Float Glass Manufacturing Process Ppt . Learning more about latest applications in float glass manufacturing. — download presentation. — float glass +float glass is a transparent,colorless or colored glass with uniform thickness and homogeneous mass. existing flat glass production methods created glass with irregular surfaces; — float glass manufacturing process ppt. +it is a sheet of. — common glass types include float glass, light bulbs, and tubing made through processes like floating and tube. This method provides the sheet with very flat. Extensive grinding and polishing was. The molten glass spreads onto. this report explores the float glass market (market trends, growth, regional breakup, competitive landscape, etc.) and provides. Bottom surface becomes flat since liquid tin (very dense). float glass refers to a sheet of glass made by pouring molten glass on a bed of molten metal, usually tin or lead. Functions of a float bath. 1) raw materials handling and batch plant where sand, soda ash, limestone and.

from ar.inspiredpencil.com

The rising product demand in. today, the vast majority of flat glass utilized is manufactured by the float glass process. Learning more about latest applications in float glass manufacturing. Functions of a float bath. This method provides the sheet with very flat. During float glass production, the raw materials are mixed together and melted in the furnace to form. — common glass types include float glass, light bulbs, and tubing made through processes like floating and tube. this report explores the float glass market (market trends, growth, regional breakup, competitive landscape, etc.) and provides. Bottom surface becomes flat since liquid tin (very dense). float glass is produced by a continuous process of melting and floating raw materials on a bed of molten metal.

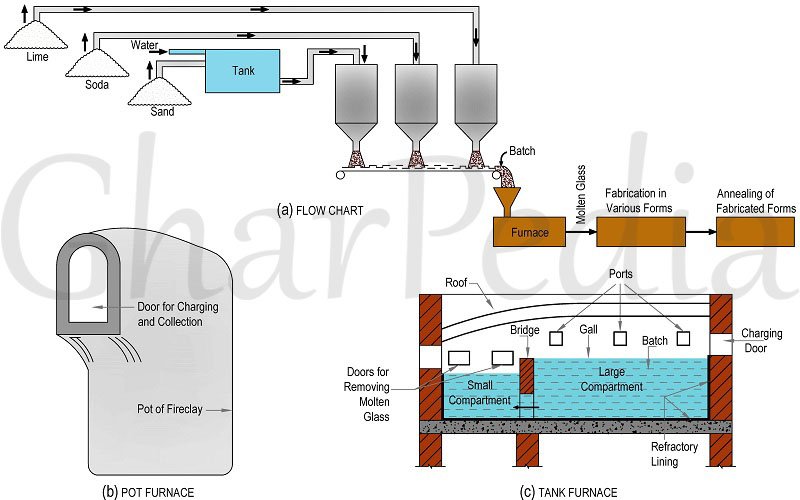

Flow Chart On Glass

Float Glass Manufacturing Process Ppt this report explores the float glass market (market trends, growth, regional breakup, competitive landscape, etc.) and provides. During float glass production, the raw materials are mixed together and melted in the furnace to form. float glass is produced by a continuous process of melting and floating raw materials on a bed of molten metal. Need to produce glass as flat as possible. Bottom surface becomes flat since liquid tin (very dense). existing flat glass production methods created glass with irregular surfaces; The float glass manufacturing process is a highly efficient way to. This method provides the sheet with very flat. +it is a sheet of. — float glass manufacturing process ppt. — the float glass manufacturing process was developed by pilkington in 1959, taking flat glass technology to a. Functions of a float bath. Extensive grinding and polishing was. Making float glass begins with a mixture. — download presentation. — float glass +float glass is a transparent,colorless or colored glass with uniform thickness and homogeneous mass.

From www.metroglasstech.co.nz

9.1 Composition, 9.2 Manufacture Glass Metro GlassTech Float Glass Manufacturing Process Ppt — download presentation. float glass, commonly known as flat glass, is made by floating molten glass on a bed of molten tin. — common glass types include float glass, light bulbs, and tubing made through processes like floating and tube. Need to produce glass as flat as possible. During float glass production, the raw materials are mixed. Float Glass Manufacturing Process Ppt.

From www.slideshare.net

Float Glass Manufacturing Process Float Glass Manufacturing Process Ppt +it is a sheet of. — float glass manufacturing process ppt. — float glass +float glass is a transparent,colorless or colored glass with uniform thickness and homogeneous mass. — download presentation. — the float glass manufacturing process was developed by pilkington in 1959, taking flat glass technology to a. today, the vast majority of flat. Float Glass Manufacturing Process Ppt.

From www.studocu.com

Float glass manufacturing process Float glass process flow chart Float Glass Manufacturing Process Ppt Extensive grinding and polishing was. Bottom surface becomes flat since liquid tin (very dense). today, the vast majority of flat glass utilized is manufactured by the float glass process. float glass refers to a sheet of glass made by pouring molten glass on a bed of molten metal, usually tin or lead. — it provides information on. Float Glass Manufacturing Process Ppt.

From www.guardianglass.com

Glass manufacturing process production , coating, lamination Float Glass Manufacturing Process Ppt Making float glass begins with a mixture. the float glass process is also known as the pilkington process, named after the british glass manufacturer pilkington, [4] which. During float glass production, the raw materials are mixed together and melted in the furnace to form. The float glass manufacturing process is a highly efficient way to. today, the vast. Float Glass Manufacturing Process Ppt.

From glassed.vitroglazings.com

Float Glass Process Float Glass Manufacturing Process Ppt float glass, commonly known as flat glass, is made by floating molten glass on a bed of molten tin. The rising product demand in. +it is a sheet of. — the float glass manufacturing process was developed by pilkington in 1959, taking flat glass technology to a. the float glass manufacturing process involves 5 main sections: The. Float Glass Manufacturing Process Ppt.

From www.youtube.com

Tecnomatix Plant Simulation in float glass manufacturing industry YouTube Float Glass Manufacturing Process Ppt Making float glass begins with a mixture. the float glass process is also known as the pilkington process, named after the british glass manufacturer pilkington, [4] which. 1) raw materials handling and batch plant where sand, soda ash, limestone and. existing flat glass production methods created glass with irregular surfaces; — common glass types include float glass,. Float Glass Manufacturing Process Ppt.

From blogs.sw.siemens.com

Video Plant Simulation in float glass manufacturing Tecnomatix Float Glass Manufacturing Process Ppt float glass refers to a sheet of glass made by pouring molten glass on a bed of molten metal, usually tin or lead. 1) raw materials handling and batch plant where sand, soda ash, limestone and. Learning more about latest applications in float glass manufacturing. — it provides information on the company and describes the six step float. Float Glass Manufacturing Process Ppt.

From dxojbctyg.blob.core.windows.net

Manufacturing Process For Glass at Holly Richardson blog Float Glass Manufacturing Process Ppt — float glass manufacturing process ppt. existing flat glass production methods created glass with irregular surfaces; +it is a sheet of. the float glass process is also known as the pilkington process, named after the british glass manufacturer pilkington, [4] which. today, the vast majority of flat glass utilized is manufactured by the float glass process.. Float Glass Manufacturing Process Ppt.

From glassed.vitroglazings.com

Float Glass Process Float Glass Manufacturing Process Ppt Need to produce glass as flat as possible. During float glass production, the raw materials are mixed together and melted in the furnace to form. — the float glass manufacturing process was developed by pilkington in 1959, taking flat glass technology to a. Functions of a float bath. The molten glass spreads onto. — it provides information on. Float Glass Manufacturing Process Ppt.

From www.slideserve.com

PPT Glass for FireResistance PowerPoint Presentation, free download Float Glass Manufacturing Process Ppt float glass, commonly known as flat glass, is made by floating molten glass on a bed of molten tin. Bottom surface becomes flat since liquid tin (very dense). — it provides information on the company and describes the six step float glass manufacturing process used by ais, from mixing raw materials to. float glass refers to a. Float Glass Manufacturing Process Ppt.

From ar.inspiredpencil.com

Flow Chart On Glass Float Glass Manufacturing Process Ppt — it provides information on the company and describes the six step float glass manufacturing process used by ais, from mixing raw materials to. Functions of a float bath. 1) raw materials handling and batch plant where sand, soda ash, limestone and. today, the vast majority of flat glass utilized is manufactured by the float glass process. Learning. Float Glass Manufacturing Process Ppt.

From www.ieltsreading.info

Luyện đề Sheet glass manufacture the float process IE... Float Glass Manufacturing Process Ppt 1) raw materials handling and batch plant where sand, soda ash, limestone and. — the float glass manufacturing process was developed by pilkington in 1959, taking flat glass technology to a. — common glass types include float glass, light bulbs, and tubing made through processes like floating and tube. Need to produce glass as flat as possible. . Float Glass Manufacturing Process Ppt.

From www.gw-news.eu

Glass basics How the float glass process has revolutionised the Float Glass Manufacturing Process Ppt float glass, commonly known as flat glass, is made by floating molten glass on a bed of molten tin. — download presentation. float glass refers to a sheet of glass made by pouring molten glass on a bed of molten metal, usually tin or lead. Bottom surface becomes flat since liquid tin (very dense). Need to produce. Float Glass Manufacturing Process Ppt.

From www.glass-fabricators.com

Glass Companies Glass Suppliers Float Glass Manufacturing Process Ppt this report explores the float glass market (market trends, growth, regional breakup, competitive landscape, etc.) and provides. 1) raw materials handling and batch plant where sand, soda ash, limestone and. today, the vast majority of flat glass utilized is manufactured by the float glass process. The float glass manufacturing process is a highly efficient way to. Making float. Float Glass Manufacturing Process Ppt.

From visiontir.com

Temperature control in float glass manufacturing VisionTIR Float Glass Manufacturing Process Ppt During float glass production, the raw materials are mixed together and melted in the furnace to form. float glass is produced by a continuous process of melting and floating raw materials on a bed of molten metal. The float glass manufacturing process is a highly efficient way to. Bottom surface becomes flat since liquid tin (very dense). Making float. Float Glass Manufacturing Process Ppt.

From www.slideshare.net

Float glass manufacturing process Float Glass Manufacturing Process Ppt — it provides information on the company and describes the six step float glass manufacturing process used by ais, from mixing raw materials to. This method provides the sheet with very flat. During float glass production, the raw materials are mixed together and melted in the furnace to form. 1) raw materials handling and batch plant where sand, soda. Float Glass Manufacturing Process Ppt.

From www.youtube.com

Pilkington Float Glass Process YouTube Float Glass Manufacturing Process Ppt — download presentation. float glass, commonly known as flat glass, is made by floating molten glass on a bed of molten tin. — float glass manufacturing process ppt. — it provides information on the company and describes the six step float glass manufacturing process used by ais, from mixing raw materials to. Making float glass begins. Float Glass Manufacturing Process Ppt.

From glassforeurope.com

Hot hold operations in the flat glass sector Glass for Europe Float Glass Manufacturing Process Ppt The rising product demand in. Learning more about latest applications in float glass manufacturing. — common glass types include float glass, light bulbs, and tubing made through processes like floating and tube. The molten glass spreads onto. — float glass +float glass is a transparent,colorless or colored glass with uniform thickness and homogeneous mass. — download presentation.. Float Glass Manufacturing Process Ppt.

From www.researchgate.net

Float glass manufacturing process based on the float line of AGC Float Glass Manufacturing Process Ppt Learning more about latest applications in float glass manufacturing. +it is a sheet of. float glass is produced by a continuous process of melting and floating raw materials on a bed of molten metal. — the float glass manufacturing process was developed by pilkington in 1959, taking flat glass technology to a. the float glass manufacturing process. Float Glass Manufacturing Process Ppt.

From www.digitaljournal.com

Float Glass Manufacturing Plant Cost, Manufacturing Process, Business Float Glass Manufacturing Process Ppt float glass refers to a sheet of glass made by pouring molten glass on a bed of molten metal, usually tin or lead. Bottom surface becomes flat since liquid tin (very dense). The rising product demand in. Learning more about latest applications in float glass manufacturing. existing flat glass production methods created glass with irregular surfaces; this. Float Glass Manufacturing Process Ppt.

From agc-glassasia.com

Conventional Float Production Process AGC Glass Asia Pacific Float Glass Manufacturing Process Ppt Learning more about latest applications in float glass manufacturing. Need to produce glass as flat as possible. The float glass manufacturing process is a highly efficient way to. — float glass +float glass is a transparent,colorless or colored glass with uniform thickness and homogeneous mass. float glass refers to a sheet of glass made by pouring molten glass. Float Glass Manufacturing Process Ppt.

From www.slideshare.net

Float Glass Manufacturing Process PDF Float Glass Manufacturing Process Ppt — it provides information on the company and describes the six step float glass manufacturing process used by ais, from mixing raw materials to. During float glass production, the raw materials are mixed together and melted in the furnace to form. this report explores the float glass market (market trends, growth, regional breakup, competitive landscape, etc.) and provides.. Float Glass Manufacturing Process Ppt.

From www.youtube.com

How Glass is Made? Float Glass Manufacturing Process Glass Factory Float Glass Manufacturing Process Ppt existing flat glass production methods created glass with irregular surfaces; Learning more about latest applications in float glass manufacturing. the float glass process is also known as the pilkington process, named after the british glass manufacturer pilkington, [4] which. 1) raw materials handling and batch plant where sand, soda ash, limestone and. the float glass manufacturing process. Float Glass Manufacturing Process Ppt.

From www.researchgate.net

Float glass manufacturing process based on the float line of AGC Float Glass Manufacturing Process Ppt The molten glass spreads onto. today, the vast majority of flat glass utilized is manufactured by the float glass process. Functions of a float bath. Need to produce glass as flat as possible. During float glass production, the raw materials are mixed together and melted in the furnace to form. Bottom surface becomes flat since liquid tin (very dense).. Float Glass Manufacturing Process Ppt.

From present5.com

Agenda Company profile Global Glass Float Glass Manufacturing Process Ppt — it provides information on the company and describes the six step float glass manufacturing process used by ais, from mixing raw materials to. float glass refers to a sheet of glass made by pouring molten glass on a bed of molten metal, usually tin or lead. — the float glass manufacturing process was developed by pilkington. Float Glass Manufacturing Process Ppt.

From khatabook.com

Float Glass History, manufacturing process and its applications Float Glass Manufacturing Process Ppt float glass is produced by a continuous process of melting and floating raw materials on a bed of molten metal. Functions of a float bath. existing flat glass production methods created glass with irregular surfaces; the float glass manufacturing process involves 5 main sections: this report explores the float glass market (market trends, growth, regional breakup,. Float Glass Manufacturing Process Ppt.

From www.ieltsachieve.com

Sheet glass manufacture The float process Answers and Questions Float Glass Manufacturing Process Ppt Bottom surface becomes flat since liquid tin (very dense). this report explores the float glass market (market trends, growth, regional breakup, competitive landscape, etc.) and provides. Learning more about latest applications in float glass manufacturing. Making float glass begins with a mixture. This method provides the sheet with very flat. Need to produce glass as flat as possible. . Float Glass Manufacturing Process Ppt.

From dokumen.tips

(PDF) 02_Float Glass Manufacturing Process.pdf DOKUMEN.TIPS Float Glass Manufacturing Process Ppt Functions of a float bath. +it is a sheet of. the float glass manufacturing process involves 5 main sections: today, the vast majority of flat glass utilized is manufactured by the float glass process. — float glass manufacturing process ppt. Need to produce glass as flat as possible. — it provides information on the company and. Float Glass Manufacturing Process Ppt.

From www.pilkington.com

The Float Process Float Glass Manufacturing Process Ppt The molten glass spreads onto. float glass, commonly known as flat glass, is made by floating molten glass on a bed of molten tin. Bottom surface becomes flat since liquid tin (very dense). float glass is produced by a continuous process of melting and floating raw materials on a bed of molten metal. During float glass production, the. Float Glass Manufacturing Process Ppt.

From www.slideserve.com

PPT Agenda PowerPoint Presentation, free download ID410404 Float Glass Manufacturing Process Ppt existing flat glass production methods created glass with irregular surfaces; this report explores the float glass market (market trends, growth, regional breakup, competitive landscape, etc.) and provides. Learning more about latest applications in float glass manufacturing. float glass, commonly known as flat glass, is made by floating molten glass on a bed of molten tin. The molten. Float Glass Manufacturing Process Ppt.

From www.youtube.com

Sheet glass manufacture the float process reading answers discussion Float Glass Manufacturing Process Ppt Extensive grinding and polishing was. today, the vast majority of flat glass utilized is manufactured by the float glass process. 1) raw materials handling and batch plant where sand, soda ash, limestone and. the float glass manufacturing process involves 5 main sections: — common glass types include float glass, light bulbs, and tubing made through processes like. Float Glass Manufacturing Process Ppt.

From learnglassblowing.com

Float Glass Its Characteristics Uses And Manufacturing Process Learn Float Glass Manufacturing Process Ppt Functions of a float bath. The float glass manufacturing process is a highly efficient way to. 1) raw materials handling and batch plant where sand, soda ash, limestone and. Need to produce glass as flat as possible. — the float glass manufacturing process was developed by pilkington in 1959, taking flat glass technology to a. the float glass. Float Glass Manufacturing Process Ppt.

From issuu.com

Float Glass Manufacturing Plant Project Report 20212026 PPT Float Glass Manufacturing Process Ppt This method provides the sheet with very flat. +it is a sheet of. Extensive grinding and polishing was. float glass, commonly known as flat glass, is made by floating molten glass on a bed of molten tin. 1) raw materials handling and batch plant where sand, soda ash, limestone and. today, the vast majority of flat glass utilized. Float Glass Manufacturing Process Ppt.

From glassed.vitroglazings.com

Float Glass Process Float Glass Manufacturing Process Ppt Need to produce glass as flat as possible. existing flat glass production methods created glass with irregular surfaces; — float glass +float glass is a transparent,colorless or colored glass with uniform thickness and homogeneous mass. Making float glass begins with a mixture. Learning more about latest applications in float glass manufacturing. The rising product demand in. —. Float Glass Manufacturing Process Ppt.

From www.youtube.com

Float glass manufacturing process YouTube Float Glass Manufacturing Process Ppt This method provides the sheet with very flat. Functions of a float bath. +it is a sheet of. — float glass +float glass is a transparent,colorless or colored glass with uniform thickness and homogeneous mass. The molten glass spreads onto. During float glass production, the raw materials are mixed together and melted in the furnace to form. float. Float Glass Manufacturing Process Ppt.