Expansion Joint Spring Rate . Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. This guide describes in detail the applications and capabilities of fabric expansion joints, provides information on standard expansion joints and. An expansion joint is a specially engineered product inserted in a rigid piping system to achieve one or more of the following: Metal bellows spring rate 13 metal bellows spring rate is the force required to compress, extend or angulate the bellows. In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial forces and moments required to move an expansion.

from www.triadbellows.com

Metal bellows spring rate 13 metal bellows spring rate is the force required to compress, extend or angulate the bellows. In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial forces and moments required to move an expansion. An expansion joint is a specially engineered product inserted in a rigid piping system to achieve one or more of the following: Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. This guide describes in detail the applications and capabilities of fabric expansion joints, provides information on standard expansion joints and.

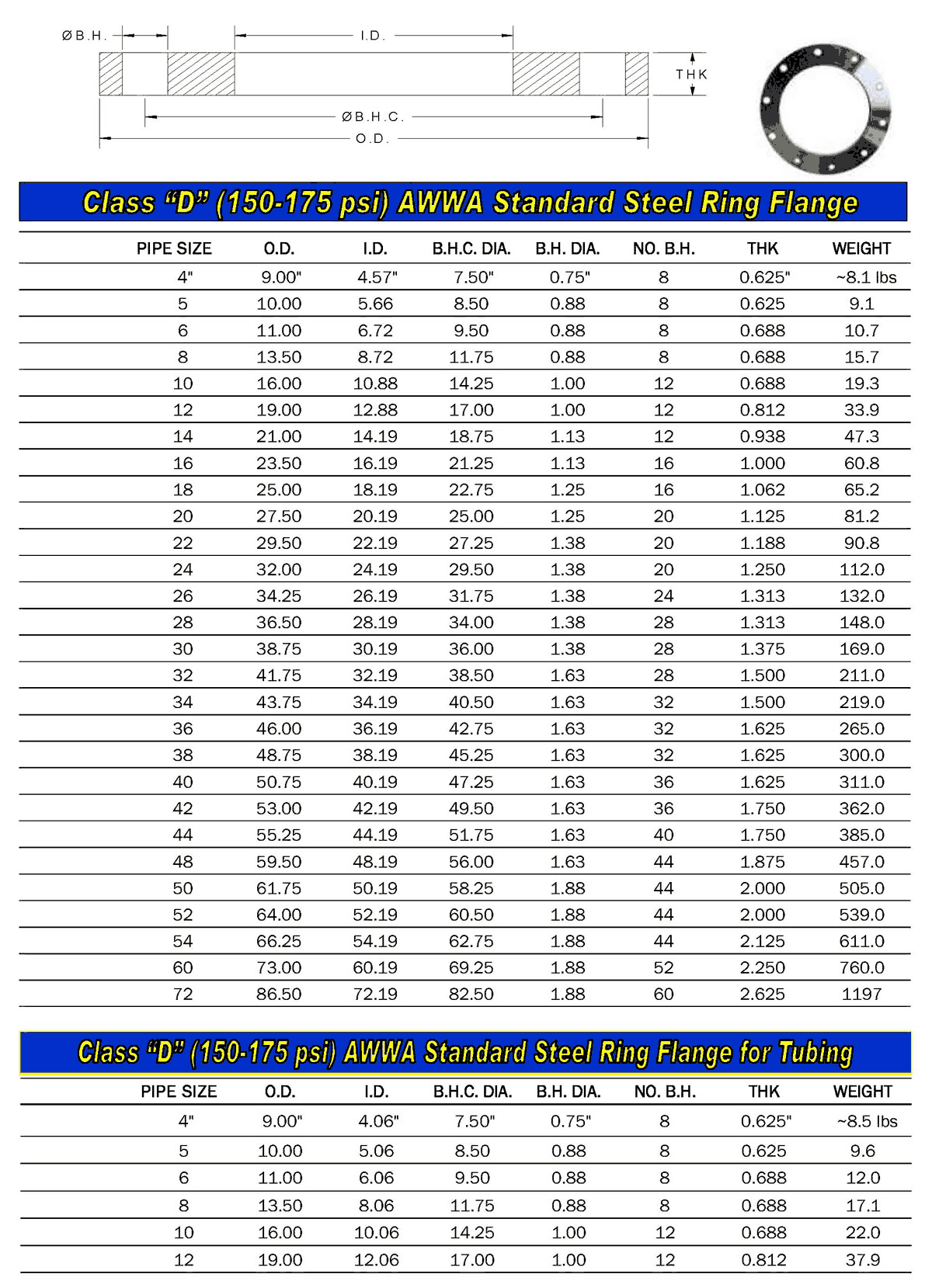

Flange Dimension Chart Expansion Joint Manufacturers

Expansion Joint Spring Rate Metal bellows spring rate 13 metal bellows spring rate is the force required to compress, extend or angulate the bellows. An expansion joint is a specially engineered product inserted in a rigid piping system to achieve one or more of the following: Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial forces and moments required to move an expansion. Metal bellows spring rate 13 metal bellows spring rate is the force required to compress, extend or angulate the bellows. This guide describes in detail the applications and capabilities of fabric expansion joints, provides information on standard expansion joints and.

From www.pumpsandsystems.com

A User’s Guide to Expansion Joint Control Units Pumps & Systems Expansion Joint Spring Rate Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. Metal bellows spring rate 13 metal bellows spring rate is the force required to compress, extend or angulate the bellows. An expansion joint is a specially engineered product inserted in a rigid. Expansion Joint Spring Rate.

From www.holzrubber.com

Series 320EZ Lightweight Piping Expansion Joint Holz Rubber Expansion Joint Spring Rate An expansion joint is a specially engineered product inserted in a rigid piping system to achieve one or more of the following: Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. Metal bellows spring rate 13 metal bellows spring rate is. Expansion Joint Spring Rate.

From www.iqsdirectory.com

Expansion Joints Types, Characteristics, Uses & Benefits Expansion Joint Spring Rate Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial forces and moments required to move an expansion. An expansion joint is a specially. Expansion Joint Spring Rate.

From www.holzrubber.com

Series300PressureVacuumRatingsExpansionJoint Holz Rubber Expansion Joint Spring Rate Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. An expansion joint is a specially engineered product inserted in a rigid piping system to achieve one or more of the following: Metal bellows spring rate 13 metal bellows spring rate is. Expansion Joint Spring Rate.

From www.hydroflexhose.com

HydroFlex Hose Rubber Expansion Joints Expansion Joint Spring Rate Metal bellows spring rate 13 metal bellows spring rate is the force required to compress, extend or angulate the bellows. Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. In order to evaluate the loads upon piping, supports, or equipment, it. Expansion Joint Spring Rate.

From www.sintalowhardware.com

Sintalow Hardware Pte. Ltd. Singapore pipes, Valves Singapore, pipes Expansion Joint Spring Rate Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial forces and moments required to move an expansion. This guide describes in detail the. Expansion Joint Spring Rate.

From www.researchgate.net

Spring Rate of the Hydroformed bellows. Download Scientific Diagram Expansion Joint Spring Rate An expansion joint is a specially engineered product inserted in a rigid piping system to achieve one or more of the following: Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. In order to evaluate the loads upon piping, supports, or. Expansion Joint Spring Rate.

From www.mason-uk.co.uk

Series 1004 Four Arch Low Spring Rate, Large Movement Expansion Joints Expansion Joint Spring Rate Metal bellows spring rate 13 metal bellows spring rate is the force required to compress, extend or angulate the bellows. This guide describes in detail the applications and capabilities of fabric expansion joints, provides information on standard expansion joints and. An expansion joint is a specially engineered product inserted in a rigid piping system to achieve one or more of. Expansion Joint Spring Rate.

From www.iqsdirectory.com

Expansion Joints Types, Characteristics, Uses & Benefits Expansion Joint Spring Rate Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. An expansion joint is a specially engineered product inserted in a rigid piping system to achieve one or more of the following: Metal bellows spring rate 13 metal bellows spring rate is. Expansion Joint Spring Rate.

From www.triadbellows.com

Stainless Steel Exhaust Bellows Data Sheets Expansion Joint Spring Rate Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial forces and moments required to move an expansion. An expansion joint is a specially. Expansion Joint Spring Rate.

From flexonics.com

Single Metal Expansion Joints 14" and 16" Size Expansion Joint Spring Rate This guide describes in detail the applications and capabilities of fabric expansion joints, provides information on standard expansion joints and. In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial forces and moments required to move an expansion. Metal bellows spring rate 13 metal bellows spring rate is the force required to. Expansion Joint Spring Rate.

From www.iqsdirectory.com

Expansion Joints Types, Characteristics, Uses & Benefits Expansion Joint Spring Rate This guide describes in detail the applications and capabilities of fabric expansion joints, provides information on standard expansion joints and. An expansion joint is a specially engineered product inserted in a rigid piping system to achieve one or more of the following: In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial. Expansion Joint Spring Rate.

From www.thespringstore.com

Spring Rate Calculator The Spring Store Over 70 Trillion Custom Expansion Joint Spring Rate This guide describes in detail the applications and capabilities of fabric expansion joints, provides information on standard expansion joints and. In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial forces and moments required to move an expansion. An expansion joint is a specially engineered product inserted in a rigid piping system. Expansion Joint Spring Rate.

From nefariousracing.com

Coilover Spring Rates The Ultimate Guide in 2024 (With Charts) Expansion Joint Spring Rate An expansion joint is a specially engineered product inserted in a rigid piping system to achieve one or more of the following: Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. This guide describes in detail the applications and capabilities of. Expansion Joint Spring Rate.

From www.airedalesprings.co.uk

How Do You Calculate a Spring’s Rate? Airedale Springs Expansion Joint Spring Rate Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. Metal bellows spring rate 13 metal bellows spring rate is the force required to compress, extend or angulate the bellows. An expansion joint is a specially engineered product inserted in a rigid. Expansion Joint Spring Rate.

From kadant.com

Kadant Inc. Understanding Expansion Joint Industry Terminology Expansion Joint Spring Rate Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. This guide describes in detail the applications and capabilities of fabric expansion joints, provides information on standard expansion joints and. Metal bellows spring rate 13 metal bellows spring rate is the force. Expansion Joint Spring Rate.

From www.masonhn.com

NBR EPDM Flexible rubber expansion joints,mason Flexible rubber bellow Expansion Joint Spring Rate Metal bellows spring rate 13 metal bellows spring rate is the force required to compress, extend or angulate the bellows. An expansion joint is a specially engineered product inserted in a rigid piping system to achieve one or more of the following: In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial. Expansion Joint Spring Rate.

From www.ntsuae.com

SS Expansion joints Bellow DN40300 BalanceII TWI Expansion Joint Spring Rate This guide describes in detail the applications and capabilities of fabric expansion joints, provides information on standard expansion joints and. Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. An expansion joint is a specially engineered product inserted in a rigid. Expansion Joint Spring Rate.

From www.jalopyjournal.com

Technical Spring Rates The H.A.M.B. Expansion Joint Spring Rate This guide describes in detail the applications and capabilities of fabric expansion joints, provides information on standard expansion joints and. Metal bellows spring rate 13 metal bellows spring rate is the force required to compress, extend or angulate the bellows. In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial forces and. Expansion Joint Spring Rate.

From www.missioncriticalmagazine.com

How to Select Proper Expansion Joints for Mission Critical Applications Expansion Joint Spring Rate This guide describes in detail the applications and capabilities of fabric expansion joints, provides information on standard expansion joints and. In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial forces and moments required to move an expansion. Expansion joint is its spring rate, defined as the axial pull per unit cir. Expansion Joint Spring Rate.

From www.youtube.com

Compression spring design Force, Rate and Deflection YouTube Expansion Joint Spring Rate Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial forces and moments required to move an expansion. This guide describes in detail the. Expansion Joint Spring Rate.

From www.researchgate.net

Set up for Spring Rate Testing of the Hydroformed bellows. Download Expansion Joint Spring Rate In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial forces and moments required to move an expansion. Metal bellows spring rate 13 metal bellows spring rate is the force required to compress, extend or angulate the bellows. This guide describes in detail the applications and capabilities of fabric expansion joints, provides. Expansion Joint Spring Rate.

From www.vrogue.co

What Is The Need Of Expansion Joints And Bellows In P vrogue.co Expansion Joint Spring Rate Metal bellows spring rate 13 metal bellows spring rate is the force required to compress, extend or angulate the bellows. Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. In order to evaluate the loads upon piping, supports, or equipment, it. Expansion Joint Spring Rate.

From mcasuspension.com

Spring Rates & Motion Ratios Explained MCA Suspension Expansion Joint Spring Rate In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial forces and moments required to move an expansion. This guide describes in detail the applications and capabilities of fabric expansion joints, provides information on standard expansion joints and. Expansion joint is its spring rate, defined as the axial pull per unit cir. Expansion Joint Spring Rate.

From www.ditec-adam.de

Universal Expansion Joint Expansion Joint Spring Rate In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial forces and moments required to move an expansion. Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. An expansion joint is a specially. Expansion Joint Spring Rate.

From low-offset.com

Easy Spring Rate Conversion Guide with Chart & Calculator Low Offset Expansion Joint Spring Rate Metal bellows spring rate 13 metal bellows spring rate is the force required to compress, extend or angulate the bellows. An expansion joint is a specially engineered product inserted in a rigid piping system to achieve one or more of the following: In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial. Expansion Joint Spring Rate.

From www.ditec-adam.de

Seals Expansion Joint Spring Rate An expansion joint is a specially engineered product inserted in a rigid piping system to achieve one or more of the following: Metal bellows spring rate 13 metal bellows spring rate is the force required to compress, extend or angulate the bellows. In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial. Expansion Joint Spring Rate.

From www.mwcomponents.com

How to Select an Extension Spring Spring Rate, Design, Etc. MW… Expansion Joint Spring Rate Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. An expansion joint is a specially engineered product inserted in a rigid piping system to achieve one or more of the following: In order to evaluate the loads upon piping, supports, or. Expansion Joint Spring Rate.

From www.onallcylinders.com

Quick Tech Determining Spring Rate Correction for AngleMounted Expansion Joint Spring Rate Metal bellows spring rate 13 metal bellows spring rate is the force required to compress, extend or angulate the bellows. Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. In order to evaluate the loads upon piping, supports, or equipment, it. Expansion Joint Spring Rate.

From www.iqsdirectory.com

Expansion Joints Types, Characteristics, Uses & Benefits Expansion Joint Spring Rate Metal bellows spring rate 13 metal bellows spring rate is the force required to compress, extend or angulate the bellows. An expansion joint is a specially engineered product inserted in a rigid piping system to achieve one or more of the following: This guide describes in detail the applications and capabilities of fabric expansion joints, provides information on standard expansion. Expansion Joint Spring Rate.

From www.iqsdirectory.com

Expansion Joints Types, Characteristics, Uses & Benefits Expansion Joint Spring Rate Metal bellows spring rate 13 metal bellows spring rate is the force required to compress, extend or angulate the bellows. An expansion joint is a specially engineered product inserted in a rigid piping system to achieve one or more of the following: In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial. Expansion Joint Spring Rate.

From kenovel.be

Lateral expansion joint with double bellow kenovel.be Industrial Expansion Joint Spring Rate Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. An expansion joint is a specially engineered product inserted in a rigid piping system to achieve one or more of the following: In order to evaluate the loads upon piping, supports, or. Expansion Joint Spring Rate.

From www.badgerind.com

Metal Bellows Spring Rate Badger Industries Expansion Joint Spring Rate An expansion joint is a specially engineered product inserted in a rigid piping system to achieve one or more of the following: Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. This guide describes in detail the applications and capabilities of. Expansion Joint Spring Rate.

From www.triadbellows.com

Flange Dimension Chart Expansion Joint Manufacturers Expansion Joint Spring Rate An expansion joint is a specially engineered product inserted in a rigid piping system to achieve one or more of the following: Expansion joint is its spring rate, defined as the axial pull per unit cir cumference of the shell divided by the axial spread of the j9int and has. In order to evaluate the loads upon piping, supports, or. Expansion Joint Spring Rate.

From sfpathway.com

AU Universal Expansion Joint SF Pathway Expansion Joint Spring Rate Metal bellows spring rate 13 metal bellows spring rate is the force required to compress, extend or angulate the bellows. In order to evaluate the loads upon piping, supports, or equipment, it is necessary to determine the axial forces and moments required to move an expansion. This guide describes in detail the applications and capabilities of fabric expansion joints, provides. Expansion Joint Spring Rate.