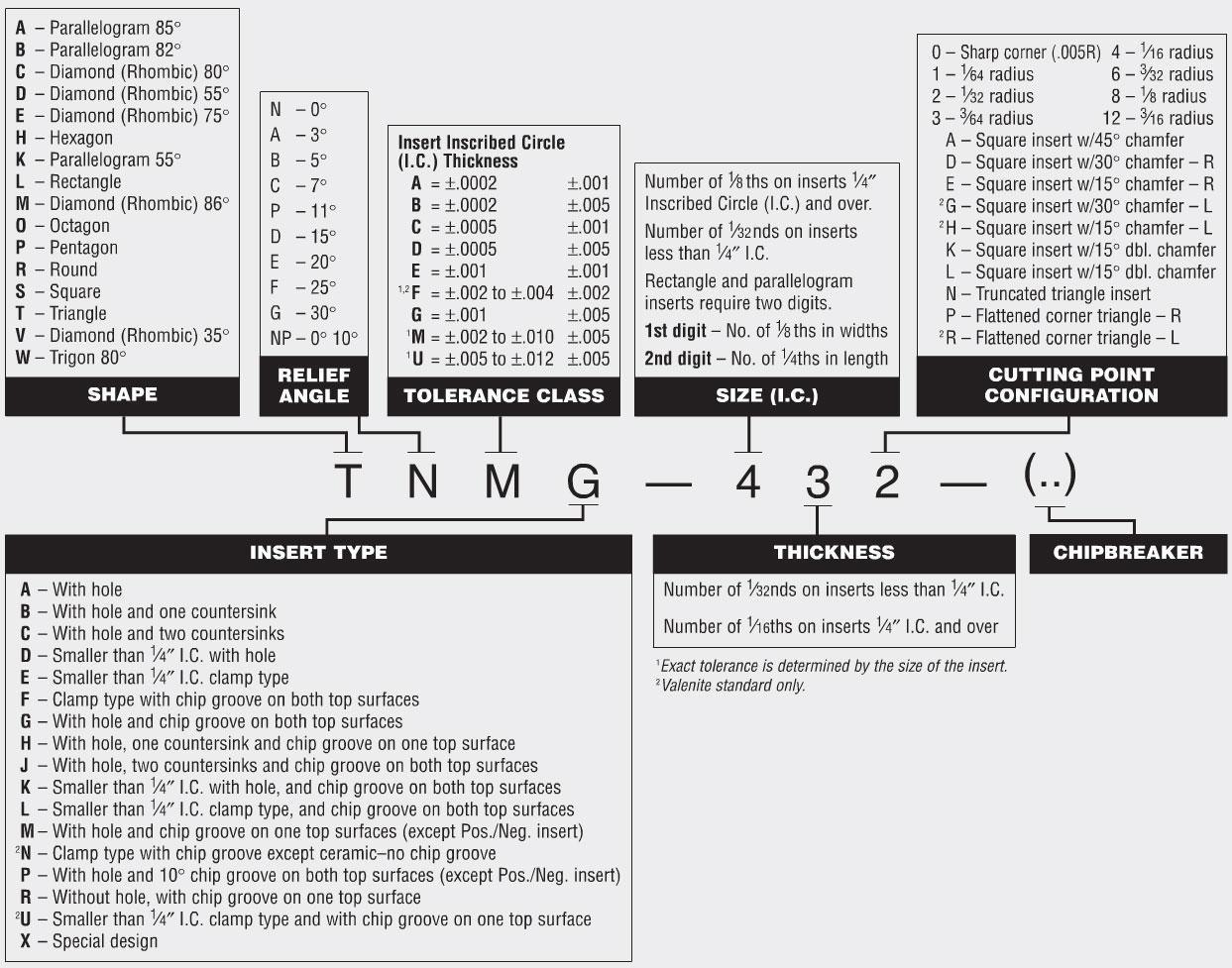

Carbide Insert Guide . These tables show the ansi and iso insert designations for indexable inserts for turning. Learn how to read the ansi insert code system & download a free carbide insert chart. Proper selection of cutting conditions, such as minimized depth of cut and appropriate feed rate, can significantly extend tool life. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. A given insert can be specified in either ansi (american) or iso (metric) designations. Selecting the right insert grade. Learn how to identify indexable inserts and insert shapes. Learn more about carbide inserts, and how to buy the right carbide. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this.

from ponasa.condesan-ecoandes.org

These tables show the ansi and iso insert designations for indexable inserts for turning. Learn how to read the ansi insert code system & download a free carbide insert chart. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Learn how to identify indexable inserts and insert shapes. A given insert can be specified in either ansi (american) or iso (metric) designations. Selecting the right insert grade. Proper selection of cutting conditions, such as minimized depth of cut and appropriate feed rate, can significantly extend tool life. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. Learn more about carbide inserts, and how to buy the right carbide.

Carbide Insert Identification Chart Ponasa

Carbide Insert Guide Learn more about carbide inserts, and how to buy the right carbide. Selecting the right insert grade. Learn how to read the ansi insert code system & download a free carbide insert chart. Learn how to identify indexable inserts and insert shapes. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Learn more about carbide inserts, and how to buy the right carbide. Proper selection of cutting conditions, such as minimized depth of cut and appropriate feed rate, can significantly extend tool life. These tables show the ansi and iso insert designations for indexable inserts for turning. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. A given insert can be specified in either ansi (american) or iso (metric) designations.

From katherinewall.z13.web.core.windows.net

Carbide Insert Chart Pdf Carbide Insert Guide Learn how to identify indexable inserts and insert shapes. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. These tables show the ansi and iso insert designations for indexable inserts for turning. Learn how to read the ansi insert code system & download a free carbide insert chart. A. Carbide Insert Guide.

From www.toollink.co.th

Toollink Co., Ltd. Shape&Size Toollink Co., Ltd. Carbide Insert Guide Learn how to read the ansi insert code system & download a free carbide insert chart. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. Proper selection of cutting conditions, such as minimized depth of cut and appropriate feed rate, can significantly extend tool life. Selecting the right insert. Carbide Insert Guide.

From ponasa.condesan-ecoandes.org

Carbide Depot Insert Designation Chart Ponasa Carbide Insert Guide Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. Selecting the right insert grade. Learn how to read the ansi insert code system & download a free carbide insert chart. A given insert can be specified in either ansi (american) or iso (metric) designations. Proper selection of cutting conditions,. Carbide Insert Guide.

From ponasa.condesan-ecoandes.org

Carbide Insert Identification Chart Ponasa Carbide Insert Guide Learn how to identify indexable inserts and insert shapes. A given insert can be specified in either ansi (american) or iso (metric) designations. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking. Carbide Insert Guide.

From www.alibaba.com

Tungsten Carbide Inserts Cnc Cutting Toolscnmg Cvd/pvd Coated Buy Carbide Insert Guide Learn how to identify indexable inserts and insert shapes. Selecting the right insert grade. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. Proper selection of cutting conditions, such as minimized depth of cut and appropriate feed rate, can significantly extend tool life. Regardless of component size, material or. Carbide Insert Guide.

From rdbarrett.co.uk

How to Identify Carbide Inserts R.D. Barrett Carbide Insert Guide Learn how to identify indexable inserts and insert shapes. Learn how to read the ansi insert code system & download a free carbide insert chart. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. These tables show the ansi and iso insert designations for indexable inserts for. Carbide Insert Guide.

From www.grainger.com

METABO Carbide Insert, Size 11mm, 4 Edges, PK10 49EX47SQ4 Carbide Carbide Insert Guide Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Selecting the right insert grade. These tables show the ansi and iso insert designations for indexable inserts for. Carbide Insert Guide.

From www.wodenco.com

How to Select the Right Carbide Inserts The Ultimate Guide Wodenco Carbide Insert Guide Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. Selecting the right insert grade. Learn how to read the ansi insert code system & download a free carbide insert chart. These tables show the ansi and iso insert designations for indexable inserts for turning. Regardless of component size, material. Carbide Insert Guide.

From www.ebay.com.au

10pc TCMT 110204 110208 Turning Boring Indexable Lathe Carbide Inserts Carbide Insert Guide These tables show the ansi and iso insert designations for indexable inserts for turning. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Learn more about carbide. Carbide Insert Guide.

From huanatools.com

An InDepth Guide On Carbide Inserts For Aluminum Huana Tools Carbide Insert Guide These tables show the ansi and iso insert designations for indexable inserts for turning. Learn more about carbide inserts, and how to buy the right carbide. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Proper selection of cutting conditions, such as minimized depth of cut and. Carbide Insert Guide.

From huanatools.com

Complete application of carbide Inserts Huana Tools Carbide Insert Guide Proper selection of cutting conditions, such as minimized depth of cut and appropriate feed rate, can significantly extend tool life. Learn how to identify indexable inserts and insert shapes. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Learn more about carbide inserts, and how to buy. Carbide Insert Guide.

From precotools.en.made-in-china.com

China Tungsten Carbide Indexable Inserts China Carbide Tips, Tungsten Carbide Insert Guide A given insert can be specified in either ansi (american) or iso (metric) designations. Learn more about carbide inserts, and how to buy the right carbide. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. Learn how to identify indexable inserts and insert shapes. Learn how to read the. Carbide Insert Guide.

From www.cnc-tool.com

CNC Solid Carbide Inserts S21 Carbide Insert Guide Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Learn more about carbide inserts, and how to buy the right carbide. Proper selection of cutting conditions, such as minimized depth of cut and appropriate feed rate, can significantly extend tool life. Learn how to identify indexable inserts. Carbide Insert Guide.

From mavink.com

Carbide Turning Inserts Chart Carbide Insert Guide Proper selection of cutting conditions, such as minimized depth of cut and appropriate feed rate, can significantly extend tool life. These tables show the ansi and iso insert designations for indexable inserts for turning. Learn how to identify indexable inserts and insert shapes. Learn more about carbide inserts, and how to buy the right carbide. A given insert can be. Carbide Insert Guide.

From www.icarbide.com

how to understand milling carbide inserts icarbide Carbide Insert Guide Selecting the right insert grade. Learn more about carbide inserts, and how to buy the right carbide. Proper selection of cutting conditions, such as minimized depth of cut and appropriate feed rate, can significantly extend tool life. Learn how to identify indexable inserts and insert shapes. These tables show the ansi and iso insert designations for indexable inserts for turning.. Carbide Insert Guide.

From mavink.com

Carbide Turning Inserts Chart Carbide Insert Guide Learn how to identify indexable inserts and insert shapes. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. These tables show the ansi and iso insert designations for indexable inserts for turning. Proper selection of cutting conditions, such as minimized depth of cut and appropriate feed rate, can significantly. Carbide Insert Guide.

From ovienterprises.com

Carbide Insert Ovienterprises Carbide Insert Guide Proper selection of cutting conditions, such as minimized depth of cut and appropriate feed rate, can significantly extend tool life. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to. Carbide Insert Guide.

From www.grizzly.com

3/8" TCMT Carbide Insert Turning Set, 5 pc. at Carbide Insert Guide Proper selection of cutting conditions, such as minimized depth of cut and appropriate feed rate, can significantly extend tool life. Learn more about carbide inserts, and how to buy the right carbide. Learn how to read the ansi insert code system & download a free carbide insert chart. Regardless of component size, material or design, the carbide insert grade you. Carbide Insert Guide.

From www.pinterest.com

Carbide Insert Chart Carbide Insert Guide Learn more about carbide inserts, and how to buy the right carbide. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. Selecting the right insert grade. A. Carbide Insert Guide.

From bceweb.org

Carbide Insert Identification Chart A Visual Reference of Charts Carbide Insert Guide Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. Selecting the right insert grade. Learn how to identify indexable inserts and insert shapes. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Learn how to read. Carbide Insert Guide.

From toolnotes.com

Carbide Insert Identification Systems ToolNotes Carbide Insert Guide Learn more about carbide inserts, and how to buy the right carbide. Selecting the right insert grade. Learn how to read the ansi insert code system & download a free carbide insert chart. A given insert can be specified in either ansi (american) or iso (metric) designations. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping. Carbide Insert Guide.

From www.tpsearchtool.com

Carbide Insert Grade Comparison Chart Images Carbide Insert Guide Learn more about carbide inserts, and how to buy the right carbide. These tables show the ansi and iso insert designations for indexable inserts for turning. Learn how to read the ansi insert code system & download a free carbide insert chart. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to. Carbide Insert Guide.

From www.alibaba.com

Carbide Insert Identification Chart Buy Carbide Insert Identification Carbide Insert Guide Learn how to read the ansi insert code system & download a free carbide insert chart. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. Learn how to identify indexable inserts and insert shapes. A given insert can be specified in either ansi (american) or iso (metric) designations. Selecting. Carbide Insert Guide.

From ponasa.condesan-ecoandes.org

Carbide Insert Identification Chart Ponasa Carbide Insert Guide Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Selecting the right insert grade. A given insert can be specified in either ansi (american) or iso (metric). Carbide Insert Guide.

From katherinewall.z13.web.core.windows.net

Carbide Insert Identification Chart Pdf Carbide Insert Guide Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. A given insert can be specified in either ansi (american) or iso (metric) designations. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. Learn more about carbide. Carbide Insert Guide.

From www.mmc-carbide.com

Turning Inserts Identification Technical Info/Cutting Formula Carbide Insert Guide Learn more about carbide inserts, and how to buy the right carbide. These tables show the ansi and iso insert designations for indexable inserts for turning. Learn how to identify indexable inserts and insert shapes. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. Learn how to read the. Carbide Insert Guide.

From huanatools.com

How to choose the right carbide turning insert Huana Tools Carbide Insert Guide Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. Selecting the right insert grade. Learn more about carbide inserts, and how to buy the right carbide. Proper selection of cutting conditions, such as minimized depth of cut and appropriate feed rate, can significantly extend tool life. Learn how to. Carbide Insert Guide.

From mungfali.com

Tool Identification Chart Carbide Insert Guide Learn how to read the ansi insert code system & download a free carbide insert chart. Selecting the right insert grade. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Proper selection of cutting conditions, such as minimized depth of cut and appropriate feed rate, can significantly. Carbide Insert Guide.

From www.kennametal.com

Selecting Carbide Inserts for Metalworking Kennametal Carbide Insert Guide Selecting the right insert grade. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. Proper selection of cutting conditions, such as minimized depth of cut and appropriate feed rate, can significantly extend tool life. Learn more about carbide inserts, and how to buy the right carbide. These tables show. Carbide Insert Guide.

From sitcouae.co

Buy Premium Quality Carbide Inserts Online in Dubai UAE Carbide Insert Guide Learn more about carbide inserts, and how to buy the right carbide. These tables show the ansi and iso insert designations for indexable inserts for turning. Selecting the right insert grade. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Proper selection of cutting conditions, such as. Carbide Insert Guide.

From www.southern-tool.com

Easy Wood EWT Carbide Inserts Carbide Insert Guide Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. Learn how to identify indexable inserts and insert shapes. Learn more about carbide inserts, and how to buy. Carbide Insert Guide.

From zzyftools.com

Carbide CNC Inserts for CNC Lathe Machine CNMG120404 Carbide Insert Guide A given insert can be specified in either ansi (american) or iso (metric) designations. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Learn how to identify indexable inserts and insert shapes. Learn more about carbide inserts, and how to buy the right carbide. Selecting inserts with. Carbide Insert Guide.

From mavink.com

Carbide Insert Grade Chart Carbide Insert Guide Learn how to read the ansi insert code system & download a free carbide insert chart. Learn how to identify indexable inserts and insert shapes. Selecting the right insert grade. A given insert can be specified in either ansi (american) or iso (metric) designations. These tables show the ansi and iso insert designations for indexable inserts for turning. Proper selection. Carbide Insert Guide.

From rdbarrett.co.uk

How to Identify Carbide Inserts R.D. Barrett Carbide Insert Guide A given insert can be specified in either ansi (american) or iso (metric) designations. Selecting the right insert grade. Proper selection of cutting conditions, such as minimized depth of cut and appropriate feed rate, can significantly extend tool life. Selecting inserts with a tougher carbide grade and geometries that reduce premature chipping or breaking is key to achieving this. Learn. Carbide Insert Guide.

From www.amazon.co.uk

Sandvik Coromant QCut 151.2 Carbide Parting Insert, GC1125 Grade Carbide Insert Guide Selecting the right insert grade. Proper selection of cutting conditions, such as minimized depth of cut and appropriate feed rate, can significantly extend tool life. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Learn how to read the ansi insert code system & download a free. Carbide Insert Guide.