Solder Mask Problems . Solder resist ink is not even attached to the plate surface. Some of the most common solder mask issues include pinholes, delamination, overcuring, and undercuring. Pinholes are tiny holes or voids that can appear on the surface of the cured solder mask,. Knowledge of prevalent solder resist defects makes it easier to identify and rectify the solder mask errors during the design phase. Solder masks can face several issues, however: Crazing, delamination, peeling, and the presence of waxy or oily residues. Solder mask is a critical layer of insulative lacquer applied to a printed circuit board (pcb) that prevents solder from bridging between conductive traces and causing shorts. Mixing time for soldermask ink. The solder mask is a thin layer of polymer applied to the surface of the pcb to protect the underlying copper circuit and provide insulation. Here are some of the most common problems encountered with pcb soldermask: However, during pcb manufacturing, various problems. Soldermask adhesion problems occur when the soldermask fails to bond properly to the pcb surface, leading to peeling, flaking, or lifting. Common pcb soldermask problems & solutions.

from www.protoexpress.com

Common pcb soldermask problems & solutions. Solder masks can face several issues, however: However, during pcb manufacturing, various problems. Some of the most common solder mask issues include pinholes, delamination, overcuring, and undercuring. The solder mask is a thin layer of polymer applied to the surface of the pcb to protect the underlying copper circuit and provide insulation. Soldermask adhesion problems occur when the soldermask fails to bond properly to the pcb surface, leading to peeling, flaking, or lifting. Solder resist ink is not even attached to the plate surface. Pinholes are tiny holes or voids that can appear on the surface of the cured solder mask,. Crazing, delamination, peeling, and the presence of waxy or oily residues. Knowledge of prevalent solder resist defects makes it easier to identify and rectify the solder mask errors during the design phase.

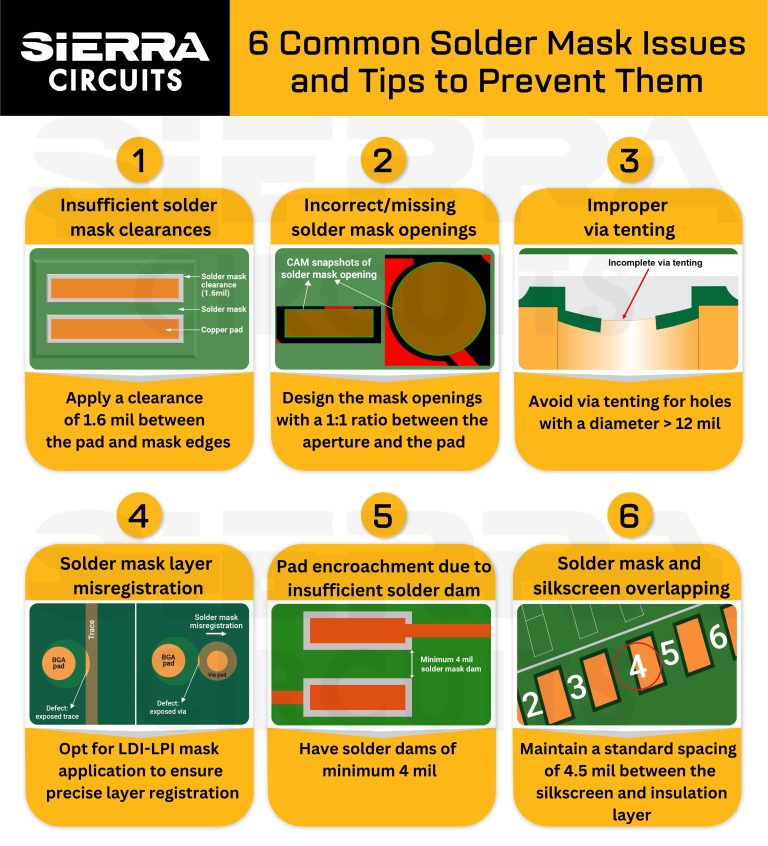

6 Common Solder Mask Errors in PCBs Sierra Circuits

Solder Mask Problems Some of the most common solder mask issues include pinholes, delamination, overcuring, and undercuring. Common pcb soldermask problems & solutions. Solder mask is a critical layer of insulative lacquer applied to a printed circuit board (pcb) that prevents solder from bridging between conductive traces and causing shorts. Pinholes are tiny holes or voids that can appear on the surface of the cured solder mask,. Knowledge of prevalent solder resist defects makes it easier to identify and rectify the solder mask errors during the design phase. Some of the most common solder mask issues include pinholes, delamination, overcuring, and undercuring. Here are some of the most common problems encountered with pcb soldermask: However, during pcb manufacturing, various problems. Soldermask adhesion problems occur when the soldermask fails to bond properly to the pcb surface, leading to peeling, flaking, or lifting. Solder masks can face several issues, however: Crazing, delamination, peeling, and the presence of waxy or oily residues. Mixing time for soldermask ink. Solder resist ink is not even attached to the plate surface. The solder mask is a thin layer of polymer applied to the surface of the pcb to protect the underlying copper circuit and provide insulation.

From www.solder.net

Solder Mask Repair and Coating Services at BEST Inc Solder Mask Problems Here are some of the most common problems encountered with pcb soldermask: Solder resist ink is not even attached to the plate surface. However, during pcb manufacturing, various problems. Soldermask adhesion problems occur when the soldermask fails to bond properly to the pcb surface, leading to peeling, flaking, or lifting. Pinholes are tiny holes or voids that can appear on. Solder Mask Problems.

From resources.orcad.com

Guide to PCB Solder Mask Defect Solder Mask Problems Solder masks can face several issues, however: Common pcb soldermask problems & solutions. Here are some of the most common problems encountered with pcb soldermask: Knowledge of prevalent solder resist defects makes it easier to identify and rectify the solder mask errors during the design phase. Pinholes are tiny holes or voids that can appear on the surface of the. Solder Mask Problems.

From www.protoexpress.com

What is Solder Mask Layer? Sierra Circuits Solder Mask Problems Here are some of the most common problems encountered with pcb soldermask: Some of the most common solder mask issues include pinholes, delamination, overcuring, and undercuring. Common pcb soldermask problems & solutions. Soldermask adhesion problems occur when the soldermask fails to bond properly to the pcb surface, leading to peeling, flaking, or lifting. Solder resist ink is not even attached. Solder Mask Problems.

From www.protoexpress.com

6 Common Solder Mask Errors in PCBs Sierra Circuits Solder Mask Problems Crazing, delamination, peeling, and the presence of waxy or oily residues. Some of the most common solder mask issues include pinholes, delamination, overcuring, and undercuring. Solder mask is a critical layer of insulative lacquer applied to a printed circuit board (pcb) that prevents solder from bridging between conductive traces and causing shorts. The solder mask is a thin layer of. Solder Mask Problems.

From www.protoexpress.com

6 Common Solder Mask Errors in PCBs Sierra Circuits Solder Mask Problems Solder masks can face several issues, however: However, during pcb manufacturing, various problems. Soldermask adhesion problems occur when the soldermask fails to bond properly to the pcb surface, leading to peeling, flaking, or lifting. Solder mask is a critical layer of insulative lacquer applied to a printed circuit board (pcb) that prevents solder from bridging between conductive traces and causing. Solder Mask Problems.

From www.protoexpress.com

6 Common Solder Mask Errors in PCBs Sierra Circuits Solder Mask Problems Common pcb soldermask problems & solutions. Here are some of the most common problems encountered with pcb soldermask: Soldermask adhesion problems occur when the soldermask fails to bond properly to the pcb surface, leading to peeling, flaking, or lifting. Solder masks can face several issues, however: Solder resist ink is not even attached to the plate surface. However, during pcb. Solder Mask Problems.

From www.nextpcb.com

Solder Mask Expansion An Essential Consideration in PCB Design and Solder Mask Problems Solder masks can face several issues, however: Crazing, delamination, peeling, and the presence of waxy or oily residues. Solder resist ink is not even attached to the plate surface. Some of the most common solder mask issues include pinholes, delamination, overcuring, and undercuring. The solder mask is a thin layer of polymer applied to the surface of the pcb to. Solder Mask Problems.

From hilelectronic.com

How Solder Masks Improve PCB Assembly and Reliability Solder Mask Problems Solder mask is a critical layer of insulative lacquer applied to a printed circuit board (pcb) that prevents solder from bridging between conductive traces and causing shorts. Mixing time for soldermask ink. Solder masks can face several issues, however: Common pcb soldermask problems & solutions. Here are some of the most common problems encountered with pcb soldermask: Knowledge of prevalent. Solder Mask Problems.

From www.protoexpress.com

6 Common Solder Mask Errors in PCBs Sierra Circuits Solder Mask Problems Common pcb soldermask problems & solutions. Solder mask is a critical layer of insulative lacquer applied to a printed circuit board (pcb) that prevents solder from bridging between conductive traces and causing shorts. Knowledge of prevalent solder resist defects makes it easier to identify and rectify the solder mask errors during the design phase. Soldermask adhesion problems occur when the. Solder Mask Problems.

From hilelectronic.com

How Solder Masks Improve PCB Assembly and Reliability Solder Mask Problems Solder resist ink is not even attached to the plate surface. Knowledge of prevalent solder resist defects makes it easier to identify and rectify the solder mask errors during the design phase. Mixing time for soldermask ink. Crazing, delamination, peeling, and the presence of waxy or oily residues. Here are some of the most common problems encountered with pcb soldermask:. Solder Mask Problems.

From www.protoexpress.com

6 Common Solder Mask Errors in PCBs Sierra Circuits Solder Mask Problems Knowledge of prevalent solder resist defects makes it easier to identify and rectify the solder mask errors during the design phase. Here are some of the most common problems encountered with pcb soldermask: Pinholes are tiny holes or voids that can appear on the surface of the cured solder mask,. Solder mask is a critical layer of insulative lacquer applied. Solder Mask Problems.

From electronics.stackexchange.com

pcb Problem isolating vias. Solder mask offset Electrical Solder Mask Problems However, during pcb manufacturing, various problems. Solder masks can face several issues, however: Common pcb soldermask problems & solutions. Mixing time for soldermask ink. The solder mask is a thin layer of polymer applied to the surface of the pcb to protect the underlying copper circuit and provide insulation. Solder resist ink is not even attached to the plate surface.. Solder Mask Problems.

From randy-clemmons.blogspot.com

PCB Designer Soldermask on viaholes with ENIG finish. Solder Mask Problems Knowledge of prevalent solder resist defects makes it easier to identify and rectify the solder mask errors during the design phase. Pinholes are tiny holes or voids that can appear on the surface of the cured solder mask,. Some of the most common solder mask issues include pinholes, delamination, overcuring, and undercuring. The solder mask is a thin layer of. Solder Mask Problems.

From www.wellpcb.com

6 Steps To Understand The Solder Mask And How To Design Solder Mask Problems Common pcb soldermask problems & solutions. The solder mask is a thin layer of polymer applied to the surface of the pcb to protect the underlying copper circuit and provide insulation. Solder masks can face several issues, however: However, during pcb manufacturing, various problems. Here are some of the most common problems encountered with pcb soldermask: Crazing, delamination, peeling, and. Solder Mask Problems.

From hilelectronic.com

What Does Solder Mask Bridge Mean and How Can You Prevent It Solder Mask Problems Soldermask adhesion problems occur when the soldermask fails to bond properly to the pcb surface, leading to peeling, flaking, or lifting. Here are some of the most common problems encountered with pcb soldermask: Knowledge of prevalent solder resist defects makes it easier to identify and rectify the solder mask errors during the design phase. Solder masks can face several issues,. Solder Mask Problems.

From www.pcbaaa.com

PCB solder mask an ultimate guide for beginners IBE Electronics Solder Mask Problems Some of the most common solder mask issues include pinholes, delamination, overcuring, and undercuring. Crazing, delamination, peeling, and the presence of waxy or oily residues. Common pcb soldermask problems & solutions. Solder masks can face several issues, however: Soldermask adhesion problems occur when the soldermask fails to bond properly to the pcb surface, leading to peeling, flaking, or lifting. Solder. Solder Mask Problems.

From www.protoexpress.com

6 Common Solder Mask Errors in PCBs Sierra Circuits Solder Mask Problems Solder masks can face several issues, however: Soldermask adhesion problems occur when the soldermask fails to bond properly to the pcb surface, leading to peeling, flaking, or lifting. Some of the most common solder mask issues include pinholes, delamination, overcuring, and undercuring. Solder mask is a critical layer of insulative lacquer applied to a printed circuit board (pcb) that prevents. Solder Mask Problems.

From www.linkedin.com

Common Solder Mask Issues With PCBs Solder Mask Problems Here are some of the most common problems encountered with pcb soldermask: Solder mask is a critical layer of insulative lacquer applied to a printed circuit board (pcb) that prevents solder from bridging between conductive traces and causing shorts. Some of the most common solder mask issues include pinholes, delamination, overcuring, and undercuring. Knowledge of prevalent solder resist defects makes. Solder Mask Problems.

From electronics.stackexchange.com

pcb Problem isolating vias. Solder mask offset Electrical Solder Mask Problems Here are some of the most common problems encountered with pcb soldermask: Solder resist ink is not even attached to the plate surface. Common pcb soldermask problems & solutions. The solder mask is a thin layer of polymer applied to the surface of the pcb to protect the underlying copper circuit and provide insulation. Soldermask adhesion problems occur when the. Solder Mask Problems.

From reversepcb.com

How to Solder Mask PCBs The Basics and Common Mistakes Solder Mask Problems Soldermask adhesion problems occur when the soldermask fails to bond properly to the pcb surface, leading to peeling, flaking, or lifting. However, during pcb manufacturing, various problems. Solder mask is a critical layer of insulative lacquer applied to a printed circuit board (pcb) that prevents solder from bridging between conductive traces and causing shorts. Common pcb soldermask problems & solutions.. Solder Mask Problems.

From www.linkedin.com

What is Peelable Solder Mask? Solder Mask Problems Some of the most common solder mask issues include pinholes, delamination, overcuring, and undercuring. Solder mask is a critical layer of insulative lacquer applied to a printed circuit board (pcb) that prevents solder from bridging between conductive traces and causing shorts. Knowledge of prevalent solder resist defects makes it easier to identify and rectify the solder mask errors during the. Solder Mask Problems.

From www.raypcb.com

What is the Significance of Solder Mask Defined Pads in Solder Pad PCBs Solder Mask Problems Here are some of the most common problems encountered with pcb soldermask: Knowledge of prevalent solder resist defects makes it easier to identify and rectify the solder mask errors during the design phase. Mixing time for soldermask ink. Solder mask is a critical layer of insulative lacquer applied to a printed circuit board (pcb) that prevents solder from bridging between. Solder Mask Problems.

From resources.pcb.cadence.com

The Designer’s Guide to PCB Solder Defects Solder Mask Problems Solder mask is a critical layer of insulative lacquer applied to a printed circuit board (pcb) that prevents solder from bridging between conductive traces and causing shorts. Soldermask adhesion problems occur when the soldermask fails to bond properly to the pcb surface, leading to peeling, flaking, or lifting. Knowledge of prevalent solder resist defects makes it easier to identify and. Solder Mask Problems.

From www.reddit.com

White Solder Mask PCB Issues and Manufacturers PrintedCircuitBoard Solder Mask Problems Here are some of the most common problems encountered with pcb soldermask: Pinholes are tiny holes or voids that can appear on the surface of the cured solder mask,. The solder mask is a thin layer of polymer applied to the surface of the pcb to protect the underlying copper circuit and provide insulation. Crazing, delamination, peeling, and the presence. Solder Mask Problems.

From www.nextpcb.com

Solder Mask Material Everything You Need to Know NextPCB Solder Mask Problems Crazing, delamination, peeling, and the presence of waxy or oily residues. However, during pcb manufacturing, various problems. Soldermask adhesion problems occur when the soldermask fails to bond properly to the pcb surface, leading to peeling, flaking, or lifting. Mixing time for soldermask ink. The solder mask is a thin layer of polymer applied to the surface of the pcb to. Solder Mask Problems.

From www.jigsawcad.com

Let the experts talk about Can you remove solder mask [Solved] Solder Mask Problems Some of the most common solder mask issues include pinholes, delamination, overcuring, and undercuring. Common pcb soldermask problems & solutions. Soldermask adhesion problems occur when the soldermask fails to bond properly to the pcb surface, leading to peeling, flaking, or lifting. Here are some of the most common problems encountered with pcb soldermask: Knowledge of prevalent solder resist defects makes. Solder Mask Problems.

From www.circuits-diy.com

PCB Solder Mask What is it & Why do you need it? Solder Mask Problems The solder mask is a thin layer of polymer applied to the surface of the pcb to protect the underlying copper circuit and provide insulation. Knowledge of prevalent solder resist defects makes it easier to identify and rectify the solder mask errors during the design phase. Here are some of the most common problems encountered with pcb soldermask: Some of. Solder Mask Problems.

From www.nextpcb.com

Solder Mask Expansion An Essential Consideration in PCB Design and Solder Mask Problems Common pcb soldermask problems & solutions. Here are some of the most common problems encountered with pcb soldermask: Crazing, delamination, peeling, and the presence of waxy or oily residues. Solder masks can face several issues, however: Solder resist ink is not even attached to the plate surface. The solder mask is a thin layer of polymer applied to the surface. Solder Mask Problems.

From electronics.stackexchange.com

pcb Where do these solder mask pot holes/marks come from Solder Mask Problems Pinholes are tiny holes or voids that can appear on the surface of the cured solder mask,. Solder resist ink is not even attached to the plate surface. Soldermask adhesion problems occur when the soldermask fails to bond properly to the pcb surface, leading to peeling, flaking, or lifting. Common pcb soldermask problems & solutions. Mixing time for soldermask ink.. Solder Mask Problems.

From www.protoexpress.com

6 Common Solder Mask Errors in PCBs Sierra Circuits Solder Mask Problems Crazing, delamination, peeling, and the presence of waxy or oily residues. Mixing time for soldermask ink. Pinholes are tiny holes or voids that can appear on the surface of the cured solder mask,. Soldermask adhesion problems occur when the soldermask fails to bond properly to the pcb surface, leading to peeling, flaking, or lifting. Solder mask is a critical layer. Solder Mask Problems.

From hilelectronic.com

What Does Solder Mask Bridge Mean and How Can You Prevent It Solder Mask Problems Solder resist ink is not even attached to the plate surface. Crazing, delamination, peeling, and the presence of waxy or oily residues. Knowledge of prevalent solder resist defects makes it easier to identify and rectify the solder mask errors during the design phase. Solder mask is a critical layer of insulative lacquer applied to a printed circuit board (pcb) that. Solder Mask Problems.

From www.mclpcb.com

PCB Issue Guide Solutions for Common PCB Problems Solder Mask Problems The solder mask is a thin layer of polymer applied to the surface of the pcb to protect the underlying copper circuit and provide insulation. Crazing, delamination, peeling, and the presence of waxy or oily residues. Here are some of the most common problems encountered with pcb soldermask: Solder resist ink is not even attached to the plate surface. Knowledge. Solder Mask Problems.

From www.bestpcbs.com

Key Challenges in Solder Mask Printing for Heavy Copper PCBs PCB Solder Mask Problems Solder masks can face several issues, however: Crazing, delamination, peeling, and the presence of waxy or oily residues. Here are some of the most common problems encountered with pcb soldermask: Soldermask adhesion problems occur when the soldermask fails to bond properly to the pcb surface, leading to peeling, flaking, or lifting. Pinholes are tiny holes or voids that can appear. Solder Mask Problems.

From www.aimsolder.com

FluxCrazed Solder Mask AIM Solder Solder Mask Problems Knowledge of prevalent solder resist defects makes it easier to identify and rectify the solder mask errors during the design phase. Pinholes are tiny holes or voids that can appear on the surface of the cured solder mask,. Some of the most common solder mask issues include pinholes, delamination, overcuring, and undercuring. Solder masks can face several issues, however: However,. Solder Mask Problems.

From www.nextpcb.com

What Is Solder Mask Dam? — NextPCB Solder Mask Problems Solder masks can face several issues, however: Some of the most common solder mask issues include pinholes, delamination, overcuring, and undercuring. Soldermask adhesion problems occur when the soldermask fails to bond properly to the pcb surface, leading to peeling, flaking, or lifting. However, during pcb manufacturing, various problems. Mixing time for soldermask ink. Solder resist ink is not even attached. Solder Mask Problems.