Wind Turbine Bearing Failure Rate . — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. — failure rate correction is a modification procedure of the absolute value of onshore wind turbine failure rates; It infers the failure rate of floating offshore wind turbines so that it can reflect the failure properties of floating offshore wind turbines. The gearbox is one of the. — according to the latest statistics from the database, the majority of wind turbine gearbox failures (76%) are caused by the bearings. — wind turbines fail around twice every year with an average downtime of 150 h per failure. Wind turbine main bearing rating lives are determined using iso 281 and iso/ts 16281 and are required by iec. bearings are crucial components that decide whether or not a wind turbine can work smoothly and that have a significant.

from theramreview.com

bearings are crucial components that decide whether or not a wind turbine can work smoothly and that have a significant. — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. — wind turbines fail around twice every year with an average downtime of 150 h per failure. — according to the latest statistics from the database, the majority of wind turbine gearbox failures (76%) are caused by the bearings. Wind turbine main bearing rating lives are determined using iso 281 and iso/ts 16281 and are required by iec. The gearbox is one of the. It infers the failure rate of floating offshore wind turbines so that it can reflect the failure properties of floating offshore wind turbines. — failure rate correction is a modification procedure of the absolute value of onshore wind turbine failure rates;

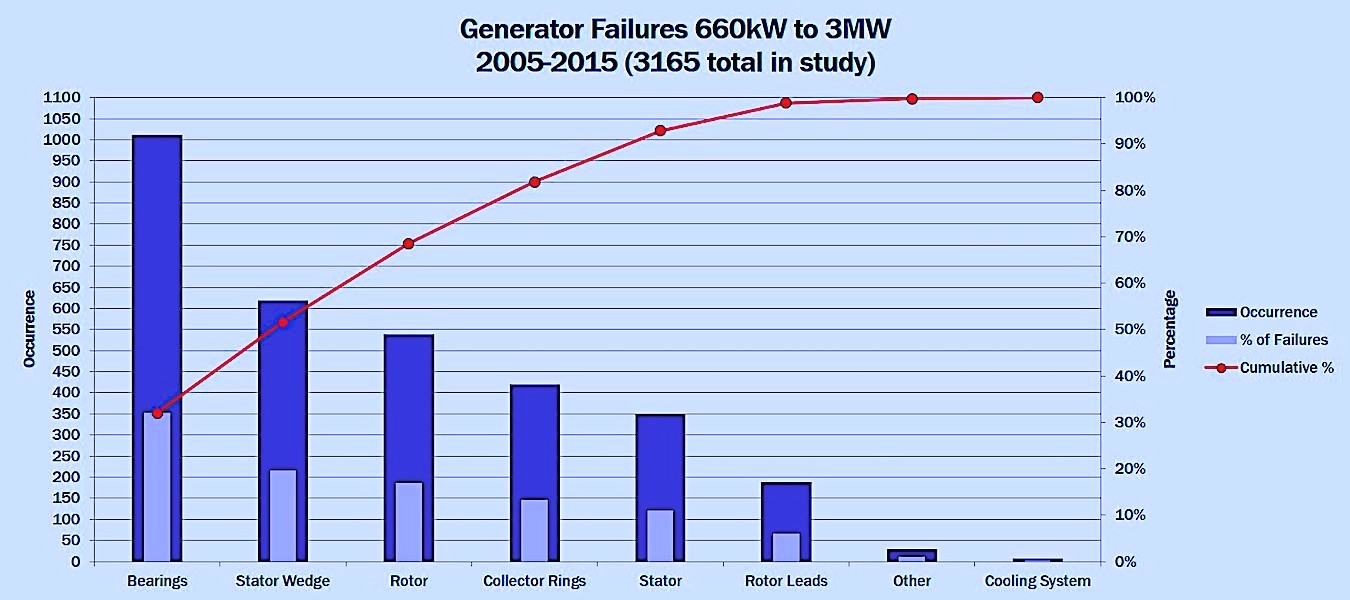

What Do Wind Generator Failures Really Look Like? THE RAM REVIEW

Wind Turbine Bearing Failure Rate — wind turbines fail around twice every year with an average downtime of 150 h per failure. It infers the failure rate of floating offshore wind turbines so that it can reflect the failure properties of floating offshore wind turbines. — wind turbines fail around twice every year with an average downtime of 150 h per failure. Wind turbine main bearing rating lives are determined using iso 281 and iso/ts 16281 and are required by iec. The gearbox is one of the. — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. — according to the latest statistics from the database, the majority of wind turbine gearbox failures (76%) are caused by the bearings. — failure rate correction is a modification procedure of the absolute value of onshore wind turbine failure rates; bearings are crucial components that decide whether or not a wind turbine can work smoothly and that have a significant.

From www.mdpi.com

JMSE Free FullText Failure Rate Assessment for Onshore and Wind Turbine Bearing Failure Rate — wind turbines fail around twice every year with an average downtime of 150 h per failure. The gearbox is one of the. bearings are crucial components that decide whether or not a wind turbine can work smoothly and that have a significant. — failure rate correction is a modification procedure of the absolute value of onshore. Wind Turbine Bearing Failure Rate.

From www.energy.gov

Statistics Show Bearing Problems Cause the Majority of Wind Turbine Wind Turbine Bearing Failure Rate It infers the failure rate of floating offshore wind turbines so that it can reflect the failure properties of floating offshore wind turbines. — wind turbines fail around twice every year with an average downtime of 150 h per failure. Wind turbine main bearing rating lives are determined using iso 281 and iso/ts 16281 and are required by iec.. Wind Turbine Bearing Failure Rate.

From www.mdpi.com

Energies Free FullText Failure Modes, Effects and Criticality Wind Turbine Bearing Failure Rate Wind turbine main bearing rating lives are determined using iso 281 and iso/ts 16281 and are required by iec. The gearbox is one of the. — according to the latest statistics from the database, the majority of wind turbine gearbox failures (76%) are caused by the bearings. — in this paper, a finite element model is established to. Wind Turbine Bearing Failure Rate.

From www.mdpi.com

Lubricants Free FullText A Review of Research on Wind Turbine Wind Turbine Bearing Failure Rate — wind turbines fail around twice every year with an average downtime of 150 h per failure. — failure rate correction is a modification procedure of the absolute value of onshore wind turbine failure rates; — according to the latest statistics from the database, the majority of wind turbine gearbox failures (76%) are caused by the bearings.. Wind Turbine Bearing Failure Rate.

From www.mdpi.com

Lubricants Free FullText A Review of Research on Wind Turbine Wind Turbine Bearing Failure Rate It infers the failure rate of floating offshore wind turbines so that it can reflect the failure properties of floating offshore wind turbines. — according to the latest statistics from the database, the majority of wind turbine gearbox failures (76%) are caused by the bearings. bearings are crucial components that decide whether or not a wind turbine can. Wind Turbine Bearing Failure Rate.

From www.windpowerengineering.com

Extending the life of wind turbines with prognostics and data modeling Wind Turbine Bearing Failure Rate The gearbox is one of the. — wind turbines fail around twice every year with an average downtime of 150 h per failure. — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. Wind turbine main bearing rating lives are determined using iso 281 and iso/ts 16281 and are. Wind Turbine Bearing Failure Rate.

From www.researchgate.net

14. Failure mode classifications of largescale wind turbine bearings Wind Turbine Bearing Failure Rate It infers the failure rate of floating offshore wind turbines so that it can reflect the failure properties of floating offshore wind turbines. The gearbox is one of the. — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. — wind turbines fail around twice every year with an. Wind Turbine Bearing Failure Rate.

From energycentral.com

5 Crucial Onshore Wind Turbine Components to Monitor to Stop Failure Wind Turbine Bearing Failure Rate — wind turbines fail around twice every year with an average downtime of 150 h per failure. — failure rate correction is a modification procedure of the absolute value of onshore wind turbine failure rates; It infers the failure rate of floating offshore wind turbines so that it can reflect the failure properties of floating offshore wind turbines.. Wind Turbine Bearing Failure Rate.

From www.mdpi.com

Lubricants Free FullText A Review of Research on Wind Turbine Wind Turbine Bearing Failure Rate Wind turbine main bearing rating lives are determined using iso 281 and iso/ts 16281 and are required by iec. — according to the latest statistics from the database, the majority of wind turbine gearbox failures (76%) are caused by the bearings. bearings are crucial components that decide whether or not a wind turbine can work smoothly and that. Wind Turbine Bearing Failure Rate.

From www.mdpi.com

Lubricants Free FullText A Review of Research on Wind Turbine Wind Turbine Bearing Failure Rate bearings are crucial components that decide whether or not a wind turbine can work smoothly and that have a significant. The gearbox is one of the. — wind turbines fail around twice every year with an average downtime of 150 h per failure. Wind turbine main bearing rating lives are determined using iso 281 and iso/ts 16281 and. Wind Turbine Bearing Failure Rate.

From www.researchgate.net

Failure of wind turbine blades, bearing and anchor bolts in different Wind Turbine Bearing Failure Rate — failure rate correction is a modification procedure of the absolute value of onshore wind turbine failure rates; — according to the latest statistics from the database, the majority of wind turbine gearbox failures (76%) are caused by the bearings. bearings are crucial components that decide whether or not a wind turbine can work smoothly and that. Wind Turbine Bearing Failure Rate.

From www.researchgate.net

The failure rates and downtime for components in a turbine (Source Wind Turbine Bearing Failure Rate — wind turbines fail around twice every year with an average downtime of 150 h per failure. — failure rate correction is a modification procedure of the absolute value of onshore wind turbine failure rates; Wind turbine main bearing rating lives are determined using iso 281 and iso/ts 16281 and are required by iec. It infers the failure. Wind Turbine Bearing Failure Rate.

From ar.inspiredpencil.com

Wind Turbine Failure Wind Turbine Bearing Failure Rate It infers the failure rate of floating offshore wind turbines so that it can reflect the failure properties of floating offshore wind turbines. — failure rate correction is a modification procedure of the absolute value of onshore wind turbine failure rates; Wind turbine main bearing rating lives are determined using iso 281 and iso/ts 16281 and are required by. Wind Turbine Bearing Failure Rate.

From www.researchgate.net

Percentage of failures for components of wind turbine Download Wind Turbine Bearing Failure Rate Wind turbine main bearing rating lives are determined using iso 281 and iso/ts 16281 and are required by iec. — according to the latest statistics from the database, the majority of wind turbine gearbox failures (76%) are caused by the bearings. bearings are crucial components that decide whether or not a wind turbine can work smoothly and that. Wind Turbine Bearing Failure Rate.

From www.mdpi.com

JMSE Free FullText Failure Rate Assessment for Onshore and Wind Turbine Bearing Failure Rate Wind turbine main bearing rating lives are determined using iso 281 and iso/ts 16281 and are required by iec. bearings are crucial components that decide whether or not a wind turbine can work smoothly and that have a significant. — wind turbines fail around twice every year with an average downtime of 150 h per failure. The gearbox. Wind Turbine Bearing Failure Rate.

From vdocuments.mx

Reliability Analysis for Wind Turbinesvides evidence of how turbine Wind Turbine Bearing Failure Rate — according to the latest statistics from the database, the majority of wind turbine gearbox failures (76%) are caused by the bearings. Wind turbine main bearing rating lives are determined using iso 281 and iso/ts 16281 and are required by iec. — failure rate correction is a modification procedure of the absolute value of onshore wind turbine failure. Wind Turbine Bearing Failure Rate.

From digital.library.unt.edu

Failure Atlas for Rolling Bearings in Wind Turbines UNT Digital Library Wind Turbine Bearing Failure Rate — failure rate correction is a modification procedure of the absolute value of onshore wind turbine failure rates; bearings are crucial components that decide whether or not a wind turbine can work smoothly and that have a significant. — wind turbines fail around twice every year with an average downtime of 150 h per failure. —. Wind Turbine Bearing Failure Rate.

From www.resonantlinktechnology.com

Renewables Resonant Link Technology Wind Turbine Bearing Failure Rate — according to the latest statistics from the database, the majority of wind turbine gearbox failures (76%) are caused by the bearings. bearings are crucial components that decide whether or not a wind turbine can work smoothly and that have a significant. — wind turbines fail around twice every year with an average downtime of 150 h. Wind Turbine Bearing Failure Rate.

From www.researchgate.net

3. Wind Turbine Failure Rate and Caused Downtime [2.21] Download Wind Turbine Bearing Failure Rate The gearbox is one of the. It infers the failure rate of floating offshore wind turbines so that it can reflect the failure properties of floating offshore wind turbines. — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. bearings are crucial components that decide whether or not a. Wind Turbine Bearing Failure Rate.

From www.researchgate.net

Distribution of average failure rates over windturbine subsystems Wind Turbine Bearing Failure Rate bearings are crucial components that decide whether or not a wind turbine can work smoothly and that have a significant. It infers the failure rate of floating offshore wind turbines so that it can reflect the failure properties of floating offshore wind turbines. — wind turbines fail around twice every year with an average downtime of 150 h. Wind Turbine Bearing Failure Rate.

From www.researchgate.net

Distribution of average failure rates over windturbine subsystems Wind Turbine Bearing Failure Rate — wind turbines fail around twice every year with an average downtime of 150 h per failure. — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. It infers the failure rate of floating offshore wind turbines so that it can reflect the failure properties of floating offshore wind. Wind Turbine Bearing Failure Rate.

From www.researchgate.net

(PDF) A Review of Research on Wind Turbine Bearings’ Failure Analysis Wind Turbine Bearing Failure Rate It infers the failure rate of floating offshore wind turbines so that it can reflect the failure properties of floating offshore wind turbines. — wind turbines fail around twice every year with an average downtime of 150 h per failure. bearings are crucial components that decide whether or not a wind turbine can work smoothly and that have. Wind Turbine Bearing Failure Rate.

From www.windpowerengineering.com

Why integrated bearing designs reduce windturbine gearbox failures Wind Turbine Bearing Failure Rate Wind turbine main bearing rating lives are determined using iso 281 and iso/ts 16281 and are required by iec. — wind turbines fail around twice every year with an average downtime of 150 h per failure. bearings are crucial components that decide whether or not a wind turbine can work smoothly and that have a significant. It infers. Wind Turbine Bearing Failure Rate.

From www.researchgate.net

(PDF) Failure analysis of bearing in wind turbine generator Wind Turbine Bearing Failure Rate Wind turbine main bearing rating lives are determined using iso 281 and iso/ts 16281 and are required by iec. — wind turbines fail around twice every year with an average downtime of 150 h per failure. — according to the latest statistics from the database, the majority of wind turbine gearbox failures (76%) are caused by the bearings.. Wind Turbine Bearing Failure Rate.

From www.researchgate.net

(PDF) Failure Modes, Effects and Criticality Analysis for Wind Turbines Wind Turbine Bearing Failure Rate It infers the failure rate of floating offshore wind turbines so that it can reflect the failure properties of floating offshore wind turbines. — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. — wind turbines fail around twice every year with an average downtime of 150 h per. Wind Turbine Bearing Failure Rate.

From www.researchgate.net

Average failure rates for wind turbine (WT) components from different Wind Turbine Bearing Failure Rate — according to the latest statistics from the database, the majority of wind turbine gearbox failures (76%) are caused by the bearings. Wind turbine main bearing rating lives are determined using iso 281 and iso/ts 16281 and are required by iec. — failure rate correction is a modification procedure of the absolute value of onshore wind turbine failure. Wind Turbine Bearing Failure Rate.

From www.engineeringworldchannel.com

Why Do Wind Turbines Fail? Wind Turbine Bearing Failure Rate — wind turbines fail around twice every year with an average downtime of 150 h per failure. — according to the latest statistics from the database, the majority of wind turbine gearbox failures (76%) are caused by the bearings. bearings are crucial components that decide whether or not a wind turbine can work smoothly and that have. Wind Turbine Bearing Failure Rate.

From theramreview.com

What Do Wind Generator Failures Really Look Like? THE RAM REVIEW Wind Turbine Bearing Failure Rate — failure rate correction is a modification procedure of the absolute value of onshore wind turbine failure rates; — according to the latest statistics from the database, the majority of wind turbine gearbox failures (76%) are caused by the bearings. — in this paper, a finite element model is established to calculate the subsurface stress of the. Wind Turbine Bearing Failure Rate.

From www.reliabilityconnect.com

Wind Turbines Electrical Reliability RELIABILITY CONNECT® Wind Turbine Bearing Failure Rate Wind turbine main bearing rating lives are determined using iso 281 and iso/ts 16281 and are required by iec. — failure rate correction is a modification procedure of the absolute value of onshore wind turbine failure rates; — according to the latest statistics from the database, the majority of wind turbine gearbox failures (76%) are caused by the. Wind Turbine Bearing Failure Rate.

From www.mdpi.com

JMSE Free FullText Failure Rate Assessment for Onshore and Wind Turbine Bearing Failure Rate — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. — failure rate correction is a modification procedure of the absolute value of onshore wind turbine failure rates; The gearbox is one of the. Wind turbine main bearing rating lives are determined using iso 281 and iso/ts 16281 and. Wind Turbine Bearing Failure Rate.

From www.mdpi.com

JMSE Free FullText Failure Rate Assessment for Onshore and Wind Turbine Bearing Failure Rate — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. bearings are crucial components that decide whether or not a wind turbine can work smoothly and that have a significant. It infers the failure rate of floating offshore wind turbines so that it can reflect the failure properties of. Wind Turbine Bearing Failure Rate.

From www.researchgate.net

Failure rates for wind turbine subassemblies working onshore and Wind Turbine Bearing Failure Rate It infers the failure rate of floating offshore wind turbines so that it can reflect the failure properties of floating offshore wind turbines. — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. bearings are crucial components that decide whether or not a wind turbine can work smoothly and. Wind Turbine Bearing Failure Rate.

From www.mdpi.com

Lubricants Free FullText A Review of Research on Wind Turbine Wind Turbine Bearing Failure Rate — in this paper, a finite element model is established to calculate the subsurface stress of the main shaft. bearings are crucial components that decide whether or not a wind turbine can work smoothly and that have a significant. — wind turbines fail around twice every year with an average downtime of 150 h per failure. It. Wind Turbine Bearing Failure Rate.

From digital.library.unt.edu

Wind Turbine Gearbox Failure Modes A Brief UNT Digital Library Wind Turbine Bearing Failure Rate — wind turbines fail around twice every year with an average downtime of 150 h per failure. — failure rate correction is a modification procedure of the absolute value of onshore wind turbine failure rates; The gearbox is one of the. — according to the latest statistics from the database, the majority of wind turbine gearbox failures. Wind Turbine Bearing Failure Rate.

From www.researchgate.net

Failure rate upper confidence limit (1 − α) of the wind turbine under Wind Turbine Bearing Failure Rate It infers the failure rate of floating offshore wind turbines so that it can reflect the failure properties of floating offshore wind turbines. — according to the latest statistics from the database, the majority of wind turbine gearbox failures (76%) are caused by the bearings. bearings are crucial components that decide whether or not a wind turbine can. Wind Turbine Bearing Failure Rate.