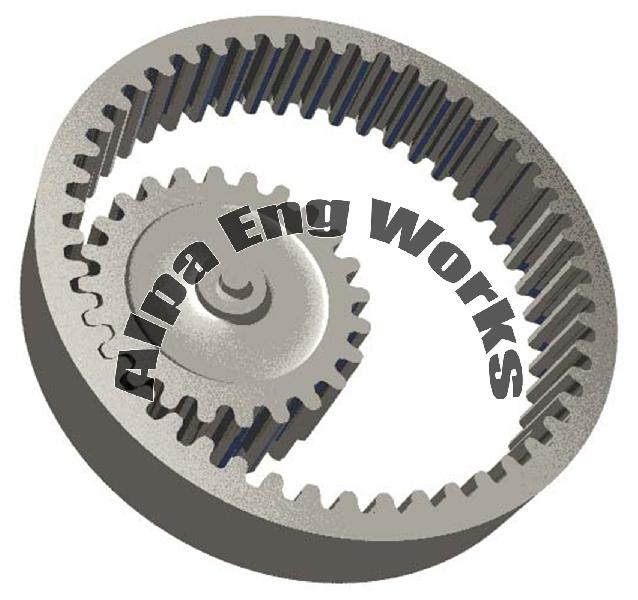

Internal Spur Gears . Spur gears are simple and straightforward, yet highly versatile and suitable for use in a wide range of applications, industries and environments. Internal spur gears, on the other hand, have teeth on the inside surface of the cylinder, allowing an external gear to sit inside and rotate in the same. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. Key spur gear advantages include:. The gear teeth of an internal gear typically mesh with the teeth of a spur gear. These gears are composed of a cylindrical shape. They also enable a velocity change without a. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. The spur gear is the first choice option for gears except when high speeds, loads, and ratios direct. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances.

from www.exportersindia.com

They also enable a velocity change without a. Internal spur gears, on the other hand, have teeth on the inside surface of the cylinder, allowing an external gear to sit inside and rotate in the same. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. The spur gear is the first choice option for gears except when high speeds, loads, and ratios direct. Key spur gear advantages include:. Spur gears are simple and straightforward, yet highly versatile and suitable for use in a wide range of applications, industries and environments. The gear teeth of an internal gear typically mesh with the teeth of a spur gear. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. These gears are composed of a cylindrical shape.

Polished Cast Iron Internal Spur Gears, for Industrial Use, Feature

Internal Spur Gears These gears are composed of a cylindrical shape. The gear teeth of an internal gear typically mesh with the teeth of a spur gear. They also enable a velocity change without a. These gears are composed of a cylindrical shape. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. Spur gears are simple and straightforward, yet highly versatile and suitable for use in a wide range of applications, industries and environments. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. Internal spur gears, on the other hand, have teeth on the inside surface of the cylinder, allowing an external gear to sit inside and rotate in the same. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. The spur gear is the first choice option for gears except when high speeds, loads, and ratios direct. Key spur gear advantages include:.

From

Internal Spur Gears These gears are composed of a cylindrical shape. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. The gear teeth of an internal gear typically mesh with the teeth of a spur gear. Spur gears are simple and straightforward, yet highly versatile and suitable for use in. Internal Spur Gears.

From

Internal Spur Gears Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. The gear teeth of an internal gear typically mesh with the teeth of a spur gear. Spur gears are simple and straightforward, yet highly versatile and suitable for use in a wide range of applications, industries and environments. Key. Internal Spur Gears.

From

Internal Spur Gears They also enable a velocity change without a. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. The spur gear is the first choice option for gears except when high speeds, loads, and ratios direct. Key spur gear advantages include:. Internal spur gears, on the other hand, have. Internal Spur Gears.

From

Internal Spur Gears Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. The gear teeth of an internal gear typically mesh with the teeth of a spur gear. Internal spur gears, on the other hand, have teeth on the inside surface of the cylinder, allowing an external gear to sit. Internal Spur Gears.

From

Internal Spur Gears Key spur gear advantages include:. Spur gears are simple and straightforward, yet highly versatile and suitable for use in a wide range of applications, industries and environments. Internal spur gears, on the other hand, have teeth on the inside surface of the cylinder, allowing an external gear to sit inside and rotate in the same. The spur gear is the. Internal Spur Gears.

From

Internal Spur Gears Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. These gears. Internal Spur Gears.

From

Internal Spur Gears The gear teeth of an internal gear typically mesh with the teeth of a spur gear. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. Spur gears are simple and straightforward, yet highly. Internal Spur Gears.

From www.tec-science.com

External and internal toothing of gears tecscience Internal Spur Gears The spur gear is the first choice option for gears except when high speeds, loads, and ratios direct. Key spur gear advantages include:. These gears are composed of a cylindrical shape. Spur gears are simple and straightforward, yet highly versatile and suitable for use in a wide range of applications, industries and environments. Internal spur gears, on the other hand,. Internal Spur Gears.

From www.indiamart.com

Internal Spur Gears, Round, Excellent Engineering ID 4813769873 Internal Spur Gears These gears are composed of a cylindrical shape. The gear teeth of an internal gear typically mesh with the teeth of a spur gear. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. Internal spur gears, on the other hand, have teeth on the inside surface of the cylinder, allowing an external gear to. Internal Spur Gears.

From

Internal Spur Gears Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. Key spur gear advantages include:. Spur gears are simple and straightforward, yet highly versatile and suitable for. Internal Spur Gears.

From

Internal Spur Gears They also enable a velocity change without a. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. The gear teeth of an internal gear typically mesh with the teeth of a spur gear. These gears are composed of a cylindrical shape. Key spur gear advantages include:. In its. Internal Spur Gears.

From

Internal Spur Gears Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. The spur gear is the first choice option for gears except when high speeds, loads, and ratios direct. These gears are composed of a cylindrical shape. They also enable a velocity change without a. Internal gear is a. Internal Spur Gears.

From vestavia.eu

spur gears cutting Internal Spur Gears Spur gears are simple and straightforward, yet highly versatile and suitable for use in a wide range of applications, industries and environments. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. These gears are composed of a cylindrical shape. Internal gears provide designers with the ability to achieve higher contact and drive ratios than. Internal Spur Gears.

From

Internal Spur Gears The gear teeth of an internal gear typically mesh with the teeth of a spur gear. They also enable a velocity change without a. Key spur gear advantages include:. These gears are composed of a cylindrical shape. Internal spur gears, on the other hand, have teeth on the inside surface of the cylinder, allowing an external gear to sit inside. Internal Spur Gears.

From ultragear.co.za

Capabilities Ultragear Internal Spur Gears Key spur gear advantages include:. These gears are composed of a cylindrical shape. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. The spur gear is the first choice option for gears except when high speeds, loads, and ratios direct. In its manufacturing, because of its shape,. Internal Spur Gears.

From fractory.com

Types of Gears Gear Parameters & Tooth Profiles Fractory Internal Spur Gears Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. The gear teeth of an internal gear typically mesh with the teeth of a spur gear. Internal spur gears, on the other hand, have teeth on the inside surface of the cylinder, allowing an external gear to sit inside. Internal Spur Gears.

From vestavia.eu

Efficient Gearing Solution Internal Spur Gears The gear teeth of an internal gear typically mesh with the teeth of a spur gear. Internal spur gears, on the other hand, have teeth on the inside surface of the cylinder, allowing an external gear to sit inside and rotate in the same. Internal gear is a gear with its teeth cut in the internal surface of a cylinder. Internal Spur Gears.

From

Internal Spur Gears Internal spur gears, on the other hand, have teeth on the inside surface of the cylinder, allowing an external gear to sit inside and rotate in the same. The gear teeth of an internal gear typically mesh with the teeth of a spur gear. Spur gears are simple and straightforward, yet highly versatile and suitable for use in a wide. Internal Spur Gears.

From

Internal Spur Gears In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. Internal spur gears, on the other hand, have teeth on the inside surface of the cylinder, allowing an external gear to sit inside and rotate in the same. These gears are composed of a cylindrical shape. Spur gears are simple and straightforward, yet highly versatile. Internal Spur Gears.

From www.exportersindia.com

Mild Steel Internal Spur Gear at Rs 800 / Number in Navsari Asar Internal Spur Gears Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. The spur gear is the first choice option for gears except when high speeds, loads, and ratios direct. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur. Internal Spur Gears.

From

Internal Spur Gears They also enable a velocity change without a. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. Spur gears are simple and straightforward, yet highly versatile and suitable for use in a wide. Internal Spur Gears.

From

Internal Spur Gears The gear teeth of an internal gear typically mesh with the teeth of a spur gear. They also enable a velocity change without a. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. Spur gears are simple and straightforward, yet highly versatile and suitable for use in. Internal Spur Gears.

From www.youtube.com

Internal Spur Gear Design and Animation in Unigraphics C for CAD Internal Spur Gears The spur gear is the first choice option for gears except when high speeds, loads, and ratios direct. The gear teeth of an internal gear typically mesh with the teeth of a spur gear. They also enable a velocity change without a. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears. Internal Spur Gears.

From

Internal Spur Gears These gears are composed of a cylindrical shape. The spur gear is the first choice option for gears except when high speeds, loads, and ratios direct. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. Spur gears are simple and straightforward, yet highly versatile and suitable for. Internal Spur Gears.

From

Internal Spur Gears They also enable a velocity change without a. The gear teeth of an internal gear typically mesh with the teeth of a spur gear. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. Key spur gear advantages include:. Internal gears provide designers with the ability to achieve higher. Internal Spur Gears.

From

Internal Spur Gears Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. These gears are composed of a cylindrical shape. They also enable a velocity change without a. Key. Internal Spur Gears.

From

Internal Spur Gears In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. These gears are composed of a cylindrical shape. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. The gear teeth of an internal gear typically mesh with the teeth of a spur. Internal Spur Gears.

From www.croixgear.com

Spur Gears Internal Spur Gears Croix Gear Internal Spur Gears Spur gears are simple and straightforward, yet highly versatile and suitable for use in a wide range of applications, industries and environments. The gear teeth of an internal gear typically mesh with the teeth of a spur gear. Internal spur gears, on the other hand, have teeth on the inside surface of the cylinder, allowing an external gear to sit. Internal Spur Gears.

From vestavia.eu

Efficient Gearing Solution Internal Spur Gears Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. Internal spur. Internal Spur Gears.

From

Internal Spur Gears In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. The spur gear is the first choice option for gears except when high speeds, loads, and ratios direct. Spur gears are simple and straightforward, yet highly versatile and suitable for use in a wide range of applications, industries and environments. Internal gear is a gear. Internal Spur Gears.

From

Internal Spur Gears Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. Key spur gear advantages include:. In its manufacturing, because of its shape, the usual hobbing machine used in spur gear. These gears are composed of a cylindrical shape. They also enable a velocity change without a. Spur gears. Internal Spur Gears.

From

Internal Spur Gears Key spur gear advantages include:. Internal spur gears, on the other hand, have teeth on the inside surface of the cylinder, allowing an external gear to sit inside and rotate in the same. The spur gear is the first choice option for gears except when high speeds, loads, and ratios direct. These gears are composed of a cylindrical shape. Internal. Internal Spur Gears.

From www.transmissions-gears.com

Nitriding Internal Spur Gear With Internal Spline Internal Spur Gears Internal gear is a gear with its teeth cut in the internal surface of a cylinder and meshes with spur gears. Internal spur gears, on the other hand, have teeth on the inside surface of the cylinder, allowing an external gear to sit inside and rotate in the same. The gear teeth of an internal gear typically mesh with the. Internal Spur Gears.

From www.helical-bevelgear.com

Corrosion Resistance Internal Spur Gear , Customized Steel Internal Internal Spur Gears Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. Key spur gear advantages include:. Spur gears are simple and straightforward, yet highly versatile and suitable for use in a wide range of applications, industries and environments. These gears are composed of a cylindrical shape. In its manufacturing,. Internal Spur Gears.

From

Internal Spur Gears The gear teeth of an internal gear typically mesh with the teeth of a spur gear. Internal gears provide designers with the ability to achieve higher contact and drive ratios than standard spur gears at shorter center distances. The spur gear is the first choice option for gears except when high speeds, loads, and ratios direct. Key spur gear advantages. Internal Spur Gears.