Best Material For Water Jet . the alloys of aluminum: pure waterjet cutting process is less invasive compared to abrasive waterjet cutting. This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various composites. The cutting force is enough to cut thick materials of extreme strength. However, it's the right combination of hardness, density,. Abrasive waterjet is used to cut. The jet stream is also. Stainless steel 304, 316, and acetol, are considered the right materials for water. the largest uses for pure waterjet cutting today involve soft materials like gasket, foam, disposable diapers, tissue paper,. pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and carpet. the best material appears to be almandine garnet. This includes the hardest metals, alloys, plastics, glass, and other materials.

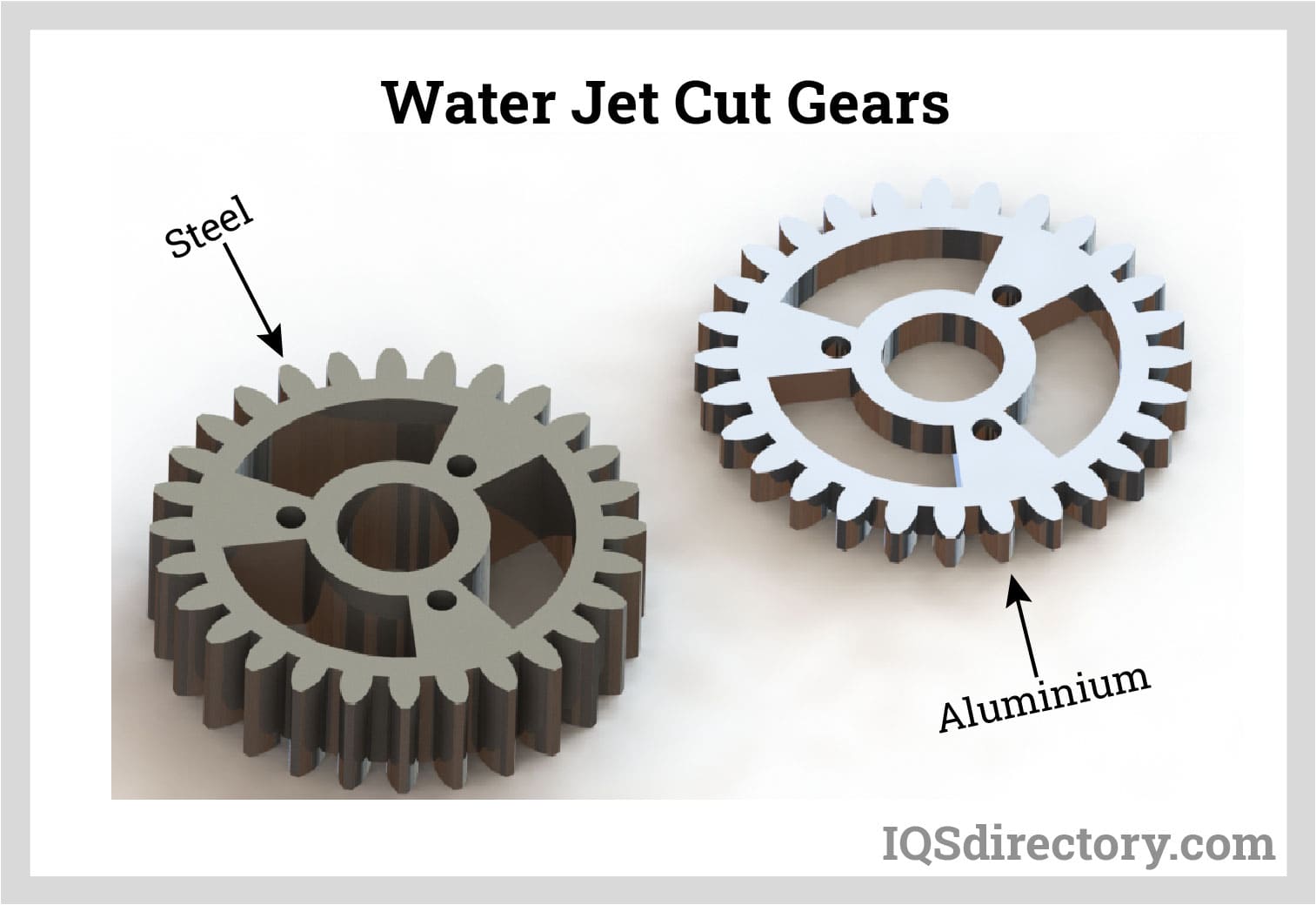

from www.iqsdirectory.com

This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various composites. the largest uses for pure waterjet cutting today involve soft materials like gasket, foam, disposable diapers, tissue paper,. the alloys of aluminum: The jet stream is also. the best material appears to be almandine garnet. Abrasive waterjet is used to cut. This includes the hardest metals, alloys, plastics, glass, and other materials. The cutting force is enough to cut thick materials of extreme strength. However, it's the right combination of hardness, density,. pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and carpet.

Water Jet Cutting What Is It? How Does It Work? Types, Uses

Best Material For Water Jet The jet stream is also. the best material appears to be almandine garnet. Abrasive waterjet is used to cut. pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and carpet. This includes the hardest metals, alloys, plastics, glass, and other materials. Stainless steel 304, 316, and acetol, are considered the right materials for water. The jet stream is also. the alloys of aluminum: pure waterjet cutting process is less invasive compared to abrasive waterjet cutting. However, it's the right combination of hardness, density,. the largest uses for pure waterjet cutting today involve soft materials like gasket, foam, disposable diapers, tissue paper,. This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various composites. The cutting force is enough to cut thick materials of extreme strength.

From www.eppowergrit.com

High Pressure & Waterjet Cutting EP Power Grit Best Material For Water Jet Stainless steel 304, 316, and acetol, are considered the right materials for water. Abrasive waterjet is used to cut. The jet stream is also. pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and carpet. This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various. Best Material For Water Jet.

From dute-scarboro99.blogspot.com

how fast is a water jet cutter dutescarboro99 Best Material For Water Jet the best material appears to be almandine garnet. This includes the hardest metals, alloys, plastics, glass, and other materials. pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and carpet. Stainless steel 304, 316, and acetol, are considered the right materials for water. pure waterjet cutting process is less invasive compared to. Best Material For Water Jet.

From onestopfluidpower.co.uk

Water Jet Capabilities One Stop Fluid Power Best Material For Water Jet Stainless steel 304, 316, and acetol, are considered the right materials for water. This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various composites. the largest uses for pure waterjet cutting today involve soft materials like gasket, foam, disposable diapers, tissue paper,. This includes the hardest metals, alloys, plastics, glass,. Best Material For Water Jet.

From inbound.cammmetals.com

What Materials Can be Cut With a Waterjet? Best Material For Water Jet pure waterjet cutting process is less invasive compared to abrasive waterjet cutting. The cutting force is enough to cut thick materials of extreme strength. This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various composites. Abrasive waterjet is used to cut. However, it's the right combination of hardness, density,. Stainless. Best Material For Water Jet.

From www.iqsdirectory.com

Water Jet Cutting What Is It? How Does It Work? Types, Uses Best Material For Water Jet pure waterjet cutting process is less invasive compared to abrasive waterjet cutting. the best material appears to be almandine garnet. However, it's the right combination of hardness, density,. pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and carpet. The jet stream is also. This includes the hardest metals, alloys, plastics, glass,. Best Material For Water Jet.

From www.aluminiumtrading.co.za

Water Jet Cutting Aluminium Trading Best Material For Water Jet This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various composites. pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and carpet. the largest uses for pure waterjet cutting today involve soft materials like gasket, foam, disposable diapers, tissue paper,. However, it's the right. Best Material For Water Jet.

From 1stclassplumber.com

Water Jetting First Class Plumbing Best Material For Water Jet This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various composites. the largest uses for pure waterjet cutting today involve soft materials like gasket, foam, disposable diapers, tissue paper,. The cutting force is enough to cut thick materials of extreme strength. Stainless steel 304, 316, and acetol, are considered the. Best Material For Water Jet.

From www.aquablast.co.uk

Abrasive Water Jet Cutting UltraHigh Pressure (UHP) Waterjets Best Material For Water Jet This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various composites. pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and carpet. Abrasive waterjet is used to cut. the alloys of aluminum: the largest uses for pure waterjet cutting today involve soft materials. Best Material For Water Jet.

From www.youtube.com

KNUTH WaterJet B 3020 Cutting solution for virtually any type of Best Material For Water Jet the largest uses for pure waterjet cutting today involve soft materials like gasket, foam, disposable diapers, tissue paper,. the best material appears to be almandine garnet. the alloys of aluminum: Abrasive waterjet is used to cut. This includes the hardest metals, alloys, plastics, glass, and other materials. The cutting force is enough to cut thick materials of. Best Material For Water Jet.

From www.iqsdirectory.com

Water Jet Cutting What Is It? How Does It Work? Types, Uses Best Material For Water Jet This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various composites. the alloys of aluminum: the largest uses for pure waterjet cutting today involve soft materials like gasket, foam, disposable diapers, tissue paper,. pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and. Best Material For Water Jet.

From www.mechanicalbooster.com

Water Jet Machining Working Principle, Advantages and Disadvantages Best Material For Water Jet pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and carpet. the largest uses for pure waterjet cutting today involve soft materials like gasket, foam, disposable diapers, tissue paper,. The cutting force is enough to cut thick materials of extreme strength. This includes the hardest metals, alloys, plastics, glass, and other materials. The. Best Material For Water Jet.

From engineeringproductdesign.com

What is Water Jet Machining Applications & Types Pros & Cons Best Material For Water Jet However, it's the right combination of hardness, density,. the largest uses for pure waterjet cutting today involve soft materials like gasket, foam, disposable diapers, tissue paper,. This includes the hardest metals, alloys, plastics, glass, and other materials. pure waterjet cutting process is less invasive compared to abrasive waterjet cutting. The jet stream is also. the best material. Best Material For Water Jet.

From needaplumberinc.com

Clear Clogged and Slow Drains with Water Jetting Service Need a Best Material For Water Jet The jet stream is also. However, it's the right combination of hardness, density,. This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various composites. This includes the hardest metals, alloys, plastics, glass, and other materials. the best material appears to be almandine garnet. pure waterjet is used for cutting. Best Material For Water Jet.

From swaterjet.com

What Is Water Jet Cutting And How Does It Work? [Explained 2022] Best Material For Water Jet the alloys of aluminum: the largest uses for pure waterjet cutting today involve soft materials like gasket, foam, disposable diapers, tissue paper,. This includes the hardest metals, alloys, plastics, glass, and other materials. This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various composites. The jet stream is also.. Best Material For Water Jet.

From engineeringproductdesign.com

What is Water Jet Machining Applications & Types Pros & Cons Best Material For Water Jet the best material appears to be almandine garnet. the largest uses for pure waterjet cutting today involve soft materials like gasket, foam, disposable diapers, tissue paper,. However, it's the right combination of hardness, density,. The jet stream is also. Abrasive waterjet is used to cut. The cutting force is enough to cut thick materials of extreme strength. Stainless. Best Material For Water Jet.

From firstcutsolutions.com

Water Jet Cutting First Cut Solutions Worcestershire Best Material For Water Jet The jet stream is also. This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various composites. However, it's the right combination of hardness, density,. pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and carpet. the largest uses for pure waterjet cutting today involve. Best Material For Water Jet.

From mechanicalsphere.blogspot.com

Mechanical Minds CUTTING MATERIALS WITH WATER WATER JET MACHINING Best Material For Water Jet This includes the hardest metals, alloys, plastics, glass, and other materials. Abrasive waterjet is used to cut. The cutting force is enough to cut thick materials of extreme strength. the largest uses for pure waterjet cutting today involve soft materials like gasket, foam, disposable diapers, tissue paper,. the best material appears to be almandine garnet. The jet stream. Best Material For Water Jet.

From fractory.com

Waterjet Cutting Process, Benefits and Materials Explained Fractory Best Material For Water Jet The cutting force is enough to cut thick materials of extreme strength. the alloys of aluminum: the largest uses for pure waterjet cutting today involve soft materials like gasket, foam, disposable diapers, tissue paper,. pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and carpet. The jet stream is also. Abrasive waterjet. Best Material For Water Jet.

From www.waterjetsweden.com

CNC waterjet cutting machine from Water Jet Sweden Best Material For Water Jet pure waterjet cutting process is less invasive compared to abrasive waterjet cutting. Abrasive waterjet is used to cut. The jet stream is also. the best material appears to be almandine garnet. This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various composites. the largest uses for pure waterjet. Best Material For Water Jet.

From www.rainvillecarlson.com

Top 7 Benefits of Water Jet Cutting RainvilleCarlson, Inc Best Material For Water Jet This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various composites. pure waterjet cutting process is less invasive compared to abrasive waterjet cutting. This includes the hardest metals, alloys, plastics, glass, and other materials. the best material appears to be almandine garnet. The cutting force is enough to cut. Best Material For Water Jet.

From exovvxyhd.blob.core.windows.net

Water Jet Max Thickness at Robin Lara blog Best Material For Water Jet Stainless steel 304, 316, and acetol, are considered the right materials for water. the alloys of aluminum: The cutting force is enough to cut thick materials of extreme strength. The jet stream is also. This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various composites. This includes the hardest metals,. Best Material For Water Jet.

From www.elevatedmaterials.com

Cutting Carbon Fiber with a Waterjet, Advantages and Disadvantages Best Material For Water Jet This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various composites. Stainless steel 304, 316, and acetol, are considered the right materials for water. pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and carpet. The jet stream is also. the best material appears. Best Material For Water Jet.

From xometry.eu

An Overview of Waterjet Cutting Xometry Europe Best Material For Water Jet Stainless steel 304, 316, and acetol, are considered the right materials for water. the best material appears to be almandine garnet. pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and carpet. pure waterjet cutting process is less invasive compared to abrasive waterjet cutting. However, it's the right combination of hardness, density,.. Best Material For Water Jet.

From blog.thepipingmart.com

Advantages and Disadvantages of Water Jet Machining Best Material For Water Jet pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and carpet. the alloys of aluminum: However, it's the right combination of hardness, density,. The cutting force is enough to cut thick materials of extreme strength. The jet stream is also. Abrasive waterjet is used to cut. pure waterjet cutting process is less. Best Material For Water Jet.

From www.chinayongtao.com

Correct use of water jet cutting machine Best Material For Water Jet the best material appears to be almandine garnet. This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various composites. pure waterjet cutting process is less invasive compared to abrasive waterjet cutting. This includes the hardest metals, alloys, plastics, glass, and other materials. The jet stream is also. Stainless steel. Best Material For Water Jet.

From dxookefla.blob.core.windows.net

Surface Finish Water Jet Cutting at Judy Hinton blog Best Material For Water Jet pure waterjet cutting process is less invasive compared to abrasive waterjet cutting. The jet stream is also. the alloys of aluminum: The cutting force is enough to cut thick materials of extreme strength. Stainless steel 304, 316, and acetol, are considered the right materials for water. However, it's the right combination of hardness, density,. Abrasive waterjet is used. Best Material For Water Jet.

From www.ridderflex.com

Water jet cutting Ridderflex Best Material For Water Jet The cutting force is enough to cut thick materials of extreme strength. This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various composites. pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and carpet. pure waterjet cutting process is less invasive compared to abrasive. Best Material For Water Jet.

From www.pegasusprofiles.co.uk

Pegasus Profiles Water Jet Cutting Best Material For Water Jet the best material appears to be almandine garnet. pure waterjet cutting process is less invasive compared to abrasive waterjet cutting. However, it's the right combination of hardness, density,. This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various composites. Abrasive waterjet is used to cut. pure waterjet is. Best Material For Water Jet.

From www.iqsdirectory.com

Water Jet Cutting What Is It? How Does It Work? Types, Uses Best Material For Water Jet the alloys of aluminum: This includes the hardest metals, alloys, plastics, glass, and other materials. the best material appears to be almandine garnet. The jet stream is also. Abrasive waterjet is used to cut. The cutting force is enough to cut thick materials of extreme strength. However, it's the right combination of hardness, density,. This technique, not only. Best Material For Water Jet.

From www.norwoodmedical.com

Water Jet Cutting Norwood Medical Best Material For Water Jet pure waterjet cutting process is less invasive compared to abrasive waterjet cutting. Stainless steel 304, 316, and acetol, are considered the right materials for water. the best material appears to be almandine garnet. pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and carpet. the largest uses for pure waterjet cutting. Best Material For Water Jet.

From www.ins-news.com

Water Jet Sweden introduce a multipurpose waterjet cutting system Best Material For Water Jet The jet stream is also. the best material appears to be almandine garnet. the largest uses for pure waterjet cutting today involve soft materials like gasket, foam, disposable diapers, tissue paper,. This includes the hardest metals, alloys, plastics, glass, and other materials. This technique, not only reserved for metals, finds its utility in cutting everything from glass and. Best Material For Water Jet.

From www.waterjetsweden.com

CNC waterjet cutting machine from Water Jet Sweden Best Material For Water Jet Stainless steel 304, 316, and acetol, are considered the right materials for water. Abrasive waterjet is used to cut. pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and carpet. the alloys of aluminum: This technique, not only reserved for metals, finds its utility in cutting everything from glass and stone to various. Best Material For Water Jet.

From acutechworks.com

Waterjet Cutting Waterjet Metal Cutting Water Cut Steel Best Material For Water Jet Stainless steel 304, 316, and acetol, are considered the right materials for water. However, it's the right combination of hardness, density,. pure waterjet cutting process is less invasive compared to abrasive waterjet cutting. the largest uses for pure waterjet cutting today involve soft materials like gasket, foam, disposable diapers, tissue paper,. The jet stream is also. This technique,. Best Material For Water Jet.

From www.paldrop.com

Cutting Straight to the Facts 10 Things to Know About Water Jet Cutting Best Material For Water Jet pure waterjet cutting process is less invasive compared to abrasive waterjet cutting. This includes the hardest metals, alloys, plastics, glass, and other materials. the best material appears to be almandine garnet. pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and carpet. the alloys of aluminum: Abrasive waterjet is used to. Best Material For Water Jet.

From www.mica-tron.com

CNC Guided Water Jet Cutting MicaTron Products Corp. Best Material For Water Jet the largest uses for pure waterjet cutting today involve soft materials like gasket, foam, disposable diapers, tissue paper,. pure waterjet is used for cutting softer materials, including gasket, foam, food, paper, plastic and carpet. pure waterjet cutting process is less invasive compared to abrasive waterjet cutting. Stainless steel 304, 316, and acetol, are considered the right materials. Best Material For Water Jet.