Optical Lens Inspection . When a lens or lens system is introduced, visual inspection becomes optical inspection. A lens can be identified automatically at the time of inspection, thanks to code and engraving reading capabilities. These systems use optic lenses,. There are many examples of optical inspection systems. Defects matter when it comes to optical surfaces, but knowing what types of flaws are acceptable requires a combination of surface inspection. For batch processes, «smart tray management» makes it. 1.1 this procedure describes the visual examination that may be. A vision inspection system, also called a machine vision system, automates the process of visually assessing your products at the end of the production line. Procedure for visual and optical inspection. Leverage traditional and artificial intelligence (ai) vision inspection to automatically find lens defects and anomalies.

from www.yilens-spectaclelens.com

There are many examples of optical inspection systems. 1.1 this procedure describes the visual examination that may be. A lens can be identified automatically at the time of inspection, thanks to code and engraving reading capabilities. These systems use optic lenses,. When a lens or lens system is introduced, visual inspection becomes optical inspection. Procedure for visual and optical inspection. A vision inspection system, also called a machine vision system, automates the process of visually assessing your products at the end of the production line. Leverage traditional and artificial intelligence (ai) vision inspection to automatically find lens defects and anomalies. For batch processes, «smart tray management» makes it. Defects matter when it comes to optical surfaces, but knowing what types of flaws are acceptable requires a combination of surface inspection.

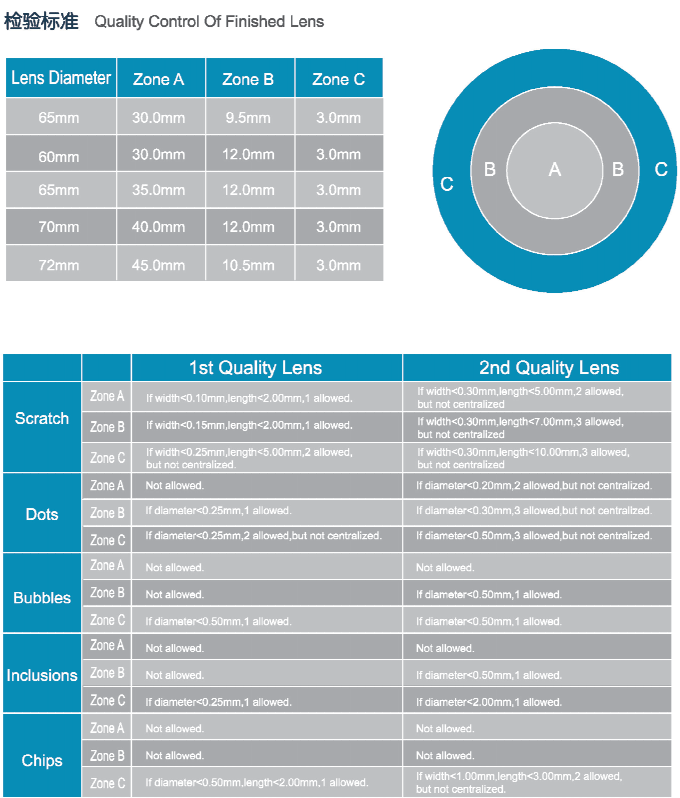

LENS INSPECTION STANDARD

Optical Lens Inspection For batch processes, «smart tray management» makes it. There are many examples of optical inspection systems. For batch processes, «smart tray management» makes it. 1.1 this procedure describes the visual examination that may be. Procedure for visual and optical inspection. These systems use optic lenses,. Leverage traditional and artificial intelligence (ai) vision inspection to automatically find lens defects and anomalies. A lens can be identified automatically at the time of inspection, thanks to code and engraving reading capabilities. Defects matter when it comes to optical surfaces, but knowing what types of flaws are acceptable requires a combination of surface inspection. A vision inspection system, also called a machine vision system, automates the process of visually assessing your products at the end of the production line. When a lens or lens system is introduced, visual inspection becomes optical inspection.

From www.youtube.com

MEASUREMENT OF THE DIMENSIONS OF OPTICAL LENSES. CREATION OF AN Optical Lens Inspection 1.1 this procedure describes the visual examination that may be. For batch processes, «smart tray management» makes it. There are many examples of optical inspection systems. Leverage traditional and artificial intelligence (ai) vision inspection to automatically find lens defects and anomalies. Defects matter when it comes to optical surfaces, but knowing what types of flaws are acceptable requires a combination. Optical Lens Inspection.

From www.anyrgb.com

Telecentric Lens, Automated optical inspection, reliability Engineering Optical Lens Inspection A vision inspection system, also called a machine vision system, automates the process of visually assessing your products at the end of the production line. A lens can be identified automatically at the time of inspection, thanks to code and engraving reading capabilities. 1.1 this procedure describes the visual examination that may be. For batch processes, «smart tray management» makes. Optical Lens Inspection.

From www.yilens-spectaclelens.com

LENS INSPECTION STANDARD Optical Lens Inspection Leverage traditional and artificial intelligence (ai) vision inspection to automatically find lens defects and anomalies. When a lens or lens system is introduced, visual inspection becomes optical inspection. A vision inspection system, also called a machine vision system, automates the process of visually assessing your products at the end of the production line. These systems use optic lenses,. A lens. Optical Lens Inspection.

From www.pressebox.com

Quality Assurance for Eyeglass Lenses New Inspection Lamps for Optical Optical Lens Inspection These systems use optic lenses,. For batch processes, «smart tray management» makes it. Procedure for visual and optical inspection. When a lens or lens system is introduced, visual inspection becomes optical inspection. A vision inspection system, also called a machine vision system, automates the process of visually assessing your products at the end of the production line. A lens can. Optical Lens Inspection.

From www.shanghai-optics.com

Lens Assembly Inspection Case Study Shanghai Optics Optical Lens Inspection A vision inspection system, also called a machine vision system, automates the process of visually assessing your products at the end of the production line. A lens can be identified automatically at the time of inspection, thanks to code and engraving reading capabilities. Leverage traditional and artificial intelligence (ai) vision inspection to automatically find lens defects and anomalies. 1.1 this. Optical Lens Inspection.

From www.corning.com

Precision Optics and Inspection Optics Precision Optical Systems Optical Lens Inspection A vision inspection system, also called a machine vision system, automates the process of visually assessing your products at the end of the production line. For batch processes, «smart tray management» makes it. 1.1 this procedure describes the visual examination that may be. When a lens or lens system is introduced, visual inspection becomes optical inspection. Leverage traditional and artificial. Optical Lens Inspection.

From www.cottandco.com

Carl Zeiss Optical Inspection / Scope Optical Lens Inspection Procedure for visual and optical inspection. A vision inspection system, also called a machine vision system, automates the process of visually assessing your products at the end of the production line. 1.1 this procedure describes the visual examination that may be. When a lens or lens system is introduced, visual inspection becomes optical inspection. Defects matter when it comes to. Optical Lens Inspection.

From www.opto-e.com

Telecentric lenses for the inspection of microplates Opto Engineering Optical Lens Inspection Leverage traditional and artificial intelligence (ai) vision inspection to automatically find lens defects and anomalies. A lens can be identified automatically at the time of inspection, thanks to code and engraving reading capabilities. 1.1 this procedure describes the visual examination that may be. When a lens or lens system is introduced, visual inspection becomes optical inspection. Procedure for visual and. Optical Lens Inspection.

From mmsis.com

Automated Optical Inspection (AOI) MMS Optical Lens Inspection Leverage traditional and artificial intelligence (ai) vision inspection to automatically find lens defects and anomalies. For batch processes, «smart tray management» makes it. 1.1 this procedure describes the visual examination that may be. There are many examples of optical inspection systems. These systems use optic lenses,. When a lens or lens system is introduced, visual inspection becomes optical inspection. Defects. Optical Lens Inspection.

From www.youtube.com

Eyeglasses Final Inspection and Verification per ANSI Standard YouTube Optical Lens Inspection A lens can be identified automatically at the time of inspection, thanks to code and engraving reading capabilities. Defects matter when it comes to optical surfaces, but knowing what types of flaws are acceptable requires a combination of surface inspection. 1.1 this procedure describes the visual examination that may be. When a lens or lens system is introduced, visual inspection. Optical Lens Inspection.

From www.attocube.com

Lens Inspection Metrology Optical Lens Inspection Leverage traditional and artificial intelligence (ai) vision inspection to automatically find lens defects and anomalies. For batch processes, «smart tray management» makes it. A lens can be identified automatically at the time of inspection, thanks to code and engraving reading capabilities. Procedure for visual and optical inspection. Defects matter when it comes to optical surfaces, but knowing what types of. Optical Lens Inspection.

From idc-gmbh.ch

Keyence VHX video microscope optical inspection lens IDC Innovation Optical Lens Inspection Defects matter when it comes to optical surfaces, but knowing what types of flaws are acceptable requires a combination of surface inspection. 1.1 this procedure describes the visual examination that may be. These systems use optic lenses,. A lens can be identified automatically at the time of inspection, thanks to code and engraving reading capabilities. There are many examples of. Optical Lens Inspection.

From www.phasics.com

Optical components and assemblies Optical testing systems Phasics Optical Lens Inspection A lens can be identified automatically at the time of inspection, thanks to code and engraving reading capabilities. Defects matter when it comes to optical surfaces, but knowing what types of flaws are acceptable requires a combination of surface inspection. 1.1 this procedure describes the visual examination that may be. These systems use optic lenses,. Leverage traditional and artificial intelligence. Optical Lens Inspection.

From www.youtube.com

Full automatic lens inspection YouTube Optical Lens Inspection Procedure for visual and optical inspection. A vision inspection system, also called a machine vision system, automates the process of visually assessing your products at the end of the production line. Defects matter when it comes to optical surfaces, but knowing what types of flaws are acceptable requires a combination of surface inspection. A lens can be identified automatically at. Optical Lens Inspection.

From www.youtube.com

Fully automatic inspection of lenses and optics YouTube Optical Lens Inspection For batch processes, «smart tray management» makes it. There are many examples of optical inspection systems. Defects matter when it comes to optical surfaces, but knowing what types of flaws are acceptable requires a combination of surface inspection. Leverage traditional and artificial intelligence (ai) vision inspection to automatically find lens defects and anomalies. 1.1 this procedure describes the visual examination. Optical Lens Inspection.

From www.optment.com

INSPECTIONHigh Precision Glass Optical Lenses, Prisms & Windows Optical Lens Inspection 1.1 this procedure describes the visual examination that may be. These systems use optic lenses,. Procedure for visual and optical inspection. For batch processes, «smart tray management» makes it. There are many examples of optical inspection systems. A vision inspection system, also called a machine vision system, automates the process of visually assessing your products at the end of the. Optical Lens Inspection.

From avantierinc.com

Optical Metrology Avantier Inc. Optical Lens Inspection For batch processes, «smart tray management» makes it. A vision inspection system, also called a machine vision system, automates the process of visually assessing your products at the end of the production line. Procedure for visual and optical inspection. 1.1 this procedure describes the visual examination that may be. There are many examples of optical inspection systems. A lens can. Optical Lens Inspection.

From www.industrialvision.co.uk

Industrial Vision Systems Contact Lens Inspection Contact Lens Optical Lens Inspection When a lens or lens system is introduced, visual inspection becomes optical inspection. There are many examples of optical inspection systems. A vision inspection system, also called a machine vision system, automates the process of visually assessing your products at the end of the production line. Leverage traditional and artificial intelligence (ai) vision inspection to automatically find lens defects and. Optical Lens Inspection.

From www.electronicsforu.com

Automated Optical Inspection In SMT Environment Must Read Optical Lens Inspection There are many examples of optical inspection systems. A vision inspection system, also called a machine vision system, automates the process of visually assessing your products at the end of the production line. When a lens or lens system is introduced, visual inspection becomes optical inspection. For batch processes, «smart tray management» makes it. These systems use optic lenses,. 1.1. Optical Lens Inspection.

From www.laserfocusworld.com

Optical Imaging Inspection applications push imaging lenses into the Optical Lens Inspection These systems use optic lenses,. For batch processes, «smart tray management» makes it. A vision inspection system, also called a machine vision system, automates the process of visually assessing your products at the end of the production line. Defects matter when it comes to optical surfaces, but knowing what types of flaws are acceptable requires a combination of surface inspection.. Optical Lens Inspection.

From www.opto-e.com

Hole inspection lenses for 360° inside view in perfect focus PCHI series Optical Lens Inspection 1.1 this procedure describes the visual examination that may be. There are many examples of optical inspection systems. Leverage traditional and artificial intelligence (ai) vision inspection to automatically find lens defects and anomalies. When a lens or lens system is introduced, visual inspection becomes optical inspection. Defects matter when it comes to optical surfaces, but knowing what types of flaws. Optical Lens Inspection.

From www.youtube.com

Inspection of optical lenses and flats with machine vision from STEMMER Optical Lens Inspection A vision inspection system, also called a machine vision system, automates the process of visually assessing your products at the end of the production line. These systems use optic lenses,. Leverage traditional and artificial intelligence (ai) vision inspection to automatically find lens defects and anomalies. Procedure for visual and optical inspection. For batch processes, «smart tray management» makes it. Defects. Optical Lens Inspection.

From www.jenoptik.com

Vision systems for optical inspection Jenoptik Optical Lens Inspection 1.1 this procedure describes the visual examination that may be. These systems use optic lenses,. Procedure for visual and optical inspection. When a lens or lens system is introduced, visual inspection becomes optical inspection. For batch processes, «smart tray management» makes it. There are many examples of optical inspection systems. Leverage traditional and artificial intelligence (ai) vision inspection to automatically. Optical Lens Inspection.

From www.jenoptik.com

UV Objective Lenses for Inspection Procedures Jenoptik Optical Lens Inspection 1.1 this procedure describes the visual examination that may be. For batch processes, «smart tray management» makes it. A lens can be identified automatically at the time of inspection, thanks to code and engraving reading capabilities. There are many examples of optical inspection systems. These systems use optic lenses,. Procedure for visual and optical inspection. A vision inspection system, also. Optical Lens Inspection.

From www.indiamart.com

Automated Optical Inspection at Rs 1950000/pack Optical Inspection Optical Lens Inspection Defects matter when it comes to optical surfaces, but knowing what types of flaws are acceptable requires a combination of surface inspection. A lens can be identified automatically at the time of inspection, thanks to code and engraving reading capabilities. Procedure for visual and optical inspection. A vision inspection system, also called a machine vision system, automates the process of. Optical Lens Inspection.

From www.esa.int

ESA Optics lab lens inspection Optical Lens Inspection These systems use optic lenses,. 1.1 this procedure describes the visual examination that may be. For batch processes, «smart tray management» makes it. A lens can be identified automatically at the time of inspection, thanks to code and engraving reading capabilities. When a lens or lens system is introduced, visual inspection becomes optical inspection. There are many examples of optical. Optical Lens Inspection.

From www.opticalquartzglass.com

Vertical Spherical Interferometer Optical Measuring Instrument For Optical Lens Inspection There are many examples of optical inspection systems. A lens can be identified automatically at the time of inspection, thanks to code and engraving reading capabilities. 1.1 this procedure describes the visual examination that may be. For batch processes, «smart tray management» makes it. Procedure for visual and optical inspection. Defects matter when it comes to optical surfaces, but knowing. Optical Lens Inspection.

From www.edmdept.com

Optical 3D Inspection Lens Set & Difference Comparison Optical Lens Inspection A lens can be identified automatically at the time of inspection, thanks to code and engraving reading capabilities. These systems use optic lenses,. 1.1 this procedure describes the visual examination that may be. When a lens or lens system is introduced, visual inspection becomes optical inspection. Procedure for visual and optical inspection. A vision inspection system, also called a machine. Optical Lens Inspection.

From www.dreamstime.com

Reflex Lens, Warranty Technical Inspection, Optical Maintenance Stock Optical Lens Inspection When a lens or lens system is introduced, visual inspection becomes optical inspection. For batch processes, «smart tray management» makes it. Leverage traditional and artificial intelligence (ai) vision inspection to automatically find lens defects and anomalies. A lens can be identified automatically at the time of inspection, thanks to code and engraving reading capabilities. These systems use optic lenses,. 1.1. Optical Lens Inspection.

From www.zeiss.pt

Como são fabricadas as lentes oftálmicas? Optical Lens Inspection Procedure for visual and optical inspection. Defects matter when it comes to optical surfaces, but knowing what types of flaws are acceptable requires a combination of surface inspection. 1.1 this procedure describes the visual examination that may be. For batch processes, «smart tray management» makes it. These systems use optic lenses,. Leverage traditional and artificial intelligence (ai) vision inspection to. Optical Lens Inspection.

From chinarke.en.made-in-china.com

China Optical Lens Use for Fastener Sorting Machine Vision Inspection Optical Lens Inspection These systems use optic lenses,. When a lens or lens system is introduced, visual inspection becomes optical inspection. There are many examples of optical inspection systems. 1.1 this procedure describes the visual examination that may be. Defects matter when it comes to optical surfaces, but knowing what types of flaws are acceptable requires a combination of surface inspection. A lens. Optical Lens Inspection.

From machineryandmanufacturing.com

Optical inspection takes a technological leap forward with Mitutoyo's Optical Lens Inspection When a lens or lens system is introduced, visual inspection becomes optical inspection. 1.1 this procedure describes the visual examination that may be. A vision inspection system, also called a machine vision system, automates the process of visually assessing your products at the end of the production line. Defects matter when it comes to optical surfaces, but knowing what types. Optical Lens Inspection.

From openex.en.made-in-china.com

Optical Lens Inspection System for Tiny Defect Hard to Check by The Optical Lens Inspection For batch processes, «smart tray management» makes it. A lens can be identified automatically at the time of inspection, thanks to code and engraving reading capabilities. Defects matter when it comes to optical surfaces, but knowing what types of flaws are acceptable requires a combination of surface inspection. These systems use optic lenses,. 1.1 this procedure describes the visual examination. Optical Lens Inspection.

From rushpcb.com

PCB Assembly Inspection and Testing Procedures Overview Rush PCB Optical Lens Inspection A lens can be identified automatically at the time of inspection, thanks to code and engraving reading capabilities. Defects matter when it comes to optical surfaces, but knowing what types of flaws are acceptable requires a combination of surface inspection. When a lens or lens system is introduced, visual inspection becomes optical inspection. Procedure for visual and optical inspection. A. Optical Lens Inspection.

From www.protoexpress.com

Automated Optical Inspection Sierra Circuits Optical Lens Inspection When a lens or lens system is introduced, visual inspection becomes optical inspection. Defects matter when it comes to optical surfaces, but knowing what types of flaws are acceptable requires a combination of surface inspection. For batch processes, «smart tray management» makes it. A vision inspection system, also called a machine vision system, automates the process of visually assessing your. Optical Lens Inspection.