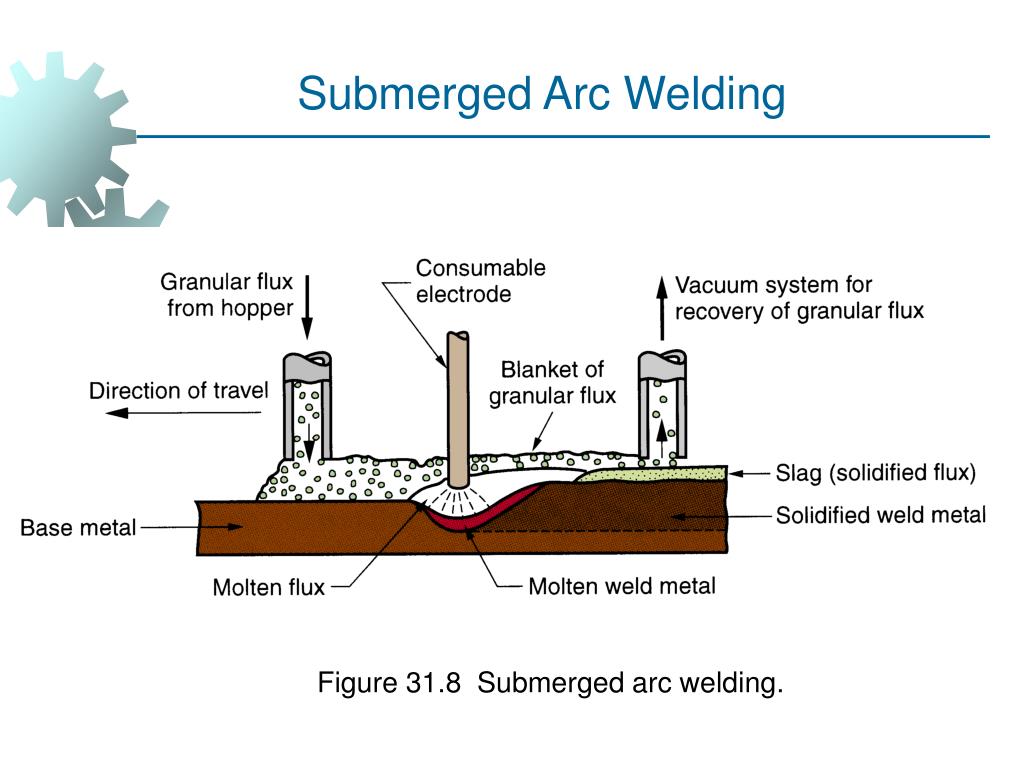

Submerged Arc Welding Inert Gas . It uses a special covering called flux to make sure the welding arc and the melted metal stay. A blanket of powdered flux. In submerged arc welding, it is a process in which continuously fed electrodes, and a blanket of fusible fluxes become conductive when melted and provide a current path between the part and the electrode. Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. Gas tungsten arc welding (gtaw) is an electric arc welding process that produces an arc between a nonconsumable electrode and the work to be welded. Welding processes are manual metal or shielded metal arc welding (mma or sma), metal inert gas arc (mig), tungsten inert gas (tig), submerged arc. Submerged arc welding (saw) is a fast and efficient method that produces deep and neat welds.

from www.slideserve.com

Welding processes are manual metal or shielded metal arc welding (mma or sma), metal inert gas arc (mig), tungsten inert gas (tig), submerged arc. A blanket of powdered flux. In submerged arc welding, it is a process in which continuously fed electrodes, and a blanket of fusible fluxes become conductive when melted and provide a current path between the part and the electrode. Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. It uses a special covering called flux to make sure the welding arc and the melted metal stay. Gas tungsten arc welding (gtaw) is an electric arc welding process that produces an arc between a nonconsumable electrode and the work to be welded. Submerged arc welding (saw) is a fast and efficient method that produces deep and neat welds.

PPT WELDING PROCESSES PowerPoint Presentation, free download ID4492187

Submerged Arc Welding Inert Gas In submerged arc welding, it is a process in which continuously fed electrodes, and a blanket of fusible fluxes become conductive when melted and provide a current path between the part and the electrode. Submerged arc welding (saw) is a fast and efficient method that produces deep and neat welds. In submerged arc welding, it is a process in which continuously fed electrodes, and a blanket of fusible fluxes become conductive when melted and provide a current path between the part and the electrode. A blanket of powdered flux. It uses a special covering called flux to make sure the welding arc and the melted metal stay. Gas tungsten arc welding (gtaw) is an electric arc welding process that produces an arc between a nonconsumable electrode and the work to be welded. Welding processes are manual metal or shielded metal arc welding (mma or sma), metal inert gas arc (mig), tungsten inert gas (tig), submerged arc. Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates.

From learnmechanical.com

Tungsten Inert Gas Welding Construction, Working Principle Submerged Arc Welding Inert Gas Gas tungsten arc welding (gtaw) is an electric arc welding process that produces an arc between a nonconsumable electrode and the work to be welded. A blanket of powdered flux. Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. It uses a special covering. Submerged Arc Welding Inert Gas.

From www.dreamstime.com

Metal Inert Gas (MIG) Welding Stock Image Image of steel, process Submerged Arc Welding Inert Gas Welding processes are manual metal or shielded metal arc welding (mma or sma), metal inert gas arc (mig), tungsten inert gas (tig), submerged arc. Gas tungsten arc welding (gtaw) is an electric arc welding process that produces an arc between a nonconsumable electrode and the work to be welded. Gas metal arc welding (gmaw) is one fusion welding process where. Submerged Arc Welding Inert Gas.

From blog.thepipingmart.com

How Does Metal Arc Welding Work And What Are Its Types? Submerged Arc Welding Inert Gas Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. Gas tungsten arc welding (gtaw) is an electric arc welding process that produces an arc between a nonconsumable electrode and the work to be welded. Welding processes are manual metal or shielded metal arc welding. Submerged Arc Welding Inert Gas.

From www.twi-global.com

Metal Inert Gas (MIG) Welding Process and Applications TWI Submerged Arc Welding Inert Gas It uses a special covering called flux to make sure the welding arc and the melted metal stay. Submerged arc welding (saw) is a fast and efficient method that produces deep and neat welds. Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. Welding. Submerged Arc Welding Inert Gas.

From www.kjellberg.de

Gasshielded metal arc welding Kjellberg Submerged Arc Welding Inert Gas Gas tungsten arc welding (gtaw) is an electric arc welding process that produces an arc between a nonconsumable electrode and the work to be welded. Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. Submerged arc welding (saw) is a fast and efficient method. Submerged Arc Welding Inert Gas.

From www.youtube.com

Differences between Tungsten Inert Gas (TIG) welding and Submerged Arc Submerged Arc Welding Inert Gas Submerged arc welding (saw) is a fast and efficient method that produces deep and neat welds. Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. Gas tungsten arc welding (gtaw) is an electric arc welding process that produces an arc between a nonconsumable electrode. Submerged Arc Welding Inert Gas.

From www.elprocus.com

Submerged Arc Welding (SAW) Working, Advantages, and Disadvantages Submerged Arc Welding Inert Gas Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. Gas tungsten arc welding (gtaw) is an electric arc welding process that produces an arc between a nonconsumable electrode and the work to be welded. A blanket of powdered flux. Submerged arc welding (saw) is. Submerged Arc Welding Inert Gas.

From www.canadianmetalworking.com

What About Submerged Arc Welding? Canadian Metalworking Submerged Arc Welding Inert Gas A blanket of powdered flux. Submerged arc welding (saw) is a fast and efficient method that produces deep and neat welds. In submerged arc welding, it is a process in which continuously fed electrodes, and a blanket of fusible fluxes become conductive when melted and provide a current path between the part and the electrode. Welding processes are manual metal. Submerged Arc Welding Inert Gas.

From www.pinterest.com

Tungsten Inert Gas (TIG) Welding process, Gas tungsten arc welding Submerged Arc Welding Inert Gas Submerged arc welding (saw) is a fast and efficient method that produces deep and neat welds. A blanket of powdered flux. Welding processes are manual metal or shielded metal arc welding (mma or sma), metal inert gas arc (mig), tungsten inert gas (tig), submerged arc. Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is. Submerged Arc Welding Inert Gas.

From www.canadianmetalworking.com

Submerged arc welding tech tips and fundamentals Submerged Arc Welding Inert Gas It uses a special covering called flux to make sure the welding arc and the melted metal stay. A blanket of powdered flux. Submerged arc welding (saw) is a fast and efficient method that produces deep and neat welds. Gas tungsten arc welding (gtaw) is an electric arc welding process that produces an arc between a nonconsumable electrode and the. Submerged Arc Welding Inert Gas.

From www.alamy.com

argon arc welding, Inert gas shielded arc welding in a Stock Submerged Arc Welding Inert Gas Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. It uses a special covering called flux to make sure the welding arc and the melted metal stay. Submerged arc welding (saw) is a fast and efficient method that produces deep and neat welds. Welding. Submerged Arc Welding Inert Gas.

From learnwithmayur.blogspot.com

What is Metal Inert Gas (MIG) Welding Process Introduction, Working Submerged Arc Welding Inert Gas A blanket of powdered flux. It uses a special covering called flux to make sure the welding arc and the melted metal stay. Welding processes are manual metal or shielded metal arc welding (mma or sma), metal inert gas arc (mig), tungsten inert gas (tig), submerged arc. Gas metal arc welding (gmaw) is one fusion welding process where the electric. Submerged Arc Welding Inert Gas.

From weldingmachinesbestbuy.blogspot.com

Submerged Arc Welding Machine Diagram Submerged Arc Welding Inert Gas It uses a special covering called flux to make sure the welding arc and the melted metal stay. Gas tungsten arc welding (gtaw) is an electric arc welding process that produces an arc between a nonconsumable electrode and the work to be welded. Submerged arc welding (saw) is a fast and efficient method that produces deep and neat welds. In. Submerged Arc Welding Inert Gas.

From studylib.net

Submerged Arc Welding Submerged Arc Welding Inert Gas A blanket of powdered flux. Welding processes are manual metal or shielded metal arc welding (mma or sma), metal inert gas arc (mig), tungsten inert gas (tig), submerged arc. In submerged arc welding, it is a process in which continuously fed electrodes, and a blanket of fusible fluxes become conductive when melted and provide a current path between the part. Submerged Arc Welding Inert Gas.

From www.alamy.com

Gas tungsten arc welding GTAW or tungsten inert gas TIG Stock Photo Alamy Submerged Arc Welding Inert Gas Submerged arc welding (saw) is a fast and efficient method that produces deep and neat welds. A blanket of powdered flux. Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. Welding processes are manual metal or shielded metal arc welding (mma or sma), metal. Submerged Arc Welding Inert Gas.

From electricalworkbook.com

What is Tungsten Inert Gas Welding? Process, Diagram, Advantages Submerged Arc Welding Inert Gas Welding processes are manual metal or shielded metal arc welding (mma or sma), metal inert gas arc (mig), tungsten inert gas (tig), submerged arc. Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. A blanket of powdered flux. Submerged arc welding (saw) is a. Submerged Arc Welding Inert Gas.

From www.mechanicaleducation.com

Tungsten Inert Gas Welding Process, Advantages, Disadvantages And Submerged Arc Welding Inert Gas It uses a special covering called flux to make sure the welding arc and the melted metal stay. A blanket of powdered flux. Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. Gas tungsten arc welding (gtaw) is an electric arc welding process that. Submerged Arc Welding Inert Gas.

From www.wikiwand.com

Submerged arc welding Wikiwand Submerged Arc Welding Inert Gas A blanket of powdered flux. Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. It uses a special covering called flux to make sure the welding arc and the melted metal stay. Gas tungsten arc welding (gtaw) is an electric arc welding process that. Submerged Arc Welding Inert Gas.

From exossvpxf.blob.core.windows.net

Inert Gases Used In Welding at Kristi Woodward blog Submerged Arc Welding Inert Gas A blanket of powdered flux. In submerged arc welding, it is a process in which continuously fed electrodes, and a blanket of fusible fluxes become conductive when melted and provide a current path between the part and the electrode. Submerged arc welding (saw) is a fast and efficient method that produces deep and neat welds. Gas tungsten arc welding (gtaw). Submerged Arc Welding Inert Gas.

From millmachining.com

Submerged Arc Welding Submerged Arc Welding Inert Gas Submerged arc welding (saw) is a fast and efficient method that produces deep and neat welds. In submerged arc welding, it is a process in which continuously fed electrodes, and a blanket of fusible fluxes become conductive when melted and provide a current path between the part and the electrode. Gas tungsten arc welding (gtaw) is an electric arc welding. Submerged Arc Welding Inert Gas.

From www.oerlikon-welding.com

Submerged Arc Welding Process Oerlikon Submerged Arc Welding Inert Gas Gas tungsten arc welding (gtaw) is an electric arc welding process that produces an arc between a nonconsumable electrode and the work to be welded. Submerged arc welding (saw) is a fast and efficient method that produces deep and neat welds. Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable. Submerged Arc Welding Inert Gas.

From www.alamy.com

argon arc welding, Inert gas shielded arc welding in a Stock Submerged Arc Welding Inert Gas Gas tungsten arc welding (gtaw) is an electric arc welding process that produces an arc between a nonconsumable electrode and the work to be welded. It uses a special covering called flux to make sure the welding arc and the melted metal stay. In submerged arc welding, it is a process in which continuously fed electrodes, and a blanket of. Submerged Arc Welding Inert Gas.

From www.youtube.com

TIG welding Tungsten Inert Gas welding GTAW welding Gas tungsten Submerged Arc Welding Inert Gas In submerged arc welding, it is a process in which continuously fed electrodes, and a blanket of fusible fluxes become conductive when melted and provide a current path between the part and the electrode. Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. Welding. Submerged Arc Welding Inert Gas.

From www.researchgate.net

Metal inert gas welding process. Download Scientific Diagram Submerged Arc Welding Inert Gas A blanket of powdered flux. In submerged arc welding, it is a process in which continuously fed electrodes, and a blanket of fusible fluxes become conductive when melted and provide a current path between the part and the electrode. It uses a special covering called flux to make sure the welding arc and the melted metal stay. Gas metal arc. Submerged Arc Welding Inert Gas.

From www.youtube.com

Differences between Gas Metal Arc Welding (GMAW) and Submerged Arc Submerged Arc Welding Inert Gas Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. In submerged arc welding, it is a process in which continuously fed electrodes, and a blanket of fusible fluxes become conductive when melted and provide a current path between the part and the electrode. It. Submerged Arc Welding Inert Gas.

From www.youtube.com

TIG Tungsten Inert gas Arc Welding construction and Working Submerged Arc Welding Inert Gas Gas tungsten arc welding (gtaw) is an electric arc welding process that produces an arc between a nonconsumable electrode and the work to be welded. Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. It uses a special covering called flux to make sure. Submerged Arc Welding Inert Gas.

From fractory.com

Submerged Arc Welding (SAW) Explained Fractory Submerged Arc Welding Inert Gas Gas tungsten arc welding (gtaw) is an electric arc welding process that produces an arc between a nonconsumable electrode and the work to be welded. It uses a special covering called flux to make sure the welding arc and the melted metal stay. A blanket of powdered flux. Submerged arc welding (saw) is a fast and efficient method that produces. Submerged Arc Welding Inert Gas.

From workshopinsider.com

Insider's Guide to Submerged Arc Welding (SAW) Insider Submerged Arc Welding Inert Gas In submerged arc welding, it is a process in which continuously fed electrodes, and a blanket of fusible fluxes become conductive when melted and provide a current path between the part and the electrode. Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. It. Submerged Arc Welding Inert Gas.

From weldguru.com

Arc Welding Explained What Is It & How Does It Work? Weld Guru Submerged Arc Welding Inert Gas In submerged arc welding, it is a process in which continuously fed electrodes, and a blanket of fusible fluxes become conductive when melted and provide a current path between the part and the electrode. A blanket of powdered flux. Gas tungsten arc welding (gtaw) is an electric arc welding process that produces an arc between a nonconsumable electrode and the. Submerged Arc Welding Inert Gas.

From www.slideserve.com

PPT WELDING PROCESSES PowerPoint Presentation, free download ID4492187 Submerged Arc Welding Inert Gas In submerged arc welding, it is a process in which continuously fed electrodes, and a blanket of fusible fluxes become conductive when melted and provide a current path between the part and the electrode. A blanket of powdered flux. Submerged arc welding (saw) is a fast and efficient method that produces deep and neat welds. It uses a special covering. Submerged Arc Welding Inert Gas.

From www.researchgate.net

Schematic of the MIG (metal inert gas) welding process. For MAG (metal Submerged Arc Welding Inert Gas Submerged arc welding (saw) is a fast and efficient method that produces deep and neat welds. Welding processes are manual metal or shielded metal arc welding (mma or sma), metal inert gas arc (mig), tungsten inert gas (tig), submerged arc. Gas tungsten arc welding (gtaw) is an electric arc welding process that produces an arc between a nonconsumable electrode and. Submerged Arc Welding Inert Gas.

From www.researchgate.net

Process diagram of tungsten inert gas (TIG) welding Download Submerged Arc Welding Inert Gas Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. A blanket of powdered flux. In submerged arc welding, it is a process in which continuously fed electrodes, and a blanket of fusible fluxes become conductive when melted and provide a current path between the. Submerged Arc Welding Inert Gas.

From www.open.edu

Gas shielded arc welding processes (TIG/MIG/MAG) OpenLearn Open Submerged Arc Welding Inert Gas It uses a special covering called flux to make sure the welding arc and the melted metal stay. Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. In submerged arc welding, it is a process in which continuously fed electrodes, and a blanket of. Submerged Arc Welding Inert Gas.

From avopix.com

Diagram of Metal inert gas welding (MIG) Royalty Free Stock Vector Submerged Arc Welding Inert Gas Gas metal arc welding (gmaw) is one fusion welding process where the electric arc is established between a consumable wire electrode and the base plates. Welding processes are manual metal or shielded metal arc welding (mma or sma), metal inert gas arc (mig), tungsten inert gas (tig), submerged arc. Submerged arc welding (saw) is a fast and efficient method that. Submerged Arc Welding Inert Gas.

From www.youtube.com

SUBMERGED ARC WELDING How submerged arc welding works. YouTube Submerged Arc Welding Inert Gas Submerged arc welding (saw) is a fast and efficient method that produces deep and neat welds. In submerged arc welding, it is a process in which continuously fed electrodes, and a blanket of fusible fluxes become conductive when melted and provide a current path between the part and the electrode. A blanket of powdered flux. Gas metal arc welding (gmaw). Submerged Arc Welding Inert Gas.