Crankshaft Hardening Process . Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. There are similarities in the. This article will explain how. This article will explain how continuous. This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Nearly simutlaneously t, occo (usa) and russia developed commercial processes.

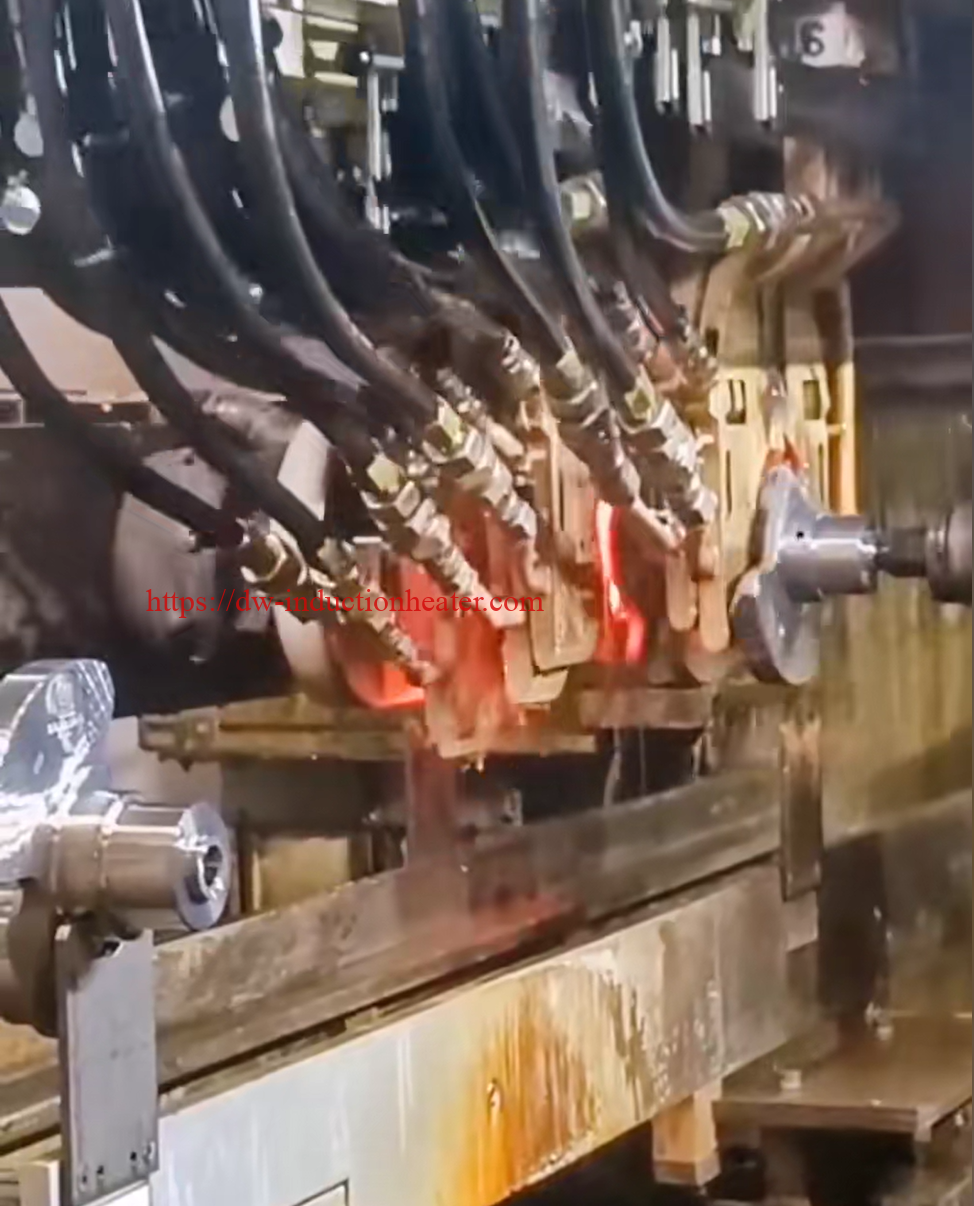

from dw-inductionheater.com

This article will explain how. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. There are similarities in the. This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. Nearly simutlaneously t, occo (usa) and russia developed commercial processes. This article will explain how continuous. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts.

Induction Hardening of Crankshafts Machine for Engine Crankshaft

Crankshaft Hardening Process Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. This article will explain how. There are similarities in the. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Nearly simutlaneously t, occo (usa) and russia developed commercial processes. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. This article will explain how continuous. This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general.

From dw-inductionheater.com

Induction Hardening of Crankshafts Machine for Engine Crankshaft Crankshaft Hardening Process Nearly simutlaneously t, occo (usa) and russia developed commercial processes. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. This article will explain how. This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. Induction heat treatment is traditionally a popular choice for hardening and tempering. Crankshaft Hardening Process.

From inductionheattreatment.com

Crankshaft Induction Hardening Machine The Leading Induction Heating Crankshaft Hardening Process Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. This article will explain how. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. There are similarities in the.. Crankshaft Hardening Process.

From www.youtube.com

Crankshaft Hardening The Crankshaft Heat Treatment Process YouTube Crankshaft Hardening Process This article will explain how. This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. There are similarities in the. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening.. Crankshaft Hardening Process.

From www.youtube.com

Crankshaft Induction Hardening YouTube Crankshaft Hardening Process This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. Nearly simutlaneously t, occo (usa) and russia developed commercial processes. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. There are similarities in the. Induction heat treatment is traditionally a popular choice for hardening. Crankshaft Hardening Process.

From dw-inductionheater.com

Induction Hardening of Crankshafts Machine for Engine Crankshaft Crankshaft Hardening Process Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. This article will explain how continuous. There are similarities in the. Nearly simutlaneously t, occo (usa) and russia developed commercial processes. Induction heat treatment is traditionally a popular. Crankshaft Hardening Process.

From www.haertetechnik-folz.de

Induction hardening Crankshaft Hardening Process Nearly simutlaneously t, occo (usa) and russia developed commercial processes. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. This article will explain how. This article will explain how continuous. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. This article focuses on induction technologies used. Crankshaft Hardening Process.

From www.aliexpress.com

ExactCastingHardeningNitridingCrankshaftForToyota3LHigh Crankshaft Hardening Process This article will explain how continuous. This article will explain how. Nearly simutlaneously t, occo (usa) and russia developed commercial processes. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Shape and size distortion and total indicated runout (tir). Crankshaft Hardening Process.

From dw-inductionheater.com

Induction crankshaft hardening surface to increase the durability Crankshaft Hardening Process This article will explain how continuous. Nearly simutlaneously t, occo (usa) and russia developed commercial processes. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. This article will explain how. There are similarities in the. Induction heat. Crankshaft Hardening Process.

From www.youtube.com

crankshaft hardening by induction heating YouTube Crankshaft Hardening Process Nearly simutlaneously t, occo (usa) and russia developed commercial processes. There are similarities in the. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. This article will explain how. This article will explain how continuous. Induction heat. Crankshaft Hardening Process.

From www.youtube.com

Crankshaft Hardening The benefits of induction heating YouTube Crankshaft Hardening Process This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. There are similarities in the. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Nearly simutlaneously t, occo (usa) and russia developed commercial processes. Induction heat treatment is traditionally a popular choice for hardening and tempering. Crankshaft Hardening Process.

From dw-inductionheater.com

Induction crankshaft hardening surface to increase the durability Crankshaft Hardening Process This article will explain how. This article will explain how continuous. Nearly simutlaneously t, occo (usa) and russia developed commercial processes. There are similarities in the. This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Shape. Crankshaft Hardening Process.

From dw-inductionheater.com

Induction crankshaft hardening surface to increase the durability Crankshaft Hardening Process Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. There are similarities in the. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. Induction heat treatment is traditionally. Crankshaft Hardening Process.

From margariteo-moose.blogspot.com

Hardening Process Images / Laser Hardening For Metalworking Toolmaking Crankshaft Hardening Process There are similarities in the. Nearly simutlaneously t, occo (usa) and russia developed commercial processes. This article will explain how. This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Induction heat treatment is traditionally a popular. Crankshaft Hardening Process.

From dw-inductionheater.com

Induction crankshaft hardening surface to increase the durability Crankshaft Hardening Process There are similarities in the. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. Induction heat treatment is traditionally. Crankshaft Hardening Process.

From www.youtube.com

Induction hardening crankshaft hardening Engineering YouTube Crankshaft Hardening Process There are similarities in the. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Nearly simutlaneously t, occo (usa) and russia developed commercial processes. This article will explain how continuous. This article will explain how. This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. Induction. Crankshaft Hardening Process.

From dw-inductionheater.com

Induction crankshaft hardening surface to increase the durability Crankshaft Hardening Process This article will explain how. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Nearly simutlaneously t, occo (usa) and russia developed commercial processes. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Shape and size distortion and total indicated runout (tir) are very important parameters of the. Crankshaft Hardening Process.

From www.longwear-nitriding.co.uk

Overview of the nitride hardening process Crankshaft Hardening Process There are similarities in the. Nearly simutlaneously t, occo (usa) and russia developed commercial processes. This article will explain how. This article will explain how continuous. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. This article. Crankshaft Hardening Process.

From longwear-nitriding.co.uk

Overview of the nitride hardening process Crankshaft Hardening Process Nearly simutlaneously t, occo (usa) and russia developed commercial processes. This article will explain how continuous. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. There are similarities in the. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. This article focuses on induction technologies used. Crankshaft Hardening Process.

From www.engineeringinhindi.com

What is Hardening Heat Treatment Process why it is used, its Crankshaft Hardening Process Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. This article will explain how continuous. Induction heat treatment is. Crankshaft Hardening Process.

From dw-inductionheater.com

Induction crankshaft hardening surface to increase the durability Crankshaft Hardening Process This article will explain how. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. Nearly simutlaneously t, occo (usa). Crankshaft Hardening Process.

From dw-inductionheater.com

Induction crankshaft hardening surface to increase the durability Crankshaft Hardening Process This article will explain how. This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. This article will explain how continuous. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft. Crankshaft Hardening Process.

From decho-marine.com

Why Crankshaft Hardening is Essential for Engine Performance Decho Marine Crankshaft Hardening Process There are similarities in the. Nearly simutlaneously t, occo (usa) and russia developed commercial processes. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. Induction heat treatment is traditionally a popular choice for hardening and tempering of. Crankshaft Hardening Process.

From fluxtrol.com

Fluxtrol Optimizing Performance of Crankshaft Hardening Inductors Crankshaft Hardening Process Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. There are similarities in the. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. This article will explain how. This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general.. Crankshaft Hardening Process.

From dw-inductionheater.com

Induction Hardening of Crankshafts Machine for Engine Crankshaft Crankshaft Hardening Process This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Nearly simutlaneously t, occo (usa) and russia developed commercial processes. This article will explain how. Shape and size distortion and total indicated runout (tir) are very important. Crankshaft Hardening Process.

From www.scribd.com

Steel Crankshaft Hardening PDF Process Management Steel Crankshaft Hardening Process This article will explain how. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. Nearly simutlaneously t, occo (usa) and russia developed commercial processes. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. There are similarities in the. This article will explain how continuous. This article. Crankshaft Hardening Process.

From www.youtube.com

induction hardening of crankshaft YouTube Crankshaft Hardening Process There are similarities in the. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. This article will explain how continuous. This article will explain how. This article focuses on induction technologies used for surface hardening and tempering. Crankshaft Hardening Process.

From dw-inductionheater.com

Induction Hardening of Crankshafts Machine for Engine Crankshaft Crankshaft Hardening Process This article will explain how. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Nearly simutlaneously t, occo (usa) and russia developed commercial processes. There are similarities in the. This article focuses on induction technologies used for. Crankshaft Hardening Process.

From www.researchgate.net

(PDF) 3D simulation of induction hardening on truck crankshaft Crankshaft Hardening Process This article will explain how continuous. Nearly simutlaneously t, occo (usa) and russia developed commercial processes. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. There are similarities in the. This article will explain how. This article. Crankshaft Hardening Process.

From www.youtube.com

Crankshaft Induction Hardening Quenching Machine Shaft Heat Treatment Crankshaft Hardening Process This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. There are similarities in the. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. This article will explain how. This article will explain how continuous. Induction heat treatment is traditionally a popular choice for. Crankshaft Hardening Process.

From www.youtube.com

NSI Crankshaft Induction Hardening YouTube Crankshaft Hardening Process This article will explain how continuous. This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. There are similarities in the. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. This. Crankshaft Hardening Process.

From www.scantechlaser.com

Laser Surface Hardening of crankshaft Scantech Laser Crankshaft Hardening Process This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. There are similarities in the. This article will explain how continuous. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality. Crankshaft Hardening Process.

From gamma.app

Proses Induction Hardening Crankshaft Crankshaft Hardening Process Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. There are similarities in the. This article will explain how continuous. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. Nearly simutlaneously. Crankshaft Hardening Process.

From www.clubgti.com

Crankshaft types and differences Crankshaft Hardening Process Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. This article will explain how. This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. Nearly simutlaneously t, occo (usa) and russia developed commercial processes. Induction heat treatment is traditionally a popular choice for hardening. Crankshaft Hardening Process.

From www.ahtcorp.com

Induction Hardening Process AHT Crankshaft Hardening Process Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. This article focuses on induction technologies used for surface hardening and tempering of automotive crankshafts, and provides general. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. This article will explain how continuous. Nearly simutlaneously t, occo (usa) and. Crankshaft Hardening Process.

From www.cbsengineeringuk.co.uk

Induction Hardening CBS Engineering Crankshaft Hardening Process Shape and size distortion and total indicated runout (tir) are very important parameters of the crankshaft hardening. There are similarities in the. This article will explain how. Nearly simutlaneously t, occo (usa) and russia developed commercial processes. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. This article focuses on induction technologies used for. Crankshaft Hardening Process.