Rockwell Hardness Number For Brass . Our conversion chart will provide you with precise correlations, enabling you to make informed decisions based on your specific. Cartridge brass contains about 30% zinc by. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection and process optimization. Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Our hardness conversion table facilitates the seamless transition between brinell hardness and rockwell hardness scales, and vice versa.

from atrona.com

Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) Our hardness conversion table facilitates the seamless transition between brinell hardness and rockwell hardness scales, and vice versa. Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. Cartridge brass contains about 30% zinc by. Our conversion chart will provide you with precise correlations, enabling you to make informed decisions based on your specific. The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection and process optimization.

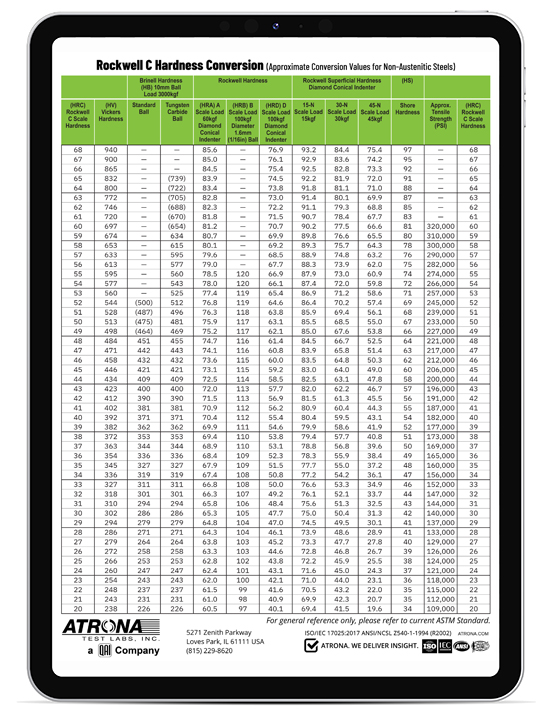

Rockwell C Hardness Conversion Chart PDF ATRONA Test Labs Loves

Rockwell Hardness Number For Brass Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) Our hardness conversion table facilitates the seamless transition between brinell hardness and rockwell hardness scales, and vice versa. Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection and process optimization. Our conversion chart will provide you with precise correlations, enabling you to make informed decisions based on your specific. The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Cartridge brass contains about 30% zinc by. Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several.

From dokumen.tips

(PDF) 004 Approximate Hardness Conversion Numbers for · PDF file004 Rockwell Hardness Number For Brass Cartridge brass contains about 30% zinc by. Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of. Rockwell Hardness Number For Brass.

From mavink.com

Rockwell Hardness Scale Conversion Chart Rockwell Hardness Number For Brass Our conversion chart will provide you with precise correlations, enabling you to make informed decisions based on your specific. The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is. Rockwell Hardness Number For Brass.

From www.admiralsteel.com

Hardness Conversion Tables Rockwell Hardness Number For Brass The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection and process optimization. Our hardness conversion table facilitates the seamless transition between brinell hardness. Rockwell Hardness Number For Brass.

From einvoice.fpt.com.vn

The Rockwell Metal Hardness Scales Explained, 54 OFF Rockwell Hardness Number For Brass Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection and process optimization. Cartridge brass contains about 30% zinc by. Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) Our conversion chart will provide you with precise correlations, enabling you to make informed. Rockwell Hardness Number For Brass.

From exyizwuie.blob.core.windows.net

Convert Psi To Rockwell Hardness at James Pitt blog Rockwell Hardness Number For Brass The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. Cartridge brass contains about 30%. Rockwell Hardness Number For Brass.

From www.yorksaw.com

Rockwell Hardness Guide What it is, How to Measure, & More Rockwell Hardness Number For Brass Our conversion chart will provide you with precise correlations, enabling you to make informed decisions based on your specific. The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Our hardness conversion table facilitates the seamless transition between brinell hardness and rockwell hardness scales, and vice versa. Hrb. Rockwell Hardness Number For Brass.

From www.cnccookbook.com

Hardness Conversion Chart, Calculator & Tests for Rockwell, Brinell Rockwell Hardness Number For Brass Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) Our hardness conversion table facilitates the seamless transition between brinell hardness and rockwell hardness scales, and vice versa. Cartridge brass contains about 30% zinc by. The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Understanding. Rockwell Hardness Number For Brass.

From klanpaxiq.blob.core.windows.net

Rockwell Hardness Scale Conversion at Maryann Lucas blog Rockwell Hardness Number For Brass Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection and process optimization. Cartridge brass contains about 30% zinc by. Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns. Rockwell Hardness Number For Brass.

From printablemathias.z13.web.core.windows.net

Rockwell Hardness Chart Pdf Rockwell Hardness Number For Brass The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Our conversion chart will provide you with precise correlations, enabling you to make informed decisions based on your specific. Our hardness conversion table facilitates the seamless transition between brinell hardness and rockwell hardness scales, and vice versa. Cartridge. Rockwell Hardness Number For Brass.

From chart.conaresvirtual.edu.sv

Rockwell Conversion Chart Rockwell Hardness Number For Brass Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. Cartridge brass contains about 30% zinc by. Our hardness conversion table facilitates the seamless transition between brinell hardness and rockwell hardness scales, and vice versa. Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) Our conversion. Rockwell Hardness Number For Brass.

From www.hardnessgauge.com

What is the Rockwell Scale? Hardness Tester Rockwell Hardness Number For Brass Our conversion chart will provide you with precise correlations, enabling you to make informed decisions based on your specific. Cartridge brass contains about 30% zinc by. Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and. Rockwell Hardness Number For Brass.

From www.yorksaw.com

Rockwell Hardness Guide What it is, How to Measure, & More Rockwell Hardness Number For Brass Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection and process optimization. The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Our hardness conversion table facilitates the seamless transition between brinell hardness. Rockwell Hardness Number For Brass.

From www.scribd.com

Brinell Hardness Conversion Chart Rockwell Hardness Number For Brass Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Our conversion chart will provide you with precise correlations, enabling you to make informed decisions based on. Rockwell Hardness Number For Brass.

From www.tec-science.com

Rockwell hardness test tecscience Rockwell Hardness Number For Brass Cartridge brass contains about 30% zinc by. Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) Our conversion chart will provide you with precise correlations, enabling you to make informed decisions based on your specific. Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. Understanding. Rockwell Hardness Number For Brass.

From classhirsch.z21.web.core.windows.net

Steel Rockwell Hardness Chart For Metals Rockwell Hardness Number For Brass Our conversion chart will provide you with precise correlations, enabling you to make informed decisions based on your specific. Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. Cartridge brass contains about 30% zinc by. The. Rockwell Hardness Number For Brass.

From dxolfthyd.blob.core.windows.net

Rockwell Hardness Scale Metals at Michael Oyler blog Rockwell Hardness Number For Brass Cartridge brass contains about 30% zinc by. Our hardness conversion table facilitates the seamless transition between brinell hardness and rockwell hardness scales, and vice versa. Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) Understanding the. Rockwell Hardness Number For Brass.

From klanpaxiq.blob.core.windows.net

Rockwell Hardness Scale Conversion at Maryann Lucas blog Rockwell Hardness Number For Brass Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) Our hardness conversion table facilitates the seamless transition between brinell hardness and rockwell hardness scales, and vice versa. The rockwell hardness number (b) for brass lies in. Rockwell Hardness Number For Brass.

From atrona.com

Rockwell C Hardness Conversion Chart PDF ATRONA Test Labs Loves Rockwell Hardness Number For Brass The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Our conversion chart will provide you with precise correlations, enabling you to make informed decisions based on your specific. Cartridge brass contains about 30% zinc by. Our hardness conversion table facilitates the seamless transition between brinell hardness and. Rockwell Hardness Number For Brass.

From www.alamy.com

. The Bell System technical journal . I® 40,000 50,000 60,000 70,000 Rockwell Hardness Number For Brass Our hardness conversion table facilitates the seamless transition between brinell hardness and rockwell hardness scales, and vice versa. Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for. Rockwell Hardness Number For Brass.

From colorscale.z28.web.core.windows.net

hardness scale metal hardness chart Rockwell hardness chart Rockwell Hardness Number For Brass The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. Our conversion chart will provide you with precise correlations, enabling you to make informed decisions based on. Rockwell Hardness Number For Brass.

From www.researchgate.net

Pre and post Rockwell hardness number for Group A. Download Table Rockwell Hardness Number For Brass Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. Cartridge brass contains about 30% zinc by. Our hardness conversion table facilitates the seamless transition between brinell hardness and rockwell hardness scales, and vice versa. Our conversion chart will provide you with precise correlations, enabling you to make informed. Rockwell Hardness Number For Brass.

From www.researchgate.net

Rockwell Hardness Number of Chopped Download Scientific Diagram Rockwell Hardness Number For Brass The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Our hardness conversion table facilitates the seamless transition between brinell hardness and rockwell hardness scales, and vice versa. Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) Cartridge brass contains about 30% zinc by. Understanding. Rockwell Hardness Number For Brass.

From chordcharts.z28.web.core.windows.net

rockwell hardness scales chart Hardness rockwell scale material scales Rockwell Hardness Number For Brass Cartridge brass contains about 30% zinc by. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection and process optimization. Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. Approximate hardness conversion no.s for. Rockwell Hardness Number For Brass.

From www.brystartools.com

Hardness Conversion Chart Rockwell "C" Hardness Range Rockwell Hardness Number For Brass Cartridge brass contains about 30% zinc by. Our conversion chart will provide you with precise correlations, enabling you to make informed decisions based on your specific. The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge. Rockwell Hardness Number For Brass.

From excelchart.z28.web.core.windows.net

mineral hardness scale chart Mohs scale of mineral hardness geologyhere Rockwell Hardness Number For Brass Cartridge brass contains about 30% zinc by. The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. Understanding the relationship between hardness scales (such as brinell, rockwell,. Rockwell Hardness Number For Brass.

From brokeasshome.com

rockwell hardness table metals Rockwell Hardness Number For Brass Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) Cartridge brass contains about 30% zinc by. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection and process optimization. The rockwell hardness number (b) for brass lies in the range of 55 to. Rockwell Hardness Number For Brass.

From mungfali.com

Rockwell Hardness Scale Chart Rockwell Hardness Number For Brass Our hardness conversion table facilitates the seamless transition between brinell hardness and rockwell hardness scales, and vice versa. Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) Our conversion chart will provide you with precise correlations, enabling you to make informed decisions based on your specific. Cartridge brass contains about 30% zinc by. The rockwell hardness number. Rockwell Hardness Number For Brass.

From brokeasshome.com

Rockwell Hardness Table Conversion Rockwell Hardness Number For Brass Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. Our conversion chart will provide you with precise correlations, enabling you to make informed decisions based on your specific. Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) Cartridge brass contains about 30% zinc by. The. Rockwell Hardness Number For Brass.

From brokeasshome.com

Rockwell Hardness Table Conversion Rockwell Hardness Number For Brass Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection and process optimization.. Rockwell Hardness Number For Brass.

From www.researchgate.net

Scale "A" Rockwell hardness values for both alloys after different Rockwell Hardness Number For Brass Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. Our conversion chart will provide you with precise correlations, enabling you to make informed decisions based on your specific. The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of. Rockwell Hardness Number For Brass.

From mavink.com

Rockwell Hardness Scale Metals Chart Rockwell Hardness Number For Brass Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns c26000 (260 brass), h10 temper) [24] several. The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Our hardness conversion table facilitates the seamless transition between brinell hardness and rockwell hardness scales, and vice. Rockwell Hardness Number For Brass.

From www.brystartools.com

Hardness Conversion Chart Rockwell "B" Hardness Range Rockwell Hardness Number For Brass Our conversion chart will provide you with precise correlations, enabling you to make informed decisions based on your specific. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection and process optimization. Hrb 55 (low brass, uns c24000, h01 temper) to hrb 93 (cartridge brass, uns. Rockwell Hardness Number For Brass.

From exovuvasf.blob.core.windows.net

Rockwell Hardness Test Calculation at Sung Lawson blog Rockwell Hardness Number For Brass Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection and process optimization. Cartridge brass contains about 30% zinc by. The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Our conversion chart will. Rockwell Hardness Number For Brass.

From chordcharts.z28.web.core.windows.net

rockwell b and c scale chart Hardness scale rockwell vs vickers at Rockwell Hardness Number For Brass Cartridge brass contains about 30% zinc by. Our conversion chart will provide you with precise correlations, enabling you to make informed decisions based on your specific. The rockwell hardness number (b) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers). Rockwell Hardness Number For Brass.

From www.scribd.com

Hardness Conversion Table Approximate Equivalents of Rockwell B Rockwell Hardness Number For Brass Approximate hardness conversion no.s for cartridge brass (70&perc cu 30% zn alloy) Our hardness conversion table facilitates the seamless transition between brinell hardness and rockwell hardness scales, and vice versa. Understanding the relationship between hardness scales (such as brinell, rockwell, and vickers) and tensile strength for these alloys is essential for accurate material selection and process optimization. Our conversion chart. Rockwell Hardness Number For Brass.