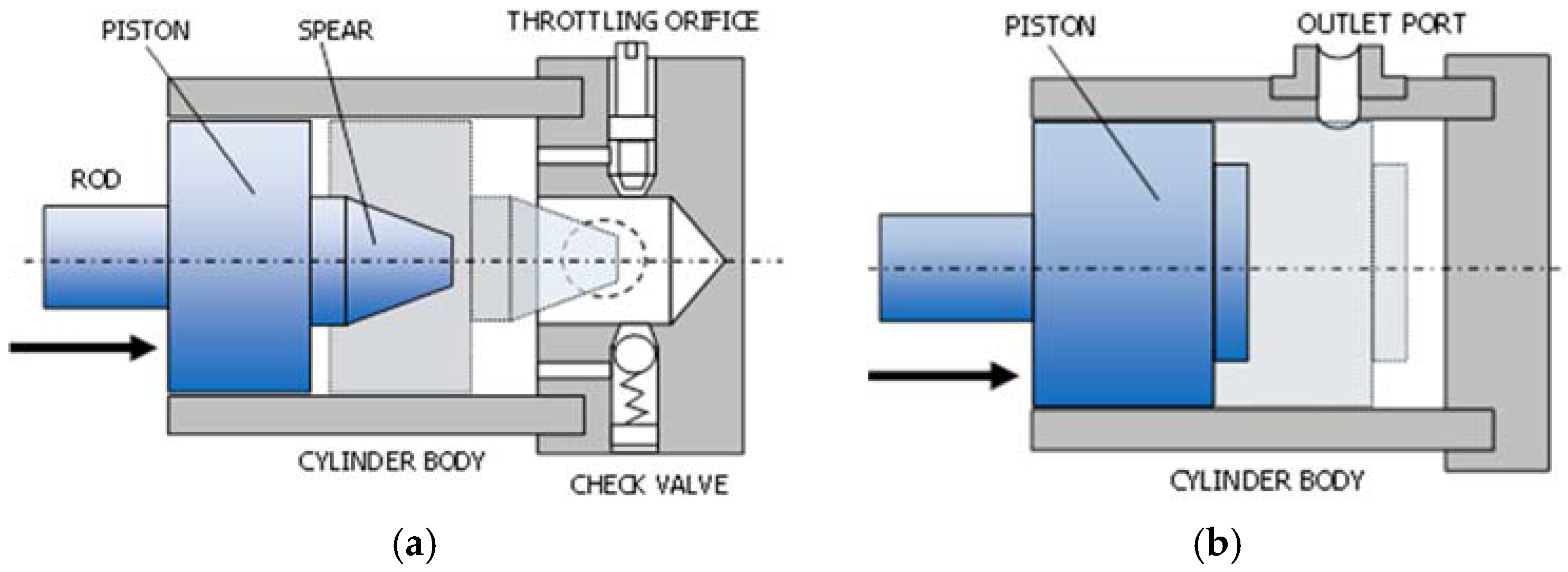

Pneumatic Cylinder Cushioning System . There are roughly three methods for damping specific pneumatic cylinders. by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches the end of its travel. one of the main functions of a pneumatic cylinder is to decelerate the piston of the cylinder at the end of the stroke. three types of end cushioning. Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. Using a displacement encoder, a proportional.

from www.mdpi.com

one of the main functions of a pneumatic cylinder is to decelerate the piston of the cylinder at the end of the stroke. by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches the end of its travel. There are roughly three methods for damping specific pneumatic cylinders. Using a displacement encoder, a proportional. three types of end cushioning. Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap.

Energies Free FullText Experimental Study of 3D Movement in

Pneumatic Cylinder Cushioning System There are roughly three methods for damping specific pneumatic cylinders. one of the main functions of a pneumatic cylinder is to decelerate the piston of the cylinder at the end of the stroke. ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches the end of its travel. Using a displacement encoder, a proportional. by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. three types of end cushioning. There are roughly three methods for damping specific pneumatic cylinders. Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap.

From exozahtrg.blob.core.windows.net

Cushioning In Hydraulic Cylinder at Charlotte Robb blog Pneumatic Cylinder Cushioning System three types of end cushioning. ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches the end of its travel. Using a displacement encoder, a proportional. There are roughly three methods for damping specific pneumatic cylinders. Any contact between the piston and end cap would be negligible,. Pneumatic Cylinder Cushioning System.

From www.icvega.com

Vega Excellence—Cushioning • Vega Cylinders Official Blog Pneumatic Cylinder Cushioning System by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. There are roughly three methods for damping specific pneumatic cylinders. one of the main functions of a pneumatic cylinder is to decelerate the piston of the cylinder at the end of the stroke. Using a displacement encoder,. Pneumatic Cylinder Cushioning System.

From www.youtube.com

Hydraulic Training Hydraulic cylinder cushioning YouTube Pneumatic Cylinder Cushioning System ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches the end of its travel. by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. Using a displacement encoder, a proportional. three types of end. Pneumatic Cylinder Cushioning System.

From www.youtube.com

Cylinders With Cushioning YouTube Pneumatic Cylinder Cushioning System There are roughly three methods for damping specific pneumatic cylinders. Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. three types of end cushioning. ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches the. Pneumatic Cylinder Cushioning System.

From www.scribd.com

Hydraulic Cylinder Cushioning PDF Piston Cylinder (Engine) Pneumatic Cylinder Cushioning System one of the main functions of a pneumatic cylinder is to decelerate the piston of the cylinder at the end of the stroke. Using a displacement encoder, a proportional. There are roughly three methods for damping specific pneumatic cylinders. Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end. Pneumatic Cylinder Cushioning System.

From jhfoster.com

What Is Cushioning in Pneumatic Cylinders? JHFOSTER Pneumatic Cylinder Cushioning System ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches the end of its travel. Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. Using a displacement encoder, a proportional. one of the main functions. Pneumatic Cylinder Cushioning System.

From www.e-pneumatic.com

How Pneumatic Cylinder Work? Described Instructions Pneumatic Blog Pneumatic Cylinder Cushioning System ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches the end of its travel. by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. Any contact between the piston and end cap would be negligible,. Pneumatic Cylinder Cushioning System.

From hydraquip.co.uk

BSPP Double Acting, Adjustable Cushioning Gen 2 ISO15552 Pneumatic Cylinder Cushioning System three types of end cushioning. Using a displacement encoder, a proportional. one of the main functions of a pneumatic cylinder is to decelerate the piston of the cylinder at the end of the stroke. by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. There are. Pneumatic Cylinder Cushioning System.

From www.hkdivedi.com

CUSHIONING HYDRAULIC CYLINDER WORKING PRINCIPLE ENGINEERING APPLICATIONS Pneumatic Cylinder Cushioning System ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches the end of its travel. three types of end cushioning. by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. Using a displacement encoder, a. Pneumatic Cylinder Cushioning System.

From slidetodoc.com

Hydraulic Cylinders and Cushioning Devices Introduction Hydraulic cylinders Pneumatic Cylinder Cushioning System Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. Using a displacement encoder, a proportional. by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. three types of end cushioning. one of the main. Pneumatic Cylinder Cushioning System.

From www.vegacylinders.com

Hydraulic Cylinders with EndStroke Cushioning • Vega Cylinders Pneumatic Cylinder Cushioning System by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. three types of end cushioning. Using a displacement encoder, a proportional. Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. ideal pneumatic cushioning occurs. Pneumatic Cylinder Cushioning System.

From www.youtube.com

Adjustable cushioning Advantages YouTube Pneumatic Cylinder Cushioning System Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. three types of end cushioning. There are roughly three methods for damping specific pneumatic cylinders. one of the main functions of a pneumatic cylinder is to decelerate the piston of the cylinder at the end of the. Pneumatic Cylinder Cushioning System.

From library.automationdirect.com

Pneumatic Actuator (Air Cylinder) Basics Pneumatic Cylinder Cushioning System Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. Using a displacement encoder, a proportional. by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. one of the main functions of a pneumatic cylinder is. Pneumatic Cylinder Cushioning System.

From www.mdpi.com

Energies Free FullText Experimental Study of 3D Movement in Pneumatic Cylinder Cushioning System Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches the end of its travel. three types of end cushioning. There are roughly three methods for. Pneumatic Cylinder Cushioning System.

From www.eurekamagazine.co.uk

Self adjusting pneumatic cushioning system Pneumatic Cylinder Cushioning System three types of end cushioning. ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches the end of its travel. one of the main functions of a pneumatic cylinder is to decelerate the piston of the cylinder at the end of the stroke. by minimizing. Pneumatic Cylinder Cushioning System.

From www.machinedesign.com

Pneumatic Cylinder EndofTravel Cushioning Machine Design Pneumatic Cylinder Cushioning System Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. one of the main functions of a pneumatic cylinder is to decelerate the piston of the. Pneumatic Cylinder Cushioning System.

From exozahtrg.blob.core.windows.net

Cushioning In Hydraulic Cylinder at Charlotte Robb blog Pneumatic Cylinder Cushioning System Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. There are roughly three methods for damping specific pneumatic cylinders. one of the main functions of. Pneumatic Cylinder Cushioning System.

From www.youtube.com

Optimize machine efficiency and cylinder cycle time with ideal Pneumatic Cylinder Cushioning System by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. There are roughly three methods for damping specific pneumatic cylinders. Using a displacement encoder, a proportional. ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches. Pneumatic Cylinder Cushioning System.

From store.camozzi.co.uk

Why Consider AutoCushioning Pneumatic Cylinders? Camozzi Automation Ltd Pneumatic Cylinder Cushioning System by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. three types of end cushioning. Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. one of the main functions of a pneumatic cylinder is. Pneumatic Cylinder Cushioning System.

From blog.rangercaradoc.com

What Is Cushioning (In Hydraulic Cylinders) And Why Is It Important? Pneumatic Cylinder Cushioning System Using a displacement encoder, a proportional. Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. There are roughly three methods for damping specific pneumatic cylinders. by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. . Pneumatic Cylinder Cushioning System.

From www.youtube.com

Hydraulic Cushioning In A Cylinder YouTube Pneumatic Cylinder Cushioning System Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. three types of end cushioning. Using a displacement encoder, a proportional. ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches the end of its travel.. Pneumatic Cylinder Cushioning System.

From www.pneumaticsolenoid-valve.com

SC Series Standard Pneumatic Air Cylinder Double Acting Series Pneumatic Cylinder Cushioning System Using a displacement encoder, a proportional. Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches the end of its travel. three types of end cushioning.. Pneumatic Cylinder Cushioning System.

From www.rowse-pneumatics.co.uk

What Is Pneumatic Cylinder Cushioning? Rowse Pneumatics Pneumatic Cylinder Cushioning System Using a displacement encoder, a proportional. There are roughly three methods for damping specific pneumatic cylinders. one of the main functions of a pneumatic cylinder is to decelerate the piston of the cylinder at the end of the stroke. by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder. Pneumatic Cylinder Cushioning System.

From www.industryupdate.com.au

PNEUMATIC ACTUATORS INCLUDE ADAPTIVE CUSHIONING SYSTEM Industry Pneumatic Cylinder Cushioning System Using a displacement encoder, a proportional. Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches the end of its travel. by minimizing cylinder shock, vibration. Pneumatic Cylinder Cushioning System.

From jhfoster.com

What Is Cushioning in Pneumatic Cylinders? JHFOSTER Pneumatic Cylinder Cushioning System ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches the end of its travel. Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. by minimizing cylinder shock, vibration and oscillations in the system, ideal. Pneumatic Cylinder Cushioning System.

From www.ien.eu

More Productivity with Cushioned Pneumatic Cylinders Pneumatic Cylinder Cushioning System There are roughly three methods for damping specific pneumatic cylinders. three types of end cushioning. Using a displacement encoder, a proportional. by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. Any contact between the piston and end cap would be negligible, so the piston would not. Pneumatic Cylinder Cushioning System.

From store.camozzi.co.uk

ISO 6432 Pneumatic Cylinder with AutoCushioning Camozzi Automation Ltd Pneumatic Cylinder Cushioning System ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches the end of its travel. Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. by minimizing cylinder shock, vibration and oscillations in the system, ideal. Pneumatic Cylinder Cushioning System.

From www.youtube.com

How to adjust cushion on air cylinder YouTube Pneumatic Cylinder Cushioning System There are roughly three methods for damping specific pneumatic cylinders. ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches the end of its travel. three types of end cushioning. Any contact between the piston and end cap would be negligible, so the piston would not rebound. Pneumatic Cylinder Cushioning System.

From www.mdpi.com

Sustainability Free FullText Simulation of Hydraulic Cylinder Pneumatic Cylinder Cushioning System one of the main functions of a pneumatic cylinder is to decelerate the piston of the cylinder at the end of the stroke. Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. There are roughly three methods for damping specific pneumatic cylinders. three types of end. Pneumatic Cylinder Cushioning System.

From alonzoking.blogspot.com

Double Acting Cylinder With Cushioning Symbol Standard Cylinders Pneumatic Cylinder Cushioning System There are roughly three methods for damping specific pneumatic cylinders. Using a displacement encoder, a proportional. Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches the. Pneumatic Cylinder Cushioning System.

From www.pneumaticsolenoid-valve.com

SC Series Standard Pneumatic Air Cylinder Double Acting Series Pneumatic Cylinder Cushioning System Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. three types of end cushioning. ideal pneumatic cushioning occurs when all kinetic energy is dissipated. Pneumatic Cylinder Cushioning System.

From www.youtube.com

Mechanisms of Cushioning at Hydraulic Cylinder How it works ميكانيزم Pneumatic Cylinder Cushioning System ideal pneumatic cushioning occurs when all kinetic energy is dissipated to decelerate the piston to exactly zero velocity when it reaches the end of its travel. There are roughly three methods for damping specific pneumatic cylinders. Using a displacement encoder, a proportional. three types of end cushioning. Any contact between the piston and end cap would be negligible,. Pneumatic Cylinder Cushioning System.

From jhfoster.com

What Is Cushioning in Pneumatic Cylinders? JHFOSTER Pneumatic Cylinder Cushioning System three types of end cushioning. There are roughly three methods for damping specific pneumatic cylinders. Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. . Pneumatic Cylinder Cushioning System.

From www.iqsdirectory.com

Pneumatic Cylinder What Is It? How Does It Work? Types Of Pneumatic Cylinder Cushioning System Using a displacement encoder, a proportional. one of the main functions of a pneumatic cylinder is to decelerate the piston of the cylinder at the end of the stroke. Any contact between the piston and end cap would be negligible, so the piston would not rebound off the end cap. three types of end cushioning. ideal pneumatic. Pneumatic Cylinder Cushioning System.

From www.youtube.com

Explain cushioning of pneumatic cylinder kaise karte hain Hydraulic Pneumatic Cylinder Cushioning System three types of end cushioning. one of the main functions of a pneumatic cylinder is to decelerate the piston of the cylinder at the end of the stroke. by minimizing cylinder shock, vibration and oscillations in the system, ideal cushioning extends the operational life of the cylinder and its. Any contact between the piston and end cap. Pneumatic Cylinder Cushioning System.