How Flat Do Jointer Tables Need To Be . The jointer helps you flatten one face of a workpiece, and then square one edge adjacent to that face: This tip demonstrates how to set jointer tables perfectly and quickly, ensuring you get flat surfaces every time. I discovered that the out feed table is not flat. Reasonable spec would be.005 or less. If they can do that, they're good. Therefore, you don’t want to press a flexible piece into full contact with the tables during feeding. To work correctly, the tables must also be parallel to one another. Jointers only do one basic thing and that is make a surface flat. Ok, the in feed table is not flat. Ten 1000ths = one 100th which is absolutely fine on a table saw, but would be very poor for a. The idea of jointing is to gradually remove the high spots in order to bring the surface into a flat plane. Instead, press down just enough to keep the knives from slapping the piece upward. If they can only almost do that. I need advice on what to do next. Flatness isn’t the only important thing.

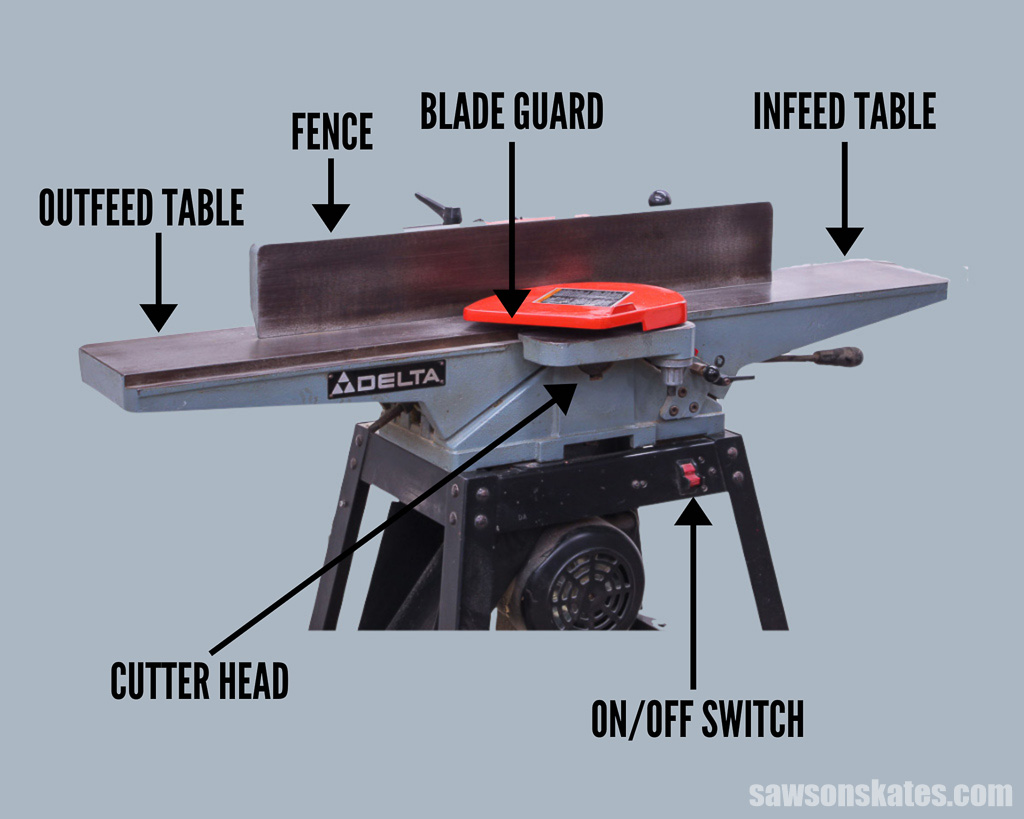

from sawsonskates.com

If they can only almost do that. To work correctly, the tables must also be parallel to one another. Instead, press down just enough to keep the knives from slapping the piece upward. If they can do that, they're good. This tip demonstrates how to set jointer tables perfectly and quickly, ensuring you get flat surfaces every time. I discovered that the out feed table is not flat. The idea of jointing is to gradually remove the high spots in order to bring the surface into a flat plane. Therefore, you don’t want to press a flexible piece into full contact with the tables during feeding. Flatness isn’t the only important thing. I need advice on what to do next.

Jointer vs Planer (Differences & Which to Buy First) Saws on Skates®

How Flat Do Jointer Tables Need To Be Reasonable spec would be.005 or less. Reasonable spec would be.005 or less. If they can do that, they're good. Ten 1000ths = one 100th which is absolutely fine on a table saw, but would be very poor for a. I discovered that the out feed table is not flat. The idea of jointing is to gradually remove the high spots in order to bring the surface into a flat plane. Jointers only do one basic thing and that is make a surface flat. Therefore, you don’t want to press a flexible piece into full contact with the tables during feeding. The jointer helps you flatten one face of a workpiece, and then square one edge adjacent to that face: To work correctly, the tables must also be parallel to one another. Flatness isn’t the only important thing. This tip demonstrates how to set jointer tables perfectly and quickly, ensuring you get flat surfaces every time. I need advice on what to do next. Ok, the in feed table is not flat. Instead, press down just enough to keep the knives from slapping the piece upward. If they can only almost do that.

From thehabitofwoodworking.com

Do I Need A Jointer For Woodworking? The Habit of Woodworking How Flat Do Jointer Tables Need To Be The jointer helps you flatten one face of a workpiece, and then square one edge adjacent to that face: I need advice on what to do next. If they can only almost do that. Instead, press down just enough to keep the knives from slapping the piece upward. Ok, the in feed table is not flat. I discovered that the. How Flat Do Jointer Tables Need To Be.

From www.pinterest.com.mx

Ultimate Jointer Push Block Woodworking projects, Wood shop projects How Flat Do Jointer Tables Need To Be Jointers only do one basic thing and that is make a surface flat. To work correctly, the tables must also be parallel to one another. Therefore, you don’t want to press a flexible piece into full contact with the tables during feeding. The jointer helps you flatten one face of a workpiece, and then square one edge adjacent to that. How Flat Do Jointer Tables Need To Be.

From www.youtube.com

Wood Jointer Tips for Setting Up and Using a Jointer YouTube How Flat Do Jointer Tables Need To Be The jointer helps you flatten one face of a workpiece, and then square one edge adjacent to that face: Instead, press down just enough to keep the knives from slapping the piece upward. Jointers only do one basic thing and that is make a surface flat. I need advice on what to do next. This tip demonstrates how to set. How Flat Do Jointer Tables Need To Be.

From www.woodsmith.com

Top Jointer Technique Woodsmith How Flat Do Jointer Tables Need To Be If they can do that, they're good. Ok, the in feed table is not flat. Jointers only do one basic thing and that is make a surface flat. I need advice on what to do next. Flatness isn’t the only important thing. To work correctly, the tables must also be parallel to one another. I discovered that the out feed. How Flat Do Jointer Tables Need To Be.

From www.diynetwork.com

How to Adjust a Jointer howtos DIY How Flat Do Jointer Tables Need To Be The jointer helps you flatten one face of a workpiece, and then square one edge adjacent to that face: The idea of jointing is to gradually remove the high spots in order to bring the surface into a flat plane. Ten 1000ths = one 100th which is absolutely fine on a table saw, but would be very poor for a.. How Flat Do Jointer Tables Need To Be.

From alvalewis.blogspot.com

Benchtop Jointer Extension Table alvalewis How Flat Do Jointer Tables Need To Be To work correctly, the tables must also be parallel to one another. This tip demonstrates how to set jointer tables perfectly and quickly, ensuring you get flat surfaces every time. The jointer helps you flatten one face of a workpiece, and then square one edge adjacent to that face: If they can do that, they're good. The idea of jointing. How Flat Do Jointer Tables Need To Be.

From cutthewood.com

How To Use The Jointer For Woodworking Cut The Wood How Flat Do Jointer Tables Need To Be I discovered that the out feed table is not flat. I need advice on what to do next. The jointer helps you flatten one face of a workpiece, and then square one edge adjacent to that face: The idea of jointing is to gradually remove the high spots in order to bring the surface into a flat plane. Therefore, you. How Flat Do Jointer Tables Need To Be.

From sawsonskates.com

Jointer vs Planer (Differences & Which to Buy First) Saws on Skates® How Flat Do Jointer Tables Need To Be Jointers only do one basic thing and that is make a surface flat. Ok, the in feed table is not flat. If they can only almost do that. If they can do that, they're good. Reasonable spec would be.005 or less. I need advice on what to do next. Flatness isn’t the only important thing. This tip demonstrates how to. How Flat Do Jointer Tables Need To Be.

From www.pinterest.com

DIY jointer extension tables for Beaver 3800 Table extension How Flat Do Jointer Tables Need To Be The idea of jointing is to gradually remove the high spots in order to bring the surface into a flat plane. I need advice on what to do next. Reasonable spec would be.005 or less. Ten 1000ths = one 100th which is absolutely fine on a table saw, but would be very poor for a. This tip demonstrates how to. How Flat Do Jointer Tables Need To Be.

From www.pinterest.com

It may not be the most versatile machine in the shop, but without a How Flat Do Jointer Tables Need To Be Jointers only do one basic thing and that is make a surface flat. The idea of jointing is to gradually remove the high spots in order to bring the surface into a flat plane. If they can only almost do that. I need advice on what to do next. The jointer helps you flatten one face of a workpiece, and. How Flat Do Jointer Tables Need To Be.

From shuntool.com

Choosing The Right Size Jointer For Your Woodworking Needs ShunTool How Flat Do Jointer Tables Need To Be Ok, the in feed table is not flat. To work correctly, the tables must also be parallel to one another. This tip demonstrates how to set jointer tables perfectly and quickly, ensuring you get flat surfaces every time. Ten 1000ths = one 100th which is absolutely fine on a table saw, but would be very poor for a. Instead, press. How Flat Do Jointer Tables Need To Be.

From www.wwgoa.com

How to Use a Jointer Learn How to Master the Jointer WWGOA How Flat Do Jointer Tables Need To Be Jointers only do one basic thing and that is make a surface flat. I need advice on what to do next. The jointer helps you flatten one face of a workpiece, and then square one edge adjacent to that face: Flatness isn’t the only important thing. Therefore, you don’t want to press a flexible piece into full contact with the. How Flat Do Jointer Tables Need To Be.

From www.finepowertools.com

Jointer vs Planer Differences. Which One Do I Need First? How Flat Do Jointer Tables Need To Be The jointer helps you flatten one face of a workpiece, and then square one edge adjacent to that face: To work correctly, the tables must also be parallel to one another. Instead, press down just enough to keep the knives from slapping the piece upward. The idea of jointing is to gradually remove the high spots in order to bring. How Flat Do Jointer Tables Need To Be.

From www.finewoodworking.com

How to Adjust a Jointer's Outfeed Table Perfectly FineWoodworking How Flat Do Jointer Tables Need To Be Instead, press down just enough to keep the knives from slapping the piece upward. The jointer helps you flatten one face of a workpiece, and then square one edge adjacent to that face: If they can only almost do that. Ok, the in feed table is not flat. Therefore, you don’t want to press a flexible piece into full contact. How Flat Do Jointer Tables Need To Be.

From www.youtube.com

Simple Table Extensions for a Benchtop Jointer YouTube How Flat Do Jointer Tables Need To Be Instead, press down just enough to keep the knives from slapping the piece upward. To work correctly, the tables must also be parallel to one another. Jointers only do one basic thing and that is make a surface flat. The idea of jointing is to gradually remove the high spots in order to bring the surface into a flat plane.. How Flat Do Jointer Tables Need To Be.

From pressbooks.bccampus.ca

Parts of the Jointer Woodworking Machinery How Flat Do Jointer Tables Need To Be Jointers only do one basic thing and that is make a surface flat. Therefore, you don’t want to press a flexible piece into full contact with the tables during feeding. Ten 1000ths = one 100th which is absolutely fine on a table saw, but would be very poor for a. If they can only almost do that. The jointer helps. How Flat Do Jointer Tables Need To Be.

From www.wwgoa.com

Jointing on the Table Saw How to Easily Joint without a Jointer How Flat Do Jointer Tables Need To Be I discovered that the out feed table is not flat. The idea of jointing is to gradually remove the high spots in order to bring the surface into a flat plane. Ten 1000ths = one 100th which is absolutely fine on a table saw, but would be very poor for a. Ok, the in feed table is not flat. To. How Flat Do Jointer Tables Need To Be.

From www.woodsmith.com

Top Jointer Technique Woodsmith How Flat Do Jointer Tables Need To Be If they can only almost do that. Flatness isn’t the only important thing. I discovered that the out feed table is not flat. If they can do that, they're good. The idea of jointing is to gradually remove the high spots in order to bring the surface into a flat plane. Jointers only do one basic thing and that is. How Flat Do Jointer Tables Need To Be.

From www.finewoodworking.com

Jointer table extensions FineWoodworking How Flat Do Jointer Tables Need To Be Instead, press down just enough to keep the knives from slapping the piece upward. I need advice on what to do next. Reasonable spec would be.005 or less. Ten 1000ths = one 100th which is absolutely fine on a table saw, but would be very poor for a. Flatness isn’t the only important thing. Therefore, you don’t want to press. How Flat Do Jointer Tables Need To Be.

From www.finewoodworking.com

How to Adjust a Jointer's Outfeed Table Perfectly FineWoodworking How Flat Do Jointer Tables Need To Be To work correctly, the tables must also be parallel to one another. Flatness isn’t the only important thing. Therefore, you don’t want to press a flexible piece into full contact with the tables during feeding. Ok, the in feed table is not flat. I need advice on what to do next. Reasonable spec would be.005 or less. Jointers only do. How Flat Do Jointer Tables Need To Be.

From www.wwgoa.com

Jointing on the Table Saw How to Easily Joint without a Jointer How Flat Do Jointer Tables Need To Be Flatness isn’t the only important thing. Jointers only do one basic thing and that is make a surface flat. I discovered that the out feed table is not flat. Therefore, you don’t want to press a flexible piece into full contact with the tables during feeding. If they can only almost do that. Ok, the in feed table is not. How Flat Do Jointer Tables Need To Be.

From www.wwgoa.com

How to Use a Jointer Learn How to Master the Jointer WWGOA How Flat Do Jointer Tables Need To Be If they can only almost do that. Ok, the in feed table is not flat. If they can do that, they're good. To work correctly, the tables must also be parallel to one another. I discovered that the out feed table is not flat. This tip demonstrates how to set jointer tables perfectly and quickly, ensuring you get flat surfaces. How Flat Do Jointer Tables Need To Be.

From shuntool.com

Exploring The Tilt Function Of Jointer Tables Everything You Need To How Flat Do Jointer Tables Need To Be Reasonable spec would be.005 or less. The jointer helps you flatten one face of a workpiece, and then square one edge adjacent to that face: Ten 1000ths = one 100th which is absolutely fine on a table saw, but would be very poor for a. If they can do that, they're good. Jointers only do one basic thing and that. How Flat Do Jointer Tables Need To Be.

From www.youtube.com

Jointer Setup // How To Set Outfeed Table Height For Perfect Cuts YouTube How Flat Do Jointer Tables Need To Be Jointers only do one basic thing and that is make a surface flat. The jointer helps you flatten one face of a workpiece, and then square one edge adjacent to that face: Reasonable spec would be.005 or less. Ok, the in feed table is not flat. If they can do that, they're good. Instead, press down just enough to keep. How Flat Do Jointer Tables Need To Be.

From www.woodsmith.com

Top Jointer Technique Woodsmith How Flat Do Jointer Tables Need To Be Ok, the in feed table is not flat. This tip demonstrates how to set jointer tables perfectly and quickly, ensuring you get flat surfaces every time. I need advice on what to do next. To work correctly, the tables must also be parallel to one another. Reasonable spec would be.005 or less. Flatness isn’t the only important thing. If they. How Flat Do Jointer Tables Need To Be.

From shuntool.com

Do I Need A Jointer For Making A Table? Here's What You Should Know How Flat Do Jointer Tables Need To Be Therefore, you don’t want to press a flexible piece into full contact with the tables during feeding. I discovered that the out feed table is not flat. Ten 1000ths = one 100th which is absolutely fine on a table saw, but would be very poor for a. The idea of jointing is to gradually remove the high spots in order. How Flat Do Jointer Tables Need To Be.

From shuntool.com

Understanding How Jointer Tables Tilt For Bevel Edges ShunTool How Flat Do Jointer Tables Need To Be I need advice on what to do next. Jointers only do one basic thing and that is make a surface flat. Therefore, you don’t want to press a flexible piece into full contact with the tables during feeding. I discovered that the out feed table is not flat. If they can do that, they're good. If they can only almost. How Flat Do Jointer Tables Need To Be.

From www.woodmagazine.com

Adjust Tables for Jointer Accuracy Wood How Flat Do Jointer Tables Need To Be The jointer helps you flatten one face of a workpiece, and then square one edge adjacent to that face: Therefore, you don’t want to press a flexible piece into full contact with the tables during feeding. If they can only almost do that. Ten 1000ths = one 100th which is absolutely fine on a table saw, but would be very. How Flat Do Jointer Tables Need To Be.

From masterthewood.com

What is a Jointer? The Basics you need How Flat Do Jointer Tables Need To Be If they can only almost do that. Instead, press down just enough to keep the knives from slapping the piece upward. I discovered that the out feed table is not flat. Jointers only do one basic thing and that is make a surface flat. The idea of jointing is to gradually remove the high spots in order to bring the. How Flat Do Jointer Tables Need To Be.

From www.pinterest.com

How to Build a Jointer Jig for Your Table Saw woodworkingjigsaw How Flat Do Jointer Tables Need To Be The jointer helps you flatten one face of a workpiece, and then square one edge adjacent to that face: The idea of jointing is to gradually remove the high spots in order to bring the surface into a flat plane. This tip demonstrates how to set jointer tables perfectly and quickly, ensuring you get flat surfaces every time. Jointers only. How Flat Do Jointer Tables Need To Be.

From wallpaperstein21.blogspot.com

Bench Jointer Review Wallpaper Stein How Flat Do Jointer Tables Need To Be Therefore, you don’t want to press a flexible piece into full contact with the tables during feeding. Ok, the in feed table is not flat. This tip demonstrates how to set jointer tables perfectly and quickly, ensuring you get flat surfaces every time. If they can do that, they're good. Jointers only do one basic thing and that is make. How Flat Do Jointer Tables Need To Be.

From www.wwgoa.com

How to Use a Jointer Learn How to Master the Jointer WWGOA How Flat Do Jointer Tables Need To Be If they can do that, they're good. Reasonable spec would be.005 or less. Ten 1000ths = one 100th which is absolutely fine on a table saw, but would be very poor for a. The idea of jointing is to gradually remove the high spots in order to bring the surface into a flat plane. Therefore, you don’t want to press. How Flat Do Jointer Tables Need To Be.

From baileigh.com

Jointer Table EntryLevel Jointer Baileigh Industrial How Flat Do Jointer Tables Need To Be Reasonable spec would be.005 or less. Ten 1000ths = one 100th which is absolutely fine on a table saw, but would be very poor for a. Flatness isn’t the only important thing. If they can only almost do that. Ok, the in feed table is not flat. If they can do that, they're good. This tip demonstrates how to set. How Flat Do Jointer Tables Need To Be.

From www.youtube.com

How to Adjust Hammer A341 Jointer/Planer Tables YouTube How Flat Do Jointer Tables Need To Be I need advice on what to do next. Jointers only do one basic thing and that is make a surface flat. Ten 1000ths = one 100th which is absolutely fine on a table saw, but would be very poor for a. I discovered that the out feed table is not flat. Flatness isn’t the only important thing. Instead, press down. How Flat Do Jointer Tables Need To Be.

From www.wwgoa.com

How to Use a Jointer Learn How to Master the Jointer WWGOA How Flat Do Jointer Tables Need To Be This tip demonstrates how to set jointer tables perfectly and quickly, ensuring you get flat surfaces every time. If they can only almost do that. Therefore, you don’t want to press a flexible piece into full contact with the tables during feeding. Reasonable spec would be.005 or less. To work correctly, the tables must also be parallel to one another.. How Flat Do Jointer Tables Need To Be.