Wire Rope Damage Standards . The inspection must consist of observation of wire ropes (running. Most standards require that rope is to be removed if the outer wire wear exceeds 1/3 of the original outer wire diameter. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. Pushing the rope for more life will create a dangerous situation. Spections do not require untwisting (opening) of wire ropes or booming down. The inspector must obey the broken wire standard; Diameter reduction is a critical deterioration factor. Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: This is not easy to. A daily visual inspection the person handling.

from mavink.com

This is not easy to. Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: Spections do not require untwisting (opening) of wire ropes or booming down. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. Pushing the rope for more life will create a dangerous situation. The inspector must obey the broken wire standard; Most standards require that rope is to be removed if the outer wire wear exceeds 1/3 of the original outer wire diameter. A daily visual inspection the person handling. Diameter reduction is a critical deterioration factor. The inspection must consist of observation of wire ropes (running.

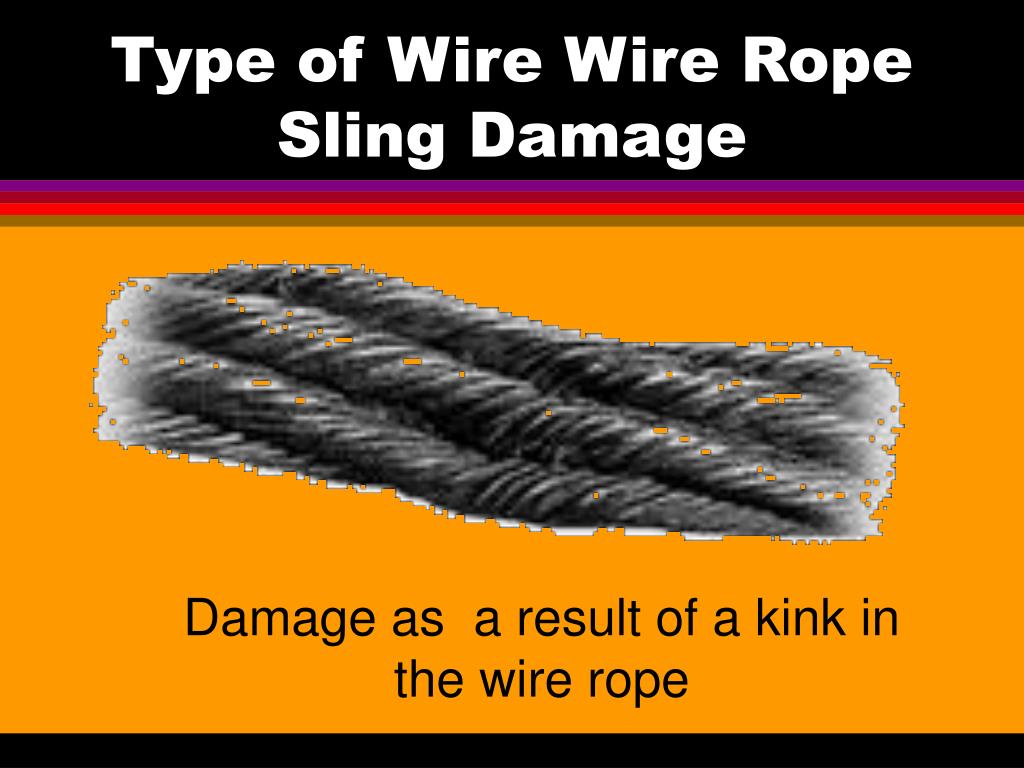

Wire Rope Sling Damage

Wire Rope Damage Standards Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. Diameter reduction is a critical deterioration factor. A daily visual inspection the person handling. Spections do not require untwisting (opening) of wire ropes or booming down. The inspector must obey the broken wire standard; Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: The inspection must consist of observation of wire ropes (running. Pushing the rope for more life will create a dangerous situation. This is not easy to. Most standards require that rope is to be removed if the outer wire wear exceeds 1/3 of the original outer wire diameter.

From www.katradis.com

Wire Rope Inspection & Maintenance A full guide Katradis Wire Rope Damage Standards The inspector must obey the broken wire standard; Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: Pushing the rope for more life will create a dangerous situation. Diameter reduction is a critical deterioration factor. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use. Wire Rope Damage Standards.

From mavink.com

Wire Rope Damage Chart Wire Rope Damage Standards Most standards require that rope is to be removed if the outer wire wear exceeds 1/3 of the original outer wire diameter. Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: Diameter reduction is a critical deterioration factor. Spections do not require untwisting (opening) of wire ropes or booming down. Pushing the rope for. Wire Rope Damage Standards.

From www.seaa.net

Wire Rope Sling Inspection and Removal Updates Steel Erectors Association of America Wire Rope Damage Standards Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: Pushing the rope for more life will create a dangerous situation. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. Most standards require that rope is to be removed if. Wire Rope Damage Standards.

From www.youtube.com

Criteria for Rejection of Wire Rope sling Discard Criteria of Wire Rope Sling YouTube Wire Rope Damage Standards The inspection must consist of observation of wire ropes (running. This is not easy to. Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. Diameter reduction is a critical deterioration. Wire Rope Damage Standards.

From mobilebridges.tpub.com

Figure 10. 40 Wire rope damage Wire Rope Damage Standards Pushing the rope for more life will create a dangerous situation. Diameter reduction is a critical deterioration factor. Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: A daily visual inspection the person handling. Most standards require that rope is to be removed if the outer wire wear exceeds 1/3 of the original outer. Wire Rope Damage Standards.

From www.iqsdirectory.com

Wire Rope What Is It? How Is It Made? Uses, Metals Wire Rope Damage Standards A daily visual inspection the person handling. Most standards require that rope is to be removed if the outer wire wear exceeds 1/3 of the original outer wire diameter. Spections do not require untwisting (opening) of wire ropes or booming down. This is not easy to. Diameter reduction is a critical deterioration factor. The inspection must consist of observation of. Wire Rope Damage Standards.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Wire Rope Damage Standards Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: This is not easy to. The inspection must consist of observation of wire ropes (running. Most standards require that rope is to be removed if the outer wire wear exceeds 1/3 of the original outer wire diameter. Diameter reduction is a critical deterioration factor. The. Wire Rope Damage Standards.

From mavink.com

Wire Rope Damage Types Wire Rope Damage Standards A daily visual inspection the person handling. Diameter reduction is a critical deterioration factor. Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: Most standards require that rope is to be removed if the outer wire wear exceeds 1/3 of the original outer wire diameter. Pushing the rope for more life will create a. Wire Rope Damage Standards.

From macmorwebsitewebapp.azurewebsites.net

Wire Rope vs Chain Slings MacMor Industries Wire Rope Damage Standards Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: Spections do not require untwisting (opening) of wire ropes or booming down. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. The inspector must obey the broken wire standard; Most. Wire Rope Damage Standards.

From www.mazzellacompanies.com

What Is Wire Rope? Understanding the Specifications and Construction Wire Rope Damage Standards Pushing the rope for more life will create a dangerous situation. The inspection must consist of observation of wire ropes (running. Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent.. Wire Rope Damage Standards.

From www.slideshare.net

Crane wire rope damage and inspection methods Wire Rope Damage Standards The inspector must obey the broken wire standard; The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. A daily visual inspection the person handling. The inspection must consist of observation of wire ropes (running. Both amse standard b30.9 and osha require that wire ropes receive. Wire Rope Damage Standards.

From www.oceanproperty.co.th

How To Inspect Wire Rope Slings According To ASME Standards, 50 OFF Wire Rope Damage Standards Pushing the rope for more life will create a dangerous situation. Spections do not require untwisting (opening) of wire ropes or booming down. The inspector must obey the broken wire standard; Diameter reduction is a critical deterioration factor. Most standards require that rope is to be removed if the outer wire wear exceeds 1/3 of the original outer wire diameter.. Wire Rope Damage Standards.

From store.iti.com

Wire Rope Inspection Guidelines (25/pack) ITI Bookstore Wire Rope Damage Standards The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. A daily visual inspection the person handling. This is not easy to. The inspection must consist of observation of wire ropes (running. Pushing the rope for more life will create a dangerous situation. Diameter reduction is. Wire Rope Damage Standards.

From www.youtube.com

How to Inspect a Wire Rope Lifting Sling to OSHA and ASME Standards L1 YouTube Wire Rope Damage Standards Most standards require that rope is to be removed if the outer wire wear exceeds 1/3 of the original outer wire diameter. The inspection must consist of observation of wire ropes (running. Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: Pushing the rope for more life will create a dangerous situation. This is. Wire Rope Damage Standards.

From www.mazzellacompanies.com

How to Inspect Wire Rope Slings According to ASME B30.9 Standards Wire Rope Damage Standards Most standards require that rope is to be removed if the outer wire wear exceeds 1/3 of the original outer wire diameter. The inspection must consist of observation of wire ropes (running. The inspector must obey the broken wire standard; Diameter reduction is a critical deterioration factor. The inspection must consist of observation of wire ropes (running and standing) that. Wire Rope Damage Standards.

From www.mazzellacompanies.com

What Are ASME’s Inspection Standards for Lever Hoists? Wire Rope Damage Standards The inspector must obey the broken wire standard; Spections do not require untwisting (opening) of wire ropes or booming down. A daily visual inspection the person handling. This is not easy to. Most standards require that rope is to be removed if the outer wire wear exceeds 1/3 of the original outer wire diameter. Both amse standard b30.9 and osha. Wire Rope Damage Standards.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Wire Rope Damage Standards A daily visual inspection the person handling. Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: Spections do not require untwisting (opening) of wire ropes or booming down. This is not easy to. The inspector must obey the broken wire standard; Most standards require that rope is to be removed if the outer wire. Wire Rope Damage Standards.

From www.slideshare.net

Crane wire rope damage and inspection methods Wire Rope Damage Standards Pushing the rope for more life will create a dangerous situation. This is not easy to. Diameter reduction is a critical deterioration factor. Spections do not require untwisting (opening) of wire ropes or booming down. A daily visual inspection the person handling. The inspector must obey the broken wire standard; Both amse standard b30.9 and osha require that wire ropes. Wire Rope Damage Standards.

From www.mazzellacompanies.com

How to Inspect Wire Rope Slings According to ASME B30.9 Standards Wire Rope Damage Standards Most standards require that rope is to be removed if the outer wire wear exceeds 1/3 of the original outer wire diameter. The inspector must obey the broken wire standard; The inspection must consist of observation of wire ropes (running. A daily visual inspection the person handling. Both amse standard b30.9 and osha require that wire ropes receive two types. Wire Rope Damage Standards.

From viperwrl.com

3 Common Wire Rope Damage Types Wire Rope Damage Standards The inspector must obey the broken wire standard; Pushing the rope for more life will create a dangerous situation. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. This is not easy to. The inspection must consist of observation of wire ropes (running. Both amse. Wire Rope Damage Standards.

From www.maintworld.com

Steel Wire Rope Failures Who Is Accountable? HSE Maintworld Wire Rope Damage Standards Spections do not require untwisting (opening) of wire ropes or booming down. A daily visual inspection the person handling. This is not easy to. The inspector must obey the broken wire standard; The inspection must consist of observation of wire ropes (running. Diameter reduction is a critical deterioration factor. Both amse standard b30.9 and osha require that wire ropes receive. Wire Rope Damage Standards.

From www.hndfcrane.com

Crane Wire Rope Damage And Wear Dafang Crane Wire Rope Damage Standards Diameter reduction is a critical deterioration factor. The inspector must obey the broken wire standard; Most standards require that rope is to be removed if the outer wire wear exceeds 1/3 of the original outer wire diameter. Pushing the rope for more life will create a dangerous situation. Spections do not require untwisting (opening) of wire ropes or booming down.. Wire Rope Damage Standards.

From www.slideshare.net

Crane wire rope damage and inspection methods Wire Rope Damage Standards Pushing the rope for more life will create a dangerous situation. The inspector must obey the broken wire standard; A daily visual inspection the person handling. Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: Spections do not require untwisting (opening) of wire ropes or booming down. This is not easy to. The inspection. Wire Rope Damage Standards.

From www.lift-it.com

Wire Rope Sling Inspection Criteria LiftIt® Manufacturing Wire Rope Damage Standards Most standards require that rope is to be removed if the outer wire wear exceeds 1/3 of the original outer wire diameter. Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: Pushing the rope for more life will create a dangerous situation. The inspection must consist of observation of wire ropes (running. Spections do. Wire Rope Damage Standards.

From www.slideshare.net

Safe Rigging Training Wire Rope Damage Standards Pushing the rope for more life will create a dangerous situation. The inspector must obey the broken wire standard; The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. This is not easy to. The inspection must consist of observation of wire ropes (running. Spections do. Wire Rope Damage Standards.

From www.mazzellacompanies.com

What Is the Inspection Criteria for Fall Protection Wire Rope SRLs? Wire Rope Damage Standards Spections do not require untwisting (opening) of wire ropes or booming down. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. The inspector must obey the broken wire standard; Diameter reduction is a critical deterioration factor. A daily visual inspection the person handling. Most standards. Wire Rope Damage Standards.

From mavink.com

Wire Rope Sling Damage Wire Rope Damage Standards The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. This is not easy to. Diameter reduction is a critical deterioration factor. Most standards require that rope is to be removed if the outer wire wear exceeds 1/3 of the original outer wire diameter. Both amse. Wire Rope Damage Standards.

From www.drillsafe.co.za

WIRE ROPE DEFECTS — DrillSafe Wire Rope Damage Standards Pushing the rope for more life will create a dangerous situation. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. The inspection must consist of observation of wire ropes (running. Most standards require that rope is to be removed if the outer wire wear exceeds. Wire Rope Damage Standards.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Wire Rope Damage Standards The inspector must obey the broken wire standard; Most standards require that rope is to be removed if the outer wire wear exceeds 1/3 of the original outer wire diameter. This is not easy to. Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: Spections do not require untwisting (opening) of wire ropes or. Wire Rope Damage Standards.

From www.mdpi.com

Applied Sciences Free FullText New OnLine MFL Testing Method and Apparatus for Winding Wire Rope Damage Standards The inspector must obey the broken wire standard; This is not easy to. Diameter reduction is a critical deterioration factor. A daily visual inspection the person handling. Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: Spections do not require untwisting (opening) of wire ropes or booming down. The inspection must consist of observation. Wire Rope Damage Standards.

From www.equipmentandcontracting.com

How to Prevent Hoist Wire Rope Failures Equipment & Contracting Wire Rope Damage Standards Pushing the rope for more life will create a dangerous situation. Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. A daily visual inspection the person handling. The inspection must. Wire Rope Damage Standards.

From www.scribd.com

IWRC Wire Rope™ Standard Specification Ropes PDF Php Manufactured Goods Wire Rope Damage Standards A daily visual inspection the person handling. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. Spections do not require untwisting (opening) of wire ropes or booming down. The inspector must obey the broken wire standard; The inspection must consist of observation of wire ropes. Wire Rope Damage Standards.

From mavink.com

Wire Rope Sling Damage Wire Rope Damage Standards Diameter reduction is a critical deterioration factor. Both amse standard b30.9 and osha require that wire ropes receive two types of inspections: Spections do not require untwisting (opening) of wire ropes or booming down. A daily visual inspection the person handling. The inspection must consist of observation of wire ropes (running. The inspector must obey the broken wire standard; The. Wire Rope Damage Standards.

From www.slideshare.net

Crane wire rope damage and inspection methods Wire Rope Damage Standards Spections do not require untwisting (opening) of wire ropes or booming down. Diameter reduction is a critical deterioration factor. This is not easy to. A daily visual inspection the person handling. The inspection must consist of observation of wire ropes (running. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use. Wire Rope Damage Standards.

From www.slideshare.net

Crane wire rope damage and inspection methods Wire Rope Damage Standards A daily visual inspection the person handling. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent. Pushing the rope for more life will create a dangerous situation. The inspection must consist of observation of wire ropes (running. Both amse standard b30.9 and osha require that. Wire Rope Damage Standards.