Dry Coating Battery . Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries. It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing. Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material.

from mavink.com

Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries. Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing.

Battery Electrode Manufacturing Process

Dry Coating Battery Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries. Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport. It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing. Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material.

From www.press.bmwgroup.com

Battery Cell Competence Center coating and drying of the electrode Dry Coating Battery Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport. It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing. Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings.. Dry Coating Battery.

From batteryindustry.tech

Adphos Thermal Processing new drying solution for anode and cathode Dry Coating Battery Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport. Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries. It′s important to note,. Dry Coating Battery.

From www.weatherall-uk.com

Gas Monitoring for Lithium Ion Battery Electrode manufacturing Drying Dry Coating Battery It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing. Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the. Dry Coating Battery.

From rheonics.com

Battery production Slurry Mixing and Coating » Rheonics Dry Coating Battery Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery. Dry Coating Battery.

From www.tycorun.com

Analysis of advantages and application of dry electrode technology Dry Coating Battery It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing. Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the. Dry Coating Battery.

From www.teslarati.com

Volkswagen to adopt Tesla’s dry coating process for battery production Dry Coating Battery Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport. It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing. Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings.. Dry Coating Battery.

From mavink.com

Battery Electrode Manufacturing Process Dry Coating Battery Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries. It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing. Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport. Our review paper comprehensively examines the dry battery electrode technology used. Dry Coating Battery.

From www.youtube.com

PowerCo SE's Dry Coating Battery Process Could Save VW Hundreds Of Dry Coating Battery It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing. Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries.. Dry Coating Battery.

From www.mdpi.com

WEVJ Free FullText Optimized LiFePO4Based Cathode Production for Dry Coating Battery Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport. Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing.. Dry Coating Battery.

From www.youtube.com

Battery coating machine Continuous and Intermittent Coating Machine Dry Coating Battery Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing. Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic. Dry Coating Battery.

From www.youtube.com

Lithium battery coating technology production process YouTube Dry Coating Battery Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries. It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery. Dry Coating Battery.

From pressroom-rbt.com

Laser drying of electrode coating in lithiumion batteries IDEEL Dry Coating Battery Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport. Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. Our review paper. Dry Coating Battery.

From www.mtixtl.com

Automatic Battery Electrode Coating System with Slurry Feeder, Coater Dry Coating Battery It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. Our review paper comprehensively examines the dry battery electrode technology used in libs, which. Dry Coating Battery.

From www.takomabattery.com

lithium battery coated electrode piece drying technology and defects Dry Coating Battery Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. It′s important to note, however, that calendering. Dry Coating Battery.

From tdk-ventures.com

Why We Invested in AM Batteries and Their Dry Electrode Technology Dry Coating Battery Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries. Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. It′s important to. Dry Coating Battery.

From www.eenewseurope.com

Continuous dry coating process for battery electrodes cuts costs Dry Coating Battery Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport. Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries. Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. It′s important to note,. Dry Coating Battery.

From www.takomabattery.com

All solid state battery dry electrode process, advantages and Dry Coating Battery Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing. Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport.. Dry Coating Battery.

From www.press.bmwgroup.com

Battery Cell Competence Center coating and drying of the electrode Dry Coating Battery Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. Scalable dry electrode process is essential for. Dry Coating Battery.

From www.fraunhofer.de

Environmentally friendly manufacture of battery electrodes Dry Coating Battery Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries. It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing.. Dry Coating Battery.

From www.takomabattery.com

All solid state battery dry electrode process, advantages and Dry Coating Battery It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. Our review paper comprehensively examines the dry battery electrode technology used in libs, which. Dry Coating Battery.

From www.takomabattery.com

lithium battery coated electrode piece drying technology and defects Dry Coating Battery Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. It′s important to note, however, that calendering. Dry Coating Battery.

From auto.economictimes.indiatimes.com

Thomas Schmall Volkswagen masters drycoating battery process with Dry Coating Battery Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and. Dry Coating Battery.

From www.press.bmwgroup.com

Battery Cell Competence Center coating and drying of the electrode Dry Coating Battery Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods. Dry Coating Battery.

From pubs.rsc.org

A 5 Vclass cobaltfree battery cathode with high loading enabled by Dry Coating Battery It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic. Dry Coating Battery.

From www.mdpi.com

Batteries Free FullText Strategies and Challenge of Thick Dry Coating Battery Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing. Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport.. Dry Coating Battery.

From www.electricmotorengineering.com

Energy storage for the electric car. Dry electrode coating technology Dry Coating Battery Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of. Dry Coating Battery.

From blog.upsbatterycenter.com

Dry Coating Active Battery Materials at VW News about Energy Storage Dry Coating Battery Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries. It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing. Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings.. Dry Coating Battery.

From mavink.com

Battery Electrode Manufacturing Process Dry Coating Battery Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries. It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing.. Dry Coating Battery.

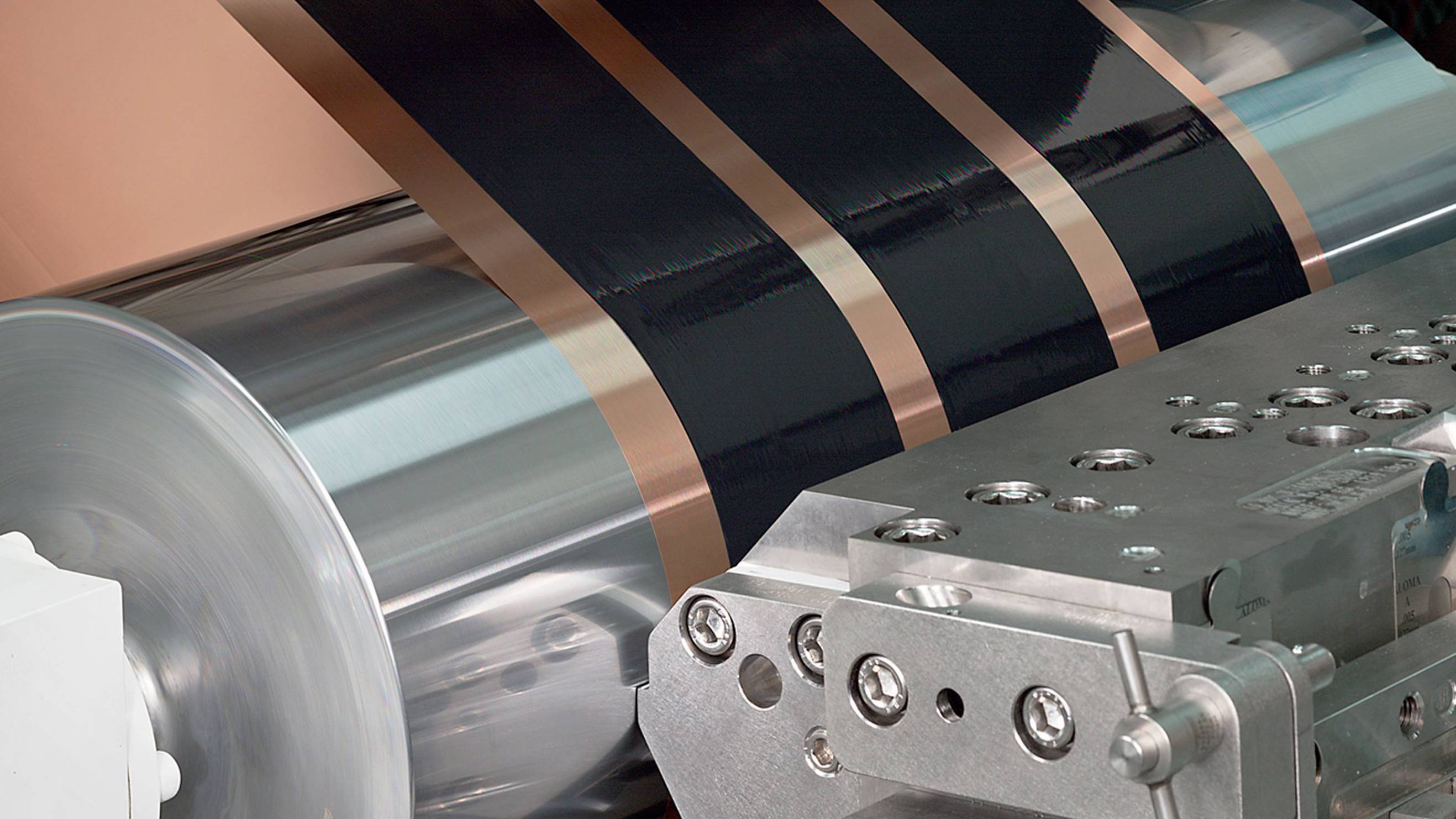

From www.durr.com

Simultaneous twosided electrode coating and drying Dürr Dry Coating Battery Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries. It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery. Dry Coating Battery.

From esst.cip.com.cn

Preparation and characterization of solventfree dry electrodes for Dry Coating Battery Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and. Dry Coating Battery.

From www.durr.com

Simultaneous twosided electrode coating and drying Dürr Dry Coating Battery Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport. Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and. Dry Coating Battery.

From europe.autonews.com

VW could cut costs with drycoating battery process Automotive News Dry Coating Battery Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries. Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing.. Dry Coating Battery.

From www.youtube.com

Can Dry Battery Electrodes Really Work? YouTube Dry Coating Battery Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport. Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries. It′s important to note, however, that calendering is but one of several dry coating techniques explored in battery manufacturing. Dry coating is an innovative process in battery cell production that. Dry Coating Battery.

From www.youtube.com

Battery technology from lab to fab YouTube Dry Coating Battery Conventional slurry casting fabrications in ssbs suffer from fragility, solvent sensitivity, and blocked ionic transport. Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries. Dry coating is an. Dry Coating Battery.

From www.iws.fraunhofer.de

DRYtraec® Environmentally friendly dry coating of battery electrodes Dry Coating Battery Dry coating is an innovative process in battery cell production that is revolutionising traditional methods of electrode production and deals with the question of how the material. Our review paper comprehensively examines the dry battery electrode technology used in libs, which implies the use of no solvents to produce dry electrodes or coatings. It′s important to note, however, that calendering. Dry Coating Battery.