Lathe Machine Threading Formula . For this practice exercise for threading, you will need a piece of round material, turned to an outside tread diameter. It works for both metric and inch based. Threading is a complex machining operation if you look at the big. Using a tap handle is the most common method of. Threading on a lathe is a fundamental metalworking process used to create screws, bolts, and other fasteners. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. Threading on a lathe can be a complex. Using either a parting tool or a specially ground tool, make an undercut. This document presents some of the more common techniques for threading on the manual engine lathe. Key concepts include thread size, thread pitch, and. To cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. Have you ever looked at a lathe threading chart and felt completely lost? Don't worry, you're not alone. The following diagrams and formulas will be. This writing is done to provide a general insight into threading.

from extrudesign.com

Threading on a lathe is a fundamental metalworking process used to create screws, bolts, and other fasteners. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. For this practice exercise for threading, you will need a piece of round material, turned to an outside tread diameter. The following diagrams and formulas will be. This writing is done to provide a general insight into threading. Have you ever looked at a lathe threading chart and felt completely lost? Don't worry, you're not alone. This document presents some of the more common techniques for threading on the manual engine lathe. Using either a parting tool or a specially ground tool, make an undercut. Using a tap handle is the most common method of.

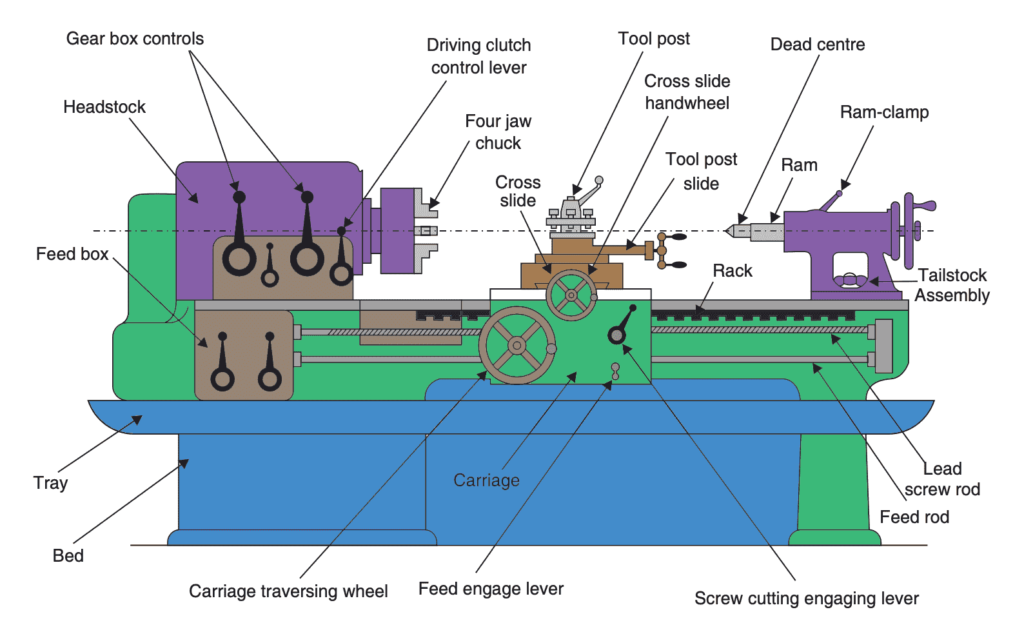

What is Lathe Machine, How does it work? ExtruDesign

Lathe Machine Threading Formula Key concepts include thread size, thread pitch, and. Using either a parting tool or a specially ground tool, make an undercut. To cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. Key concepts include thread size, thread pitch, and. It works for both metric and inch based. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. Threading on a lathe is a fundamental metalworking process used to create screws, bolts, and other fasteners. This writing is done to provide a general insight into threading. For this practice exercise for threading, you will need a piece of round material, turned to an outside tread diameter. Using a tap handle is the most common method of. Have you ever looked at a lathe threading chart and felt completely lost? This document presents some of the more common techniques for threading on the manual engine lathe. Don't worry, you're not alone. Threading is a complex machining operation if you look at the big. The following diagrams and formulas will be. Threading on a lathe can be a complex.

From www.youtube.com

How to cut a thread on a manual lathe (Intermediate method ideal for Lathe Machine Threading Formula Don't worry, you're not alone. Threading is a complex machining operation if you look at the big. Have you ever looked at a lathe threading chart and felt completely lost? This document presents some of the more common techniques for threading on the manual engine lathe. Threading on a lathe is a fundamental metalworking process used to create screws, bolts,. Lathe Machine Threading Formula.

From www.youtube.com

HOW TO THREAD ON LATHE MACHINE. EXTERNAL AND INTERNAL THREADS YouTube Lathe Machine Threading Formula This document presents some of the more common techniques for threading on the manual engine lathe. Key concepts include thread size, thread pitch, and. Have you ever looked at a lathe threading chart and felt completely lost? To cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions.. Lathe Machine Threading Formula.

From fyosanwit.blob.core.windows.net

Lathe Machine Threading Gear Calculation Formula at Shante Friend blog Lathe Machine Threading Formula Have you ever looked at a lathe threading chart and felt completely lost? Threading is a complex machining operation if you look at the big. Don't worry, you're not alone. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. To cut a correct thread on the lathe, it is. Lathe Machine Threading Formula.

From lasopavisual101.weebly.com

Lathe thread chart wm250 lasopavisual Lathe Machine Threading Formula The following diagrams and formulas will be. Using a tap handle is the most common method of. Have you ever looked at a lathe threading chart and felt completely lost? This document presents some of the more common techniques for threading on the manual engine lathe. For this practice exercise for threading, you will need a piece of round material,. Lathe Machine Threading Formula.

From www.youtube.com

How to make a thread with the help of lathe machine YouTube Lathe Machine Threading Formula The following diagrams and formulas will be. Using a tap handle is the most common method of. Key concepts include thread size, thread pitch, and. Threading on a lathe can be a complex. This document presents some of the more common techniques for threading on the manual engine lathe. It works for both metric and inch based. Threading on a. Lathe Machine Threading Formula.

From pametno21.blogspot.com

Formula Of Speed pametno Lathe Machine Threading Formula Threading on a lathe is a fundamental metalworking process used to create screws, bolts, and other fasteners. Threading on a lathe can be a complex. Using either a parting tool or a specially ground tool, make an undercut. Have you ever looked at a lathe threading chart and felt completely lost? For this practice exercise for threading, you will need. Lathe Machine Threading Formula.

From www.youtube.com

Full Norton Lathe Machines Thread Chart 2 YouTube Lathe Machine Threading Formula Don't worry, you're not alone. Threading on a lathe can be a complex. This document presents some of the more common techniques for threading on the manual engine lathe. Threading on a lathe is a fundamental metalworking process used to create screws, bolts, and other fasteners. Have you ever looked at a lathe threading chart and felt completely lost? Using. Lathe Machine Threading Formula.

From www.youtube.com

Full Norton Lathe Machine Thread Chart YouTube Lathe Machine Threading Formula Threading is a complex machining operation if you look at the big. The following diagrams and formulas will be. This writing is done to provide a general insight into threading. Threading on a lathe can be a complex. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. Using a. Lathe Machine Threading Formula.

From jbcmachine.com

Threading Services JBC Machine, Inc. Lathe Machine Threading Formula Have you ever looked at a lathe threading chart and felt completely lost? To cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. Key concepts include thread size, thread pitch, and. Threading is a complex machining operation if you look at the big. Using either a parting. Lathe Machine Threading Formula.

From www.pinterest.co.uk

http//www.lathes.co.uk/southbend9inch/ Lathe, Metal lathe tools Lathe Machine Threading Formula Using either a parting tool or a specially ground tool, make an undercut. This writing is done to provide a general insight into threading. The following diagrams and formulas will be. For this practice exercise for threading, you will need a piece of round material, turned to an outside tread diameter. This calculates the change gears needed to cut a. Lathe Machine Threading Formula.

From www.youtube.com

Lathe machine threading chart, and Gear Calculation, YouTube Lathe Machine Threading Formula To cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. This document presents some of the more common techniques for threading on the manual engine lathe. This writing is done to provide a general insight into threading. The following diagrams and formulas will be. Don't worry, you're. Lathe Machine Threading Formula.

From www.prajval.in

Prajval.in Lathe Machine Threading Formula For this practice exercise for threading, you will need a piece of round material, turned to an outside tread diameter. Threading is a complex machining operation if you look at the big. Threading on a lathe can be a complex. To cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will. Lathe Machine Threading Formula.

From www.pinterest.es

Pin on Metal lathe projects Lathe Machine Threading Formula Threading on a lathe is a fundamental metalworking process used to create screws, bolts, and other fasteners. Don't worry, you're not alone. This document presents some of the more common techniques for threading on the manual engine lathe. Using a tap handle is the most common method of. To cut a correct thread on the lathe, it is necessary first. Lathe Machine Threading Formula.

From www.youtube.com

THREAD CUTTING GEAR CALCULATION FORMULA ON LATHE M/C IN हिंदी YouTube Lathe Machine Threading Formula Threading on a lathe can be a complex. The following diagrams and formulas will be. To cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. Don't worry, you're not alone. Threading on a lathe is a fundamental metalworking process used to create screws, bolts, and other fasteners.. Lathe Machine Threading Formula.

From maldives.desertcart.com

Buy Lathe Turning Tool, 1/2" Shank 7 Pieces Carbide Lathe Threading Lathe Machine Threading Formula This writing is done to provide a general insight into threading. The following diagrams and formulas will be. Threading is a complex machining operation if you look at the big. Key concepts include thread size, thread pitch, and. This document presents some of the more common techniques for threading on the manual engine lathe. It works for both metric and. Lathe Machine Threading Formula.

From extrudesign.com

What is Lathe Machine, How does it work? ExtruDesign Lathe Machine Threading Formula Using either a parting tool or a specially ground tool, make an undercut. Key concepts include thread size, thread pitch, and. Threading is a complex machining operation if you look at the big. This writing is done to provide a general insight into threading. The following diagrams and formulas will be. To cut a correct thread on the lathe, it. Lathe Machine Threading Formula.

From www.youtube.com

G76 Taper Threading Canned Cycle / CNC Taper Turning Program / G76 Lathe Machine Threading Formula Threading is a complex machining operation if you look at the big. Don't worry, you're not alone. It works for both metric and inch based. To cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. Key concepts include thread size, thread pitch, and. The following diagrams and. Lathe Machine Threading Formula.

From www.studypool.com

SOLUTION Lathe machine formula for cutting speed Studypool Lathe Machine Threading Formula Threading on a lathe is a fundamental metalworking process used to create screws, bolts, and other fasteners. Using either a parting tool or a specially ground tool, make an undercut. It works for both metric and inch based. To cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper. Lathe Machine Threading Formula.

From www.lzcncmachine.com

Q1322 Pipe Threading Lathe Machine Pipe Threading Lathe Machine Lathe Machine Threading Formula Have you ever looked at a lathe threading chart and felt completely lost? Threading is a complex machining operation if you look at the big. Using a tap handle is the most common method of. To cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. Using either. Lathe Machine Threading Formula.

From iscclimatecollaborative.org

ENotes Manufacturing Processes, 53 OFF Lathe Machine Threading Formula This document presents some of the more common techniques for threading on the manual engine lathe. It works for both metric and inch based. To cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. Threading is a complex machining operation if you look at the big. Using. Lathe Machine Threading Formula.

From www.youtube.com

Thread Operation on lathe cutting Threading. YouTube Lathe Machine Threading Formula This document presents some of the more common techniques for threading on the manual engine lathe. Threading on a lathe is a fundamental metalworking process used to create screws, bolts, and other fasteners. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. Threading is a complex machining operation if. Lathe Machine Threading Formula.

From www.indiamart.com

Mild Steel Machining on CNC Lathe, Maximum Turning Length 665 Mm Lathe Machine Threading Formula Threading is a complex machining operation if you look at the big. To cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. Using either a parting tool or a specially ground tool, make an undercut. For this practice exercise for threading, you will need a piece of. Lathe Machine Threading Formula.

From atelier-yuwa.ciao.jp

Lathe Machine Threading Formula atelieryuwa.ciao.jp Lathe Machine Threading Formula Threading is a complex machining operation if you look at the big. This writing is done to provide a general insight into threading. Using either a parting tool or a specially ground tool, make an undercut. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. Don't worry, you're not. Lathe Machine Threading Formula.

From atelier-yuwa.ciao.jp

Lathe Machine Threading Formula atelieryuwa.ciao.jp Lathe Machine Threading Formula Using either a parting tool or a specially ground tool, make an undercut. The following diagrams and formulas will be. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. This document presents some of the more common techniques for threading on the manual engine lathe. Threading on a lathe. Lathe Machine Threading Formula.

From exoqkbmpn.blob.core.windows.net

Lathe Machine Rpm Formula at Evelyn Blackmon blog Lathe Machine Threading Formula The following diagrams and formulas will be. Threading is a complex machining operation if you look at the big. Don't worry, you're not alone. Using a tap handle is the most common method of. Threading on a lathe is a fundamental metalworking process used to create screws, bolts, and other fasteners. This document presents some of the more common techniques. Lathe Machine Threading Formula.

From gateformulame.blogspot.com

GATE FORMULA MECHANICAL Lathe & Shaper Formulas Lathe Machine Threading Formula The following diagrams and formulas will be. This writing is done to provide a general insight into threading. It works for both metric and inch based. This document presents some of the more common techniques for threading on the manual engine lathe. Using either a parting tool or a specially ground tool, make an undercut. For this practice exercise for. Lathe Machine Threading Formula.

From www.carousell.ph

Lathe Machine (Threading) Machine Shop, Commercial & Industrial Lathe Machine Threading Formula This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. Key concepts include thread size, thread pitch, and. It works for both metric and inch based. Using either a parting tool or a specially ground tool, make an undercut. To cut a correct thread on the lathe, it is necessary. Lathe Machine Threading Formula.

From www.youtube.com

How to Cut Double Start thread in Inch On Lathe Machine Compound Lathe Machine Threading Formula It works for both metric and inch based. Threading on a lathe can be a complex. Don't worry, you're not alone. Using a tap handle is the most common method of. Threading on a lathe is a fundamental metalworking process used to create screws, bolts, and other fasteners. For this practice exercise for threading, you will need a piece of. Lathe Machine Threading Formula.

From atelier-yuwa.ciao.jp

Lathe Machine Threading Formula atelieryuwa.ciao.jp Lathe Machine Threading Formula The following diagrams and formulas will be. For this practice exercise for threading, you will need a piece of round material, turned to an outside tread diameter. Threading is a complex machining operation if you look at the big. This document presents some of the more common techniques for threading on the manual engine lathe. Don't worry, you're not alone.. Lathe Machine Threading Formula.

From gateformulame.blogspot.com

GATE FORMULA MECHANICAL Lathe & Shaper Formulas Lathe Machine Threading Formula This document presents some of the more common techniques for threading on the manual engine lathe. Using either a parting tool or a specially ground tool, make an undercut. Threading on a lathe is a fundamental metalworking process used to create screws, bolts, and other fasteners. Threading is a complex machining operation if you look at the big. This calculates. Lathe Machine Threading Formula.

From atelier-yuwa.ciao.jp

Lathe Machine Threading Formula atelieryuwa.ciao.jp Lathe Machine Threading Formula Using a tap handle is the most common method of. For this practice exercise for threading, you will need a piece of round material, turned to an outside tread diameter. Threading is a complex machining operation if you look at the big. Using either a parting tool or a specially ground tool, make an undercut. The following diagrams and formulas. Lathe Machine Threading Formula.

From atelier-yuwa.ciao.jp

Lathe Machine Threading Formula atelieryuwa.ciao.jp Lathe Machine Threading Formula This writing is done to provide a general insight into threading. Threading is a complex machining operation if you look at the big. Threading on a lathe can be a complex. The following diagrams and formulas will be. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. Don't worry,. Lathe Machine Threading Formula.

From mae.ufl.edu

Threading on Lathe Lathe Machine Threading Formula Using either a parting tool or a specially ground tool, make an undercut. Threading on a lathe is a fundamental metalworking process used to create screws, bolts, and other fasteners. Don't worry, you're not alone. For this practice exercise for threading, you will need a piece of round material, turned to an outside tread diameter. This calculates the change gears. Lathe Machine Threading Formula.

From www.youtube.com

Lathe Machining Time Calculation Example Simple Turning YouTube Lathe Machine Threading Formula To cut a correct thread on the lathe, it is necessary first to make calculations so that the thread will have proper dimensions. Threading on a lathe can be a complex. For this practice exercise for threading, you will need a piece of round material, turned to an outside tread diameter. Key concepts include thread size, thread pitch, and. Don't. Lathe Machine Threading Formula.

From www.youtube.com

Thread making on lathe machine Mechanical Eng Parul Lathe Machine Threading Formula Don't worry, you're not alone. Threading on a lathe can be a complex. This calculates the change gears needed to cut a given thread on lathes that use up to 6 change gears. This writing is done to provide a general insight into threading. To cut a correct thread on the lathe, it is necessary first to make calculations so. Lathe Machine Threading Formula.