Conveyor Belt Head Pulley Slippage . When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley or that it’s pulling to one side of the conveyor. One common cause of conveyor belt slippage is exceeding the conveyor system’s weight limit when transporting materials and products. If your slippage is caused by a belt that is too heavy for the motors, a conveyor belt that isn’t strong enough to carry your materials, or a conveyor belt with a surface that is too slippery. 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding. Mistracking can lead to several problems, from shortened service life due to uneven belt wear to shutting down the entire line.

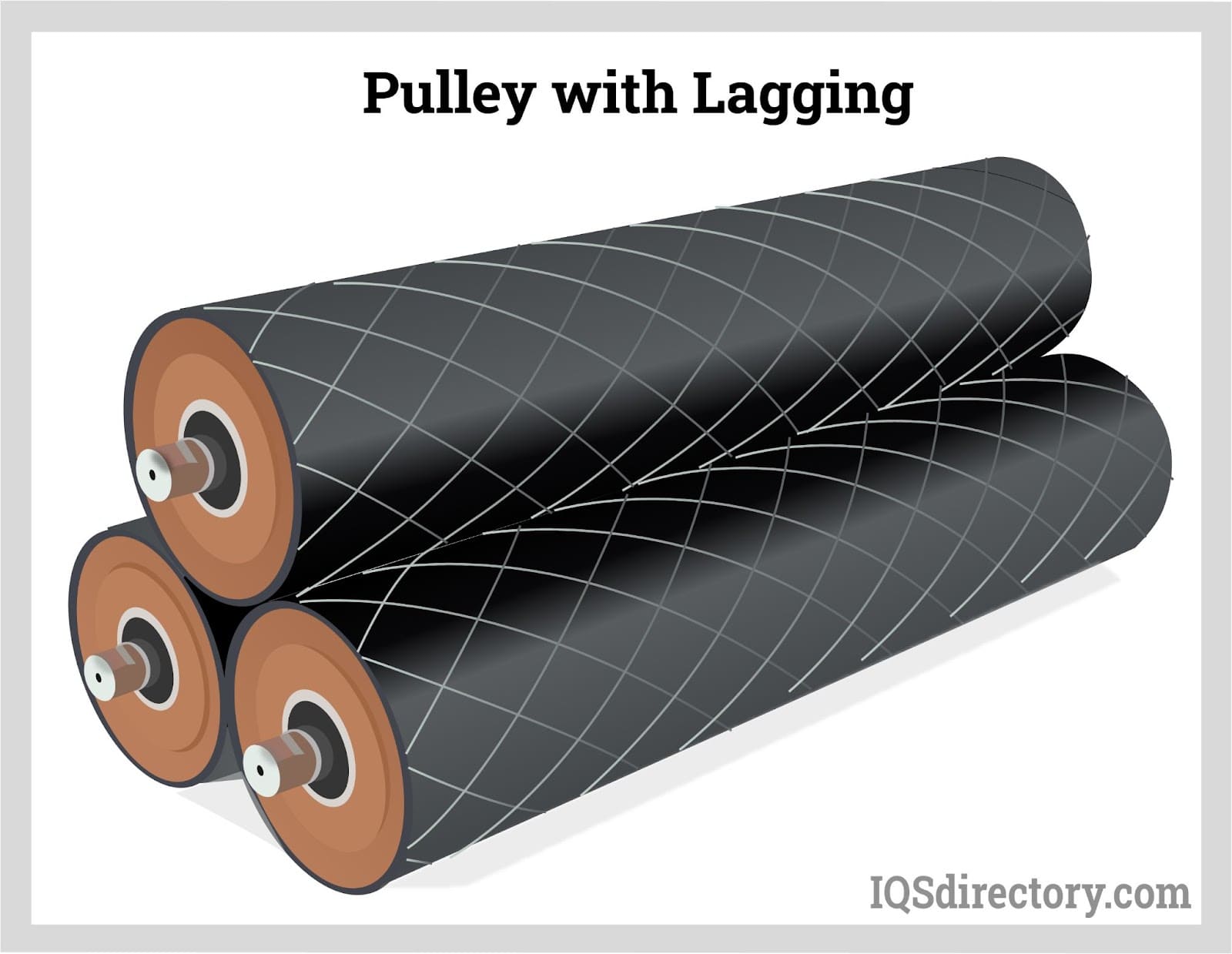

from www.iqsdirectory.com

One common cause of conveyor belt slippage is exceeding the conveyor system’s weight limit when transporting materials and products. If your slippage is caused by a belt that is too heavy for the motors, a conveyor belt that isn’t strong enough to carry your materials, or a conveyor belt with a surface that is too slippery. Mistracking can lead to several problems, from shortened service life due to uneven belt wear to shutting down the entire line. When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley or that it’s pulling to one side of the conveyor. 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding.

Belt Conveyors Components, Types, Design, and Applications

Conveyor Belt Head Pulley Slippage 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding. One common cause of conveyor belt slippage is exceeding the conveyor system’s weight limit when transporting materials and products. If your slippage is caused by a belt that is too heavy for the motors, a conveyor belt that isn’t strong enough to carry your materials, or a conveyor belt with a surface that is too slippery. When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley or that it’s pulling to one side of the conveyor. Mistracking can lead to several problems, from shortened service life due to uneven belt wear to shutting down the entire line. 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding.

From www.rainbowbelts.com

Conveyor Belt Slippage Causes & Solutions Conveyor Belt Head Pulley Slippage Mistracking can lead to several problems, from shortened service life due to uneven belt wear to shutting down the entire line. 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding. When your belt is out of alignment, you may notice that it’s running off at the. Conveyor Belt Head Pulley Slippage.

From tw.roller.com.tw

Ceramic Pulley Lagging Eliminates Slippage Conveyor Parts Supplier│JIMWAY Conveyor Belt Head Pulley Slippage When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley or that it’s pulling to one side of the conveyor. Mistracking can lead to several problems, from shortened service life due to uneven belt wear to shutting down the entire line. If your slippage is caused by a belt that. Conveyor Belt Head Pulley Slippage.

From www.drcrollers.com.au

Conveyor Pulleys Conveyor Belt Head Pulley Slippage If your slippage is caused by a belt that is too heavy for the motors, a conveyor belt that isn’t strong enough to carry your materials, or a conveyor belt with a surface that is too slippery. 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding.. Conveyor Belt Head Pulley Slippage.

From confya.com.mx

opruiming > head pulley belt conveyor Conveyor Belt Head Pulley Slippage 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding. If your slippage is caused by a belt that is too heavy for the motors, a conveyor belt that isn’t strong enough to carry your materials, or a conveyor belt with a surface that is too slippery.. Conveyor Belt Head Pulley Slippage.

From dir.indiamart.com

Belt Conveyor Head Pulley at Best Price in India Conveyor Belt Head Pulley Slippage When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley or that it’s pulling to one side of the conveyor. One common cause of conveyor belt slippage is exceeding the conveyor system’s weight limit when transporting materials and products. If your slippage is caused by a belt that is too. Conveyor Belt Head Pulley Slippage.

From gbu-presnenskij.ru

Conveyor Pulleys Head And Tail Pulleys And More Metso, 53 OFF Conveyor Belt Head Pulley Slippage 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding. Mistracking can lead to several problems, from shortened service life due to uneven belt wear to shutting down the entire line. One common cause of conveyor belt slippage is exceeding the conveyor system’s weight limit when transporting. Conveyor Belt Head Pulley Slippage.

From www.engineersdatabase.com

Conveyor Components The Engineers Database Conveyor Belt Head Pulley Slippage 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding. One common cause of conveyor belt slippage is exceeding the conveyor system’s weight limit when transporting materials and products. Mistracking can lead to several problems, from shortened service life due to uneven belt wear to shutting down. Conveyor Belt Head Pulley Slippage.

From zejx2011.en.made-in-china.com

Replaceable Diamond Rubber Pulley Lagging to Prevent Conveyor Belt Slippage, Conveyor Drum Conveyor Belt Head Pulley Slippage 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding. When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley or that it’s pulling to one side of the conveyor. If your slippage is caused by a. Conveyor Belt Head Pulley Slippage.

From www.brelko.com

Conveyor Belt Cleaners Archives Brelko Conveyor Belt Head Pulley Slippage One common cause of conveyor belt slippage is exceeding the conveyor system’s weight limit when transporting materials and products. 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding. When your belt is out of alignment, you may notice that it’s running off at the head or. Conveyor Belt Head Pulley Slippage.

From confya.com.mx

opruiming > head pulley belt conveyor Conveyor Belt Head Pulley Slippage Mistracking can lead to several problems, from shortened service life due to uneven belt wear to shutting down the entire line. One common cause of conveyor belt slippage is exceeding the conveyor system’s weight limit when transporting materials and products. 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware. Conveyor Belt Head Pulley Slippage.

From www.indiamart.com

PVC & Mild Steel Belt Conveyor Head Pulley at Rs 7000 in Gurgaon ID 22984878312 Conveyor Belt Head Pulley Slippage 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding. Mistracking can lead to several problems, from shortened service life due to uneven belt wear to shutting down the entire line. If your slippage is caused by a belt that is too heavy for the motors, a. Conveyor Belt Head Pulley Slippage.

From www.asgco.com

Arrowhead Drive and NonDrive Rubber Conveyor Pulley Lagging ASGCO Conveyor Solutions Conveyor Belt Head Pulley Slippage If your slippage is caused by a belt that is too heavy for the motors, a conveyor belt that isn’t strong enough to carry your materials, or a conveyor belt with a surface that is too slippery. When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley or that it’s. Conveyor Belt Head Pulley Slippage.

From stokmanbv.com

Types & functions of conveyor pulleys Machinefabriek Stokman Conveyor Belt Head Pulley Slippage Mistracking can lead to several problems, from shortened service life due to uneven belt wear to shutting down the entire line. If your slippage is caused by a belt that is too heavy for the motors, a conveyor belt that isn’t strong enough to carry your materials, or a conveyor belt with a surface that is too slippery. When your. Conveyor Belt Head Pulley Slippage.

From www.beltconveyorequipment.com

Conveyor Drum Pulley Conveyor Belt Head Pulley Slippage If your slippage is caused by a belt that is too heavy for the motors, a conveyor belt that isn’t strong enough to carry your materials, or a conveyor belt with a surface that is too slippery. 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding.. Conveyor Belt Head Pulley Slippage.

From www.youtube.com

Types of Pulley Lagging Pulley lagging Conveyor Belt Pulley Lagging Drum pulley lagging Conveyor Belt Head Pulley Slippage When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley or that it’s pulling to one side of the conveyor. 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding. One common cause of conveyor belt slippage. Conveyor Belt Head Pulley Slippage.

From www.feihongconveyor.com

Jual Conveyor Belt Head Pulley Bermotif Jakarta Feihong Trading International Conveyor Belt Head Pulley Slippage If your slippage is caused by a belt that is too heavy for the motors, a conveyor belt that isn’t strong enough to carry your materials, or a conveyor belt with a surface that is too slippery. When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley or that it’s. Conveyor Belt Head Pulley Slippage.

From luffindustries.com

What is the Main Function of Conveyor Pulleys? Luff Industries Ltd Conveyor Belt Head Pulley Slippage If your slippage is caused by a belt that is too heavy for the motors, a conveyor belt that isn’t strong enough to carry your materials, or a conveyor belt with a surface that is too slippery. When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley or that it’s. Conveyor Belt Head Pulley Slippage.

From dir.indiamart.com

Belt Conveyor Head Pulley in Bengaluru, Karnataka Belt Conveyor Head Pulley Price in Bengaluru Conveyor Belt Head Pulley Slippage If your slippage is caused by a belt that is too heavy for the motors, a conveyor belt that isn’t strong enough to carry your materials, or a conveyor belt with a surface that is too slippery. Mistracking can lead to several problems, from shortened service life due to uneven belt wear to shutting down the entire line. When your. Conveyor Belt Head Pulley Slippage.

From www.tec-science.com

Slippage of the belt in belt drives tecscience Conveyor Belt Head Pulley Slippage Mistracking can lead to several problems, from shortened service life due to uneven belt wear to shutting down the entire line. 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding. If your slippage is caused by a belt that is too heavy for the motors, a. Conveyor Belt Head Pulley Slippage.

From jtconveyor.en.made-in-china.com

Belt Conveyor Drive Head Drum Rubber Pulley Lagging Sheet China TaperLock Bushings Pulley and Conveyor Belt Head Pulley Slippage When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley or that it’s pulling to one side of the conveyor. If your slippage is caused by a belt that is too heavy for the motors, a conveyor belt that isn’t strong enough to carry your materials, or a conveyor belt. Conveyor Belt Head Pulley Slippage.

From www.ibeltrepair.com

A Competely Guide for Conveyor Belt Maintenance Conveyor Belt Head Pulley Slippage 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding. If your slippage is caused by a belt that is too heavy for the motors, a conveyor belt that isn’t strong enough to carry your materials, or a conveyor belt with a surface that is too slippery.. Conveyor Belt Head Pulley Slippage.

From cgmh.com

Conveyor Pulleys Continental Global Material Handling Conveyor Belt Head Pulley Slippage One common cause of conveyor belt slippage is exceeding the conveyor system’s weight limit when transporting materials and products. Mistracking can lead to several problems, from shortened service life due to uneven belt wear to shutting down the entire line. If your slippage is caused by a belt that is too heavy for the motors, a conveyor belt that isn’t. Conveyor Belt Head Pulley Slippage.

From www.goodmaxgroup.com

Conveyor Drum Head Pully / Rubber Lagging Conveyor Pulley Marketer Goodmax Conveyor Belt Head Pulley Slippage When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley or that it’s pulling to one side of the conveyor. 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding. One common cause of conveyor belt slippage. Conveyor Belt Head Pulley Slippage.

From www.asgco.com

Arrowhead Ceramic Conveyor Pulley Lagging ASGCO Conveyor Solutions Conveyor Belt Head Pulley Slippage One common cause of conveyor belt slippage is exceeding the conveyor system’s weight limit when transporting materials and products. Mistracking can lead to several problems, from shortened service life due to uneven belt wear to shutting down the entire line. When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley. Conveyor Belt Head Pulley Slippage.

From www.linkedin.com

Why Belt Conveyor Pulleys are Essential for Industrial Success Conveyor Belt Head Pulley Slippage When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley or that it’s pulling to one side of the conveyor. Mistracking can lead to several problems, from shortened service life due to uneven belt wear to shutting down the entire line. If your slippage is caused by a belt that. Conveyor Belt Head Pulley Slippage.

From confya.com.mx

opruiming > head pulley belt conveyor Conveyor Belt Head Pulley Slippage Mistracking can lead to several problems, from shortened service life due to uneven belt wear to shutting down the entire line. When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley or that it’s pulling to one side of the conveyor. 13 rows conveyor belt systems can be extremely dangerous,. Conveyor Belt Head Pulley Slippage.

From www.oparya.com

Complete Belt Conveyor System Basic Components and Its Safety Safety World Conveyor Belt Head Pulley Slippage Mistracking can lead to several problems, from shortened service life due to uneven belt wear to shutting down the entire line. One common cause of conveyor belt slippage is exceeding the conveyor system’s weight limit when transporting materials and products. If your slippage is caused by a belt that is too heavy for the motors, a conveyor belt that isn’t. Conveyor Belt Head Pulley Slippage.

From atelier-yuwa.ciao.jp

Conveyor Pulleys Head And Tail Pulleys And More Metso Outotec atelieryuwa.ciao.jp Conveyor Belt Head Pulley Slippage If your slippage is caused by a belt that is too heavy for the motors, a conveyor belt that isn’t strong enough to carry your materials, or a conveyor belt with a surface that is too slippery. Mistracking can lead to several problems, from shortened service life due to uneven belt wear to shutting down the entire line. When your. Conveyor Belt Head Pulley Slippage.

From www.iqsdirectory.com

Belt Conveyors Components, Types, Design, and Applications Conveyor Belt Head Pulley Slippage 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding. When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley or that it’s pulling to one side of the conveyor. If your slippage is caused by a. Conveyor Belt Head Pulley Slippage.

From confya.com.mx

opruiming > head pulley belt conveyor Conveyor Belt Head Pulley Slippage If your slippage is caused by a belt that is too heavy for the motors, a conveyor belt that isn’t strong enough to carry your materials, or a conveyor belt with a surface that is too slippery. When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley or that it’s. Conveyor Belt Head Pulley Slippage.

From www.indiamart.com

2.5 Inch Mild Steel Belt Conveyor Head Pulley at Rs 6000 in Jaipur ID 22502883273 Conveyor Belt Head Pulley Slippage When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley or that it’s pulling to one side of the conveyor. One common cause of conveyor belt slippage is exceeding the conveyor system’s weight limit when transporting materials and products. Mistracking can lead to several problems, from shortened service life due. Conveyor Belt Head Pulley Slippage.

From www.indiamart.com

350650 mm Mild Steel Belt Conveyor Head Pulley at Rs 28000 in Kolkata ID 24419850212 Conveyor Belt Head Pulley Slippage Mistracking can lead to several problems, from shortened service life due to uneven belt wear to shutting down the entire line. 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding. When your belt is out of alignment, you may notice that it’s running off at the. Conveyor Belt Head Pulley Slippage.

From www.redlinesystems.com

Causes of Conveyor Belt Slippage Conveyor Belt Head Pulley Slippage One common cause of conveyor belt slippage is exceeding the conveyor system’s weight limit when transporting materials and products. When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley or that it’s pulling to one side of the conveyor. If your slippage is caused by a belt that is too. Conveyor Belt Head Pulley Slippage.

From www.iqsdirectory.com

Belt Conveyors Components, Types, Design, and Applications Conveyor Belt Head Pulley Slippage If your slippage is caused by a belt that is too heavy for the motors, a conveyor belt that isn’t strong enough to carry your materials, or a conveyor belt with a surface that is too slippery. 13 rows conveyor belt systems can be extremely dangerous, always make sure to watch your hand placement and be aware of your surrounding.. Conveyor Belt Head Pulley Slippage.

From www.youtube.com

Conveyor Belt Distance between Head pulley & Snub Pulley Head Pulley & Snub Pulley Distance Conveyor Belt Head Pulley Slippage When your belt is out of alignment, you may notice that it’s running off at the head or tail pulley or that it’s pulling to one side of the conveyor. One common cause of conveyor belt slippage is exceeding the conveyor system’s weight limit when transporting materials and products. If your slippage is caused by a belt that is too. Conveyor Belt Head Pulley Slippage.