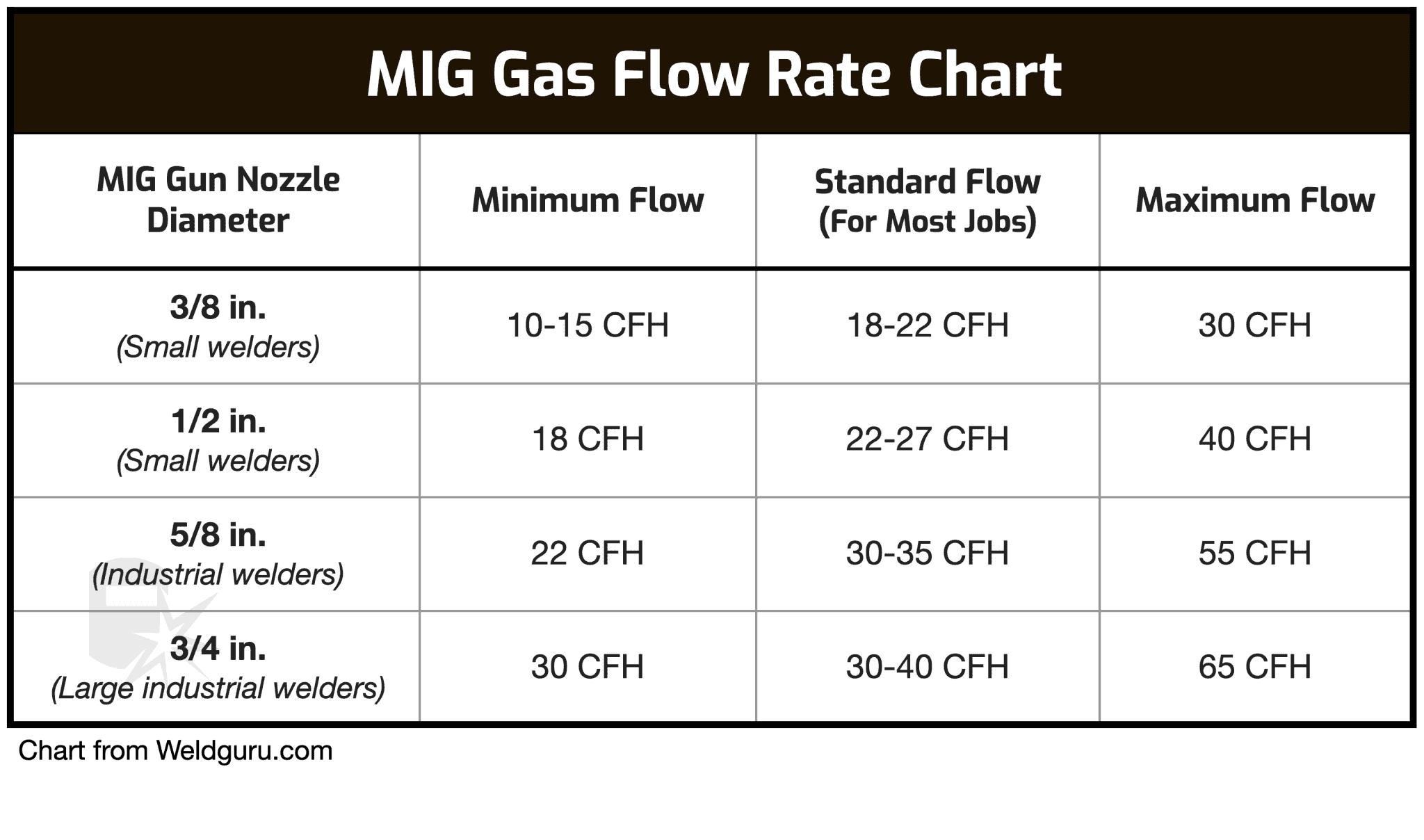

What Should The Gas Flow Rate Be On A Mig Welder . The flow rate you should use depends on the air dynamics surrounding the welding area. If you are welding outdoors, choose more flow than the one you’d apply inside. Proper gas flow ensures a consistent shield around the weld pool, preventing contamination. Recommended mig welding gas flow rates. The flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed. The most common gas used for mig welding is a 75% argon, 25% co 2 mixture. This chart can help figure out what flow rate you need based on the size ( the welders ). So what is the correct gas flow rate for welding? Gas flow rate is crucial in mig welding because it directly affects the quality of the weld. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. A few other gases are also important. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. While the ideal gas flow rate can vary depending on the factors mentioned above, here are some general guidelines for mig. Higher concentrations of helium or argon make for a. But it is not the only gas you may need.

from weldguru.com

Recommended mig welding gas flow rates. While the ideal gas flow rate can vary depending on the factors mentioned above, here are some general guidelines for mig. Gas flow rate is crucial in mig welding because it directly affects the quality of the weld. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. The flow rate you should use depends on the air dynamics surrounding the welding area. Higher concentrations of helium or argon make for a. The most common gas used for mig welding is a 75% argon, 25% co 2 mixture. If you are welding outdoors, choose more flow than the one you’d apply inside. Proper gas flow ensures a consistent shield around the weld pool, preventing contamination. But it is not the only gas you may need.

MIG Welding Gas Pressure Settings (with Charts)

What Should The Gas Flow Rate Be On A Mig Welder So what is the correct gas flow rate for welding? So what is the correct gas flow rate for welding? But it is not the only gas you may need. The flow rate you should use depends on the air dynamics surrounding the welding area. Proper gas flow ensures a consistent shield around the weld pool, preventing contamination. The most common gas used for mig welding is a 75% argon, 25% co 2 mixture. The flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed. This chart can help figure out what flow rate you need based on the size ( the welders ). A few other gases are also important. While the ideal gas flow rate can vary depending on the factors mentioned above, here are some general guidelines for mig. But make sure to take into account the different variables while selecting the flow rate. Gas flow rate is crucial in mig welding because it directly affects the quality of the weld. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. Higher concentrations of helium or argon make for a. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. If you are welding outdoors, choose more flow than the one you’d apply inside.

From www.perfectwelders.com

How To Optimize MIG Welding Shielding Gas Pressure PERFECT POWER What Should The Gas Flow Rate Be On A Mig Welder To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. A few other gases are also important. But it is not the only gas you may need. Recommended mig welding gas flow rates. But make sure to take into account. What Should The Gas Flow Rate Be On A Mig Welder.

From weldingzilla.com

MIG Welding Gas Pressure Settings (with Charts) What Should The Gas Flow Rate Be On A Mig Welder Gas flow rate is crucial in mig welding because it directly affects the quality of the weld. Recommended mig welding gas flow rates. If you are welding outdoors, choose more flow than the one you’d apply inside. The flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed. To figure out how. What Should The Gas Flow Rate Be On A Mig Welder.

From makemoneywelding.com

MIG Welding Gas Pressure Settings What Should The Gas Flow Rate Be On A Mig Welder So what is the correct gas flow rate for welding? Gas flow rate is crucial in mig welding because it directly affects the quality of the weld. The flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed. The most common gas used for mig welding is a 75% argon, 25% co. What Should The Gas Flow Rate Be On A Mig Welder.

From www.scribd.com

MIG Flow Rate Chart Welding Mechanical Engineering What Should The Gas Flow Rate Be On A Mig Welder Gas flow rate is crucial in mig welding because it directly affects the quality of the weld. While the ideal gas flow rate can vary depending on the factors mentioned above, here are some general guidelines for mig. If you are welding outdoors, choose more flow than the one you’d apply inside. The flow rate you should use depends on. What Should The Gas Flow Rate Be On A Mig Welder.

From itstillruns.com

How to Set the Gas on an MIG Welder It Still Runs What Should The Gas Flow Rate Be On A Mig Welder Gas flow rate is crucial in mig welding because it directly affects the quality of the weld. A few other gases are also important. Recommended mig welding gas flow rates. But make sure to take into account the different variables while selecting the flow rate. But it is not the only gas you may need. So what is the correct. What Should The Gas Flow Rate Be On A Mig Welder.

From gowelding.org

MIG Welding Gases Choices and Options for Most Metals What Should The Gas Flow Rate Be On A Mig Welder Gas flow rate is crucial in mig welding because it directly affects the quality of the weld. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. Proper gas flow ensures a consistent shield around the weld pool, preventing contamination. This chart can help figure out what flow rate you need based on the size (. What Should The Gas Flow Rate Be On A Mig Welder.

From weldingmastermind.com

MIG Gas Settings How to Set Gas on MIG Welder Welding Mastermind What Should The Gas Flow Rate Be On A Mig Welder The flow rate you should use depends on the air dynamics surrounding the welding area. Higher concentrations of helium or argon make for a. Recommended mig welding gas flow rates. This chart can help figure out what flow rate you need based on the size ( the welders ). So what is the correct gas flow rate for welding? While. What Should The Gas Flow Rate Be On A Mig Welder.

From itstillruns.com

How to Set the Gas on an MIG Welder It Still Runs What Should The Gas Flow Rate Be On A Mig Welder While the ideal gas flow rate can vary depending on the factors mentioned above, here are some general guidelines for mig. Gas flow rate is crucial in mig welding because it directly affects the quality of the weld. Proper gas flow ensures a consistent shield around the weld pool, preventing contamination. Higher concentrations of helium or argon make for a.. What Should The Gas Flow Rate Be On A Mig Welder.

From itstillruns.com

How to Set the Gas on an MIG Welder It Still Runs What Should The Gas Flow Rate Be On A Mig Welder This chart can help figure out what flow rate you need based on the size ( the welders ). A few other gases are also important. Proper gas flow ensures a consistent shield around the weld pool, preventing contamination. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. If you are welding outdoors, choose more. What Should The Gas Flow Rate Be On A Mig Welder.

From mavink.com

Mig Welding Gas Flow Rate Chart What Should The Gas Flow Rate Be On A Mig Welder This chart can help figure out what flow rate you need based on the size ( the welders ). But it is not the only gas you may need. Recommended mig welding gas flow rates. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip. What Should The Gas Flow Rate Be On A Mig Welder.

From weldempire.com

What Should Be the Gas Pressure for MIG Welding? Weld Empire What Should The Gas Flow Rate Be On A Mig Welder But it is not the only gas you may need. The flow rate you should use depends on the air dynamics surrounding the welding area. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. So what is the correct gas flow rate for welding? A few other gases are also important. While the ideal gas. What Should The Gas Flow Rate Be On A Mig Welder.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) What Should The Gas Flow Rate Be On A Mig Welder But make sure to take into account the different variables while selecting the flow rate. Gas flow rate is crucial in mig welding because it directly affects the quality of the weld. The flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed. The correct gas flow rate in mig welding ranges. What Should The Gas Flow Rate Be On A Mig Welder.

From www.perfectwelders.com

MIG PERFECT POWER Welders, Welding Wire, Welding Equipment What Should The Gas Flow Rate Be On A Mig Welder But it is not the only gas you may need. While the ideal gas flow rate can vary depending on the factors mentioned above, here are some general guidelines for mig. The most common gas used for mig welding is a 75% argon, 25% co 2 mixture. If you are welding outdoors, choose more flow than the one you’d apply. What Should The Gas Flow Rate Be On A Mig Welder.

From www.pinterest.com

How to Set the Gas on an MIG Welder Gas, Mig welder, Carbon steel What Should The Gas Flow Rate Be On A Mig Welder A few other gases are also important. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. The flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed. But make sure to take into account the different variables while selecting the flow rate. So what is the correct. What Should The Gas Flow Rate Be On A Mig Welder.

From www.lazada.com.my

Manooby Argon CO2 Gas Flow Meter Flow Rate Gas Shielding Welding Tool What Should The Gas Flow Rate Be On A Mig Welder The flow rate you should use depends on the air dynamics surrounding the welding area. The flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed. But it is not the only gas you may need. Proper gas flow ensures a consistent shield around the weld pool, preventing contamination. If you are. What Should The Gas Flow Rate Be On A Mig Welder.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) What Should The Gas Flow Rate Be On A Mig Welder So what is the correct gas flow rate for welding? The correct gas flow rate in mig welding ranges between 15 to 25 cfh. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. But it is not the only. What Should The Gas Flow Rate Be On A Mig Welder.

From demiwalton.z13.web.core.windows.net

Mig Welder Settings Chart What Should The Gas Flow Rate Be On A Mig Welder Proper gas flow ensures a consistent shield around the weld pool, preventing contamination. Recommended mig welding gas flow rates. So what is the correct gas flow rate for welding? To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. The. What Should The Gas Flow Rate Be On A Mig Welder.

From makemoneywelding.com

Explained Best MIG Welding Shielding Gas To Use What Should The Gas Flow Rate Be On A Mig Welder Recommended mig welding gas flow rates. The most common gas used for mig welding is a 75% argon, 25% co 2 mixture. The flow rate you should use depends on the air dynamics surrounding the welding area. The flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed. This chart can help. What Should The Gas Flow Rate Be On A Mig Welder.

From migweldingexpert.com

How to Set Gas the Flow on a MIG Welder? Mig Welding Expert What Should The Gas Flow Rate Be On A Mig Welder While the ideal gas flow rate can vary depending on the factors mentioned above, here are some general guidelines for mig. Proper gas flow ensures a consistent shield around the weld pool, preventing contamination. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of. What Should The Gas Flow Rate Be On A Mig Welder.

From weldguru.com

What Gas Should You Use for TIG Welding? (with Chart) What Should The Gas Flow Rate Be On A Mig Welder If you are welding outdoors, choose more flow than the one you’d apply inside. The most common gas used for mig welding is a 75% argon, 25% co 2 mixture. But it is not the only gas you may need. The flow rate you should use depends on the air dynamics surrounding the welding area. The flow rate, volume, and. What Should The Gas Flow Rate Be On A Mig Welder.

From reg.globaltextileexpo.com

Argon CO2 Gas Flow Meter Flow Rate Gas Shielding Welding Tool Flowmeter What Should The Gas Flow Rate Be On A Mig Welder But make sure to take into account the different variables while selecting the flow rate. While the ideal gas flow rate can vary depending on the factors mentioned above, here are some general guidelines for mig. But it is not the only gas you may need. A few other gases are also important. This chart can help figure out what. What Should The Gas Flow Rate Be On A Mig Welder.

From ronsonstorch.com

Selecting the Right Shielding Gas For Your Welding Process RonSon’s What Should The Gas Flow Rate Be On A Mig Welder So what is the correct gas flow rate for welding? The flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed. Recommended mig welding gas flow rates. Proper gas flow ensures a consistent shield around the weld pool, preventing contamination. A few other gases are also important. The most common gas used. What Should The Gas Flow Rate Be On A Mig Welder.

From itstillruns.com

How to Set the Gas on an MIG Welder It Still Runs Your Ultimate What Should The Gas Flow Rate Be On A Mig Welder The flow rate you should use depends on the air dynamics surrounding the welding area. Higher concentrations of helium or argon make for a. Recommended mig welding gas flow rates. Proper gas flow ensures a consistent shield around the weld pool, preventing contamination. If you are welding outdoors, choose more flow than the one you’d apply inside. Gas flow rate. What Should The Gas Flow Rate Be On A Mig Welder.

From mavink.com

Mig Welding Gas Flow Chart What Should The Gas Flow Rate Be On A Mig Welder But make sure to take into account the different variables while selecting the flow rate. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. Higher concentrations of helium or argon make for a. Proper gas flow ensures a consistent. What Should The Gas Flow Rate Be On A Mig Welder.

From weldersmanual.com

Gas For MIG Welding Proper Selections Welders Manual What Should The Gas Flow Rate Be On A Mig Welder So what is the correct gas flow rate for welding? The flow rate you should use depends on the air dynamics surrounding the welding area. Gas flow rate is crucial in mig welding because it directly affects the quality of the weld. But it is not the only gas you may need. To figure out how much pressure and the. What Should The Gas Flow Rate Be On A Mig Welder.

From mavink.com

Mig Welding Gas Flow Chart What Should The Gas Flow Rate Be On A Mig Welder The correct gas flow rate in mig welding ranges between 15 to 25 cfh. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. Proper gas flow ensures a consistent shield around the weld pool, preventing contamination. So what is. What Should The Gas Flow Rate Be On A Mig Welder.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) What Should The Gas Flow Rate Be On A Mig Welder A few other gases are also important. While the ideal gas flow rate can vary depending on the factors mentioned above, here are some general guidelines for mig. But make sure to take into account the different variables while selecting the flow rate. Proper gas flow ensures a consistent shield around the weld pool, preventing contamination. If you are welding. What Should The Gas Flow Rate Be On A Mig Welder.

From exohaljzb.blob.core.windows.net

Gas Regulator Setting For Mig Welding at Elaine Stewart blog What Should The Gas Flow Rate Be On A Mig Welder But it is not the only gas you may need. Recommended mig welding gas flow rates. This chart can help figure out what flow rate you need based on the size ( the welders ). But make sure to take into account the different variables while selecting the flow rate. If you are welding outdoors, choose more flow than the. What Should The Gas Flow Rate Be On A Mig Welder.

From www.youtube.com

Gas Flow Settings for MIG & TIG Welding YouTube What Should The Gas Flow Rate Be On A Mig Welder The correct gas flow rate in mig welding ranges between 15 to 25 cfh. Gas flow rate is crucial in mig welding because it directly affects the quality of the weld. While the ideal gas flow rate can vary depending on the factors mentioned above, here are some general guidelines for mig. This chart can help figure out what flow. What Should The Gas Flow Rate Be On A Mig Welder.

From www.scribd.com

MIG Flow Rate Chart Welding Gases What Should The Gas Flow Rate Be On A Mig Welder Gas flow rate is crucial in mig welding because it directly affects the quality of the weld. So what is the correct gas flow rate for welding? This chart can help figure out what flow rate you need based on the size ( the welders ). The flow rate, volume, and type of shielding gas determine transfer type when combined. What Should The Gas Flow Rate Be On A Mig Welder.

From makemoneywelding.com

MIG Welding Gas Pressure Settings What Should The Gas Flow Rate Be On A Mig Welder The flow rate you should use depends on the air dynamics surrounding the welding area. Higher concentrations of helium or argon make for a. But it is not the only gas you may need. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of. What Should The Gas Flow Rate Be On A Mig Welder.

From ronsonstorch.com

Selecting the Right Shielding Gas For Your Welding Process RonSon’s What Should The Gas Flow Rate Be On A Mig Welder While the ideal gas flow rate can vary depending on the factors mentioned above, here are some general guidelines for mig. So what is the correct gas flow rate for welding? The correct gas flow rate in mig welding ranges between 15 to 25 cfh. But it is not the only gas you may need. If you are welding outdoors,. What Should The Gas Flow Rate Be On A Mig Welder.

From workshopinsider.com

Gas Metal Arc Welding (GMAW) MIG Welding Guide What Should The Gas Flow Rate Be On A Mig Welder So what is the correct gas flow rate for welding? Recommended mig welding gas flow rates. This chart can help figure out what flow rate you need based on the size ( the welders ). The correct gas flow rate in mig welding ranges between 15 to 25 cfh. The flow rate you should use depends on the air dynamics. What Should The Gas Flow Rate Be On A Mig Welder.

From weldguru.com

Best Gas for MIG Welding What to Use (with Chart) What Should The Gas Flow Rate Be On A Mig Welder So what is the correct gas flow rate for welding? The most common gas used for mig welding is a 75% argon, 25% co 2 mixture. Recommended mig welding gas flow rates. The flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed. Gas flow rate is crucial in mig welding because. What Should The Gas Flow Rate Be On A Mig Welder.

From mavink.com

Mig Welding Gas Flow Rate Chart What Should The Gas Flow Rate Be On A Mig Welder So what is the correct gas flow rate for welding? The most common gas used for mig welding is a 75% argon, 25% co 2 mixture. Higher concentrations of helium or argon make for a. The flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed. But it is not the only. What Should The Gas Flow Rate Be On A Mig Welder.