Dry Cleaning Procedure For Food Industry . Clean and disinfect food areas and equipment between different. steps for cleaning effectively. Granular purging, scrubs, and blasting; cleaning needs to be carried out in two stages. as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. dry cleaning methods include: First use a cleaning product to remove visible dirt from surfaces and equipment, and rinse. You should do the following things: dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. dry cleaning is used primarily in zones 1 to 3 (food contact surfaces to areas outside the areas around food contact.

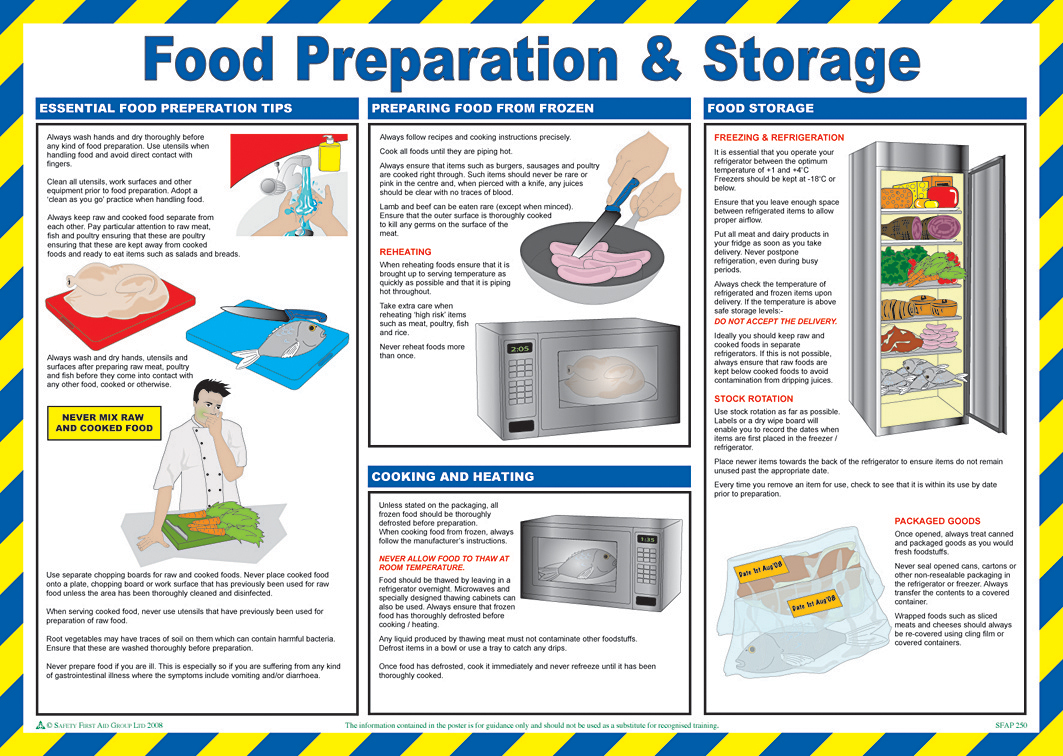

from www.safetysignsupplies.co.uk

dry cleaning is used primarily in zones 1 to 3 (food contact surfaces to areas outside the areas around food contact. steps for cleaning effectively. cleaning needs to be carried out in two stages. You should do the following things: Granular purging, scrubs, and blasting; Clean and disinfect food areas and equipment between different. dry cleaning methods include: First use a cleaning product to remove visible dirt from surfaces and equipment, and rinse. as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low.

Food Preparation Poster from Safety Sign Supplies

Dry Cleaning Procedure For Food Industry dry cleaning methods include: Clean and disinfect food areas and equipment between different. dry cleaning methods include: as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. You should do the following things: First use a cleaning product to remove visible dirt from surfaces and equipment, and rinse. dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. cleaning needs to be carried out in two stages. steps for cleaning effectively. Granular purging, scrubs, and blasting; dry cleaning is used primarily in zones 1 to 3 (food contact surfaces to areas outside the areas around food contact.

From exohnlnky.blob.core.windows.net

How To Clean Food Processing Equipment at David Agee blog Dry Cleaning Procedure For Food Industry You should do the following things: as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. steps for cleaning effectively. cleaning needs to be carried out in two stages. Granular purging, scrubs, and blasting; dry cleaning methods include: First use a cleaning product to remove visible dirt from. Dry Cleaning Procedure For Food Industry.

From weeverapps.com

The 7 Steps of Cleaning & Sanitizing food production lines Weever Dry Cleaning Procedure For Food Industry cleaning needs to be carried out in two stages. Clean and disinfect food areas and equipment between different. First use a cleaning product to remove visible dirt from surfaces and equipment, and rinse. dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. steps for cleaning effectively. dry cleaning. Dry Cleaning Procedure For Food Industry.

From www.cleanallenvironmental.ca

Clean All Environmental Services Inc. Dry Cleaning Procedure For Food Industry You should do the following things: dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. First use a cleaning product to remove visible dirt from surfaces and equipment, and rinse. as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. Granular purging,. Dry Cleaning Procedure For Food Industry.

From www.laundryheap.co.uk

The Dry Cleaning Process Laundryheap Blog Laundry & Dry Cleaning Dry Cleaning Procedure For Food Industry First use a cleaning product to remove visible dirt from surfaces and equipment, and rinse. You should do the following things: Granular purging, scrubs, and blasting; dry cleaning methods include: dry cleaning is used primarily in zones 1 to 3 (food contact surfaces to areas outside the areas around food contact. cleaning needs to be carried out. Dry Cleaning Procedure For Food Industry.

From www.pinterest.com

B Smart Dry Cleaners in Berkhamsted Alterations and Tailoring Химчистка Dry Cleaning Procedure For Food Industry dry cleaning is used primarily in zones 1 to 3 (food contact surfaces to areas outside the areas around food contact. cleaning needs to be carried out in two stages. dry cleaning methods include: as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. dry sanitation is. Dry Cleaning Procedure For Food Industry.

From www.foodqualityandsafety.com

Dry Cleaning in the Food Industry Solutions to Challenges Food Dry Cleaning Procedure For Food Industry as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. You should do the following things: cleaning needs to be carried out in two stages. steps for cleaning effectively. dry cleaning is used primarily in zones 1 to 3 (food contact surfaces to areas outside the areas around. Dry Cleaning Procedure For Food Industry.

From dungorosco.blogspot.com

what is good hygiene practices in food industry Dung Orosco Dry Cleaning Procedure For Food Industry cleaning needs to be carried out in two stages. dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. Granular purging, scrubs, and blasting; dry cleaning is used primarily in zones. Dry Cleaning Procedure For Food Industry.

From textileapex.com

What is Dry Cleaning? Commercial Dry Cleaning Process Textile Apex Dry Cleaning Procedure For Food Industry as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. Granular purging, scrubs, and blasting; You should do the following things: dry cleaning is used primarily in zones 1 to 3 (food. Dry Cleaning Procedure For Food Industry.

From www.powershow.com

PPT Cleaning And Sanitation Procedures In Food Industry JBN Cleaning Dry Cleaning Procedure For Food Industry Clean and disinfect food areas and equipment between different. dry cleaning is used primarily in zones 1 to 3 (food contact surfaces to areas outside the areas around food contact. dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. cleaning needs to be carried out in two stages. . Dry Cleaning Procedure For Food Industry.

From www.fooddocs.com

What Is the Proper Way to Sanitize a Table that Has Been Used for Dry Cleaning Procedure For Food Industry cleaning needs to be carried out in two stages. dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. You should do the following things: Clean and disinfect food areas and equipment between different. as a general rule, where dry particulate food products are handled, preference must be given to. Dry Cleaning Procedure For Food Industry.

From www.foodqualityandsafety.com

Dry Cleaning in the Food Industry Solutions to Challenges Food Dry Cleaning Procedure For Food Industry dry cleaning is used primarily in zones 1 to 3 (food contact surfaces to areas outside the areas around food contact. First use a cleaning product to remove visible dirt from surfaces and equipment, and rinse. cleaning needs to be carried out in two stages. steps for cleaning effectively. dry sanitation is a pivotal practice in. Dry Cleaning Procedure For Food Industry.

From fabricaresystems.com

How to Start a Dry Cleaning Business Fabricare Systems, LLC Dry Cleaning Procedure For Food Industry dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. Granular purging, scrubs, and blasting; cleaning needs to be carried out in two stages. as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. First use a cleaning product to remove visible. Dry Cleaning Procedure For Food Industry.

From ecosguide.com

Understanding What Is Dry Cleaning And How Dry Cleaning Process Works Dry Cleaning Procedure For Food Industry as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. You should do the following things: dry cleaning methods include: Granular purging, scrubs, and blasting; steps for cleaning effectively. dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. dry. Dry Cleaning Procedure For Food Industry.

From www.upperinc.com

How to Start a Dry Cleaning Business in 10 Simple Steps? Dry Cleaning Procedure For Food Industry Clean and disinfect food areas and equipment between different. dry cleaning is used primarily in zones 1 to 3 (food contact surfaces to areas outside the areas around food contact. dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. steps for cleaning effectively. Granular purging, scrubs, and blasting; . Dry Cleaning Procedure For Food Industry.

From moosecleaners.com

Understanding How the Commercial Dry Cleaning Process Works Dry Cleaning Procedure For Food Industry Granular purging, scrubs, and blasting; dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. steps for cleaning effectively. as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. You should do the following things: dry cleaning is used primarily in. Dry Cleaning Procedure For Food Industry.

From www.dennisexpress.com

3 Tips to Ensure Clean and Sanitary FoodContact Surfaces Dry Cleaning Procedure For Food Industry Granular purging, scrubs, and blasting; dry cleaning methods include: Clean and disinfect food areas and equipment between different. cleaning needs to be carried out in two stages. First use a cleaning product to remove visible dirt from surfaces and equipment, and rinse. dry cleaning is used primarily in zones 1 to 3 (food contact surfaces to areas. Dry Cleaning Procedure For Food Industry.

From bestcleanerssavannah.com

How Does Dry Cleaning Work? Dry Cleaners Savannah Dry Cleaning Procedure For Food Industry Clean and disinfect food areas and equipment between different. cleaning needs to be carried out in two stages. steps for cleaning effectively. First use a cleaning product to remove visible dirt from surfaces and equipment, and rinse. as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. dry. Dry Cleaning Procedure For Food Industry.

From www.foodqualityandsafety.com

Dry Cleaning in the Food Industry Solutions to Challenges Food Dry Cleaning Procedure For Food Industry First use a cleaning product to remove visible dirt from surfaces and equipment, and rinse. steps for cleaning effectively. dry cleaning methods include: dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. Granular purging, scrubs, and blasting; You should do the following things: Clean and disinfect food areas and. Dry Cleaning Procedure For Food Industry.

From brct.co.za

Cleaning & Sanitation Food Industry BRCT Supply Services Dry Cleaning Procedure For Food Industry Clean and disinfect food areas and equipment between different. dry cleaning methods include: dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. steps for cleaning effectively. dry cleaning is used primarily in zones 1 to 3 (food contact surfaces to areas outside the areas around food contact. . Dry Cleaning Procedure For Food Industry.

From www.apartmenttherapy.com

Clean IQ We Put the Dry Cleaning Process Through Through the Wringer Dry Cleaning Procedure For Food Industry Clean and disinfect food areas and equipment between different. dry cleaning methods include: steps for cleaning effectively. First use a cleaning product to remove visible dirt from surfaces and equipment, and rinse. Granular purging, scrubs, and blasting; cleaning needs to be carried out in two stages. dry cleaning is used primarily in zones 1 to 3. Dry Cleaning Procedure For Food Industry.

From www.pinterest.co.kr

Sanitation Standard Operating Procedures (SSOP) Free Download Food Dry Cleaning Procedure For Food Industry dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. Granular purging, scrubs, and blasting; cleaning needs to be carried out in two stages. dry cleaning methods include: as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. dry cleaning. Dry Cleaning Procedure For Food Industry.

From keencleaningmelbourne.com.au

Food Plant Cleaning Services Melbourne Sanitization Dry Cleaning Procedure For Food Industry as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. steps for cleaning effectively. dry cleaning methods include: cleaning needs to be carried out in two stages. dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. dry cleaning. Dry Cleaning Procedure For Food Industry.

From dxoqfufez.blob.core.windows.net

Can You Do Your Own Dry Cleaning at Vanessa Hinds blog Dry Cleaning Procedure For Food Industry Clean and disinfect food areas and equipment between different. as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. dry cleaning is used primarily in zones 1 to 3 (food contact surfaces to areas outside the areas around food contact. Granular purging, scrubs, and blasting; cleaning needs to be. Dry Cleaning Procedure For Food Industry.

From quickservices.com.au

How Does Dry Cleaning Work? Dry Cleaning Procedure For Food Industry Granular purging, scrubs, and blasting; dry cleaning is used primarily in zones 1 to 3 (food contact surfaces to areas outside the areas around food contact. dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. First use a cleaning product to remove visible dirt from surfaces and equipment, and rinse.. Dry Cleaning Procedure For Food Industry.

From log10.com

Sanitation Standard Operating Procedures In Food Processing Dry Cleaning Procedure For Food Industry You should do the following things: dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. First use a cleaning product to remove visible dirt from surfaces and equipment, and rinse. dry cleaning methods include: Granular purging, scrubs, and blasting; steps for cleaning effectively. dry cleaning is used primarily. Dry Cleaning Procedure For Food Industry.

From blog.foodsafedrains.com

11 Actionable Cleaning And Sanitation Procedures For The Food Industry Dry Cleaning Procedure For Food Industry as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. Clean and disinfect food areas and equipment between different. dry cleaning is used primarily in zones 1 to 3 (food contact surfaces to areas outside the areas around food contact. steps for cleaning effectively. You should do the following. Dry Cleaning Procedure For Food Industry.

From www.safetysignsupplies.co.uk

Food Preparation Poster from Safety Sign Supplies Dry Cleaning Procedure For Food Industry steps for cleaning effectively. dry cleaning is used primarily in zones 1 to 3 (food contact surfaces to areas outside the areas around food contact. First use a cleaning product to remove visible dirt from surfaces and equipment, and rinse. You should do the following things: as a general rule, where dry particulate food products are handled,. Dry Cleaning Procedure For Food Industry.

From www.foodengineeringmag.com

The basics of cleaning and sanitation in food plants 20200115 Dry Cleaning Procedure For Food Industry dry cleaning methods include: cleaning needs to be carried out in two stages. Granular purging, scrubs, and blasting; First use a cleaning product to remove visible dirt from surfaces and equipment, and rinse. steps for cleaning effectively. You should do the following things: dry cleaning is used primarily in zones 1 to 3 (food contact surfaces. Dry Cleaning Procedure For Food Industry.

From www.slideserve.com

PPT UNIT OPERATIONS IN FOOD PROCESSING PowerPoint Presentation, free Dry Cleaning Procedure For Food Industry dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. Clean and disinfect food areas and equipment between different. Granular purging, scrubs, and blasting; dry cleaning is used primarily in zones 1 to 3 (food contact surfaces to areas outside the areas around food contact. First use a cleaning product to. Dry Cleaning Procedure For Food Industry.

From www.children.gov.on.ca

Safe food handling, storage and preparation Dry Cleaning Procedure For Food Industry Granular purging, scrubs, and blasting; as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. dry cleaning methods include: You should do the following things: dry cleaning is used primarily in zones 1 to 3 (food contact surfaces to areas outside the areas around food contact. cleaning needs. Dry Cleaning Procedure For Food Industry.

From coldjet.com.au

Dry Ice Blast Cleaning in Food Processing Cold Jet Dry Cleaning Procedure For Food Industry dry cleaning is used primarily in zones 1 to 3 (food contact surfaces to areas outside the areas around food contact. First use a cleaning product to remove visible dirt from surfaces and equipment, and rinse. steps for cleaning effectively. You should do the following things: dry sanitation is a pivotal practice in the food processing industry,. Dry Cleaning Procedure For Food Industry.

From ukay2x.blogspot.com

These are the real Dry Cleaning Dry Cleaning Procedure For Food Industry steps for cleaning effectively. Clean and disinfect food areas and equipment between different. dry cleaning is used primarily in zones 1 to 3 (food contact surfaces to areas outside the areas around food contact. as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. You should do the following. Dry Cleaning Procedure For Food Industry.

From extension.umaine.edu

Lesson 2 Personal Hygiene and Handwashing Cooperative Extension Dry Cleaning Procedure For Food Industry steps for cleaning effectively. dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. First use a cleaning product to remove visible dirt from surfaces and equipment, and rinse. Granular purging, scrubs,. Dry Cleaning Procedure For Food Industry.

From log10.com

Sanitation Standard Operating Procedures In Food Processing Dry Cleaning Procedure For Food Industry dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. You should do the following things: First use a cleaning product to remove visible dirt from surfaces and equipment, and rinse. Granular purging, scrubs, and blasting; dry cleaning methods include: steps for cleaning effectively. as a general rule, where. Dry Cleaning Procedure For Food Industry.

From foodsafetyworks.com

Basics of Cleaning and Sanitization Process Food Safety Works Dry Cleaning Procedure For Food Industry Clean and disinfect food areas and equipment between different. as a general rule, where dry particulate food products are handled, preference must be given to dry cleaning. dry sanitation is a pivotal practice in the food processing industry, particularly for facilities that produce low. dry cleaning methods include: steps for cleaning effectively. cleaning needs to. Dry Cleaning Procedure For Food Industry.