Spur Gears Cutting . We offer full custom gear cutting specializing in manufacturing a wide variety of gear types. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. (inch units applicable for constants) spur gear design calculator. Spur gears have pitched surfaces around their circumference. To machine gear to the given module and number of teeth in the given work piece. Choose from our selection of spur gear milling cutters, including over 50 products in a wide range of styles and sizes. I also made a short video of my. Where, blank diameter = (z + 2) m. Spur gear cutting on milling machine : As you’ll notice in the image below, they also have shafts and teeth lines that are parallel to the. Tooth width = 1.5708 m. Our capabilities include spur, cast steel helical,. Tooth depth = 2.25 m. In stock and ready to ship. Calculate the gear tooth proportions.

from www.alamy.com

As you’ll notice in the image below, they also have shafts and teeth lines that are parallel to the. This article will demonstrate a simple way to cut aluminum spur gears on a small desktop cnc hobby mill. (inch units applicable for constants) spur gear design calculator. Spur gears have pitched surfaces around their circumference. Spur gear cutting on milling machine : 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Choose from our selection of spur gear milling cutters, including over 50 products in a wide range of styles and sizes. In stock and ready to ship. We offer full custom gear cutting specializing in manufacturing a wide variety of gear types. Tooth width = 1.5708 m.

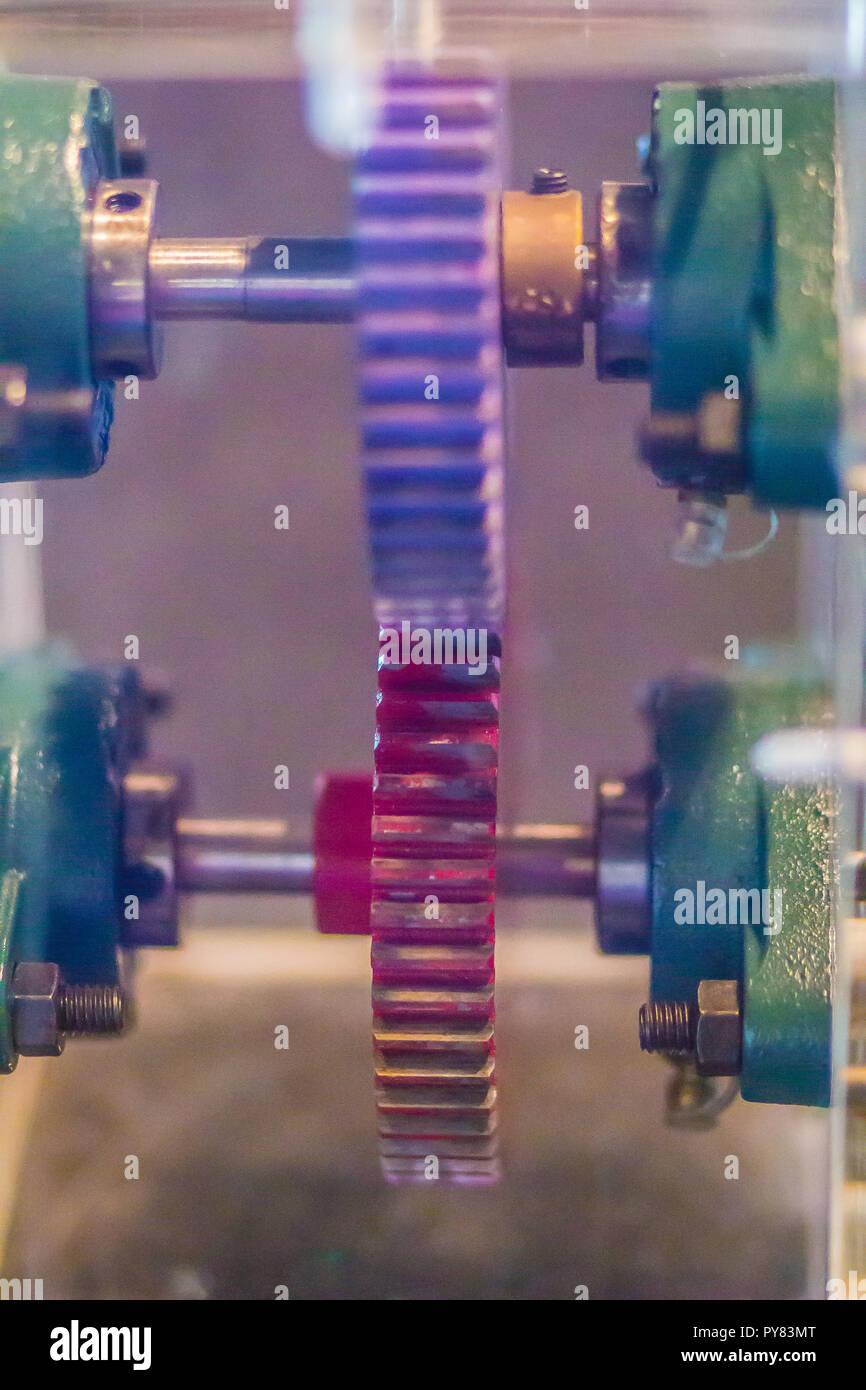

Spur gears or straightcut gears are the simplest type of gear and

Spur Gears Cutting Calculate the gear tooth proportions. We offer full custom gear cutting specializing in manufacturing a wide variety of gear types. Where, blank diameter = (z + 2) m. Tooth width = 1.5708 m. One of the most common ways of making spur gears is by using a dividing head on a milling machine. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Calculate the gear tooth proportions. This article will demonstrate a simple way to cut aluminum spur gears on a small desktop cnc hobby mill. Choose from our selection of spur gear milling cutters, including over 50 products in a wide range of styles and sizes. I also made a short video of my. Our capabilities include spur, cast steel helical,. Spur gears have pitched surfaces around their circumference. As you’ll notice in the image below, they also have shafts and teeth lines that are parallel to the. In stock and ready to ship. (inch units applicable for constants) spur gear design calculator. Spur gear cutting on milling machine :

From www.youtube.com

Cutting a Spur Gear using a Dividing Head YouTube Spur Gears Cutting Spur gear cutting on milling machine : Spur gears have pitched surfaces around their circumference. We offer full custom gear cutting specializing in manufacturing a wide variety of gear types. Choose from our selection of spur gear milling cutters, including over 50 products in a wide range of styles and sizes. Tooth depth = 2.25 m. 40 rows spur gear. Spur Gears Cutting.

From vestavia.eu

spur gears cutting Spur Gears Cutting Where, blank diameter = (z + 2) m. One of the most common ways of making spur gears is by using a dividing head on a milling machine. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Spur gear cutting on milling machine : To machine gear to the given module and number of. Spur Gears Cutting.

From www.indiamart.com

Spur Gear Cutting Services in Faridabad Spur Gears Cutting Spur gear cutting on milling machine : To machine gear to the given module and number of teeth in the given work piece. This article will demonstrate a simple way to cut aluminum spur gears on a small desktop cnc hobby mill. Choose from our selection of spur gear milling cutters, including over 50 products in a wide range of. Spur Gears Cutting.

From cncphilosophy.com

Gear cutting on a milling machine A Cnc hobbyist's guide Spur Gears Cutting (inch units applicable for constants) spur gear design calculator. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. We offer full custom gear cutting specializing in manufacturing a wide variety of gear types. Where, blank diameter = (z + 2) m. Our capabilities include spur, cast steel helical,. Tooth width = 1.5708 m. Spur. Spur Gears Cutting.

From www.linkedin.com

Understanding Spur Gears The Basics and Applications Spur Gears Cutting Calculate the gear tooth proportions. This article will demonstrate a simple way to cut aluminum spur gears on a small desktop cnc hobby mill. Our capabilities include spur, cast steel helical,. We offer full custom gear cutting specializing in manufacturing a wide variety of gear types. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional. Spur Gears Cutting.

From johnfsworkshop.org

Making large spur gears using a rotary table john f's Spur Gears Cutting Tooth depth = 2.25 m. As you’ll notice in the image below, they also have shafts and teeth lines that are parallel to the. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Choose from our selection of spur gear milling cutters, including over 50 products in a wide range of styles and sizes.. Spur Gears Cutting.

From www.iqsdirectory.com

Spur Gears Types, Uses, Benefits, and Manufacturing Spur Gears Cutting Where, blank diameter = (z + 2) m. Tooth depth = 2.25 m. We offer full custom gear cutting specializing in manufacturing a wide variety of gear types. I also made a short video of my. In stock and ready to ship. As you’ll notice in the image below, they also have shafts and teeth lines that are parallel to. Spur Gears Cutting.

From www.youtube.com

How to cut spur gears on a metal lathe with just a vertical mill slide Spur Gears Cutting Spur gear cutting on milling machine : One of the most common ways of making spur gears is by using a dividing head on a milling machine. In stock and ready to ship. Our capabilities include spur, cast steel helical,. As you’ll notice in the image below, they also have shafts and teeth lines that are parallel to the. Choose. Spur Gears Cutting.

From machiningtool.blogspot.com

Machining DIY spur gear making for change gear part 3 Spur Gears Cutting One of the most common ways of making spur gears is by using a dividing head on a milling machine. In stock and ready to ship. Calculate the gear tooth proportions. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Spur gear cutting on milling machine : Our capabilities include spur, cast steel helical,.. Spur Gears Cutting.

From drivetrainhub.com

Spur Gears Geometry of spur gears and gear meshes Spur Gears Cutting Our capabilities include spur, cast steel helical,. Calculate the gear tooth proportions. To machine gear to the given module and number of teeth in the given work piece. Tooth depth = 2.25 m. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. This article will demonstrate a simple way to cut aluminum spur gears. Spur Gears Cutting.

From www.youtube.com

BIG SPUR GEAR TEETH CUTTING YouTube Spur Gears Cutting In stock and ready to ship. Tooth depth = 2.25 m. Our capabilities include spur, cast steel helical,. Calculate the gear tooth proportions. Spur gears have pitched surfaces around their circumference. (inch units applicable for constants) spur gear design calculator. Tooth width = 1.5708 m. Where, blank diameter = (z + 2) m. Spur gear cutting on milling machine : Spur Gears Cutting.

From blog.thepipingmart.com

Gear Cutting The Process of Machining Gears ThePipingMart Blog Spur Gears Cutting To machine gear to the given module and number of teeth in the given work piece. Spur gear cutting on milling machine : Tooth depth = 2.25 m. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Where, blank diameter = (z + 2) m. This article will demonstrate a simple way to cut. Spur Gears Cutting.

From www.iqsdirectory.com

Bevel Gear What Are They? How Do They Work? Types and Uses Spur Gears Cutting Choose from our selection of spur gear milling cutters, including over 50 products in a wide range of styles and sizes. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. We offer full custom gear cutting specializing in manufacturing a wide variety of gear types. Our capabilities include spur, cast steel helical,. Spur gear. Spur Gears Cutting.

From www.youtube.com

spur gear cutting using endmills YouTube Spur Gears Cutting Choose from our selection of spur gear milling cutters, including over 50 products in a wide range of styles and sizes. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Calculate the gear tooth proportions. Tooth depth = 2.25 m. Our capabilities include spur, cast steel helical,. To machine gear to the given module. Spur Gears Cutting.

From www.youtube.com

Cutting a spur gear YouTube Spur Gears Cutting As you’ll notice in the image below, they also have shafts and teeth lines that are parallel to the. Choose from our selection of spur gear milling cutters, including over 50 products in a wide range of styles and sizes. Spur gear cutting on milling machine : 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical. Spur Gears Cutting.

From www.newmonteng.co.uk

Spur Gears Gear Cutting Newmont Engineering Spur Gears Cutting One of the most common ways of making spur gears is by using a dividing head on a milling machine. Tooth width = 1.5708 m. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Choose from our selection of spur gear milling cutters, including over 50 products in a wide range of styles and. Spur Gears Cutting.

From www.youtube.com

How to make spur gear cutting on Milling machines YouTube Spur Gears Cutting (inch units applicable for constants) spur gear design calculator. Choose from our selection of spur gear milling cutters, including over 50 products in a wide range of styles and sizes. As you’ll notice in the image below, they also have shafts and teeth lines that are parallel to the. Our capabilities include spur, cast steel helical,. Spur gears have pitched. Spur Gears Cutting.

From www.lmrgeartech.com

Gear cutting capacity LMR Gearcutting Spur Gears Cutting Our capabilities include spur, cast steel helical,. As you’ll notice in the image below, they also have shafts and teeth lines that are parallel to the. Tooth width = 1.5708 m. One of the most common ways of making spur gears is by using a dividing head on a milling machine. Calculate the gear tooth proportions. This article will demonstrate. Spur Gears Cutting.

From www.youtube.com

manufacturing of the Spur Gear Cutting key formation YouTube Spur Gears Cutting (inch units applicable for constants) spur gear design calculator. One of the most common ways of making spur gears is by using a dividing head on a milling machine. Choose from our selection of spur gear milling cutters, including over 50 products in a wide range of styles and sizes. To machine gear to the given module and number of. Spur Gears Cutting.

From www.youtube.com

spur gear cutting YouTube Spur Gears Cutting We offer full custom gear cutting specializing in manufacturing a wide variety of gear types. Choose from our selection of spur gear milling cutters, including over 50 products in a wide range of styles and sizes. Tooth width = 1.5708 m. This article will demonstrate a simple way to cut aluminum spur gears on a small desktop cnc hobby mill.. Spur Gears Cutting.

From www.youtube.com

Spur gear cutting using CNC machine YouTube Spur Gears Cutting Tooth depth = 2.25 m. As you’ll notice in the image below, they also have shafts and teeth lines that are parallel to the. (inch units applicable for constants) spur gear design calculator. Spur gears have pitched surfaces around their circumference. In stock and ready to ship. Where, blank diameter = (z + 2) m. Choose from our selection of. Spur Gears Cutting.

From autopickles.com

How Do Straight Cut Gears Work? Autopickles Spur Gears Cutting One of the most common ways of making spur gears is by using a dividing head on a milling machine. In stock and ready to ship. To machine gear to the given module and number of teeth in the given work piece. Tooth depth = 2.25 m. Spur gears have pitched surfaces around their circumference. Our capabilities include spur, cast. Spur Gears Cutting.

From www.youtube.com

Spur gear cutting operation on milling machine india technology Spur Gears Cutting Our capabilities include spur, cast steel helical,. One of the most common ways of making spur gears is by using a dividing head on a milling machine. Where, blank diameter = (z + 2) m. Spur gears have pitched surfaces around their circumference. Tooth depth = 2.25 m. This article will demonstrate a simple way to cut aluminum spur gears. Spur Gears Cutting.

From www.youtube.com

DIY spur gear cutting YouTube Spur Gears Cutting 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. I also made a short video of my. Where, blank diameter = (z + 2) m. Tooth depth = 2.25 m. This article will demonstrate a simple way to cut aluminum spur gears on a small desktop cnc hobby mill. (inch units applicable for constants). Spur Gears Cutting.

From www.youtube.com

Spur gear cutting operation YouTube Spur Gears Cutting Our capabilities include spur, cast steel helical,. One of the most common ways of making spur gears is by using a dividing head on a milling machine. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. In stock and ready to ship. Calculate the gear tooth proportions. Where, blank diameter = (z + 2). Spur Gears Cutting.

From www.youtube.com

Fellows gear shaper machine 44 teeth spur gear cutting 1.5 module Spur Gears Cutting Calculate the gear tooth proportions. Tooth depth = 2.25 m. In stock and ready to ship. I also made a short video of my. Our capabilities include spur, cast steel helical,. We offer full custom gear cutting specializing in manufacturing a wide variety of gear types. Where, blank diameter = (z + 2) m. Spur gear cutting on milling machine. Spur Gears Cutting.

From www.lampin.com

Hobbing and Gear Cutting Services by Lampin Co. Spur Gears Cutting Spur gears have pitched surfaces around their circumference. To machine gear to the given module and number of teeth in the given work piece. Tooth depth = 2.25 m. In stock and ready to ship. Choose from our selection of spur gear milling cutters, including over 50 products in a wide range of styles and sizes. Calculate the gear tooth. Spur Gears Cutting.

From www.youtube.com

Heavy spur gear cutting on manual milling machine YouTube Spur Gears Cutting One of the most common ways of making spur gears is by using a dividing head on a milling machine. In stock and ready to ship. Tooth depth = 2.25 m. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. (inch units applicable for constants) spur gear design calculator. As you’ll notice in the. Spur Gears Cutting.

From www.youtube.com

Gear Cutting Using a Mini Mill and a Rotating Table YouTube Spur Gears Cutting Where, blank diameter = (z + 2) m. This article will demonstrate a simple way to cut aluminum spur gears on a small desktop cnc hobby mill. (inch units applicable for constants) spur gear design calculator. We offer full custom gear cutting specializing in manufacturing a wide variety of gear types. Our capabilities include spur, cast steel helical,. I also. Spur Gears Cutting.

From www.youtube.com

HOW TO CUT SPUR GEARS ON A MILLING MACHINE USING A DIVIDING HEAD, MARC Spur Gears Cutting Spur gears have pitched surfaces around their circumference. As you’ll notice in the image below, they also have shafts and teeth lines that are parallel to the. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. We offer full custom gear cutting specializing in manufacturing a wide variety of gear types. This article will. Spur Gears Cutting.

From www.youtube.com

spur gear cutting process shorts YouTube Spur Gears Cutting One of the most common ways of making spur gears is by using a dividing head on a milling machine. This article will demonstrate a simple way to cut aluminum spur gears on a small desktop cnc hobby mill. We offer full custom gear cutting specializing in manufacturing a wide variety of gear types. Calculate the gear tooth proportions. As. Spur Gears Cutting.

From khkgears.net

Production Processes of Spur Gear KHK Gears Spur Gears Cutting As you’ll notice in the image below, they also have shafts and teeth lines that are parallel to the. To machine gear to the given module and number of teeth in the given work piece. Where, blank diameter = (z + 2) m. Tooth width = 1.5708 m. Tooth depth = 2.25 m. 40 rows spur gear design formula for. Spur Gears Cutting.

From www.researchgate.net

Typical cutting methods of spur gears 2 (a) shaping, (b) forming, and Spur Gears Cutting We offer full custom gear cutting specializing in manufacturing a wide variety of gear types. (inch units applicable for constants) spur gear design calculator. One of the most common ways of making spur gears is by using a dividing head on a milling machine. Spur gear cutting on milling machine : To machine gear to the given module and number. Spur Gears Cutting.

From apacinfrastructure.com.au

Gear Cutting Precision & General Fabrication Services Welding Spur Gears Cutting Where, blank diameter = (z + 2) m. Choose from our selection of spur gear milling cutters, including over 50 products in a wide range of styles and sizes. This article will demonstrate a simple way to cut aluminum spur gears on a small desktop cnc hobby mill. Spur gears have pitched surfaces around their circumference. 40 rows spur gear. Spur Gears Cutting.

From www.alamy.com

Spur gears or straightcut gears are the simplest type of gear and Spur Gears Cutting 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. In stock and ready to ship. Spur gears have pitched surfaces around their circumference. Choose from our selection of spur gear milling cutters, including over 50 products in a wide range of styles and sizes. This article will demonstrate a simple way to cut aluminum. Spur Gears Cutting.