Countersinking Angle . Countersink bits come in different angles, commonly 82 degrees and 90 degrees. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. Common countersink angles include 82°, 90°, and 100°. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. The angle of the countersink bit should match the angle of the screw head. It’s essential to design countersink holes that adhere to ansi or iso standards. These standards dictate the correct angle and diameter for. Countersinks are available with points shaped to create six distinct chamfer angles — 60°, 82°, 90°, 100°, 110° and 120° —. Choose the angle that matches the.

from www.walmart.com

The angle of the countersink bit should match the angle of the screw head. Common countersink angles include 82°, 90°, and 100°. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. It’s essential to design countersink holes that adhere to ansi or iso standards. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Countersinks are available with points shaped to create six distinct chamfer angles — 60°, 82°, 90°, 100°, 110° and 120° —. Countersink bits come in different angles, commonly 82 degrees and 90 degrees. These standards dictate the correct angle and diameter for. Choose the angle that matches the.

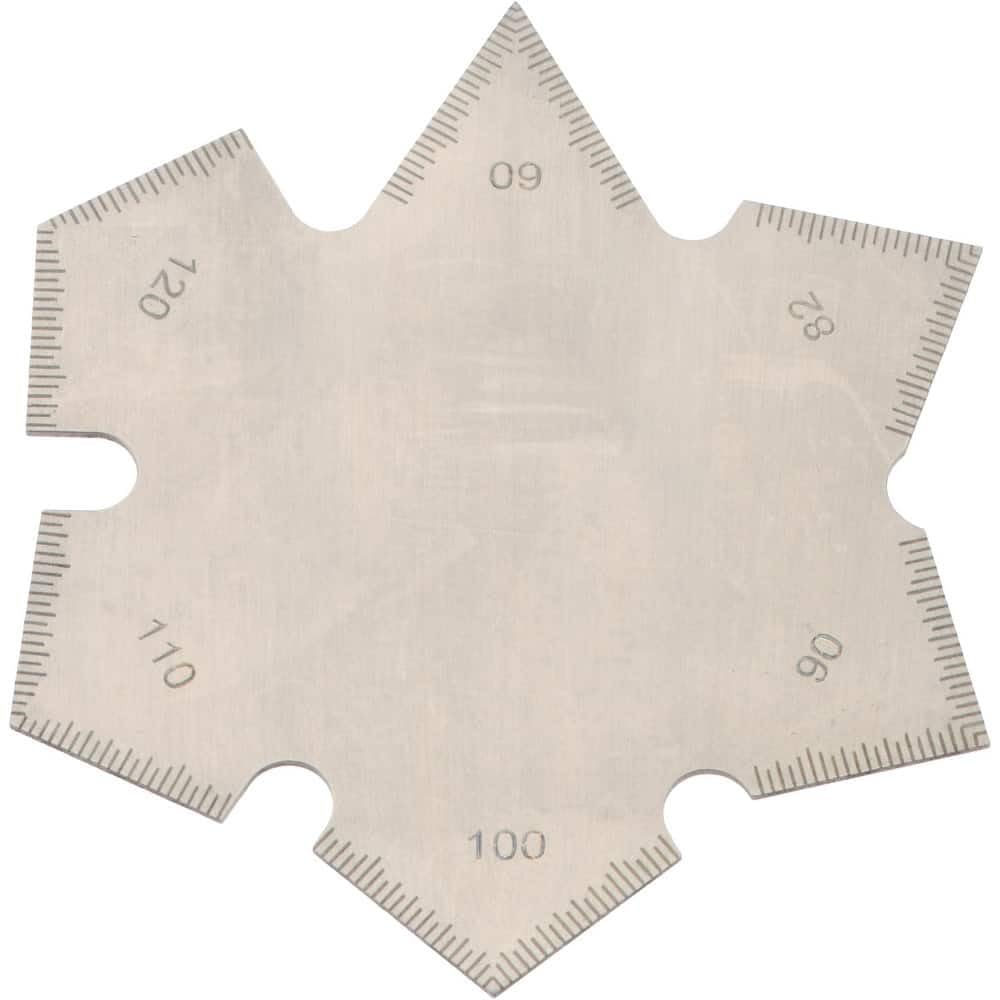

Countersink Angle Gage 60°, 82°, 90°, 100°, 110°, and 120° Angles

Countersinking Angle These standards dictate the correct angle and diameter for. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. Common countersink angles include 82°, 90°, and 100°. These standards dictate the correct angle and diameter for. The angle of the countersink bit should match the angle of the screw head. Choose the angle that matches the. It’s essential to design countersink holes that adhere to ansi or iso standards. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Countersinks are available with points shaped to create six distinct chamfer angles — 60°, 82°, 90°, 100°, 110° and 120° —. Countersink bits come in different angles, commonly 82 degrees and 90 degrees.

From www.penntoolco.com

SPI Countersink Angle Gage 137190 Penn Tool Co., Inc Countersinking Angle Countersinks are available with points shaped to create six distinct chamfer angles — 60°, 82°, 90°, 100°, 110° and 120° —. It’s essential to design countersink holes that adhere to ansi or iso standards. The angle of the countersink bit should match the angle of the screw head. Countersink bits come in different angles, commonly 82 degrees and 90 degrees.. Countersinking Angle.

From www.finepowertools.com

Countersink Angles Common Angles and Their Applications Countersinking Angle It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. It’s essential to design countersink holes that adhere to ansi or iso standards. Common countersink angles include 82°, 90°, and 100°. A countersink is an angled taper applied to a hole that allows a fastener (usually a. Countersinking Angle.

From mechheart.com

What is a Countersunk Screw? MECHHEART Countersinking Angle Countersink bits come in different angles, commonly 82 degrees and 90 degrees. Common countersink angles include 82°, 90°, and 100°. Countersinks are available with points shaped to create six distinct chamfer angles — 60°, 82°, 90°, 100°, 110° and 120° —. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw. Countersinking Angle.

From www.reddit.com

How to calculate countersink angle from hole diameter and countersink Countersinking Angle Choose the angle that matches the. It’s essential to design countersink holes that adhere to ansi or iso standards. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Countersinking is a machining process that creates a conical hole matching the angled shape of. Countersinking Angle.

From www.gdandtbasics.com

Applying Position Tolerances to Countersunk Fixed Fastener Assembly Countersinking Angle It’s essential to design countersink holes that adhere to ansi or iso standards. Choose the angle that matches the. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. These standards dictate the correct angle and diameter for. Common countersink angles include 82°, 90°, and 100°. It allows the. Countersinking Angle.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersinking Angle A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. These standards dictate the correct angle and diameter for. Common countersink. Countersinking Angle.

From mathscinotes.com

Measuring Countersink Diameter Using Gage Balls Math Encounters Blog Countersinking Angle The angle of the countersink bit should match the angle of the screw head. It’s essential to design countersink holes that adhere to ansi or iso standards. Choose the angle that matches the. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. These standards dictate the. Countersinking Angle.

From www.theengineeringknowledge.com

What is Countersink vs. Counterbore Holes in Machining The Countersinking Angle The angle of the countersink bit should match the angle of the screw head. Common countersink angles include 82°, 90°, and 100°. These standards dictate the correct angle and diameter for. Choose the angle that matches the. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance.. Countersinking Angle.

From www.mathscinotes.com

Measuring Countersink Angle Using Gage Balls Math Encounters Blog Countersinking Angle Common countersink angles include 82°, 90°, and 100°. The angle of the countersink bit should match the angle of the screw head. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Countersinking is a machining process that creates a conical hole matching the. Countersinking Angle.

From www.kristeel.com

Countersink Angle Gauge 60 to 120 Degrees Engineering Gauges Countersinking Angle Countersinks are available with points shaped to create six distinct chamfer angles — 60°, 82°, 90°, 100°, 110° and 120° —. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. It allows the fastener’s head to sit flush with the surface of the material or even below it,. Countersinking Angle.

From www.machinistguides.com

Spotfaces All About Machinist Guides Countersinking Angle The angle of the countersink bit should match the angle of the screw head. It’s essential to design countersink holes that adhere to ansi or iso standards. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. These standards dictate the correct angle and diameter for. A. Countersinking Angle.

From www.novacam.com

3D countersink measurement noncontact and automated Novacam Countersinking Angle Countersinks are available with points shaped to create six distinct chamfer angles — 60°, 82°, 90°, 100°, 110° and 120° —. Countersink bits come in different angles, commonly 82 degrees and 90 degrees. The angle of the countersink bit should match the angle of the screw head. A countersink is an angled taper applied to a hole that allows a. Countersinking Angle.

From www.ablcircuits.co.uk

PCB Hole Types Counterbore vs Countersink ABL Circuits Countersinking Angle It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. The angle of the countersink bit should match the angle of. Countersinking Angle.

From www.finepowertools.com

Countersink Angles Common Angles and Their Applications Countersinking Angle Common countersink angles include 82°, 90°, and 100°. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. Choose the angle that matches the. Countersink bits come in different angles, commonly 82 degrees and 90 degrees. Countersinking is a machining process that creates a conical hole matching. Countersinking Angle.

From megadepot.com

Buy SPI 137190, Countersink Angle Gage Mega Depot Countersinking Angle These standards dictate the correct angle and diameter for. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. It’s essential to design countersink holes that adhere to ansi or iso standards. Common countersink angles include 82°, 90°, and 100°. Choose the angle that. Countersinking Angle.

From www.gdandtbasics.com

Countersink GD&T Basics Countersinking Angle Countersink bits come in different angles, commonly 82 degrees and 90 degrees. These standards dictate the correct angle and diameter for. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. It’s essential to design countersink holes that adhere to ansi or iso standards.. Countersinking Angle.

From mechheart.com

What is a Countersunk Screw? MECHHEART Countersinking Angle The angle of the countersink bit should match the angle of the screw head. It’s essential to design countersink holes that adhere to ansi or iso standards. Countersink bits come in different angles, commonly 82 degrees and 90 degrees. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet.. Countersinking Angle.

From www.ebay.com

127406 90 Degrees Countersink HSS Drill Bit 6.3mm to 60mm eBay Countersinking Angle Choose the angle that matches the. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. It’s essential to design countersink holes that adhere to ansi or iso standards. Countersinks are available with points shaped to create six distinct chamfer angles — 60°, 82°,. Countersinking Angle.

From www.protoexpress.com

Countersink Holes in PCBs Sierra Circuits Countersinking Angle It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. Countersink bits come in different angles, commonly 82 degrees and 90 degrees. The angle of the countersink bit should match the angle of the screw head. Common countersink angles include 82°, 90°, and 100°. Countersinking is a. Countersinking Angle.

From www.grainger.com

KEO Countersink Set, 82 ° Countersink Angle, Number of Pieces 5, Cobalt Countersinking Angle It’s essential to design countersink holes that adhere to ansi or iso standards. Choose the angle that matches the. Countersink bits come in different angles, commonly 82 degrees and 90 degrees. Countersinks are available with points shaped to create six distinct chamfer angles — 60°, 82°, 90°, 100°, 110° and 120° —. It allows the fastener’s head to sit flush. Countersinking Angle.

From www.mathscinotes.com

Measuring Countersink Angle Using Gage Balls Math Encounters Blog Countersinking Angle It’s essential to design countersink holes that adhere to ansi or iso standards. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. Countersink bits come in different angles, commonly 82 degrees and 90 degrees. These standards dictate the correct angle and diameter for. Choose the angle that matches. Countersinking Angle.

From www.cnccookbook.com

Countersink Depth Calculator [ Free Machinist Tool ] Countersinking Angle Common countersink angles include 82°, 90°, and 100°. Countersink bits come in different angles, commonly 82 degrees and 90 degrees. Choose the angle that matches the. Countersinks are available with points shaped to create six distinct chamfer angles — 60°, 82°, 90°, 100°, 110° and 120° —. It’s essential to design countersink holes that adhere to ansi or iso standards.. Countersinking Angle.

From www.gdandtbasics.com

Countersink GD&T Basics Countersinking Angle Countersink bits come in different angles, commonly 82 degrees and 90 degrees. The angle of the countersink bit should match the angle of the screw head. Common countersink angles include 82°, 90°, and 100°. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. Countersinking is a. Countersinking Angle.

From informacionpublica.svet.gob.gt

Countersink Angles Common Angles And Their Applications Countersinking Angle Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. Common countersink angles include 82°, 90°, and 100°. These standards dictate the correct angle and diameter for. Countersink bits come in different angles, commonly 82 degrees and 90 degrees. Choose the angle that matches the. Countersinks are available with. Countersinking Angle.

From www.walmart.com

Countersink Angle Gage 60°, 82°, 90°, 100°, 110°, and 120° Angles Countersinking Angle The angle of the countersink bit should match the angle of the screw head. Common countersink angles include 82°, 90°, and 100°. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Choose the angle that matches the. Countersink bits come in different angles,. Countersinking Angle.

From www.wisc-online.com

Countersink Example3 OER Countersinking Angle It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. It’s essential to design countersink holes that adhere to ansi or iso standards. Countersink bits come in different angles, commonly 82 degrees and 90 degrees. Common countersink angles include 82°, 90°, and 100°. The angle of the. Countersinking Angle.

From forums.autodesk.com

Measure a countersink angle? Autodesk Community Countersinking Angle Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. The angle of the countersink bit should match the angle of the screw head. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. These standards. Countersinking Angle.

From www.bestpcbs.com

What’s the Countersink and counter bore on a PCB drawing? PCB & MCPCB Countersinking Angle It’s essential to design countersink holes that adhere to ansi or iso standards. Common countersink angles include 82°, 90°, and 100°. Countersink bits come in different angles, commonly 82 degrees and 90 degrees. These standards dictate the correct angle and diameter for. Countersinks are available with points shaped to create six distinct chamfer angles — 60°, 82°, 90°, 100°, 110°. Countersinking Angle.

From www.youtube.com

SolidWorks Drafting Tutorial Countersinks Hole Angle Bracket Countersinking Angle The angle of the countersink bit should match the angle of the screw head. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit. Countersinking Angle.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersinking Angle Choose the angle that matches the. Common countersink angles include 82°, 90°, and 100°. It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. It’s essential to design countersink holes that adhere to ansi or iso standards. A countersink is an angled taper applied to a hole. Countersinking Angle.

From www.damencnc.com

Countersink 90° d1=10,4mm d2=6mm DamenCNC B.V. Countersinking Angle Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. These standards dictate the correct angle and diameter for. It’s essential to design countersink holes that adhere to ansi or iso standards. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat. Countersinking Angle.

From www.novacam.com

3D countersink measurement noncontact and automated Novacam Countersinking Angle Choose the angle that matches the. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Countersinks are available with points shaped to create six distinct chamfer angles — 60°, 82°, 90°, 100°, 110° and 120° —. Countersinking is a machining process that creates. Countersinking Angle.

From exoobudyf.blob.core.windows.net

Countersink Angle at David Jenkins blog Countersinking Angle A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or. Countersinking is a machining process that creates a conical hole matching the angled shape of a countersunk bolt, screw, or rivet. The angle of the countersink bit should match the angle of the screw. Countersinking Angle.

From mechheart.com

What is a Countersunk Screw? MECHHEART Countersinking Angle Countersinks are available with points shaped to create six distinct chamfer angles — 60°, 82°, 90°, 100°, 110° and 120° —. Common countersink angles include 82°, 90°, and 100°. The angle of the countersink bit should match the angle of the screw head. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat. Countersinking Angle.

From engineersbible.com

Countersunk Hole Size for Flat Head Screws (ISO) The Engineer's Bible Countersinking Angle It allows the fastener’s head to sit flush with the surface of the material or even below it, creating a smooth, seamless appearance. The angle of the countersink bit should match the angle of the screw head. Common countersink angles include 82°, 90°, and 100°. Countersinks are available with points shaped to create six distinct chamfer angles — 60°, 82°,. Countersinking Angle.