Arc Weld Not Penetrating . The welding current affects mostly joint. If left unsolved, this issue can lead to root cause analysis failure. As stated in the procedure handbook of arc welding “an increase in current increases penetration…but an excessively high current will produce and erratic arc.” amperage has the biggest effect on penetration. Common causes of poor penetration in mig welding. Mig weld not penetrating into the base metal are a common problem that can be challenging to fix. What does it mean when a mig welder is not penetrating? Checking your mig welder settings. The parameters used in arc welding have different effects on the final weld shape and size. Types of weld imperfections are introduced and the nature, causes, avoidance and repair of lack of penetration at the weld root when arc welding. There are some simple fixes you. Checking the shielding gas flow rate. Adjusting the wire feed speed. There are several reasons for this, including inaccurate setup procedures, incomplete penetration of the weld, and worn out equipment.

from www.mig-welding.co.uk

Common causes of poor penetration in mig welding. What does it mean when a mig welder is not penetrating? If left unsolved, this issue can lead to root cause analysis failure. Mig weld not penetrating into the base metal are a common problem that can be challenging to fix. The welding current affects mostly joint. There are several reasons for this, including inaccurate setup procedures, incomplete penetration of the weld, and worn out equipment. The parameters used in arc welding have different effects on the final weld shape and size. Adjusting the wire feed speed. There are some simple fixes you. As stated in the procedure handbook of arc welding “an increase in current increases penetration…but an excessively high current will produce and erratic arc.” amperage has the biggest effect on penetration.

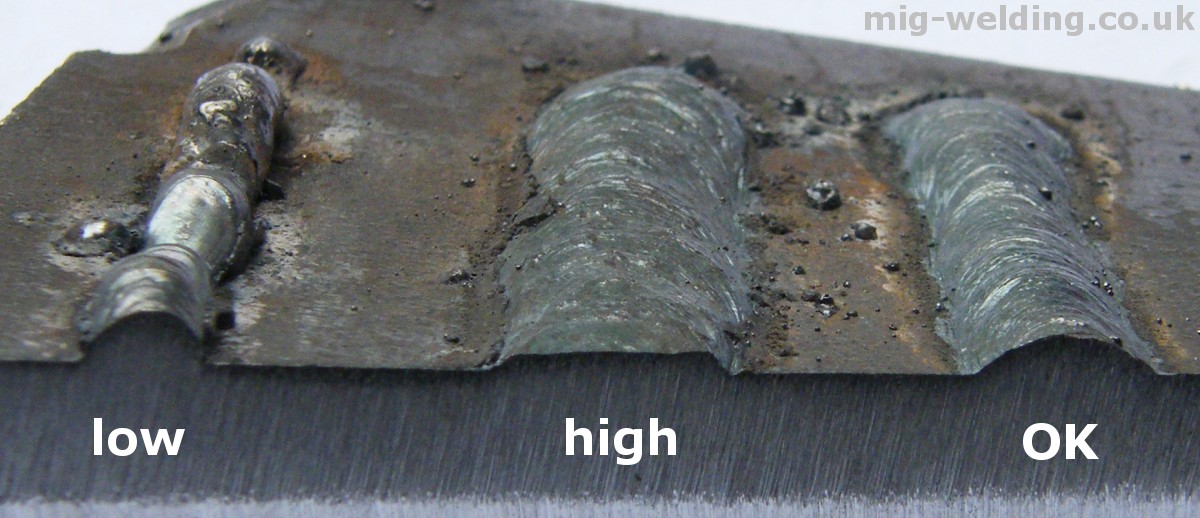

Arc Welding Faults Examples of Speed, Arc Length, and Current Problems

Arc Weld Not Penetrating Adjusting the wire feed speed. Checking the shielding gas flow rate. Checking your mig welder settings. Common causes of poor penetration in mig welding. Adjusting the wire feed speed. The welding current affects mostly joint. Mig weld not penetrating into the base metal are a common problem that can be challenging to fix. There are some simple fixes you. If left unsolved, this issue can lead to root cause analysis failure. As stated in the procedure handbook of arc welding “an increase in current increases penetration…but an excessively high current will produce and erratic arc.” amperage has the biggest effect on penetration. Types of weld imperfections are introduced and the nature, causes, avoidance and repair of lack of penetration at the weld root when arc welding. There are several reasons for this, including inaccurate setup procedures, incomplete penetration of the weld, and worn out equipment. What does it mean when a mig welder is not penetrating? The parameters used in arc welding have different effects on the final weld shape and size.

From mydesentway.com

What is Arc Welding A Comprehensive Guide With 5 Pro Tips Arc Weld Not Penetrating Checking the shielding gas flow rate. Types of weld imperfections are introduced and the nature, causes, avoidance and repair of lack of penetration at the weld root when arc welding. What does it mean when a mig welder is not penetrating? Adjusting the wire feed speed. The welding current affects mostly joint. Common causes of poor penetration in mig welding.. Arc Weld Not Penetrating.

From cartergoketravis.blogspot.com

Arc Welding Does Not Include Which of the Following Arc Weld Not Penetrating If left unsolved, this issue can lead to root cause analysis failure. What does it mean when a mig welder is not penetrating? Mig weld not penetrating into the base metal are a common problem that can be challenging to fix. Adjusting the wire feed speed. Checking your mig welder settings. Checking the shielding gas flow rate. Common causes of. Arc Weld Not Penetrating.

From www.canadianmetalworking.com

Is submerged arc welding the right process for you? Canadian Metalworking Arc Weld Not Penetrating Types of weld imperfections are introduced and the nature, causes, avoidance and repair of lack of penetration at the weld root when arc welding. The welding current affects mostly joint. Checking your mig welder settings. What does it mean when a mig welder is not penetrating? The parameters used in arc welding have different effects on the final weld shape. Arc Weld Not Penetrating.

From mavink.com

What Is Arc Welding Arc Weld Not Penetrating There are some simple fixes you. The welding current affects mostly joint. If left unsolved, this issue can lead to root cause analysis failure. Types of weld imperfections are introduced and the nature, causes, avoidance and repair of lack of penetration at the weld root when arc welding. Checking the shielding gas flow rate. Mig weld not penetrating into the. Arc Weld Not Penetrating.

From www.weldingmania.com

Why is My Wire Feed Welder not WeldingMania Arc Weld Not Penetrating If left unsolved, this issue can lead to root cause analysis failure. Checking your mig welder settings. The welding current affects mostly joint. As stated in the procedure handbook of arc welding “an increase in current increases penetration…but an excessively high current will produce and erratic arc.” amperage has the biggest effect on penetration. Common causes of poor penetration in. Arc Weld Not Penetrating.

From www.youtube.com

TIG Welding Tips and Arc Length YouTube Arc Weld Not Penetrating Checking the shielding gas flow rate. There are several reasons for this, including inaccurate setup procedures, incomplete penetration of the weld, and worn out equipment. What does it mean when a mig welder is not penetrating? As stated in the procedure handbook of arc welding “an increase in current increases penetration…but an excessively high current will produce and erratic arc.”. Arc Weld Not Penetrating.

From www.youtube.com

How to Arc Weld Welding YouTube Arc Weld Not Penetrating There are some simple fixes you. If left unsolved, this issue can lead to root cause analysis failure. As stated in the procedure handbook of arc welding “an increase in current increases penetration…but an excessively high current will produce and erratic arc.” amperage has the biggest effect on penetration. Checking the shielding gas flow rate. Mig weld not penetrating into. Arc Weld Not Penetrating.

From welderstream.com

The Complete Guide to Full Welding WelderStream Arc Weld Not Penetrating There are some simple fixes you. As stated in the procedure handbook of arc welding “an increase in current increases penetration…but an excessively high current will produce and erratic arc.” amperage has the biggest effect on penetration. Common causes of poor penetration in mig welding. Adjusting the wire feed speed. The parameters used in arc welding have different effects on. Arc Weld Not Penetrating.

From sensibledigs.com

How To Arc Weld (Simple StepbyStep Guide) Sensible Digs Arc Weld Not Penetrating There are some simple fixes you. Checking your mig welder settings. The parameters used in arc welding have different effects on the final weld shape and size. Mig weld not penetrating into the base metal are a common problem that can be challenging to fix. What does it mean when a mig welder is not penetrating? If left unsolved, this. Arc Weld Not Penetrating.

From www.mig-welding.co.uk

Arc Welding Faults Examples of Speed, Arc Length, and Current Problems Arc Weld Not Penetrating Adjusting the wire feed speed. As stated in the procedure handbook of arc welding “an increase in current increases penetration…but an excessively high current will produce and erratic arc.” amperage has the biggest effect on penetration. The welding current affects mostly joint. Checking your mig welder settings. There are some simple fixes you. There are several reasons for this, including. Arc Weld Not Penetrating.

From arcraftplasma.blogspot.com

Welding , Hardfacing , Cladding and Cutting of metals Welding Symbols Arc Weld Not Penetrating If left unsolved, this issue can lead to root cause analysis failure. There are some simple fixes you. What does it mean when a mig welder is not penetrating? There are several reasons for this, including inaccurate setup procedures, incomplete penetration of the weld, and worn out equipment. The parameters used in arc welding have different effects on the final. Arc Weld Not Penetrating.

From finemetalworking.com

Good Weld vs Bad Weld. How to Identify? (with Examples) Arc Weld Not Penetrating Common causes of poor penetration in mig welding. The parameters used in arc welding have different effects on the final weld shape and size. There are some simple fixes you. What does it mean when a mig welder is not penetrating? Checking the shielding gas flow rate. Checking your mig welder settings. Types of weld imperfections are introduced and the. Arc Weld Not Penetrating.

From weldgallery.com

Flux Core Welding Mistakes Avoid These Costly Errors! Arc Weld Not Penetrating What does it mean when a mig welder is not penetrating? Adjusting the wire feed speed. The welding current affects mostly joint. Checking the shielding gas flow rate. Common causes of poor penetration in mig welding. Checking your mig welder settings. Mig weld not penetrating into the base metal are a common problem that can be challenging to fix. There. Arc Weld Not Penetrating.

From tft-pneumatic.com

How to Identify the 7 Most Dangerous Welding Defects TFT Pneumatic Arc Weld Not Penetrating Types of weld imperfections are introduced and the nature, causes, avoidance and repair of lack of penetration at the weld root when arc welding. What does it mean when a mig welder is not penetrating? Checking your mig welder settings. There are several reasons for this, including inaccurate setup procedures, incomplete penetration of the weld, and worn out equipment. Checking. Arc Weld Not Penetrating.

From blog.thepipingmart.com

How Does Metal Arc Welding Work And What Are Its Types? Arc Weld Not Penetrating The parameters used in arc welding have different effects on the final weld shape and size. If left unsolved, this issue can lead to root cause analysis failure. As stated in the procedure handbook of arc welding “an increase in current increases penetration…but an excessively high current will produce and erratic arc.” amperage has the biggest effect on penetration. There. Arc Weld Not Penetrating.

From www.youtube.com

How Arc Welding Works YouTube Arc Weld Not Penetrating Adjusting the wire feed speed. If left unsolved, this issue can lead to root cause analysis failure. The welding current affects mostly joint. The parameters used in arc welding have different effects on the final weld shape and size. There are some simple fixes you. Checking your mig welder settings. Common causes of poor penetration in mig welding. Checking the. Arc Weld Not Penetrating.

From weldguru.com

Arc Welding Explained What Is It & How Does It Work? Weld Guru Arc Weld Not Penetrating There are several reasons for this, including inaccurate setup procedures, incomplete penetration of the weld, and worn out equipment. Types of weld imperfections are introduced and the nature, causes, avoidance and repair of lack of penetration at the weld root when arc welding. Checking the shielding gas flow rate. What does it mean when a mig welder is not penetrating?. Arc Weld Not Penetrating.

From weldguru.com

Arc Welding Explained What Is It & How Does It Work? Weld Guru Arc Weld Not Penetrating Checking the shielding gas flow rate. As stated in the procedure handbook of arc welding “an increase in current increases penetration…but an excessively high current will produce and erratic arc.” amperage has the biggest effect on penetration. Mig weld not penetrating into the base metal are a common problem that can be challenging to fix. What does it mean when. Arc Weld Not Penetrating.

From weldingproperty.com

How to Fix MiG Weld Not Your Welding Solutions Arc Weld Not Penetrating There are some simple fixes you. Types of weld imperfections are introduced and the nature, causes, avoidance and repair of lack of penetration at the weld root when arc welding. Mig weld not penetrating into the base metal are a common problem that can be challenging to fix. Common causes of poor penetration in mig welding. Checking your mig welder. Arc Weld Not Penetrating.

From www.youtube.com

Dealing with Under Welds (NonStructural) YouTube Arc Weld Not Penetrating Checking your mig welder settings. Common causes of poor penetration in mig welding. The welding current affects mostly joint. The parameters used in arc welding have different effects on the final weld shape and size. Types of weld imperfections are introduced and the nature, causes, avoidance and repair of lack of penetration at the weld root when arc welding. Adjusting. Arc Weld Not Penetrating.

From www.cwbgroup.org

How It Works What is a Backing Strip for a Welded Joint? CWB Group Arc Weld Not Penetrating Checking the shielding gas flow rate. Adjusting the wire feed speed. Types of weld imperfections are introduced and the nature, causes, avoidance and repair of lack of penetration at the weld root when arc welding. The welding current affects mostly joint. The parameters used in arc welding have different effects on the final weld shape and size. As stated in. Arc Weld Not Penetrating.

From www.canadianmetalworking.com

Submerged arc welding tech tips and fundamentals Arc Weld Not Penetrating The welding current affects mostly joint. Types of weld imperfections are introduced and the nature, causes, avoidance and repair of lack of penetration at the weld root when arc welding. Adjusting the wire feed speed. Common causes of poor penetration in mig welding. What does it mean when a mig welder is not penetrating? If left unsolved, this issue can. Arc Weld Not Penetrating.

From www.twi-global.com

What is Arc Welding? Definition and Process Types TWI Arc Weld Not Penetrating Types of weld imperfections are introduced and the nature, causes, avoidance and repair of lack of penetration at the weld root when arc welding. Checking the shielding gas flow rate. There are some simple fixes you. Checking your mig welder settings. As stated in the procedure handbook of arc welding “an increase in current increases penetration…but an excessively high current. Arc Weld Not Penetrating.

From weldguru.com

13 Common Types of Welding Defects & How to Prevent Them Arc Weld Not Penetrating The welding current affects mostly joint. The parameters used in arc welding have different effects on the final weld shape and size. Checking the shielding gas flow rate. What does it mean when a mig welder is not penetrating? There are several reasons for this, including inaccurate setup procedures, incomplete penetration of the weld, and worn out equipment. If left. Arc Weld Not Penetrating.

From www.mig-welding.co.uk

Arc Welding Faults Examples of Speed, Arc Length, and Current Problems Arc Weld Not Penetrating If left unsolved, this issue can lead to root cause analysis failure. The welding current affects mostly joint. There are some simple fixes you. Types of weld imperfections are introduced and the nature, causes, avoidance and repair of lack of penetration at the weld root when arc welding. Common causes of poor penetration in mig welding. What does it mean. Arc Weld Not Penetrating.

From www.mig-welding.co.uk

Arc Welding Faults Examples of Speed, Arc Length, and Current Problems Arc Weld Not Penetrating Checking your mig welder settings. There are several reasons for this, including inaccurate setup procedures, incomplete penetration of the weld, and worn out equipment. The welding current affects mostly joint. If left unsolved, this issue can lead to root cause analysis failure. There are some simple fixes you. Adjusting the wire feed speed. Checking the shielding gas flow rate. What. Arc Weld Not Penetrating.

From welderchoice.com

What are Types of Welding Defects? Causes, and Remedies Arc Weld Not Penetrating The parameters used in arc welding have different effects on the final weld shape and size. Adjusting the wire feed speed. Checking the shielding gas flow rate. As stated in the procedure handbook of arc welding “an increase in current increases penetration…but an excessively high current will produce and erratic arc.” amperage has the biggest effect on penetration. There are. Arc Weld Not Penetrating.

From lasolder.blogspot.com

Arc (MMA) Tutorial Sendi Datar viomag worldroid Arc Weld Not Penetrating The welding current affects mostly joint. What does it mean when a mig welder is not penetrating? There are some simple fixes you. Checking your mig welder settings. If left unsolved, this issue can lead to root cause analysis failure. As stated in the procedure handbook of arc welding “an increase in current increases penetration…but an excessively high current will. Arc Weld Not Penetrating.

From blog.thepipingmart.com

What are Welding Defects? ThePipingMart Blog Arc Weld Not Penetrating The parameters used in arc welding have different effects on the final weld shape and size. Adjusting the wire feed speed. There are several reasons for this, including inaccurate setup procedures, incomplete penetration of the weld, and worn out equipment. As stated in the procedure handbook of arc welding “an increase in current increases penetration…but an excessively high current will. Arc Weld Not Penetrating.

From marvelvietnam.com

Arc Welding Explained What Is It & How Does It Work? Weld Guru Arc Weld Not Penetrating Types of weld imperfections are introduced and the nature, causes, avoidance and repair of lack of penetration at the weld root when arc welding. There are several reasons for this, including inaccurate setup procedures, incomplete penetration of the weld, and worn out equipment. Mig weld not penetrating into the base metal are a common problem that can be challenging to. Arc Weld Not Penetrating.

From blog.thepipingmart.com

Spot Welding vs Arc Welding What's the Difference Arc Weld Not Penetrating If left unsolved, this issue can lead to root cause analysis failure. As stated in the procedure handbook of arc welding “an increase in current increases penetration…but an excessively high current will produce and erratic arc.” amperage has the biggest effect on penetration. The welding current affects mostly joint. What does it mean when a mig welder is not penetrating?. Arc Weld Not Penetrating.

From weldingtroop.com

Arc Welding vs. Spot Welding What’s the Difference? Arc Weld Not Penetrating The parameters used in arc welding have different effects on the final weld shape and size. There are several reasons for this, including inaccurate setup procedures, incomplete penetration of the weld, and worn out equipment. Checking your mig welder settings. Adjusting the wire feed speed. Checking the shielding gas flow rate. The welding current affects mostly joint. Common causes of. Arc Weld Not Penetrating.

From www.youtube.com

How to Strike an Arc Stick Welding Basics for Beginners YouTube Arc Weld Not Penetrating The parameters used in arc welding have different effects on the final weld shape and size. Adjusting the wire feed speed. What does it mean when a mig welder is not penetrating? There are several reasons for this, including inaccurate setup procedures, incomplete penetration of the weld, and worn out equipment. Common causes of poor penetration in mig welding. There. Arc Weld Not Penetrating.

From weldingproperty.com

Mig welder not 3 Common causes of poor Your Arc Weld Not Penetrating What does it mean when a mig welder is not penetrating? The welding current affects mostly joint. If left unsolved, this issue can lead to root cause analysis failure. There are some simple fixes you. Types of weld imperfections are introduced and the nature, causes, avoidance and repair of lack of penetration at the weld root when arc welding. As. Arc Weld Not Penetrating.

From www.youtube.com

Arc Welding Tips using 2 Multi Process Inverters YouTube Arc Weld Not Penetrating Types of weld imperfections are introduced and the nature, causes, avoidance and repair of lack of penetration at the weld root when arc welding. Common causes of poor penetration in mig welding. The welding current affects mostly joint. There are several reasons for this, including inaccurate setup procedures, incomplete penetration of the weld, and worn out equipment. There are some. Arc Weld Not Penetrating.