Casting Forging And Mold Drafter . This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures dense, impurity. When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the. Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. Casting excels in intricate designs, while forging is renowned for its strength and structural integrity. Engineering drawing and related documentation practices. The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded part. Castings, forgings, and molded parts. Specifically, it is the angle of the molded surfaces in the direction of mold opening.

from www.various.co.in

Engineering drawing and related documentation practices. Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures dense, impurity. Castings, forgings, and molded parts. Casting excels in intricate designs, while forging is renowned for its strength and structural integrity. The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded part. Specifically, it is the angle of the molded surfaces in the direction of mold opening. When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the.

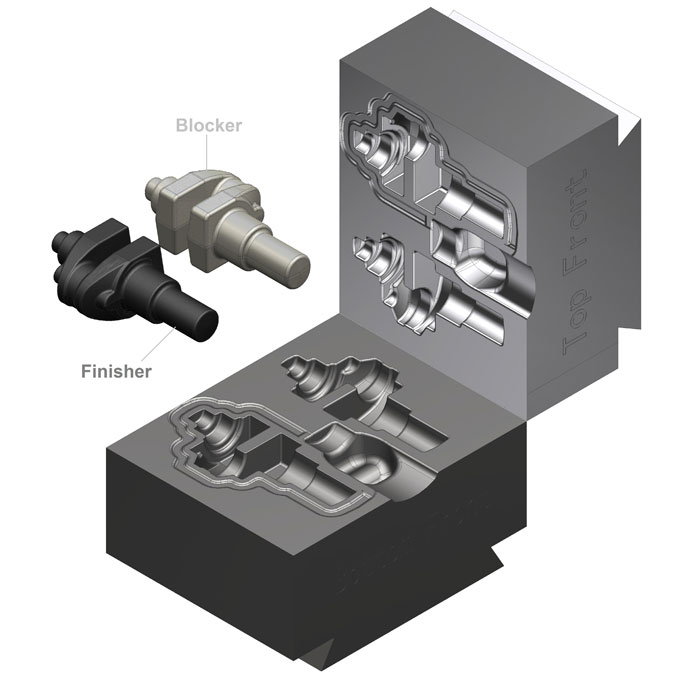

Mould For Casting Process Precision Machining Works in CNC VMC HMC

Casting Forging And Mold Drafter Castings, forgings, and molded parts. The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded part. Castings, forgings, and molded parts. Specifically, it is the angle of the molded surfaces in the direction of mold opening. Engineering drawing and related documentation practices. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures dense, impurity. When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the. Casting excels in intricate designs, while forging is renowned for its strength and structural integrity. Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations.

From medium.com

ALL ABOUT CASTING & What are castings? Casting can be a… by Casting Forging And Mold Drafter Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. Casting excels in intricate designs, while forging is renowned for its strength and structural integrity. Engineering drawing and related documentation practices. Castings, forgings, and molded parts. When developing parts for plastic injection molding, applying draft (or a taper) to the. Casting Forging And Mold Drafter.

From www.adtcmold.com

Injection mold principle and structure knowledge Casting Forging And Mold Drafter When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures dense, impurity. The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded part. Specifically, it is the. Casting Forging And Mold Drafter.

From atg-q.com

CASTINGS & Casting Forging And Mold Drafter Casting excels in intricate designs, while forging is renowned for its strength and structural integrity. Specifically, it is the angle of the molded surfaces in the direction of mold opening. The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded part. This method involves pouring molten metal into a rotating mold,. Casting Forging And Mold Drafter.

From www.ls-casting-mold.com

Casting and dies LSmojv Casting Forging And Mold Drafter Castings, forgings, and molded parts. When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the. Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. Specifically, it is the angle of the molded surfaces in the direction of mold opening. Engineering drawing and. Casting Forging And Mold Drafter.

From www.dreamstime.com

Casting in a Mold for the Production of Metal, Automatice Line Hot Casting Forging And Mold Drafter Castings, forgings, and molded parts. Engineering drawing and related documentation practices. Casting excels in intricate designs, while forging is renowned for its strength and structural integrity. Specifically, it is the angle of the molded surfaces in the direction of mold opening. The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded. Casting Forging And Mold Drafter.

From www.iqsdirectory.com

Open vs. Closed Die Process, Differences & Benefits Casting Forging And Mold Drafter This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures dense, impurity. Engineering drawing and related documentation practices. Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. The term draft angle refers to the angle designed into the mold to facilitate the. Casting Forging And Mold Drafter.

From www.cic-cic.net

Permanent Mold Castings Custom Industrials Casting Forging And Mold Drafter Specifically, it is the angle of the molded surfaces in the direction of mold opening. Casting excels in intricate designs, while forging is renowned for its strength and structural integrity. Castings, forgings, and molded parts. When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the. This method involves pouring molten metal into a. Casting Forging And Mold Drafter.

From www.dreamstime.com

Casting in a Mold for the Production of Metal, Automatice Line Hot Casting Forging And Mold Drafter Castings, forgings, and molded parts. Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. Casting excels in intricate designs, while forging is renowned for its strength and structural integrity. The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded part.. Casting Forging And Mold Drafter.

From www.dreamstime.com

Casting in a Mold for the Production of Metal, Automatice Line Hot Casting Forging And Mold Drafter Castings, forgings, and molded parts. Casting excels in intricate designs, while forging is renowned for its strength and structural integrity. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures dense, impurity. Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. When. Casting Forging And Mold Drafter.

From precisionmold.com

Aerospace Engineering & Global Machining Shop in Michigan Precision Casting Forging And Mold Drafter Specifically, it is the angle of the molded surfaces in the direction of mold opening. Castings, forgings, and molded parts. When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures dense, impurity. Casting excels in intricate. Casting Forging And Mold Drafter.

From medium.com

Casting vs. Understanding the Differences by microcare Medium Casting Forging And Mold Drafter When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the. Specifically, it is the angle of the molded surfaces in the direction of mold opening. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures dense, impurity. The term draft angle refers to the angle designed. Casting Forging And Mold Drafter.

From www.various.co.in

Mould For Casting Process Precision Machining Works in CNC VMC HMC Casting Forging And Mold Drafter The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded part. Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. Casting excels in intricate designs, while forging is renowned for its strength and structural integrity. Engineering drawing and related documentation. Casting Forging And Mold Drafter.

From www.market-prospects.com

Five Type Stamping Process To Introduce You Milling, Machining, Die Casting Forging And Mold Drafter When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the. The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded part. Engineering drawing and related documentation practices. Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and. Casting Forging And Mold Drafter.

From differencecamp.com

Casting Vs. What's The Difference? (With Comparison Table) Casting Forging And Mold Drafter Casting excels in intricate designs, while forging is renowned for its strength and structural integrity. Specifically, it is the angle of the molded surfaces in the direction of mold opening. Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. When developing parts for plastic injection molding, applying draft (or. Casting Forging And Mold Drafter.

From slideplayer.com

Introduction to Engineering Drawing and Design ppt download Casting Forging And Mold Drafter Engineering drawing and related documentation practices. Castings, forgings, and molded parts. Specifically, it is the angle of the molded surfaces in the direction of mold opening. When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the. Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and. Casting Forging And Mold Drafter.

From www.thecrucible.org

Metal Casting 101 Learn To Cast Metal [Types & Processes] Casting Forging And Mold Drafter Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded part. When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the. Engineering drawing and. Casting Forging And Mold Drafter.

From www.pinterest.com

Die Design Wide Long Rib and thick Design, Metal Casting Forging And Mold Drafter This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures dense, impurity. When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the. Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. Engineering drawing and related. Casting Forging And Mold Drafter.

From www.iacelectricals.com

& CastingsKey Differences IAC Electricals Casting Forging And Mold Drafter When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the. Specifically, it is the angle of the molded surfaces in the direction of mold opening. Castings, forgings, and molded parts. Casting excels in intricate designs, while forging is renowned for its strength and structural integrity. Engineering drawing and related documentation practices. The term. Casting Forging And Mold Drafter.

From www.intercastuk.com

Sheffield Castings Foundry Cost Efficient Casting Forging And Mold Drafter Casting excels in intricate designs, while forging is renowned for its strength and structural integrity. Specifically, it is the angle of the molded surfaces in the direction of mold opening. Castings, forgings, and molded parts. Engineering drawing and related documentation practices. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures dense, impurity.. Casting Forging And Mold Drafter.

From www.omexaerocomponent.in

Casting, Sheet Metal, EDM wire cutting, Managed Services Casting Forging And Mold Drafter Castings, forgings, and molded parts. Engineering drawing and related documentation practices. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures dense, impurity. The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded part. Casting excels in intricate designs, while forging is renowned for. Casting Forging And Mold Drafter.

From www.rapiddirect.com

Draft Angle for Injection Molding Design Guide and Practices RapidDirect Casting Forging And Mold Drafter The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded part. Casting excels in intricate designs, while forging is renowned for its strength and structural integrity. Engineering drawing and related documentation practices. Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness. Casting Forging And Mold Drafter.

From www.machinemfg.com

Extending the Lifespan of HighEnd DieCasting Mold Materials Latest Casting Forging And Mold Drafter The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded part. Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures dense, impurity. When. Casting Forging And Mold Drafter.

From www.engmark.co.uk

& Casting Engmark Engineering Marketing Agency Casting Forging And Mold Drafter This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures dense, impurity. The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded part. Specifically, it is the angle of the molded surfaces in the direction of mold opening. Engineering drawing and related documentation practices.. Casting Forging And Mold Drafter.

From yutungindustrial.en.made-in-china.com

Molds Precision and Casting China Casting Forging And Mold Drafter Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures dense, impurity. Engineering drawing and related. Casting Forging And Mold Drafter.

From forgedcomponents.com

What is the Difference Between the Casting and Process Casting Forging And Mold Drafter This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures dense, impurity. Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded part. Castings,. Casting Forging And Mold Drafter.

From www.reliance-foundry.com

Metal Melting and Pouring Life of a Casting Reliance Foundry Casting Forging And Mold Drafter Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. Casting excels in intricate designs, while forging is renowned for its strength and structural integrity. The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded part. Specifically, it is the angle. Casting Forging And Mold Drafter.

From www.tfgusa.com

Metal Processes, Methods, and Applications TFGUSA Casting Forging And Mold Drafter Castings, forgings, and molded parts. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures dense, impurity. Casting excels in intricate designs, while forging is renowned for its strength and structural integrity. When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the. Engineering drawing and related. Casting Forging And Mold Drafter.

From www.sourceonesupply.com

Castings & Industrial Supplier Casting Forging And Mold Drafter The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded part. Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. Engineering drawing and related documentation practices. When developing parts for plastic injection molding, applying draft (or a taper) to the. Casting Forging And Mold Drafter.

From www.daidokogyo.co.jp

Castings, and Related Products Daido Kogyo Co., Ltd. Casting Forging And Mold Drafter Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the. Specifically, it is the angle of the molded surfaces in the direction of mold opening. Casting excels in intricate designs, while forging is. Casting Forging And Mold Drafter.

From reinosafc.com

REINOSA Castings Casting Forging And Mold Drafter Castings, forgings, and molded parts. Casting excels in intricate designs, while forging is renowned for its strength and structural integrity. Specifically, it is the angle of the molded surfaces in the direction of mold opening. The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded part. Dfmpro for casting provides casting. Casting Forging And Mold Drafter.

From kerone.com

Different Types of Casting Process and Uses Casting Forging And Mold Drafter When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the. Specifically, it is the angle of the molded surfaces in the direction of mold opening. Casting excels in intricate designs, while forging is renowned for its strength and structural integrity. Engineering drawing and related documentation practices. This method involves pouring molten metal into. Casting Forging And Mold Drafter.

From atg-q.com

CASTINGS & Casting Forging And Mold Drafter Engineering drawing and related documentation practices. Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the. The term draft angle refers to the angle designed into the mold to facilitate the removal of. Casting Forging And Mold Drafter.

From bhuwalkacasting.com

Process Bhuwalka Castings & Pvt Ltd Casting Forging And Mold Drafter This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures dense, impurity. The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded part. Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. Specifically,. Casting Forging And Mold Drafter.

From www.youtube.com

The Basic Permanent Mold Casting Process YouTube Casting Forging And Mold Drafter When developing parts for plastic injection molding, applying draft (or a taper) to the faces of the. Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. This method involves pouring molten metal into a rotating mold, which distributes the metal uniformly and ensures dense, impurity. Castings, forgings, and molded. Casting Forging And Mold Drafter.

From precise-cast.com

What’s the difference between the stamping and casting Casting Forging And Mold Drafter Dfmpro for casting provides casting design guidelines including draft angles, fillet radius, mold wall thickness, undercuts, and wall thickness variations. The term draft angle refers to the angle designed into the mold to facilitate the removal of the molded part. Specifically, it is the angle of the molded surfaces in the direction of mold opening. This method involves pouring molten. Casting Forging And Mold Drafter.