Surface Finish For Gasket Seal . There is a direct relationship between the quality of a seal’s mating surface finish and a seal’s performance—the better the finish, the longer the seal will last. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. For a gasket to seal correctly, the mating flange sealing face, and the companion flange sealing face, must have. Irregularities in the surface can impact upon the effectiveness of the gasket’s ability to close potential leak paths and the friction values needed to keep the gasket in position. For spiral wound , kammprofile , corrukamm ,. In many cases, a “as machined”. The flange surface finish for the sealing area is commonly represented by the symbol ra. In fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance.

from www.hextechnology.com

Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. In many cases, a “as machined”. In fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. For a gasket to seal correctly, the mating flange sealing face, and the companion flange sealing face, must have. There is a direct relationship between the quality of a seal’s mating surface finish and a seal’s performance—the better the finish, the longer the seal will last. Irregularities in the surface can impact upon the effectiveness of the gasket’s ability to close potential leak paths and the friction values needed to keep the gasket in position. The flange surface finish for the sealing area is commonly represented by the symbol ra. For spiral wound , kammprofile , corrukamm ,.

Gasket Types in Oil and Gas, Explained Hex Technology

Surface Finish For Gasket Seal In many cases, a “as machined”. The flange surface finish for the sealing area is commonly represented by the symbol ra. There is a direct relationship between the quality of a seal’s mating surface finish and a seal’s performance—the better the finish, the longer the seal will last. Irregularities in the surface can impact upon the effectiveness of the gasket’s ability to close potential leak paths and the friction values needed to keep the gasket in position. For spiral wound , kammprofile , corrukamm ,. In fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. In many cases, a “as machined”. For a gasket to seal correctly, the mating flange sealing face, and the companion flange sealing face, must have. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange.

From www.youtube.com

Surface Finish ORings Gaskets Oil Seals PTFE Surface Finish For Gasket Seal In fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. The flange surface finish for the sealing area is commonly represented by the symbol ra. In many cases, a “as machined”. For a gasket to seal correctly, the mating flange sealing face, and the companion flange sealing face, must have. Fortunately, soft gaskets in. Surface Finish For Gasket Seal.

From www.ekkeagle.com

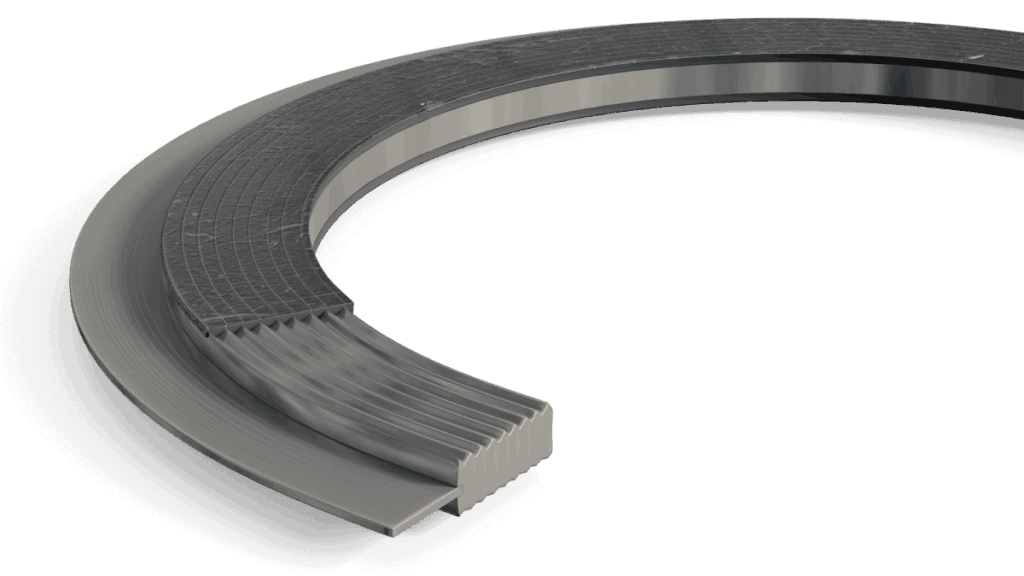

Surface Textured Mechanical Seal Eagle Industry Co., Ltd. Surface Finish For Gasket Seal The flange surface finish for the sealing area is commonly represented by the symbol ra. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. There is a direct relationship between the quality of a seal’s mating surface finish and a seal’s performance—the better the finish, the longer. Surface Finish For Gasket Seal.

From www.pumpsandsystems.com

Enhanced Surface Profiles for Gaskets Pumps & Systems Surface Finish For Gasket Seal The flange surface finish for the sealing area is commonly represented by the symbol ra. For spiral wound , kammprofile , corrukamm ,. In fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. In many cases, a “as machined”. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can. Surface Finish For Gasket Seal.

From www.enginelabs.com

Pros & Cons of MLS and Copper Gaskets Surface Finish For Gasket Seal For spiral wound , kammprofile , corrukamm ,. There is a direct relationship between the quality of a seal’s mating surface finish and a seal’s performance—the better the finish, the longer the seal will last. In fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. For a gasket to seal correctly, the mating flange. Surface Finish For Gasket Seal.

From blog.projectmaterials.com

Types of Gaskets for Flanges Soft, SWG, RTJ, Etc. • Projectmaterials Surface Finish For Gasket Seal For spiral wound , kammprofile , corrukamm ,. Irregularities in the surface can impact upon the effectiveness of the gasket’s ability to close potential leak paths and the friction values needed to keep the gasket in position. There is a direct relationship between the quality of a seal’s mating surface finish and a seal’s performance—the better the finish, the longer. Surface Finish For Gasket Seal.

From empoweringpumps.com

Impact Of Flange Finish On Gasket Performance Empowering Pumps and Surface Finish For Gasket Seal In many cases, a “as machined”. For a gasket to seal correctly, the mating flange sealing face, and the companion flange sealing face, must have. In fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. For spiral wound , kammprofile , corrukamm ,. There is a direct relationship between the quality of a seal’s. Surface Finish For Gasket Seal.

From trianglefluid.com

How to Diagnose & Seal Damaged Flange Faces Triangle Fluid Controls Ltd. Surface Finish For Gasket Seal In fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. There is a direct relationship between the quality of a seal’s mating surface finish and a seal’s performance—the better the finish, the longer the seal will last. In many cases, a “as machined”. For spiral wound , kammprofile , corrukamm ,. Fortunately, soft gaskets. Surface Finish For Gasket Seal.

From hallite.com

Surface Roughness & Finish for Bearings and Seals Hallite Surface Finish For Gasket Seal In fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. The flange surface finish for the sealing area is commonly represented by the symbol ra. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. For a gasket to seal correctly, the. Surface Finish For Gasket Seal.

From blog.enerpac.com

Choosing the Right Flange Surface Finish. an Overview of ASME, ESF and Surface Finish For Gasket Seal For spiral wound , kammprofile , corrukamm ,. The flange surface finish for the sealing area is commonly represented by the symbol ra. Irregularities in the surface can impact upon the effectiveness of the gasket’s ability to close potential leak paths and the friction values needed to keep the gasket in position. In fact, an optimal surface finish can deliver. Surface Finish For Gasket Seal.

From blog.thepipingmart.com

Why is Surface Finish Important? Understanding the Critical Raw Surface Finish For Gasket Seal For spiral wound , kammprofile , corrukamm ,. In fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. Irregularities in the surface can impact upon the effectiveness of the gasket’s ability to close potential leak paths and the friction values needed to keep the gasket in position. The flange surface finish for the sealing. Surface Finish For Gasket Seal.

From www.academyofjointintegrity.com

What is the impact of Flange Surface Finish on Gasket Performance Surface Finish For Gasket Seal For spiral wound , kammprofile , corrukamm ,. There is a direct relationship between the quality of a seal’s mating surface finish and a seal’s performance—the better the finish, the longer the seal will last. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. For a gasket. Surface Finish For Gasket Seal.

From www.hextechnology.com

Gasket Types in Oil and Gas, Explained Hex Technology Surface Finish For Gasket Seal The flange surface finish for the sealing area is commonly represented by the symbol ra. In many cases, a “as machined”. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. For spiral wound , kammprofile , corrukamm ,. For a gasket to seal correctly, the mating flange. Surface Finish For Gasket Seal.

From hallite.com

Surface Roughness & Finish for Seals and Bearings Hallite Surface Finish For Gasket Seal For a gasket to seal correctly, the mating flange sealing face, and the companion flange sealing face, must have. In fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. Irregularities in the surface can impact upon the effectiveness of the gasket’s ability to close potential leak paths and the friction values needed to keep. Surface Finish For Gasket Seal.

From blog.enerpac.com

Guide to Flange Face Finish Types Enerpac Blog Surface Finish For Gasket Seal There is a direct relationship between the quality of a seal’s mating surface finish and a seal’s performance—the better the finish, the longer the seal will last. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. In many cases, a “as machined”. The flange surface finish for. Surface Finish For Gasket Seal.

From www.slobrides.si

Slobrides d.o.o. Surface Finish For Gasket Seal Irregularities in the surface can impact upon the effectiveness of the gasket’s ability to close potential leak paths and the friction values needed to keep the gasket in position. There is a direct relationship between the quality of a seal’s mating surface finish and a seal’s performance—the better the finish, the longer the seal will last. In many cases, a. Surface Finish For Gasket Seal.

From sealfluid.it

Surface Finishes SealFluid Surface Finish For Gasket Seal Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. There is a direct relationship between the quality of a seal’s mating surface finish and a seal’s performance—the better the finish, the longer the seal will last. Irregularities in the surface can impact upon the effectiveness of the. Surface Finish For Gasket Seal.

From empoweringpumps.com

Impact Of Flange Finish On Gasket Performance Empowering Pumps and Surface Finish For Gasket Seal For spiral wound , kammprofile , corrukamm ,. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. There is a direct relationship between the quality of a seal’s mating surface finish and a seal’s performance—the better the finish, the longer the seal will last. Irregularities in the. Surface Finish For Gasket Seal.

From www.sealfaqs.com

Fundamentals of Mechanical Seals Seal FAQs Surface Finish For Gasket Seal In many cases, a “as machined”. The flange surface finish for the sealing area is commonly represented by the symbol ra. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. There is a direct relationship between the quality of a seal’s mating surface finish and a seal’s. Surface Finish For Gasket Seal.

From www.applerubber.com

What you Need to Know About Dynamic Seal Applications Hot Topics Surface Finish For Gasket Seal Irregularities in the surface can impact upon the effectiveness of the gasket’s ability to close potential leak paths and the friction values needed to keep the gasket in position. For a gasket to seal correctly, the mating flange sealing face, and the companion flange sealing face, must have. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface. Surface Finish For Gasket Seal.

From savree.com

Flange Gaskets Explained saVRee Surface Finish For Gasket Seal In fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. In many cases, a “as machined”. The flange surface finish for the sealing area is commonly represented by the symbol ra. Irregularities. Surface Finish For Gasket Seal.

From www.durlon.com

Impact of Flange Finish on Gasket Performance Durlon Surface Finish For Gasket Seal In many cases, a “as machined”. For a gasket to seal correctly, the mating flange sealing face, and the companion flange sealing face, must have. For spiral wound , kammprofile , corrukamm ,. In fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of. Surface Finish For Gasket Seal.

From www.youtube.com

Gasket Material and Surface Roughness—and How they Relate YouTube Surface Finish For Gasket Seal In many cases, a “as machined”. For a gasket to seal correctly, the mating flange sealing face, and the companion flange sealing face, must have. In fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. For spiral wound , kammprofile , corrukamm ,. Irregularities in the surface can impact upon the effectiveness of the. Surface Finish For Gasket Seal.

From www.gallagherseals.com

How Surface Finish Affects Sealing Performance Surface Finish For Gasket Seal There is a direct relationship between the quality of a seal’s mating surface finish and a seal’s performance—the better the finish, the longer the seal will last. For spiral wound , kammprofile , corrukamm ,. For a gasket to seal correctly, the mating flange sealing face, and the companion flange sealing face, must have. In many cases, a “as machined”.. Surface Finish For Gasket Seal.

From systemseals.de

Surface Finish Specification System Seals Inc. Surface Finish For Gasket Seal The flange surface finish for the sealing area is commonly represented by the symbol ra. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. Irregularities in the surface can impact upon the effectiveness of the gasket’s ability to close potential leak paths and the friction values needed. Surface Finish For Gasket Seal.

From diyquickly.com

How to Clean Aluminum Gasket Surface 10 Effective Methods Surface Finish For Gasket Seal In fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. In many cases, a “as machined”. There is a direct relationship between the quality of a seal’s mating surface finish and a seal’s performance—the better the finish, the longer the seal will last. Irregularities in the surface can impact upon the effectiveness of the. Surface Finish For Gasket Seal.

From www.iqsdirectory.com

Gasket What Is It? How Is It Made? Types Of & Safety Surface Finish For Gasket Seal The flange surface finish for the sealing area is commonly represented by the symbol ra. There is a direct relationship between the quality of a seal’s mating surface finish and a seal’s performance—the better the finish, the longer the seal will last. For a gasket to seal correctly, the mating flange sealing face, and the companion flange sealing face, must. Surface Finish For Gasket Seal.

From ahpseals.com

Seal design Viton seal American High Performance Seals Surface Finish For Gasket Seal For spiral wound , kammprofile , corrukamm ,. There is a direct relationship between the quality of a seal’s mating surface finish and a seal’s performance—the better the finish, the longer the seal will last. Irregularities in the surface can impact upon the effectiveness of the gasket’s ability to close potential leak paths and the friction values needed to keep. Surface Finish For Gasket Seal.

From hallite.com

Surface Roughness & Finish for Bearings and Seals Hallite Surface Finish For Gasket Seal For a gasket to seal correctly, the mating flange sealing face, and the companion flange sealing face, must have. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. For spiral wound , kammprofile , corrukamm ,. In many cases, a “as machined”. Irregularities in the surface can. Surface Finish For Gasket Seal.

From savree.com

Flange Face Surfaces Explained (Serrated and Smooth) saVRee Surface Finish For Gasket Seal Irregularities in the surface can impact upon the effectiveness of the gasket’s ability to close potential leak paths and the friction values needed to keep the gasket in position. In many cases, a “as machined”. For a gasket to seal correctly, the mating flange sealing face, and the companion flange sealing face, must have. For spiral wound , kammprofile ,. Surface Finish For Gasket Seal.

From www.rjsales.com

Gasket Surface Finishes RobertJames Sales, Inc. Surface Finish For Gasket Seal For a gasket to seal correctly, the mating flange sealing face, and the companion flange sealing face, must have. The flange surface finish for the sealing area is commonly represented by the symbol ra. In fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant. Surface Finish For Gasket Seal.

From www.iqsdirectory.com

Gasket What Is It? How Is It Made? Types Of & Safety Surface Finish For Gasket Seal Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. For a gasket to seal correctly, the mating flange sealing face, and the companion flange sealing face, must have. In fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. There is a. Surface Finish For Gasket Seal.

From advanced-emc.com

The Effect Surface Finish Has on PTFE Seals Advanced EMC Technologies Surface Finish For Gasket Seal In many cases, a “as machined”. For spiral wound , kammprofile , corrukamm ,. In fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. Irregularities in the surface can impact upon the effectiveness of the gasket’s ability to close potential leak paths and the friction values needed to keep the gasket in position. For. Surface Finish For Gasket Seal.

From www.toparts.com

Gaskets FKM ORing|ORing|Viton ORing|Hydraulic Seal Surface Finish For Gasket Seal Irregularities in the surface can impact upon the effectiveness of the gasket’s ability to close potential leak paths and the friction values needed to keep the gasket in position. For a gasket to seal correctly, the mating flange sealing face, and the companion flange sealing face, must have. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface. Surface Finish For Gasket Seal.

From blog.miragemachines.com

What should a good refaced flange surface finish look like? Surface Finish For Gasket Seal Irregularities in the surface can impact upon the effectiveness of the gasket’s ability to close potential leak paths and the friction values needed to keep the gasket in position. There is a direct relationship between the quality of a seal’s mating surface finish and a seal’s performance—the better the finish, the longer the seal will last. In many cases, a. Surface Finish For Gasket Seal.

From www.kemet.co.uk

Surface Finishing Tungsten Carbide Kemet Surface Finish For Gasket Seal For spiral wound , kammprofile , corrukamm ,. Fortunately, soft gaskets in the flatsealtm portfolio are very tolerant of surface finish and can compensate for a wide range of flange. In fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. There is a direct relationship between the quality of a seal’s mating surface finish. Surface Finish For Gasket Seal.