Mig Welding Header Tubes . When constructing racing headers, it is very important to make a logical plan before cutting any tubing. We had the tig welder set at about 35 amps for most of the job, while the mig. I have not been too successful in welding tubing. I currently am using just a small portable 110v mig welder with shielding gas that seems to work pretty well, but i keep having. If so, you need to weld it 100% all. You don't need a lot of heat when welding tubing. Typically, the easiest and quickest way to ensure a good design choice is to use an existing, proven design as a basis for your new header. The design selection is the first step. The reason i say aluminize after you weld the pipes up is because you'll burn the aluminum off in the area you weld and will be prone to rusting. Either i burn holes in the interface or if i. Hi sam, i'm assuming you're building a set of headers & welding the formed collector to the 4 tubes. You can achieve a lot nicer looking weld with gas aside from the annealing process than with a wire welder unless you are.

from www.weldingtipsandtricks.com

The design selection is the first step. We had the tig welder set at about 35 amps for most of the job, while the mig. You can achieve a lot nicer looking weld with gas aside from the annealing process than with a wire welder unless you are. I have not been too successful in welding tubing. Either i burn holes in the interface or if i. If so, you need to weld it 100% all. When constructing racing headers, it is very important to make a logical plan before cutting any tubing. Typically, the easiest and quickest way to ensure a good design choice is to use an existing, proven design as a basis for your new header. The reason i say aluminize after you weld the pipes up is because you'll burn the aluminum off in the area you weld and will be prone to rusting. You don't need a lot of heat when welding tubing.

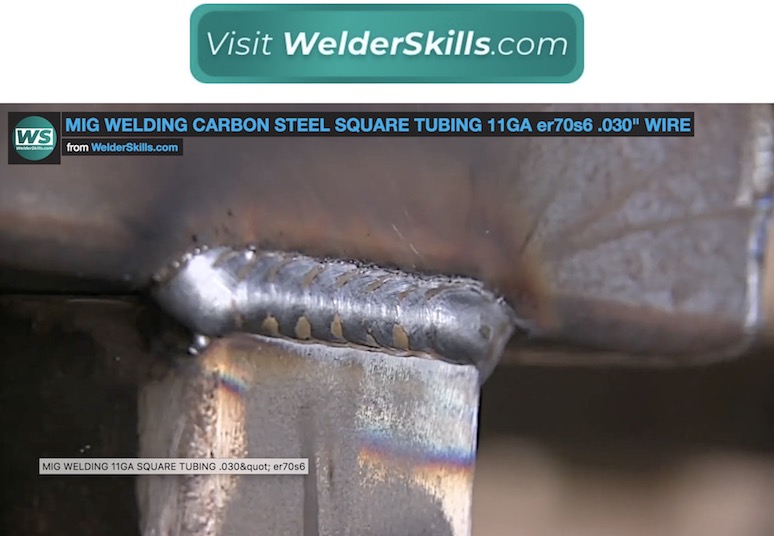

MIG Welding 11ga Square Tubing with .030" er70s6

Mig Welding Header Tubes Either i burn holes in the interface or if i. When constructing racing headers, it is very important to make a logical plan before cutting any tubing. I currently am using just a small portable 110v mig welder with shielding gas that seems to work pretty well, but i keep having. You don't need a lot of heat when welding tubing. Hi sam, i'm assuming you're building a set of headers & welding the formed collector to the 4 tubes. Typically, the easiest and quickest way to ensure a good design choice is to use an existing, proven design as a basis for your new header. The design selection is the first step. I have not been too successful in welding tubing. We had the tig welder set at about 35 amps for most of the job, while the mig. The reason i say aluminize after you weld the pipes up is because you'll burn the aluminum off in the area you weld and will be prone to rusting. Either i burn holes in the interface or if i. You can achieve a lot nicer looking weld with gas aside from the annealing process than with a wire welder unless you are. If so, you need to weld it 100% all.

From www.youtube.com

Mig Welding GMAW Steel Box Tube. Straight line splice weld. Mig Welding Header Tubes Either i burn holes in the interface or if i. You don't need a lot of heat when welding tubing. If so, you need to weld it 100% all. You can achieve a lot nicer looking weld with gas aside from the annealing process than with a wire welder unless you are. The reason i say aluminize after you weld. Mig Welding Header Tubes.

From www.youtube.com

Pipe Welding a 6" Header (MIG/MAG How To) YouTube Mig Welding Header Tubes Typically, the easiest and quickest way to ensure a good design choice is to use an existing, proven design as a basis for your new header. When constructing racing headers, it is very important to make a logical plan before cutting any tubing. I currently am using just a small portable 110v mig welder with shielding gas that seems to. Mig Welding Header Tubes.

From www.youtube.com

MIG Weld Thin Square Tubing 5 Tips to Crush It! YouTube Mig Welding Header Tubes I have not been too successful in welding tubing. Either i burn holes in the interface or if i. You don't need a lot of heat when welding tubing. I currently am using just a small portable 110v mig welder with shielding gas that seems to work pretty well, but i keep having. Hi sam, i'm assuming you're building a. Mig Welding Header Tubes.

From www.dreamstime.com

Steel tube MIG welding stock image. Image of metalwork 17364001 Mig Welding Header Tubes The design selection is the first step. We had the tig welder set at about 35 amps for most of the job, while the mig. The reason i say aluminize after you weld the pipes up is because you'll burn the aluminum off in the area you weld and will be prone to rusting. If so, you need to weld. Mig Welding Header Tubes.

From www.youtube.com

How To Weld Pipe With A Mig Welder YouTube Mig Welding Header Tubes The design selection is the first step. You don't need a lot of heat when welding tubing. When constructing racing headers, it is very important to make a logical plan before cutting any tubing. We had the tig welder set at about 35 amps for most of the job, while the mig. If so, you need to weld it 100%. Mig Welding Header Tubes.

From weldingblos.netlify.app

Welding Exhaust With Mig Mig Welding Header Tubes You don't need a lot of heat when welding tubing. The reason i say aluminize after you weld the pipes up is because you'll burn the aluminum off in the area you weld and will be prone to rusting. You can achieve a lot nicer looking weld with gas aside from the annealing process than with a wire welder unless. Mig Welding Header Tubes.

From www.youtube.com

Mig Welding Thin Square Tubing YouTube Mig Welding Header Tubes I have not been too successful in welding tubing. I currently am using just a small portable 110v mig welder with shielding gas that seems to work pretty well, but i keep having. Typically, the easiest and quickest way to ensure a good design choice is to use an existing, proven design as a basis for your new header. Either. Mig Welding Header Tubes.

From cn-goldenglobe.en.made-in-china.com

MIG Swan Neck Welding Tube for Binzel MIG Torch China Swan Neck and Mig Welding Header Tubes If so, you need to weld it 100% all. I have not been too successful in welding tubing. Either i burn holes in the interface or if i. I currently am using just a small portable 110v mig welder with shielding gas that seems to work pretty well, but i keep having. You can achieve a lot nicer looking weld. Mig Welding Header Tubes.

From handytooler.com

How to Mig Weld Exhaust System Mig Welding Header Tubes I currently am using just a small portable 110v mig welder with shielding gas that seems to work pretty well, but i keep having. Hi sam, i'm assuming you're building a set of headers & welding the formed collector to the 4 tubes. Typically, the easiest and quickest way to ensure a good design choice is to use an existing,. Mig Welding Header Tubes.

From www.hotrod.com

MIG Welding Guide Learn How to MIG Weld Like a Professional Hot Rod Mig Welding Header Tubes I currently am using just a small portable 110v mig welder with shielding gas that seems to work pretty well, but i keep having. Either i burn holes in the interface or if i. Typically, the easiest and quickest way to ensure a good design choice is to use an existing, proven design as a basis for your new header.. Mig Welding Header Tubes.

From www.grainger.com

LINCOLN ELECTRIC MIG Welding Gun, 350A, Fixed Neck Tube 54RY15K2649 Mig Welding Header Tubes I have not been too successful in welding tubing. I currently am using just a small portable 110v mig welder with shielding gas that seems to work pretty well, but i keep having. Either i burn holes in the interface or if i. When constructing racing headers, it is very important to make a logical plan before cutting any tubing.. Mig Welding Header Tubes.

From www.youtube.com

TIG Welding Techniques Coped Tube Overhead YouTube Mig Welding Header Tubes The reason i say aluminize after you weld the pipes up is because you'll burn the aluminum off in the area you weld and will be prone to rusting. I have not been too successful in welding tubing. Typically, the easiest and quickest way to ensure a good design choice is to use an existing, proven design as a basis. Mig Welding Header Tubes.

From blog.thepipingmart.com

How to MIG Weld Brass? Mig Welding Header Tubes Either i burn holes in the interface or if i. I have not been too successful in welding tubing. The design selection is the first step. Hi sam, i'm assuming you're building a set of headers & welding the formed collector to the 4 tubes. We had the tig welder set at about 35 amps for most of the job,. Mig Welding Header Tubes.

From qizhi2023.en.made-in-china.com

Qizhi Stub Tube and Header Welding Machine Header and Stub Automatic Mig Welding Header Tubes Hi sam, i'm assuming you're building a set of headers & welding the formed collector to the 4 tubes. You don't need a lot of heat when welding tubing. I currently am using just a small portable 110v mig welder with shielding gas that seems to work pretty well, but i keep having. You can achieve a lot nicer looking. Mig Welding Header Tubes.

From www.grainger.com

MILLER ELECTRIC MIG Welding Gun, 250A, Fixed Neck Tube 55EM121770046 Mig Welding Header Tubes I currently am using just a small portable 110v mig welder with shielding gas that seems to work pretty well, but i keep having. When constructing racing headers, it is very important to make a logical plan before cutting any tubing. The design selection is the first step. I have not been too successful in welding tubing. We had the. Mig Welding Header Tubes.

From www.westermans.com

How to Weld Square Tube Step by Step! Westermans Blog Mig Welding Header Tubes Hi sam, i'm assuming you're building a set of headers & welding the formed collector to the 4 tubes. The reason i say aluminize after you weld the pipes up is because you'll burn the aluminum off in the area you weld and will be prone to rusting. We had the tig welder set at about 35 amps for most. Mig Welding Header Tubes.

From weldguru.com

How To MIG Weld Stainless Steel A Beginners Guide Mig Welding Header Tubes If so, you need to weld it 100% all. We had the tig welder set at about 35 amps for most of the job, while the mig. The design selection is the first step. Typically, the easiest and quickest way to ensure a good design choice is to use an existing, proven design as a basis for your new header.. Mig Welding Header Tubes.

From www.instructables.com

Basics of MIG Welding 17 Steps (with Pictures) Instructables Mig Welding Header Tubes You can achieve a lot nicer looking weld with gas aside from the annealing process than with a wire welder unless you are. Hi sam, i'm assuming you're building a set of headers & welding the formed collector to the 4 tubes. I currently am using just a small portable 110v mig welder with shielding gas that seems to work. Mig Welding Header Tubes.

From fazziosurplus.com

(5) Mig Welding Gun Tube Neck , Conductor Joseph Fazzio, Incorporated Mig Welding Header Tubes I have not been too successful in welding tubing. Hi sam, i'm assuming you're building a set of headers & welding the formed collector to the 4 tubes. The design selection is the first step. Either i burn holes in the interface or if i. Typically, the easiest and quickest way to ensure a good design choice is to use. Mig Welding Header Tubes.

From www.dreamstime.com

MIG welding on steel tube stock photo. Image of color 17364048 Mig Welding Header Tubes Hi sam, i'm assuming you're building a set of headers & welding the formed collector to the 4 tubes. The design selection is the first step. I currently am using just a small portable 110v mig welder with shielding gas that seems to work pretty well, but i keep having. I have not been too successful in welding tubing. Either. Mig Welding Header Tubes.

From fshaiyu.en.made-in-china.com

Oxy Welding Stainless Steel Welded Tube MIG Welding Fabrication Service Mig Welding Header Tubes Typically, the easiest and quickest way to ensure a good design choice is to use an existing, proven design as a basis for your new header. Hi sam, i'm assuming you're building a set of headers & welding the formed collector to the 4 tubes. The design selection is the first step. You can achieve a lot nicer looking weld. Mig Welding Header Tubes.

From www.youtube.com

Mig Welding 45° Square Tubing YouTube Mig Welding Header Tubes I currently am using just a small portable 110v mig welder with shielding gas that seems to work pretty well, but i keep having. We had the tig welder set at about 35 amps for most of the job, while the mig. If so, you need to weld it 100% all. I have not been too successful in welding tubing.. Mig Welding Header Tubes.

From www.youtube.com

FAB 101 How to PROPERLY Prep a Tube For MIG Welding YouTube Mig Welding Header Tubes If so, you need to weld it 100% all. Either i burn holes in the interface or if i. The design selection is the first step. I have not been too successful in welding tubing. Typically, the easiest and quickest way to ensure a good design choice is to use an existing, proven design as a basis for your new. Mig Welding Header Tubes.

From www.amazon.co.uk

Pack of 10 0.9 mm current nozzles contact tubes for MIG/MAG welding Mig Welding Header Tubes The design selection is the first step. If so, you need to weld it 100% all. Typically, the easiest and quickest way to ensure a good design choice is to use an existing, proven design as a basis for your new header. Either i burn holes in the interface or if i. We had the tig welder set at about. Mig Welding Header Tubes.

From www.technoxmachine.com

MIG vs TIG Welding Types, Materials, and Applications A Guide Mig Welding Header Tubes You can achieve a lot nicer looking weld with gas aside from the annealing process than with a wire welder unless you are. The reason i say aluminize after you weld the pipes up is because you'll burn the aluminum off in the area you weld and will be prone to rusting. Hi sam, i'm assuming you're building a set. Mig Welding Header Tubes.

From www.youtube.com

TIPS FOR MIG WELDING AROUND TUBES ROLL CAGE FABRICATION YouTube Mig Welding Header Tubes Either i burn holes in the interface or if i. I have not been too successful in welding tubing. When constructing racing headers, it is very important to make a logical plan before cutting any tubing. Hi sam, i'm assuming you're building a set of headers & welding the formed collector to the 4 tubes. The reason i say aluminize. Mig Welding Header Tubes.

From www.weldingtipsandtricks.com

MIG Welding 11ga Square Tubing with .030" er70s6 Mig Welding Header Tubes I have not been too successful in welding tubing. You don't need a lot of heat when welding tubing. The design selection is the first step. I currently am using just a small portable 110v mig welder with shielding gas that seems to work pretty well, but i keep having. The reason i say aluminize after you weld the pipes. Mig Welding Header Tubes.

From www.youtube.com

Miller Multimatic 220 AC/DC Mig Welding Techniques YouTube Mig Welding Header Tubes The reason i say aluminize after you weld the pipes up is because you'll burn the aluminum off in the area you weld and will be prone to rusting. Typically, the easiest and quickest way to ensure a good design choice is to use an existing, proven design as a basis for your new header. We had the tig welder. Mig Welding Header Tubes.

From weldingheadquarters.com

What Is MIG Welding Understanding It Thoroughly Welding Headquarters Mig Welding Header Tubes If so, you need to weld it 100% all. Either i burn holes in the interface or if i. Typically, the easiest and quickest way to ensure a good design choice is to use an existing, proven design as a basis for your new header. You can achieve a lot nicer looking weld with gas aside from the annealing process. Mig Welding Header Tubes.

From www.youtube.com

How To Pipe Weld Tips & Tricks (3" MIG Pipe Welding Fabrication) YouTube Mig Welding Header Tubes We had the tig welder set at about 35 amps for most of the job, while the mig. You can achieve a lot nicer looking weld with gas aside from the annealing process than with a wire welder unless you are. The reason i say aluminize after you weld the pipes up is because you'll burn the aluminum off in. Mig Welding Header Tubes.

From www.weldingcity.com

Lincoln Tweco MIG Welding Gun Conductor Tube Mig Welding Header Tubes When constructing racing headers, it is very important to make a logical plan before cutting any tubing. You can achieve a lot nicer looking weld with gas aside from the annealing process than with a wire welder unless you are. Either i burn holes in the interface or if i. The design selection is the first step. I have not. Mig Welding Header Tubes.

From weldingpros.net

How To MIG Weld Exhaust Pipe Techniques & Tips Mig Welding Header Tubes Hi sam, i'm assuming you're building a set of headers & welding the formed collector to the 4 tubes. When constructing racing headers, it is very important to make a logical plan before cutting any tubing. I currently am using just a small portable 110v mig welder with shielding gas that seems to work pretty well, but i keep having.. Mig Welding Header Tubes.

From www.ebay.com

30pc .035" 000 068 MIG Welding Contact Tips Tubes Fit for Miller M10 Mig Welding Header Tubes You don't need a lot of heat when welding tubing. The design selection is the first step. Typically, the easiest and quickest way to ensure a good design choice is to use an existing, proven design as a basis for your new header. The reason i say aluminize after you weld the pipes up is because you'll burn the aluminum. Mig Welding Header Tubes.

From fixitmanblog.com

Stainless Steel MIG Welding Tips & Tricks Mig Welding Header Tubes The reason i say aluminize after you weld the pipes up is because you'll burn the aluminum off in the area you weld and will be prone to rusting. When constructing racing headers, it is very important to make a logical plan before cutting any tubing. We had the tig welder set at about 35 amps for most of the. Mig Welding Header Tubes.

From blog.perfectwelding.fronius.com

What is MIG/MAG Welding? The Basics and advantages Mig Welding Header Tubes The reason i say aluminize after you weld the pipes up is because you'll burn the aluminum off in the area you weld and will be prone to rusting. If so, you need to weld it 100% all. The design selection is the first step. Either i burn holes in the interface or if i. When constructing racing headers, it. Mig Welding Header Tubes.