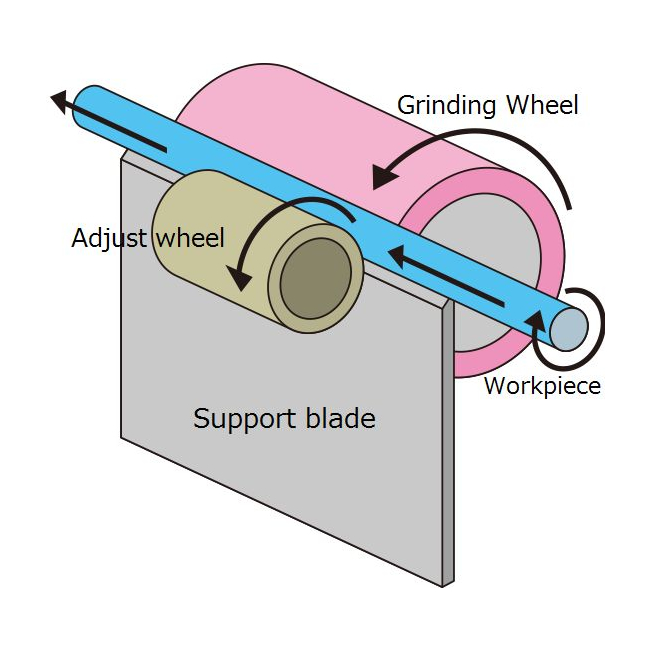

Centreless Grinding Vs Cylindrical Grinding . The fundamental difference between these two ways of grinding cylindrical shapes is how the workpiece is held. In cylindrical grinding it’s held on its axis of rotation, “between centers” while in centerless grinding it’s supported along its axial length. In the medium article, “difference between centerless grinder and cylindrical grinder,” the distinctions between centerless and cylindrical. Cylindrical grinding is usually done between centers by means of one grinding wheel. The core difference lies in how each process handles the workpiece during the grinding operation. A centerless incorporates the use of two wheels, the regulating wheel, and the grinding wheel. A centerless grinding machine usually comprises a grinding wheel, work blade, machine base, and regulating wheel. Grinding parts, whether cylindrical or prismatic in shape, creates superior surface finishes and extreme accuracy in features of size. Centerless grinding means, the cylindrical workpiece (to be ground) need not have centers drilled on its face. Comparing centerless and cylindrical grinding. Centerless grinding is a subtractive process that uses an abrasive wheel to cut material from a workpiece’s external diameter to achieve desired properties. While there are many grinding methods.

from www.allied-material.co.jp

Comparing centerless and cylindrical grinding. A centerless incorporates the use of two wheels, the regulating wheel, and the grinding wheel. The fundamental difference between these two ways of grinding cylindrical shapes is how the workpiece is held. In the medium article, “difference between centerless grinder and cylindrical grinder,” the distinctions between centerless and cylindrical. In cylindrical grinding it’s held on its axis of rotation, “between centers” while in centerless grinding it’s supported along its axial length. Cylindrical grinding is usually done between centers by means of one grinding wheel. Centerless grinding is a subtractive process that uses an abrasive wheel to cut material from a workpiece’s external diameter to achieve desired properties. Centerless grinding means, the cylindrical workpiece (to be ground) need not have centers drilled on its face. Grinding parts, whether cylindrical or prismatic in shape, creates superior surface finishes and extreme accuracy in features of size. A centerless grinding machine usually comprises a grinding wheel, work blade, machine base, and regulating wheel.

Various grinding methods|A.L.M.T. Corp.

Centreless Grinding Vs Cylindrical Grinding Cylindrical grinding is usually done between centers by means of one grinding wheel. Cylindrical grinding is usually done between centers by means of one grinding wheel. Centerless grinding means, the cylindrical workpiece (to be ground) need not have centers drilled on its face. The core difference lies in how each process handles the workpiece during the grinding operation. Grinding parts, whether cylindrical or prismatic in shape, creates superior surface finishes and extreme accuracy in features of size. A centerless incorporates the use of two wheels, the regulating wheel, and the grinding wheel. A centerless grinding machine usually comprises a grinding wheel, work blade, machine base, and regulating wheel. In cylindrical grinding it’s held on its axis of rotation, “between centers” while in centerless grinding it’s supported along its axial length. While there are many grinding methods. The fundamental difference between these two ways of grinding cylindrical shapes is how the workpiece is held. In the medium article, “difference between centerless grinder and cylindrical grinder,” the distinctions between centerless and cylindrical. Comparing centerless and cylindrical grinding. Centerless grinding is a subtractive process that uses an abrasive wheel to cut material from a workpiece’s external diameter to achieve desired properties.

From www.aaa-metals.com

Centerless Grinding Services AAA Metals Company Inc Centreless Grinding Vs Cylindrical Grinding The core difference lies in how each process handles the workpiece during the grinding operation. In cylindrical grinding it’s held on its axis of rotation, “between centers” while in centerless grinding it’s supported along its axial length. Centerless grinding means, the cylindrical workpiece (to be ground) need not have centers drilled on its face. A centerless grinding machine usually comprises. Centreless Grinding Vs Cylindrical Grinding.

From www.improprecision.com

What are the differences between centerless grinding and external grinding Centreless Grinding Vs Cylindrical Grinding Centerless grinding means, the cylindrical workpiece (to be ground) need not have centers drilled on its face. The fundamental difference between these two ways of grinding cylindrical shapes is how the workpiece is held. A centerless grinding machine usually comprises a grinding wheel, work blade, machine base, and regulating wheel. Grinding parts, whether cylindrical or prismatic in shape, creates superior. Centreless Grinding Vs Cylindrical Grinding.

From www.difference.minaprem.com

Difference Between Machining and Grinding Centreless Grinding Vs Cylindrical Grinding Comparing centerless and cylindrical grinding. The core difference lies in how each process handles the workpiece during the grinding operation. Cylindrical grinding is usually done between centers by means of one grinding wheel. In the medium article, “difference between centerless grinder and cylindrical grinder,” the distinctions between centerless and cylindrical. A centerless incorporates the use of two wheels, the regulating. Centreless Grinding Vs Cylindrical Grinding.

From www.youtube.com

Centreless Grinding Process YouTube Centreless Grinding Vs Cylindrical Grinding Centerless grinding is a subtractive process that uses an abrasive wheel to cut material from a workpiece’s external diameter to achieve desired properties. Comparing centerless and cylindrical grinding. A centerless grinding machine usually comprises a grinding wheel, work blade, machine base, and regulating wheel. Grinding parts, whether cylindrical or prismatic in shape, creates superior surface finishes and extreme accuracy in. Centreless Grinding Vs Cylindrical Grinding.

From www.google.com

Patent US20110306273 Centerless cylindrical grinding machine and Centreless Grinding Vs Cylindrical Grinding The core difference lies in how each process handles the workpiece during the grinding operation. The fundamental difference between these two ways of grinding cylindrical shapes is how the workpiece is held. Centerless grinding means, the cylindrical workpiece (to be ground) need not have centers drilled on its face. Grinding parts, whether cylindrical or prismatic in shape, creates superior surface. Centreless Grinding Vs Cylindrical Grinding.

From www.youtube.com

Cylindrical Grinding Process YouTube Centreless Grinding Vs Cylindrical Grinding A centerless grinding machine usually comprises a grinding wheel, work blade, machine base, and regulating wheel. In the medium article, “difference between centerless grinder and cylindrical grinder,” the distinctions between centerless and cylindrical. While there are many grinding methods. Centerless grinding is a subtractive process that uses an abrasive wheel to cut material from a workpiece’s external diameter to achieve. Centreless Grinding Vs Cylindrical Grinding.

From www.atdprecision.com

Centerless vs. Cylindrical Grinding Precision Grinding Applications Centreless Grinding Vs Cylindrical Grinding A centerless grinding machine usually comprises a grinding wheel, work blade, machine base, and regulating wheel. Grinding parts, whether cylindrical or prismatic in shape, creates superior surface finishes and extreme accuracy in features of size. In the medium article, “difference between centerless grinder and cylindrical grinder,” the distinctions between centerless and cylindrical. The core difference lies in how each process. Centreless Grinding Vs Cylindrical Grinding.

From www.youtube.com

Centerless Grinding Machine Magnaghi RSC350 YouTube Centreless Grinding Vs Cylindrical Grinding A centerless grinding machine usually comprises a grinding wheel, work blade, machine base, and regulating wheel. Centerless grinding means, the cylindrical workpiece (to be ground) need not have centers drilled on its face. A centerless incorporates the use of two wheels, the regulating wheel, and the grinding wheel. While there are many grinding methods. In the medium article, “difference between. Centreless Grinding Vs Cylindrical Grinding.

From nearsay.com

A Guide to Centerless Grinding R. A. Heller Co. Woodlawn NearSay Centreless Grinding Vs Cylindrical Grinding While there are many grinding methods. A centerless grinding machine usually comprises a grinding wheel, work blade, machine base, and regulating wheel. In cylindrical grinding it’s held on its axis of rotation, “between centers” while in centerless grinding it’s supported along its axial length. Comparing centerless and cylindrical grinding. Grinding parts, whether cylindrical or prismatic in shape, creates superior surface. Centreless Grinding Vs Cylindrical Grinding.

From www.vlr.eng.br

Cylindrical Grinding Diagram vlr.eng.br Centreless Grinding Vs Cylindrical Grinding The core difference lies in how each process handles the workpiece during the grinding operation. A centerless grinding machine usually comprises a grinding wheel, work blade, machine base, and regulating wheel. In cylindrical grinding it’s held on its axis of rotation, “between centers” while in centerless grinding it’s supported along its axial length. In the medium article, “difference between centerless. Centreless Grinding Vs Cylindrical Grinding.

From finemetalworking.com

What is Centerless Grinding? How Does the Machine Work? Centreless Grinding Vs Cylindrical Grinding Grinding parts, whether cylindrical or prismatic in shape, creates superior surface finishes and extreme accuracy in features of size. Centerless grinding is a subtractive process that uses an abrasive wheel to cut material from a workpiece’s external diameter to achieve desired properties. In cylindrical grinding it’s held on its axis of rotation, “between centers” while in centerless grinding it’s supported. Centreless Grinding Vs Cylindrical Grinding.

From www.atdprecision.com

Centerless vs. Cylindrical Grinding Precision Grinding Applications Centreless Grinding Vs Cylindrical Grinding The fundamental difference between these two ways of grinding cylindrical shapes is how the workpiece is held. The core difference lies in how each process handles the workpiece during the grinding operation. Comparing centerless and cylindrical grinding. Centerless grinding means, the cylindrical workpiece (to be ground) need not have centers drilled on its face. Cylindrical grinding is usually done between. Centreless Grinding Vs Cylindrical Grinding.

From www.fortemetals.com

What is Centerless Grinding? Centreless Grinding Vs Cylindrical Grinding A centerless grinding machine usually comprises a grinding wheel, work blade, machine base, and regulating wheel. Centerless grinding means, the cylindrical workpiece (to be ground) need not have centers drilled on its face. Grinding parts, whether cylindrical or prismatic in shape, creates superior surface finishes and extreme accuracy in features of size. The core difference lies in how each process. Centreless Grinding Vs Cylindrical Grinding.

From loehahwyo.blob.core.windows.net

Centreless Grinding Tolerances at Oralia Edwards blog Centreless Grinding Vs Cylindrical Grinding A centerless incorporates the use of two wheels, the regulating wheel, and the grinding wheel. The fundamental difference between these two ways of grinding cylindrical shapes is how the workpiece is held. The core difference lies in how each process handles the workpiece during the grinding operation. A centerless grinding machine usually comprises a grinding wheel, work blade, machine base,. Centreless Grinding Vs Cylindrical Grinding.

From www.mech4study.com

What is Centerless Grinding? What are difference between Centered and Centreless Grinding Vs Cylindrical Grinding A centerless grinding machine usually comprises a grinding wheel, work blade, machine base, and regulating wheel. In the medium article, “difference between centerless grinder and cylindrical grinder,” the distinctions between centerless and cylindrical. Centerless grinding is a subtractive process that uses an abrasive wheel to cut material from a workpiece’s external diameter to achieve desired properties. The core difference lies. Centreless Grinding Vs Cylindrical Grinding.

From finemetalworking.com

Cylindrical Grinding Fine MetalWorking Centreless Grinding Vs Cylindrical Grinding In the medium article, “difference between centerless grinder and cylindrical grinder,” the distinctions between centerless and cylindrical. Centerless grinding means, the cylindrical workpiece (to be ground) need not have centers drilled on its face. Grinding parts, whether cylindrical or prismatic in shape, creates superior surface finishes and extreme accuracy in features of size. A centerless grinding machine usually comprises a. Centreless Grinding Vs Cylindrical Grinding.

From finemetalworking.com

What is Centerless Grinding? How Does the Machine Work? Centreless Grinding Vs Cylindrical Grinding Grinding parts, whether cylindrical or prismatic in shape, creates superior surface finishes and extreme accuracy in features of size. A centerless incorporates the use of two wheels, the regulating wheel, and the grinding wheel. Comparing centerless and cylindrical grinding. In the medium article, “difference between centerless grinder and cylindrical grinder,” the distinctions between centerless and cylindrical. The core difference lies. Centreless Grinding Vs Cylindrical Grinding.

From finemetalworking.com

What is Centerless Grinding? How Does the Machine Work? Centreless Grinding Vs Cylindrical Grinding Grinding parts, whether cylindrical or prismatic in shape, creates superior surface finishes and extreme accuracy in features of size. In the medium article, “difference between centerless grinder and cylindrical grinder,” the distinctions between centerless and cylindrical. Cylindrical grinding is usually done between centers by means of one grinding wheel. Comparing centerless and cylindrical grinding. The fundamental difference between these two. Centreless Grinding Vs Cylindrical Grinding.

From www.slideshare.net

Guide to Centerless External Cylindrical Grinding quick introductio… Centreless Grinding Vs Cylindrical Grinding Centerless grinding means, the cylindrical workpiece (to be ground) need not have centers drilled on its face. Cylindrical grinding is usually done between centers by means of one grinding wheel. A centerless incorporates the use of two wheels, the regulating wheel, and the grinding wheel. Centerless grinding is a subtractive process that uses an abrasive wheel to cut material from. Centreless Grinding Vs Cylindrical Grinding.

From emcprecision.com

The 3 Types of Centerless Grinding EMC Precision Centreless Grinding Vs Cylindrical Grinding In the medium article, “difference between centerless grinder and cylindrical grinder,” the distinctions between centerless and cylindrical. Centerless grinding is a subtractive process that uses an abrasive wheel to cut material from a workpiece’s external diameter to achieve desired properties. The fundamental difference between these two ways of grinding cylindrical shapes is how the workpiece is held. While there are. Centreless Grinding Vs Cylindrical Grinding.

From www.slideshare.net

Guide to Centerless External Cylindrical Grinding quick introductio… Centreless Grinding Vs Cylindrical Grinding Cylindrical grinding is usually done between centers by means of one grinding wheel. Centerless grinding is a subtractive process that uses an abrasive wheel to cut material from a workpiece’s external diameter to achieve desired properties. In cylindrical grinding it’s held on its axis of rotation, “between centers” while in centerless grinding it’s supported along its axial length. The core. Centreless Grinding Vs Cylindrical Grinding.

From www.linkedin.com

What is Cylindrical grinding? Centreless Grinding Vs Cylindrical Grinding Comparing centerless and cylindrical grinding. In cylindrical grinding it’s held on its axis of rotation, “between centers” while in centerless grinding it’s supported along its axial length. A centerless grinding machine usually comprises a grinding wheel, work blade, machine base, and regulating wheel. Centerless grinding is a subtractive process that uses an abrasive wheel to cut material from a workpiece’s. Centreless Grinding Vs Cylindrical Grinding.

From aztecplastic.com

Centerless & Cylindrical Grinding Capabilities Centreless Grinding Vs Cylindrical Grinding Centerless grinding is a subtractive process that uses an abrasive wheel to cut material from a workpiece’s external diameter to achieve desired properties. Comparing centerless and cylindrical grinding. In the medium article, “difference between centerless grinder and cylindrical grinder,” the distinctions between centerless and cylindrical. A centerless incorporates the use of two wheels, the regulating wheel, and the grinding wheel.. Centreless Grinding Vs Cylindrical Grinding.

From www.westmidlandgrinding.co.uk

Centreless Grinding Process West Midland Grinding Centreless Grinding Vs Cylindrical Grinding In cylindrical grinding it’s held on its axis of rotation, “between centers” while in centerless grinding it’s supported along its axial length. The fundamental difference between these two ways of grinding cylindrical shapes is how the workpiece is held. Comparing centerless and cylindrical grinding. A centerless incorporates the use of two wheels, the regulating wheel, and the grinding wheel. While. Centreless Grinding Vs Cylindrical Grinding.

From www.allied-material.co.jp

Various grinding methods|A.L.M.T. Corp. Centreless Grinding Vs Cylindrical Grinding The fundamental difference between these two ways of grinding cylindrical shapes is how the workpiece is held. The core difference lies in how each process handles the workpiece during the grinding operation. Cylindrical grinding is usually done between centers by means of one grinding wheel. In the medium article, “difference between centerless grinder and cylindrical grinder,” the distinctions between centerless. Centreless Grinding Vs Cylindrical Grinding.

From engineeringlearn.com

Cylindrical Grinding Machine Types, Process & Working Principle Centreless Grinding Vs Cylindrical Grinding In the medium article, “difference between centerless grinder and cylindrical grinder,” the distinctions between centerless and cylindrical. Grinding parts, whether cylindrical or prismatic in shape, creates superior surface finishes and extreme accuracy in features of size. While there are many grinding methods. Comparing centerless and cylindrical grinding. Centerless grinding means, the cylindrical workpiece (to be ground) need not have centers. Centreless Grinding Vs Cylindrical Grinding.

From cool-grind.com

Cylindrical and Centerless OD Grinding Nozzle Systems CoolGrind Centreless Grinding Vs Cylindrical Grinding Centerless grinding is a subtractive process that uses an abrasive wheel to cut material from a workpiece’s external diameter to achieve desired properties. A centerless grinding machine usually comprises a grinding wheel, work blade, machine base, and regulating wheel. Centerless grinding means, the cylindrical workpiece (to be ground) need not have centers drilled on its face. Cylindrical grinding is usually. Centreless Grinding Vs Cylindrical Grinding.

From www.atdprecision.com

Centerless vs. Cylindrical Grinding Precision Grinding Applications Centreless Grinding Vs Cylindrical Grinding A centerless incorporates the use of two wheels, the regulating wheel, and the grinding wheel. The core difference lies in how each process handles the workpiece during the grinding operation. Centerless grinding means, the cylindrical workpiece (to be ground) need not have centers drilled on its face. In the medium article, “difference between centerless grinder and cylindrical grinder,” the distinctions. Centreless Grinding Vs Cylindrical Grinding.

From emcprecision.com

Centerless Grinding Capabilities Overview EMC Precision Centreless Grinding Vs Cylindrical Grinding Centerless grinding is a subtractive process that uses an abrasive wheel to cut material from a workpiece’s external diameter to achieve desired properties. Comparing centerless and cylindrical grinding. A centerless incorporates the use of two wheels, the regulating wheel, and the grinding wheel. While there are many grinding methods. In the medium article, “difference between centerless grinder and cylindrical grinder,”. Centreless Grinding Vs Cylindrical Grinding.

From www.slideshare.net

Guide to Centerless External Cylindrical Grinding quick introductio… Centreless Grinding Vs Cylindrical Grinding Grinding parts, whether cylindrical or prismatic in shape, creates superior surface finishes and extreme accuracy in features of size. Comparing centerless and cylindrical grinding. In cylindrical grinding it’s held on its axis of rotation, “between centers” while in centerless grinding it’s supported along its axial length. Centerless grinding is a subtractive process that uses an abrasive wheel to cut material. Centreless Grinding Vs Cylindrical Grinding.

From wisconsinmetaltech.com

What is Centerless Grinding? The complete guide to the process Centreless Grinding Vs Cylindrical Grinding A centerless incorporates the use of two wheels, the regulating wheel, and the grinding wheel. Grinding parts, whether cylindrical or prismatic in shape, creates superior surface finishes and extreme accuracy in features of size. Centerless grinding is a subtractive process that uses an abrasive wheel to cut material from a workpiece’s external diameter to achieve desired properties. Cylindrical grinding is. Centreless Grinding Vs Cylindrical Grinding.

From blog.indianaprecisiongrinding.com

Everything You Wanted to Know About Centerless Grinding Centreless Grinding Vs Cylindrical Grinding A centerless grinding machine usually comprises a grinding wheel, work blade, machine base, and regulating wheel. Comparing centerless and cylindrical grinding. Centerless grinding is a subtractive process that uses an abrasive wheel to cut material from a workpiece’s external diameter to achieve desired properties. Cylindrical grinding is usually done between centers by means of one grinding wheel. While there are. Centreless Grinding Vs Cylindrical Grinding.

From www.youtube.com

DIFFERENCE BETWEEN CYLINDRICAL GRINDING AND CENTRELESS GRINDING YouTube Centreless Grinding Vs Cylindrical Grinding A centerless grinding machine usually comprises a grinding wheel, work blade, machine base, and regulating wheel. A centerless incorporates the use of two wheels, the regulating wheel, and the grinding wheel. While there are many grinding methods. In cylindrical grinding it’s held on its axis of rotation, “between centers” while in centerless grinding it’s supported along its axial length. Centerless. Centreless Grinding Vs Cylindrical Grinding.

From learnmech.com

Types of Cylindrical grinding machine with Diagram Explained Centreless Grinding Vs Cylindrical Grinding Cylindrical grinding is usually done between centers by means of one grinding wheel. The fundamental difference between these two ways of grinding cylindrical shapes is how the workpiece is held. A centerless incorporates the use of two wheels, the regulating wheel, and the grinding wheel. In cylindrical grinding it’s held on its axis of rotation, “between centers” while in centerless. Centreless Grinding Vs Cylindrical Grinding.

From finemetalworking.com

What is Centerless Grinding? How Does the Machine Work? Centreless Grinding Vs Cylindrical Grinding In the medium article, “difference between centerless grinder and cylindrical grinder,” the distinctions between centerless and cylindrical. The core difference lies in how each process handles the workpiece during the grinding operation. A centerless grinding machine usually comprises a grinding wheel, work blade, machine base, and regulating wheel. While there are many grinding methods. A centerless incorporates the use of. Centreless Grinding Vs Cylindrical Grinding.