Coupling Sleeve Use . Split muff or compression shaft couplings. This is the simplest type of. A sleeve coupling is a mechanical joint commonly found in the industrial sector. The split muff coupling consists of driver and driven shafts (same diameter) with. A sleeve coupling is a mechanical device used to connect two shafts in order to transmit power and torque from one shaft to the other while accommodating. Sleeve couplings are nothing but just sort of thick hollow cylinder/pipe called as sleeve or muff. The driver & driven, both the shafts are then inserted into each. ( types of coupling ) sleeve coupling. Sleeve coupling with labelled parts. They use a special sleeve in which. It is used to join two shafts together, transmitting power from one to the other. The sleeve is manufactured keeping the diameter of the shaft in mind so that the shaft fits perfectly into the sleeve. Shaft couplings are divided into two main groups as follows: Cutout couplings allow the driving/driven halves to be disengaged without disassembling the coupling. It is used to connect two perfectly aligned shafts.

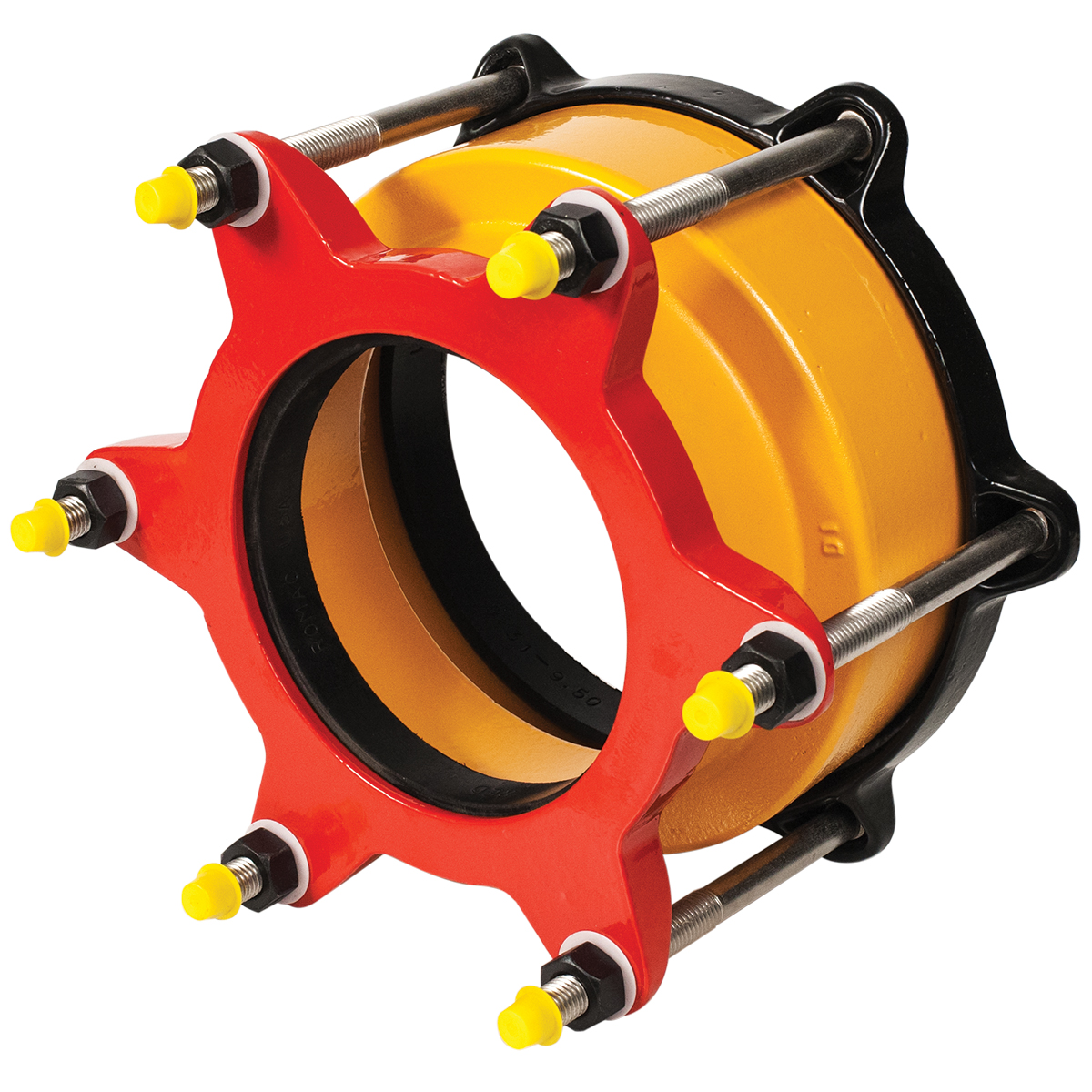

from romac.com

A sleeve coupling is a mechanical device used to connect two shafts in order to transmit power and torque from one shaft to the other while accommodating. Cutout couplings allow the driving/driven halves to be disengaged without disassembling the coupling. Sleeve couplings are nothing but just sort of thick hollow cylinder/pipe called as sleeve or muff. Sleeve coupling with labelled parts. The driver & driven, both the shafts are then inserted into each. Split muff or compression shaft couplings. A sleeve coupling is a mechanical joint commonly found in the industrial sector. The sleeve is manufactured keeping the diameter of the shaft in mind so that the shaft fits perfectly into the sleeve. They use a special sleeve in which. The split muff coupling consists of driver and driven shafts (same diameter) with.

COUPLINGS — ROMAC INDUSTRIES

Coupling Sleeve Use Split muff or compression shaft couplings. It is used to join two shafts together, transmitting power from one to the other. The driver & driven, both the shafts are then inserted into each. The sleeve is manufactured keeping the diameter of the shaft in mind so that the shaft fits perfectly into the sleeve. Shaft couplings are divided into two main groups as follows: Sleeve coupling with labelled parts. It is used to connect two perfectly aligned shafts. ( types of coupling ) sleeve coupling. A sleeve coupling is a mechanical joint commonly found in the industrial sector. Sleeve couplings are nothing but just sort of thick hollow cylinder/pipe called as sleeve or muff. Split muff or compression shaft couplings. They use a special sleeve in which. Cutout couplings allow the driving/driven halves to be disengaged without disassembling the coupling. This is the simplest type of. The split muff coupling consists of driver and driven shafts (same diameter) with. A sleeve coupling is a mechanical device used to connect two shafts in order to transmit power and torque from one shaft to the other while accommodating.

From www.amazon.com

Sleeve Coupling Insert, 9JE, EPDM Rubber Industrial Coupling Sleeve Use Sleeve coupling with labelled parts. A sleeve coupling is a mechanical device used to connect two shafts in order to transmit power and torque from one shaft to the other while accommodating. Shaft couplings are divided into two main groups as follows: Sleeve couplings are nothing but just sort of thick hollow cylinder/pipe called as sleeve or muff. Split muff. Coupling Sleeve Use.

From www.reddit.com

Different Types of Couplings r/coolguides Coupling Sleeve Use ( types of coupling ) sleeve coupling. It is used to join two shafts together, transmitting power from one to the other. The driver & driven, both the shafts are then inserted into each. Sleeve couplings are nothing but just sort of thick hollow cylinder/pipe called as sleeve or muff. Following types of rigid coupling are important from. Sleeve coupling. Coupling Sleeve Use.

From in.pinterest.com

Different Types of Couplings and Their Applications Explained Coupling Sleeve Use Cutout couplings allow the driving/driven halves to be disengaged without disassembling the coupling. A sleeve coupling is a mechanical joint commonly found in the industrial sector. It is used to join two shafts together, transmitting power from one to the other. This is the simplest type of. Sleeve coupling with labelled parts. The split muff coupling consists of driver and. Coupling Sleeve Use.

From www.pipesandfittings.com

Threaded Pipe Coupling Dimensions Chart Steel Coupling SANVO Coupling Sleeve Use This is the simplest type of. Sleeve coupling with labelled parts. They use a special sleeve in which. Cutout couplings allow the driving/driven halves to be disengaged without disassembling the coupling. The sleeve is manufactured keeping the diameter of the shaft in mind so that the shaft fits perfectly into the sleeve. A sleeve coupling is a mechanical device used. Coupling Sleeve Use.

From www.rfshydraulics.com

Quick Release Couplings RFS Hydraulics Coupling Sleeve Use They use a special sleeve in which. A sleeve coupling is a mechanical device used to connect two shafts in order to transmit power and torque from one shaft to the other while accommodating. A sleeve coupling is a mechanical joint commonly found in the industrial sector. Shaft couplings are divided into two main groups as follows: Sleeve coupling with. Coupling Sleeve Use.

From romac.com

Alpha Restrained Coupling — ROMAC INDUSTRIES Coupling Sleeve Use It is used to connect two perfectly aligned shafts. This is the simplest type of. ( types of coupling ) sleeve coupling. Cutout couplings allow the driving/driven halves to be disengaged without disassembling the coupling. Split muff or compression shaft couplings. They use a special sleeve in which. The split muff coupling consists of driver and driven shafts (same diameter). Coupling Sleeve Use.

From meroock.blogspot.com

mechanical rocks Couplings Coupling Sleeve Use Shaft couplings are divided into two main groups as follows: Sleeve couplings are nothing but just sort of thick hollow cylinder/pipe called as sleeve or muff. They use a special sleeve in which. A sleeve coupling is a mechanical device used to connect two shafts in order to transmit power and torque from one shaft to the other while accommodating.. Coupling Sleeve Use.

From samdex.eu

TaperLock Rigid Couplings SAMDEX Coupling Sleeve Use Sleeve couplings are nothing but just sort of thick hollow cylinder/pipe called as sleeve or muff. The split muff coupling consists of driver and driven shafts (same diameter) with. Cutout couplings allow the driving/driven halves to be disengaged without disassembling the coupling. A sleeve coupling is a mechanical device used to connect two shafts in order to transmit power and. Coupling Sleeve Use.

From www.agropomoc.com

Faster Coupling sleeve T2FNB3812G F KIT2FNB3812G F (86002203) Spare Coupling Sleeve Use The driver & driven, both the shafts are then inserted into each. The split muff coupling consists of driver and driven shafts (same diameter) with. ( types of coupling ) sleeve coupling. This is the simplest type of. Sleeve coupling with labelled parts. Split muff or compression shaft couplings. It is used to connect two perfectly aligned shafts. A sleeve. Coupling Sleeve Use.

From www.rock-drillingtools.com

Length 150mm 235mm Threaded Rod Coupling Sleeve High Strength Alloy Steel Coupling Sleeve Use A sleeve coupling is a mechanical joint commonly found in the industrial sector. This is the simplest type of. A sleeve coupling is a mechanical device used to connect two shafts in order to transmit power and torque from one shaft to the other while accommodating. Shaft couplings are divided into two main groups as follows: The sleeve is manufactured. Coupling Sleeve Use.

From catalog.wosupply.com

Dresser Couplings WO Supply Catalog Coupling Sleeve Use They use a special sleeve in which. Cutout couplings allow the driving/driven halves to be disengaged without disassembling the coupling. Sleeve coupling with labelled parts. This is the simplest type of. A sleeve coupling is a mechanical joint commonly found in the industrial sector. It is used to connect two perfectly aligned shafts. It is used to join two shafts. Coupling Sleeve Use.

From www.designworldonline.com

Precision sleeve couplings now include hex, square, and threaded bores Coupling Sleeve Use This is the simplest type of. It is used to join two shafts together, transmitting power from one to the other. A sleeve coupling is a mechanical joint commonly found in the industrial sector. Split muff or compression shaft couplings. The sleeve is manufactured keeping the diameter of the shaft in mind so that the shaft fits perfectly into the. Coupling Sleeve Use.

From philippinevalve.com

D.I. Sleeve Type Coupling Philippine Valve Coupling Sleeve Use It is used to join two shafts together, transmitting power from one to the other. Shaft couplings are divided into two main groups as follows: ( types of coupling ) sleeve coupling. Sleeve couplings are nothing but just sort of thick hollow cylinder/pipe called as sleeve or muff. Following types of rigid coupling are important from. Cutout couplings allow the. Coupling Sleeve Use.

From blog.thepipingmart.com

What is Sleeve Coupling? Coupling Sleeve Use A sleeve coupling is a mechanical device used to connect two shafts in order to transmit power and torque from one shaft to the other while accommodating. ( types of coupling ) sleeve coupling. It is used to connect two perfectly aligned shafts. Sleeve couplings are nothing but just sort of thick hollow cylinder/pipe called as sleeve or muff. The. Coupling Sleeve Use.

From engineeringlearn.com

Shaft Coupling Definition, Types, Uses, Working Principle & Advantages Coupling Sleeve Use Cutout couplings allow the driving/driven halves to be disengaged without disassembling the coupling. ( types of coupling ) sleeve coupling. It is used to join two shafts together, transmitting power from one to the other. The split muff coupling consists of driver and driven shafts (same diameter) with. A sleeve coupling is a mechanical device used to connect two shafts. Coupling Sleeve Use.

From www.huco.com

Rigid Couplings Coupling Sleeve Use This is the simplest type of. It is used to connect two perfectly aligned shafts. The split muff coupling consists of driver and driven shafts (same diameter) with. The driver & driven, both the shafts are then inserted into each. A sleeve coupling is a mechanical device used to connect two shafts in order to transmit power and torque from. Coupling Sleeve Use.

From romac.com

COUPLINGS — ROMAC INDUSTRIES Coupling Sleeve Use A sleeve coupling is a mechanical device used to connect two shafts in order to transmit power and torque from one shaft to the other while accommodating. Sleeve couplings are nothing but just sort of thick hollow cylinder/pipe called as sleeve or muff. Shaft couplings are divided into two main groups as follows: Sleeve coupling with labelled parts. The driver. Coupling Sleeve Use.

From ww.omnicomponentscorp.com

Precision Sleeve Couplings Coupling Sleeve Use Following types of rigid coupling are important from. Shaft couplings are divided into two main groups as follows: A sleeve coupling is a mechanical device used to connect two shafts in order to transmit power and torque from one shaft to the other while accommodating. A sleeve coupling is a mechanical joint commonly found in the industrial sector. This is. Coupling Sleeve Use.

From engineeringlearner.com

Types of Mechanical Coupling Engineering Learner Coupling Sleeve Use A sleeve coupling is a mechanical device used to connect two shafts in order to transmit power and torque from one shaft to the other while accommodating. The split muff coupling consists of driver and driven shafts (same diameter) with. It is used to connect two perfectly aligned shafts. This is the simplest type of. Following types of rigid coupling. Coupling Sleeve Use.

From www.guardiancouplings.com

General Purpose Flexible Jaw and Shaft Couplings Guardian Couplings Coupling Sleeve Use This is the simplest type of. It is used to join two shafts together, transmitting power from one to the other. Sleeve coupling with labelled parts. It is used to connect two perfectly aligned shafts. ( types of coupling ) sleeve coupling. Sleeve couplings are nothing but just sort of thick hollow cylinder/pipe called as sleeve or muff. A sleeve. Coupling Sleeve Use.

From www.supercuttool.com

Coupling sleeveSuper Cut Tool Coupling Sleeve Use A sleeve coupling is a mechanical joint commonly found in the industrial sector. This is the simplest type of. Shaft couplings are divided into two main groups as follows: Sleeve coupling with labelled parts. ( types of coupling ) sleeve coupling. Sleeve couplings are nothing but just sort of thick hollow cylinder/pipe called as sleeve or muff. The sleeve is. Coupling Sleeve Use.

From philippinevalve.com

D.I. Sleeve Type Coupling Philippine Valve Coupling Sleeve Use Split muff or compression shaft couplings. It is used to connect two perfectly aligned shafts. This is the simplest type of. They use a special sleeve in which. The driver & driven, both the shafts are then inserted into each. A sleeve coupling is a mechanical joint commonly found in the industrial sector. Cutout couplings allow the driving/driven halves to. Coupling Sleeve Use.

From www.youtube.com

Sleeve Coupling I Machine DesignI (BRB) YouTube Coupling Sleeve Use Sleeve couplings are nothing but just sort of thick hollow cylinder/pipe called as sleeve or muff. The driver & driven, both the shafts are then inserted into each. ( types of coupling ) sleeve coupling. Sleeve coupling with labelled parts. It is used to connect two perfectly aligned shafts. It is used to join two shafts together, transmitting power from. Coupling Sleeve Use.

From www.indiamart.com

Mild Steel Splined Sleeve Coupling, Rs 110 /piece Cosmos Infinite ID Coupling Sleeve Use Split muff or compression shaft couplings. The split muff coupling consists of driver and driven shafts (same diameter) with. Sleeve coupling with labelled parts. ( types of coupling ) sleeve coupling. A sleeve coupling is a mechanical joint commonly found in the industrial sector. They use a special sleeve in which. This is the simplest type of. Shaft couplings are. Coupling Sleeve Use.

From www.amazon.com

Lovejoy SFlex Coupling, JE Type Elastomer Sleeve, 1Piece Design, EPDM Coupling Sleeve Use Cutout couplings allow the driving/driven halves to be disengaged without disassembling the coupling. The sleeve is manufactured keeping the diameter of the shaft in mind so that the shaft fits perfectly into the sleeve. It is used to connect two perfectly aligned shafts. Shaft couplings are divided into two main groups as follows: The split muff coupling consists of driver. Coupling Sleeve Use.

From shopee.ph

2" (DN50) Sleeve Type Coupling / Universal Coupling / Dresser Coupling Coupling Sleeve Use They use a special sleeve in which. It is used to join two shafts together, transmitting power from one to the other. The split muff coupling consists of driver and driven shafts (same diameter) with. Split muff or compression shaft couplings. Shaft couplings are divided into two main groups as follows: Following types of rigid coupling are important from. Cutout. Coupling Sleeve Use.

From www.linkedin.com

Types Of Shaft Couplings Coupling Sleeve Use A sleeve coupling is a mechanical joint commonly found in the industrial sector. They use a special sleeve in which. A sleeve coupling is a mechanical device used to connect two shafts in order to transmit power and torque from one shaft to the other while accommodating. This is the simplest type of. Cutout couplings allow the driving/driven halves to. Coupling Sleeve Use.

From www.directindustry.com

Flexible shaft coupling BC series OEP Couplings sleeve and shear pin Coupling Sleeve Use Sleeve couplings are nothing but just sort of thick hollow cylinder/pipe called as sleeve or muff. It is used to join two shafts together, transmitting power from one to the other. Cutout couplings allow the driving/driven halves to be disengaged without disassembling the coupling. The driver & driven, both the shafts are then inserted into each. Following types of rigid. Coupling Sleeve Use.

From www.youtube.com

Types of Couplings, Usage and Applications YouTube Coupling Sleeve Use Sleeve coupling with labelled parts. Following types of rigid coupling are important from. The driver & driven, both the shafts are then inserted into each. The split muff coupling consists of driver and driven shafts (same diameter) with. Sleeve couplings are nothing but just sort of thick hollow cylinder/pipe called as sleeve or muff. A sleeve coupling is a mechanical. Coupling Sleeve Use.

From romac.com

COUPLINGS — ROMAC INDUSTRIES Coupling Sleeve Use It is used to join two shafts together, transmitting power from one to the other. The sleeve is manufactured keeping the diameter of the shaft in mind so that the shaft fits perfectly into the sleeve. It is used to connect two perfectly aligned shafts. Sleeve coupling with labelled parts. The driver & driven, both the shafts are then inserted. Coupling Sleeve Use.

From rock-drillingtool.com

Coupling Sleeve Drill Bit Connector SANDCO Coupling Sleeve Use They use a special sleeve in which. This is the simplest type of. A sleeve coupling is a mechanical device used to connect two shafts in order to transmit power and torque from one shaft to the other while accommodating. The driver & driven, both the shafts are then inserted into each. Cutout couplings allow the driving/driven halves to be. Coupling Sleeve Use.

From hvhindustrial.com

Elastomeric Couplings Elastomeric Jaw Couplings Coupling Sleeve Use It is used to connect two perfectly aligned shafts. A sleeve coupling is a mechanical device used to connect two shafts in order to transmit power and torque from one shaft to the other while accommodating. It is used to join two shafts together, transmitting power from one to the other. This is the simplest type of. The split muff. Coupling Sleeve Use.

From www.pinterest.com

Couplings sleeve are used to well connect the shank adapter to the Coupling Sleeve Use Shaft couplings are divided into two main groups as follows: It is used to join two shafts together, transmitting power from one to the other. A sleeve coupling is a mechanical joint commonly found in the industrial sector. Split muff or compression shaft couplings. A sleeve coupling is a mechanical device used to connect two shafts in order to transmit. Coupling Sleeve Use.

From www.printables.com

Coupling sleeve by 4FingerEddy Download free STL model Coupling Sleeve Use The sleeve is manufactured keeping the diameter of the shaft in mind so that the shaft fits perfectly into the sleeve. Following types of rigid coupling are important from. Cutout couplings allow the driving/driven halves to be disengaged without disassembling the coupling. Shaft couplings are divided into two main groups as follows: It is used to join two shafts together,. Coupling Sleeve Use.

From www.ebay.com

Lovejoy 35569 Size 6JE Solid Design SFlex Coupling Sleeve EPDM... Free Coupling Sleeve Use A sleeve coupling is a mechanical joint commonly found in the industrial sector. The sleeve is manufactured keeping the diameter of the shaft in mind so that the shaft fits perfectly into the sleeve. Split muff or compression shaft couplings. The driver & driven, both the shafts are then inserted into each. They use a special sleeve in which. The. Coupling Sleeve Use.