Speeds And Feeds For 6061 Aluminum . Click on the speeds in the above table to get better precision for specific parameters or use our speed and feed calculator recommended. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. I’m figuring 25mm/sec with a.8mm to 1mm doc at 20000 rpm. Sfm and feed for radial depth of cut use 0.25 x tool dia. Speeds a feeds can vary greatly on the type to endmill that you use for aluminum. Years ago, i learned rpm=cs*4/d. 1/8 2 flute down cut end mill cutting 6061 with air jet cooling. For long and extra carbide reduce feed by 50%. Am i about to screw up? Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. For general purpose carbide endmill try 600 to 800. This you can do in your head and it's close enough for most work.

from mungfali.com

For long and extra carbide reduce feed by 50%. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. For general purpose carbide endmill try 600 to 800. This you can do in your head and it's close enough for most work. Sfm and feed for radial depth of cut use 0.25 x tool dia. I’m figuring 25mm/sec with a.8mm to 1mm doc at 20000 rpm. Click on the speeds in the above table to get better precision for specific parameters or use our speed and feed calculator recommended. Speeds a feeds can vary greatly on the type to endmill that you use for aluminum. 1/8 2 flute down cut end mill cutting 6061 with air jet cooling. Years ago, i learned rpm=cs*4/d.

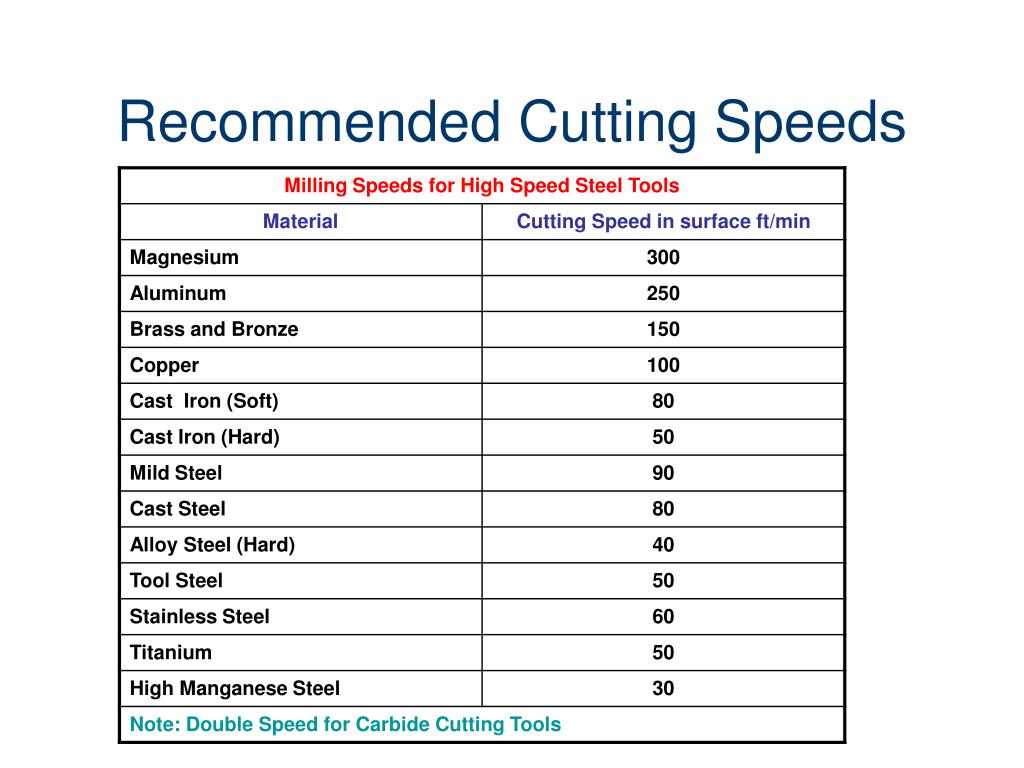

Cutting Speeds And Feeds Chart

Speeds And Feeds For 6061 Aluminum Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. This you can do in your head and it's close enough for most work. Speeds a feeds can vary greatly on the type to endmill that you use for aluminum. Am i about to screw up? Sfm and feed for radial depth of cut use 0.25 x tool dia. For long and extra carbide reduce feed by 50%. For general purpose carbide endmill try 600 to 800. 1/8 2 flute down cut end mill cutting 6061 with air jet cooling. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Click on the speeds in the above table to get better precision for specific parameters or use our speed and feed calculator recommended. Years ago, i learned rpm=cs*4/d. I’m figuring 25mm/sec with a.8mm to 1mm doc at 20000 rpm.

From weldguru.com

How To MIG Weld Aluminum Beginners Guide (with Chart) Speeds And Feeds For 6061 Aluminum Years ago, i learned rpm=cs*4/d. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. This you can do in your. Speeds And Feeds For 6061 Aluminum.

From www.zpag.net

General Guide for Cutting Speeds and Feeds for Drills Speeds And Feeds For 6061 Aluminum I’m figuring 25mm/sec with a.8mm to 1mm doc at 20000 rpm. Years ago, i learned rpm=cs*4/d. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. 1/8 2 flute down cut end mill cutting 6061 with air jet cooling. Sfm and feed for radial depth of cut. Speeds And Feeds For 6061 Aluminum.

From tubingchina.com

Speeds and Feeds for Drilling and Reaming Stainless Steel Speeds And Feeds For 6061 Aluminum Speeds a feeds can vary greatly on the type to endmill that you use for aluminum. For general purpose carbide endmill try 600 to 800. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. For long and extra carbide reduce feed by 50%. Turning speeds are. Speeds And Feeds For 6061 Aluminum.

From tubingchina.com

Speeds and Feeds for Turning Stainless Steel Speeds And Feeds For 6061 Aluminum For long and extra carbide reduce feed by 50%. Am i about to screw up? Sfm and feed for radial depth of cut use 0.25 x tool dia. This you can do in your head and it's close enough for most work. Speeds a feeds can vary greatly on the type to endmill that you use for aluminum. Years ago,. Speeds And Feeds For 6061 Aluminum.

From www.researchgate.net

Effect of rotational speed and feed rate on microstructure and Speeds And Feeds For 6061 Aluminum Years ago, i learned rpm=cs*4/d. For general purpose carbide endmill try 600 to 800. This you can do in your head and it's close enough for most work. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. For long and extra carbide reduce feed by 50%.. Speeds And Feeds For 6061 Aluminum.

From www.lakeshorecarbide.com

Lakeshore Variable speed & feed for aluminum Lakeshore Carbide Speeds And Feeds For 6061 Aluminum Speeds a feeds can vary greatly on the type to endmill that you use for aluminum. Years ago, i learned rpm=cs*4/d. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. 1/8 2 flute down cut end mill cutting 6061 with air jet cooling. Sfm and feed. Speeds And Feeds For 6061 Aluminum.

From www.youtube.com

Aluminum Feeds & Speeds Testing Lathe Insert! WW148 YouTube Speeds And Feeds For 6061 Aluminum 1/8 2 flute down cut end mill cutting 6061 with air jet cooling. Years ago, i learned rpm=cs*4/d. For general purpose carbide endmill try 600 to 800. Sfm and feed for radial depth of cut use 0.25 x tool dia. For long and extra carbide reduce feed by 50%. Turning speeds are adjusted to the feed rate of the mini. Speeds And Feeds For 6061 Aluminum.

From www.scribd.com

SGS Speeds Feeds GP PDF Metals Building Materials Speeds And Feeds For 6061 Aluminum Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. 1/8 2 flute down cut end mill cutting 6061 with air jet cooling. For long and extra carbide reduce feed by 50%. The speeds and feeds calculator may be employed for calculations of estimated. Speeds And Feeds For 6061 Aluminum.

From www.jarviscuttingtools.com

Tapping Speed Chart Jarvis Cutting Tools Speeds And Feeds For 6061 Aluminum 1/8 2 flute down cut end mill cutting 6061 with air jet cooling. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. This you can do in your head and it's close enough for most work. Speeds a feeds can vary greatly on. Speeds And Feeds For 6061 Aluminum.

From mxplus.weebly.com

T Slot Cutter Speeds And Feeds Aluminum mxplus Speeds And Feeds For 6061 Aluminum This you can do in your head and it's close enough for most work. 1/8 2 flute down cut end mill cutting 6061 with air jet cooling. I’m figuring 25mm/sec with a.8mm to 1mm doc at 20000 rpm. Sfm and feed for radial depth of cut use 0.25 x tool dia. For long and extra carbide reduce feed by 50%.. Speeds And Feeds For 6061 Aluminum.

From forum.v1e.com

Help with feeds and speeds for 6061 aluminum Advice V1 Engineering Speeds And Feeds For 6061 Aluminum Sfm and feed for radial depth of cut use 0.25 x tool dia. 1/8 2 flute down cut end mill cutting 6061 with air jet cooling. Years ago, i learned rpm=cs*4/d. Am i about to screw up? Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life. Speeds And Feeds For 6061 Aluminum.

From tubingchina.com

Speeds and Feeds for Drilling and Reaming Stainless Steel Speeds And Feeds For 6061 Aluminum Years ago, i learned rpm=cs*4/d. Am i about to screw up? For general purpose carbide endmill try 600 to 800. For long and extra carbide reduce feed by 50%. Click on the speeds in the above table to get better precision for specific parameters or use our speed and feed calculator recommended. I’m figuring 25mm/sec with a.8mm to 1mm doc. Speeds And Feeds For 6061 Aluminum.

From fyoftdscn.blob.core.windows.net

Speeds And Feeds For Aluminum Turning at Jimmy Pringle blog Speeds And Feeds For 6061 Aluminum Click on the speeds in the above table to get better precision for specific parameters or use our speed and feed calculator recommended. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Years ago, i learned rpm=cs*4/d. This you can do in your head and it's. Speeds And Feeds For 6061 Aluminum.

From caltech-mce-lab.wikidot.com

Lathe Information Caltech MCE Lab Speeds And Feeds For 6061 Aluminum Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. Speeds a feeds can vary greatly on the type to endmill that you use for aluminum. Years ago, i learned rpm=cs*4/d. For general purpose carbide endmill try 600 to 800. For long and extra. Speeds And Feeds For 6061 Aluminum.

From mungfali.com

End Mill Speed And Feed Chart Speeds And Feeds For 6061 Aluminum This you can do in your head and it's close enough for most work. For general purpose carbide endmill try 600 to 800. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. 1/8 2 flute down cut end mill cutting 6061 with air jet cooling. Am. Speeds And Feeds For 6061 Aluminum.

From hallmanufacturingsolutions.com

Hall Manufacturing Solutions Speeds And Feeds For 6061 Aluminum 1/8 2 flute down cut end mill cutting 6061 with air jet cooling. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. I’m figuring 25mm/sec with a.8mm to 1mm doc at 20000 rpm. For general purpose carbide endmill try 600 to 800. Sfm. Speeds And Feeds For 6061 Aluminum.

From mavink.com

Aluminum Speeds And Feeds Chart Speeds And Feeds For 6061 Aluminum Click on the speeds in the above table to get better precision for specific parameters or use our speed and feed calculator recommended. For general purpose carbide endmill try 600 to 800. Sfm and feed for radial depth of cut use 0.25 x tool dia. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds. Speeds And Feeds For 6061 Aluminum.

From mungfali.com

Cutting Speeds And Feeds Chart Speeds And Feeds For 6061 Aluminum 1/8 2 flute down cut end mill cutting 6061 with air jet cooling. Years ago, i learned rpm=cs*4/d. Speeds a feeds can vary greatly on the type to endmill that you use for aluminum. For long and extra carbide reduce feed by 50%. This you can do in your head and it's close enough for most work. Sfm and feed. Speeds And Feeds For 6061 Aluminum.

From mungfali.com

Titanium Feeds And Speeds Chart Speeds And Feeds For 6061 Aluminum For general purpose carbide endmill try 600 to 800. This you can do in your head and it's close enough for most work. Speeds a feeds can vary greatly on the type to endmill that you use for aluminum. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a. Speeds And Feeds For 6061 Aluminum.

From mungfali.com

Cutting Speeds And Feeds Chart Speeds And Feeds For 6061 Aluminum Years ago, i learned rpm=cs*4/d. For long and extra carbide reduce feed by 50%. Am i about to screw up? Sfm and feed for radial depth of cut use 0.25 x tool dia. This you can do in your head and it's close enough for most work. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.),. Speeds And Feeds For 6061 Aluminum.

From www.researchgate.net

Machining Conditions Workpiece Material 6061T6 Aluminum Download Table Speeds And Feeds For 6061 Aluminum This you can do in your head and it's close enough for most work. For general purpose carbide endmill try 600 to 800. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Years ago, i learned rpm=cs*4/d. For long and extra carbide reduce feed by 50%.. Speeds And Feeds For 6061 Aluminum.

From discuss.inventables.com

Easel Aluminum Speeds & Feeds XCarve Inventables Community Forum Speeds And Feeds For 6061 Aluminum Am i about to screw up? For long and extra carbide reduce feed by 50%. This you can do in your head and it's close enough for most work. Sfm and feed for radial depth of cut use 0.25 x tool dia. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm). Speeds And Feeds For 6061 Aluminum.

From mavink.com

Aluminum 6061 Sfm Chart Speeds And Feeds For 6061 Aluminum Sfm and feed for radial depth of cut use 0.25 x tool dia. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. I’m figuring 25mm/sec with a.8mm to 1mm doc at 20000 rpm. For long and extra carbide reduce feed by 50%. Speeds. Speeds And Feeds For 6061 Aluminum.

From www.researchgate.net

Chemical composition for aluminium Al 6061 Download Scientific Diagram Speeds And Feeds For 6061 Aluminum Years ago, i learned rpm=cs*4/d. For general purpose carbide endmill try 600 to 800. Speeds a feeds can vary greatly on the type to endmill that you use for aluminum. 1/8 2 flute down cut end mill cutting 6061 with air jet cooling. Am i about to screw up? Click on the speeds in the above table to get better. Speeds And Feeds For 6061 Aluminum.

From naalogic.weebly.com

Cnc router feeds and speeds for cutting 6063 aluminum naalogic Speeds And Feeds For 6061 Aluminum Sfm and feed for radial depth of cut use 0.25 x tool dia. For general purpose carbide endmill try 600 to 800. Am i about to screw up? This you can do in your head and it's close enough for most work. Speeds a feeds can vary greatly on the type to endmill that you use for aluminum. I’m figuring. Speeds And Feeds For 6061 Aluminum.

From www.practicalmachinist.com

Rigid Tapping Feeds/Speeds in AL6061 Speeds And Feeds For 6061 Aluminum This you can do in your head and it's close enough for most work. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. I’m figuring 25mm/sec with a.8mm to 1mm doc at 20000 rpm. 1/8 2 flute down cut end mill cutting 6061 with air jet. Speeds And Feeds For 6061 Aluminum.

From forum.v1e.com

Help with feeds and speeds for 6061 aluminum Advice V1 Engineering Speeds And Feeds For 6061 Aluminum For general purpose carbide endmill try 600 to 800. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. 1/8 2 flute down cut end mill cutting 6061 with air jet cooling. Am i about to screw up? Sfm and feed for radial depth of cut use. Speeds And Feeds For 6061 Aluminum.

From www.reddit.com

Anybody have any ideas for this bits feed and speed for 6061 aluminum Speeds And Feeds For 6061 Aluminum Click on the speeds in the above table to get better precision for specific parameters or use our speed and feed calculator recommended. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. I’m figuring 25mm/sec with a.8mm to 1mm doc at 20000 rpm. Years ago, i. Speeds And Feeds For 6061 Aluminum.

From www.semanticscholar.org

Figure 1 from Surface Roughness Prediction Model of 6061T6 Aluminium Speeds And Feeds For 6061 Aluminum Years ago, i learned rpm=cs*4/d. 1/8 2 flute down cut end mill cutting 6061 with air jet cooling. For general purpose carbide endmill try 600 to 800. Speeds a feeds can vary greatly on the type to endmill that you use for aluminum. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and. Speeds And Feeds For 6061 Aluminum.

From www.slideserve.com

PPT Speeds and Feeds PowerPoint Presentation, free download ID6311492 Speeds And Feeds For 6061 Aluminum This you can do in your head and it's close enough for most work. Speeds a feeds can vary greatly on the type to endmill that you use for aluminum. I’m figuring 25mm/sec with a.8mm to 1mm doc at 20000 rpm. Sfm and feed for radial depth of cut use 0.25 x tool dia. For general purpose carbide endmill try. Speeds And Feeds For 6061 Aluminum.

From www.cmc-consultants.com

Metal Machining How To Improve Finish through Speeds & Feeds Speeds And Feeds For 6061 Aluminum The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Am i about to screw up? Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. Speeds a feeds can vary. Speeds And Feeds For 6061 Aluminum.

From www.qualitytechtool.com

Premium Class End Mills Metric Quality Tech Tool Speeds And Feeds For 6061 Aluminum This you can do in your head and it's close enough for most work. Am i about to screw up? Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. Years ago, i learned rpm=cs*4/d. For long and extra carbide reduce feed by 50%.. Speeds And Feeds For 6061 Aluminum.

From www.researchgate.net

Thrust force Fz at different cutting speeds for 6061T6 material Speeds And Feeds For 6061 Aluminum For general purpose carbide endmill try 600 to 800. Click on the speeds in the above table to get better precision for specific parameters or use our speed and feed calculator recommended. For long and extra carbide reduce feed by 50%. 1/8 2 flute down cut end mill cutting 6061 with air jet cooling. Years ago, i learned rpm=cs*4/d. Am. Speeds And Feeds For 6061 Aluminum.

From lexingtoncutter.com

Feeds & Speeds Charts Lexington Cutter Speeds And Feeds For 6061 Aluminum 1/8 2 flute down cut end mill cutting 6061 with air jet cooling. Click on the speeds in the above table to get better precision for specific parameters or use our speed and feed calculator recommended. Speeds a feeds can vary greatly on the type to endmill that you use for aluminum. Turning speeds are adjusted to the feed rate. Speeds And Feeds For 6061 Aluminum.

From mellowpine.com

Speeds and Feeds Beginner Guide with Table MellowPine Speeds And Feeds For 6061 Aluminum For general purpose carbide endmill try 600 to 800. Sfm and feed for radial depth of cut use 0.25 x tool dia. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Am i about to screw up? For long and extra carbide reduce feed by 50%.. Speeds And Feeds For 6061 Aluminum.