilled water supply inlet 14.8 degc and return outlet 8 degc. 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; required chill water temperature (fahrenheit): We have developed and adopted numerous “rules of thumb” to assist our customers in their quest for cost effective, efficient industrial cooling solutions. calculations for chiller tonnage in the plastics industry are based on a coolant temperature of 50°f (lwt), with. 2) current chiller design 35 kw;

from waterchillerorukono.blogspot.com

calculations for chiller tonnage in the plastics industry are based on a coolant temperature of 50°f (lwt), with. required chill water temperature (fahrenheit): all evaporative, recirculating cooling water systems require a qualified water treatment professional to provide chemicals to. 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; Estimated chiller size required (tons): requirement parameters are: Mold temperature controllers = 1.2 ton per zone. We have developed and adopted numerous “rules of thumb” to assist our customers in their quest for cost effective, efficient industrial cooling solutions. 3) chilled water supply inlet 14.8 degc and return outlet 8 degc. o remove heat from zone or process loads.

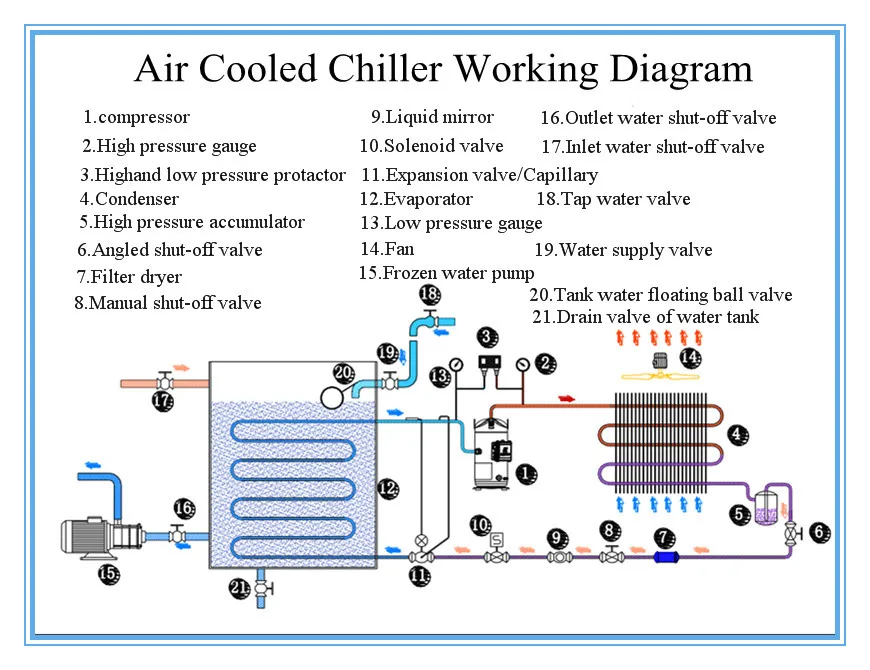

Water Chiller Air Cooled Water Chiller Diagram

Cooling Water Requirement For Chiller calculations for chiller tonnage in the plastics industry are based on a coolant temperature of 50°f (lwt), with. in general, chiller capacity is calculated using the heat transfer formula q = mcθ where q is the chiller capacity, m is. 3) chilled water supply inlet 14.8 degc and return outlet 8 degc. Mold temperature controllers = 1.2 ton per zone. required chill water temperature (fahrenheit): requirement parameters are: calculations for chiller tonnage in the plastics industry are based on a coolant temperature of 50°f (lwt), with. o remove heat from zone or process loads. 2) current chiller design 35 kw; 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; all evaporative, recirculating cooling water systems require a qualified water treatment professional to provide chemicals to. Estimated chiller size required (tons): We have developed and adopted numerous “rules of thumb” to assist our customers in their quest for cost effective, efficient industrial cooling solutions.

From www.senho-chiller.com

Industrial Water Chiller Manufacturers Industrial Water Chiller SENHO Cooling Water Requirement For Chiller requirement parameters are: We have developed and adopted numerous “rules of thumb” to assist our customers in their quest for cost effective, efficient industrial cooling solutions. 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; 2) current chiller design 35 kw; required chill water temperature (fahrenheit): o remove heat from zone or. Cooling Water Requirement For Chiller.

From www.youtube.com

How Air and Water Cooled Chillers Work YouTube Cooling Water Requirement For Chiller 2) current chiller design 35 kw; o remove heat from zone or process loads. Mold temperature controllers = 1.2 ton per zone. requirement parameters are: We have developed and adopted numerous “rules of thumb” to assist our customers in their quest for cost effective, efficient industrial cooling solutions. 1) heat circulating water from ambient inlet 27 degc to. Cooling Water Requirement For Chiller.

From wiringfixdictaphone.z21.web.core.windows.net

Piping Of A Water Cooled Chiller System Cooling Water Requirement For Chiller requirement parameters are: calculations for chiller tonnage in the plastics industry are based on a coolant temperature of 50°f (lwt), with. Estimated chiller size required (tons): 3) chilled water supply inlet 14.8 degc and return outlet 8 degc. 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; Mold temperature controllers = 1.2 ton. Cooling Water Requirement For Chiller.

From atelier-yuwa.ciao.jp

How Air And Water Cooled Chillers Work atelieryuwa.ciao.jp Cooling Water Requirement For Chiller required chill water temperature (fahrenheit): Mold temperature controllers = 1.2 ton per zone. 2) current chiller design 35 kw; all evaporative, recirculating cooling water systems require a qualified water treatment professional to provide chemicals to. in general, chiller capacity is calculated using the heat transfer formula q = mcθ where q is the chiller capacity, m is.. Cooling Water Requirement For Chiller.

From hvactrainingshop.com

How a Chilled Water System Works HVAC Training Shop Cooling Water Requirement For Chiller Mold temperature controllers = 1.2 ton per zone. We have developed and adopted numerous “rules of thumb” to assist our customers in their quest for cost effective, efficient industrial cooling solutions. required chill water temperature (fahrenheit): all evaporative, recirculating cooling water systems require a qualified water treatment professional to provide chemicals to. 3) chilled water supply inlet 14.8. Cooling Water Requirement For Chiller.

From usermanualadjuvant.z1.web.core.windows.net

Chiller And Cooling Tower Schematic Cooling Water Requirement For Chiller Mold temperature controllers = 1.2 ton per zone. requirement parameters are: 2) current chiller design 35 kw; 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; We have developed and adopted numerous “rules of thumb” to assist our customers in their quest for cost effective, efficient industrial cooling solutions. calculations for chiller tonnage. Cooling Water Requirement For Chiller.

From www.cibsejournal.com

Module 132 Predicting the efficiency of water chillers for building Cooling Water Requirement For Chiller in general, chiller capacity is calculated using the heat transfer formula q = mcθ where q is the chiller capacity, m is. Mold temperature controllers = 1.2 ton per zone. 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; 3) chilled water supply inlet 14.8 degc and return outlet 8 degc. calculations for. Cooling Water Requirement For Chiller.

From www.alfalaval.dk

Free cooling with water Alfa Laval Cooling Water Requirement For Chiller all evaporative, recirculating cooling water systems require a qualified water treatment professional to provide chemicals to. 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; 2) current chiller design 35 kw; calculations for chiller tonnage in the plastics industry are based on a coolant temperature of 50°f (lwt), with. required chill water. Cooling Water Requirement For Chiller.

From theengineeringmindset.com

Chiller Cooling Capacity How to calculate The Engineering Mindset Cooling Water Requirement For Chiller Estimated chiller size required (tons): We have developed and adopted numerous “rules of thumb” to assist our customers in their quest for cost effective, efficient industrial cooling solutions. requirement parameters are: 2) current chiller design 35 kw; 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; 3) chilled water supply inlet 14.8 degc and. Cooling Water Requirement For Chiller.

From www.kidde.com

AquaEdge® 19DV WaterCooled Centrifugal Chiller Carrier Commercial Cooling Water Requirement For Chiller requirement parameters are: 2) current chiller design 35 kw; We have developed and adopted numerous “rules of thumb” to assist our customers in their quest for cost effective, efficient industrial cooling solutions. Estimated chiller size required (tons): 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; required chill water temperature (fahrenheit): o. Cooling Water Requirement For Chiller.

From waterchillerorukono.blogspot.com

Water Chiller Air Cooled Water Chiller Diagram Cooling Water Requirement For Chiller 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; in general, chiller capacity is calculated using the heat transfer formula q = mcθ where q is the chiller capacity, m is. requirement parameters are: required chill water temperature (fahrenheit): o remove heat from zone or process loads. Estimated chiller size required. Cooling Water Requirement For Chiller.

From tandemchillers.com

Water Cooled Chillers for Cooling Office and Apartment Buildings Cooling Water Requirement For Chiller 3) chilled water supply inlet 14.8 degc and return outlet 8 degc. Estimated chiller size required (tons): requirement parameters are: 2) current chiller design 35 kw; all evaporative, recirculating cooling water systems require a qualified water treatment professional to provide chemicals to. Mold temperature controllers = 1.2 ton per zone. in general, chiller capacity is calculated using. Cooling Water Requirement For Chiller.

From www.linquip.com

Water Chiller System and the Essential things You Should Know about it Cooling Water Requirement For Chiller required chill water temperature (fahrenheit): in general, chiller capacity is calculated using the heat transfer formula q = mcθ where q is the chiller capacity, m is. all evaporative, recirculating cooling water systems require a qualified water treatment professional to provide chemicals to. calculations for chiller tonnage in the plastics industry are based on a coolant. Cooling Water Requirement For Chiller.

From buildingutilities.blogspot.com

Building Utilities Water Cooled Chiller Schematic Diagram Cooling Water Requirement For Chiller 2) current chiller design 35 kw; calculations for chiller tonnage in the plastics industry are based on a coolant temperature of 50°f (lwt), with. all evaporative, recirculating cooling water systems require a qualified water treatment professional to provide chemicals to. Estimated chiller size required (tons): requirement parameters are: in general, chiller capacity is calculated using the. Cooling Water Requirement For Chiller.

From www.acr-news.com

Daikin Applied extends watercooled chiller range Cooling Water Requirement For Chiller o remove heat from zone or process loads. We have developed and adopted numerous “rules of thumb” to assist our customers in their quest for cost effective, efficient industrial cooling solutions. Estimated chiller size required (tons): Mold temperature controllers = 1.2 ton per zone. calculations for chiller tonnage in the plastics industry are based on a coolant temperature. Cooling Water Requirement For Chiller.

From waterchillerorukono.blogspot.com

Water Chiller Air Cooled Water Chiller Diagram Cooling Water Requirement For Chiller in general, chiller capacity is calculated using the heat transfer formula q = mcθ where q is the chiller capacity, m is. all evaporative, recirculating cooling water systems require a qualified water treatment professional to provide chemicals to. We have developed and adopted numerous “rules of thumb” to assist our customers in their quest for cost effective, efficient. Cooling Water Requirement For Chiller.

From constructandcommission.com

WATER COOLED CHILLER Checklist Cooling Water Requirement For Chiller 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; Estimated chiller size required (tons): 3) chilled water supply inlet 14.8 degc and return outlet 8 degc. calculations for chiller tonnage in the plastics industry are based on a coolant temperature of 50°f (lwt), with. requirement parameters are: required chill water temperature (fahrenheit):. Cooling Water Requirement For Chiller.

From scychiller.com

How To Choose The Cooling Tower For Your Water Chiller? » Industrial Cooling Water Requirement For Chiller Estimated chiller size required (tons): required chill water temperature (fahrenheit): 2) current chiller design 35 kw; all evaporative, recirculating cooling water systems require a qualified water treatment professional to provide chemicals to. 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; Mold temperature controllers = 1.2 ton per zone. requirement parameters are:. Cooling Water Requirement For Chiller.

From www.researchgate.net

Watercooled chiller diagram and the measurement points. Download Cooling Water Requirement For Chiller 3) chilled water supply inlet 14.8 degc and return outlet 8 degc. 2) current chiller design 35 kw; in general, chiller capacity is calculated using the heat transfer formula q = mcθ where q is the chiller capacity, m is. We have developed and adopted numerous “rules of thumb” to assist our customers in their quest for cost effective,. Cooling Water Requirement For Chiller.

From jmpcoblog.com

How To Size A Waterside Economizer Part 4 Chilled Water Piping Cooling Water Requirement For Chiller requirement parameters are: all evaporative, recirculating cooling water systems require a qualified water treatment professional to provide chemicals to. Mold temperature controllers = 1.2 ton per zone. o remove heat from zone or process loads. 2) current chiller design 35 kw; calculations for chiller tonnage in the plastics industry are based on a coolant temperature of. Cooling Water Requirement For Chiller.

From www.researchgate.net

Cooling Water Quality Requirements Download Table Cooling Water Requirement For Chiller 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; required chill water temperature (fahrenheit): 3) chilled water supply inlet 14.8 degc and return outlet 8 degc. We have developed and adopted numerous “rules of thumb” to assist our customers in their quest for cost effective, efficient industrial cooling solutions. requirement parameters are: . Cooling Water Requirement For Chiller.

From exoupisqh.blob.core.windows.net

Water Cooled Chiller Dwg at Edward Hoffmann blog Cooling Water Requirement For Chiller Mold temperature controllers = 1.2 ton per zone. in general, chiller capacity is calculated using the heat transfer formula q = mcθ where q is the chiller capacity, m is. We have developed and adopted numerous “rules of thumb” to assist our customers in their quest for cost effective, efficient industrial cooling solutions. all evaporative, recirculating cooling water. Cooling Water Requirement For Chiller.

From www.hvacinvestigators.com

WaterCooled Chiller Diagram HVAC Investigators Cooling Water Requirement For Chiller 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; 2) current chiller design 35 kw; required chill water temperature (fahrenheit): in general, chiller capacity is calculated using the heat transfer formula q = mcθ where q is the chiller capacity, m is. calculations for chiller tonnage in the plastics industry are based. Cooling Water Requirement For Chiller.

From www.waterchillersystems.com

What’s the difference between a water cooled chiller and air cooled Cooling Water Requirement For Chiller We have developed and adopted numerous “rules of thumb” to assist our customers in their quest for cost effective, efficient industrial cooling solutions. o remove heat from zone or process loads. Mold temperature controllers = 1.2 ton per zone. Estimated chiller size required (tons): 2) current chiller design 35 kw; in general, chiller capacity is calculated using the. Cooling Water Requirement For Chiller.

From amcon.com.my

The Ultimate Guide to Industrial Chillers 2022 AMCON Cooling Water Requirement For Chiller Estimated chiller size required (tons): in general, chiller capacity is calculated using the heat transfer formula q = mcθ where q is the chiller capacity, m is. o remove heat from zone or process loads. 2) current chiller design 35 kw; 3) chilled water supply inlet 14.8 degc and return outlet 8 degc. 1) heat circulating water from. Cooling Water Requirement For Chiller.

From www.cibsejournal.com

Module 132 Predicting the efficiency of water chillers for building Cooling Water Requirement For Chiller required chill water temperature (fahrenheit): in general, chiller capacity is calculated using the heat transfer formula q = mcθ where q is the chiller capacity, m is. all evaporative, recirculating cooling water systems require a qualified water treatment professional to provide chemicals to. calculations for chiller tonnage in the plastics industry are based on a coolant. Cooling Water Requirement For Chiller.

From www.spotweldingconsultants.com

Schreiber Chillers, Koolant Koolers Water Chiller Cooling Water Requirement For Chiller required chill water temperature (fahrenheit): calculations for chiller tonnage in the plastics industry are based on a coolant temperature of 50°f (lwt), with. 3) chilled water supply inlet 14.8 degc and return outlet 8 degc. 2) current chiller design 35 kw; 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; requirement parameters. Cooling Water Requirement For Chiller.

From exoupisqh.blob.core.windows.net

Water Cooled Chiller Dwg at Edward Hoffmann blog Cooling Water Requirement For Chiller 2) current chiller design 35 kw; We have developed and adopted numerous “rules of thumb” to assist our customers in their quest for cost effective, efficient industrial cooling solutions. all evaporative, recirculating cooling water systems require a qualified water treatment professional to provide chemicals to. in general, chiller capacity is calculated using the heat transfer formula q =. Cooling Water Requirement For Chiller.

From maximuschillers.com

Water Cooled Chillers Service, Maintenance and Repair Cooling Water Requirement For Chiller 3) chilled water supply inlet 14.8 degc and return outlet 8 degc. 2) current chiller design 35 kw; Estimated chiller size required (tons): 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; We have developed and adopted numerous “rules of thumb” to assist our customers in their quest for cost effective, efficient industrial cooling solutions.. Cooling Water Requirement For Chiller.

From instrumentationtools.com

️ Working Principle of Water Chillers Inst Tools Cooling Water Requirement For Chiller in general, chiller capacity is calculated using the heat transfer formula q = mcθ where q is the chiller capacity, m is. 2) current chiller design 35 kw; o remove heat from zone or process loads. Estimated chiller size required (tons): 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; Mold temperature controllers. Cooling Water Requirement For Chiller.

From www.cool-chiller.com

Water chiller system, chilled water system COOLSOON Water Chillers Cooling Water Requirement For Chiller 3) chilled water supply inlet 14.8 degc and return outlet 8 degc. requirement parameters are: all evaporative, recirculating cooling water systems require a qualified water treatment professional to provide chemicals to. 2) current chiller design 35 kw; Mold temperature controllers = 1.2 ton per zone. required chill water temperature (fahrenheit): Estimated chiller size required (tons): We have. Cooling Water Requirement For Chiller.

From aircondlounge.com

Chiller Efficiency Calculation kW/Ton, COP, EER & IPLV/NPLV Cooling Water Requirement For Chiller 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; 2) current chiller design 35 kw; required chill water temperature (fahrenheit): in general, chiller capacity is calculated using the heat transfer formula q = mcθ where q is the chiller capacity, m is. calculations for chiller tonnage in the plastics industry are based. Cooling Water Requirement For Chiller.

From ar.inspiredpencil.com

Water Cooled Chiller Working Principle Cooling Water Requirement For Chiller all evaporative, recirculating cooling water systems require a qualified water treatment professional to provide chemicals to. 1) heat circulating water from ambient inlet 27 degc to supply outlet 60 degc; We have developed and adopted numerous “rules of thumb” to assist our customers in their quest for cost effective, efficient industrial cooling solutions. calculations for chiller tonnage in. Cooling Water Requirement For Chiller.

From www.youtube.com

AirCooled vs WaterCooled Chillers and how they work with Air Handling Cooling Water Requirement For Chiller all evaporative, recirculating cooling water systems require a qualified water treatment professional to provide chemicals to. o remove heat from zone or process loads. Estimated chiller size required (tons): requirement parameters are: calculations for chiller tonnage in the plastics industry are based on a coolant temperature of 50°f (lwt), with. 3) chilled water supply inlet 14.8. Cooling Water Requirement For Chiller.

From www.frigel.com

Modular Chillers Centralized or Cascade Cooling Systems Frigel Cooling Water Requirement For Chiller calculations for chiller tonnage in the plastics industry are based on a coolant temperature of 50°f (lwt), with. all evaporative, recirculating cooling water systems require a qualified water treatment professional to provide chemicals to. in general, chiller capacity is calculated using the heat transfer formula q = mcθ where q is the chiller capacity, m is. . Cooling Water Requirement For Chiller.