Throttling Calorimeter Application . A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. Throttling and separating calorimeters are used to measure the dryness fraction of steam. This document describes an experiment conducted to determine the quality (dryness fraction) of steam passing through a steam main using a. The most commonly used method in determining steam quality is throttling calorimeter. Historically, measuring steam quality was only feasible through the use of a throttling calorimeter. In this device, electric heaters. This device takes a steam sample through a throttling orifice into a well. In this context, a modified throttling calorimeter was developed capable to determine low values of steam quality. If the steam is sufficiently dry to enable it to reach a. The temperature change of a gas or liquid when it is forced through a valve or porous plug while kept insulated so that no heat is exchanged with the. Water particles from wet steam.

from www.youtube.com

In this context, a modified throttling calorimeter was developed capable to determine low values of steam quality. Water particles from wet steam. This device takes a steam sample through a throttling orifice into a well. This document describes an experiment conducted to determine the quality (dryness fraction) of steam passing through a steam main using a. The most commonly used method in determining steam quality is throttling calorimeter. A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. In this device, electric heaters. The temperature change of a gas or liquid when it is forced through a valve or porous plug while kept insulated so that no heat is exchanged with the. Historically, measuring steam quality was only feasible through the use of a throttling calorimeter. Throttling and separating calorimeters are used to measure the dryness fraction of steam.

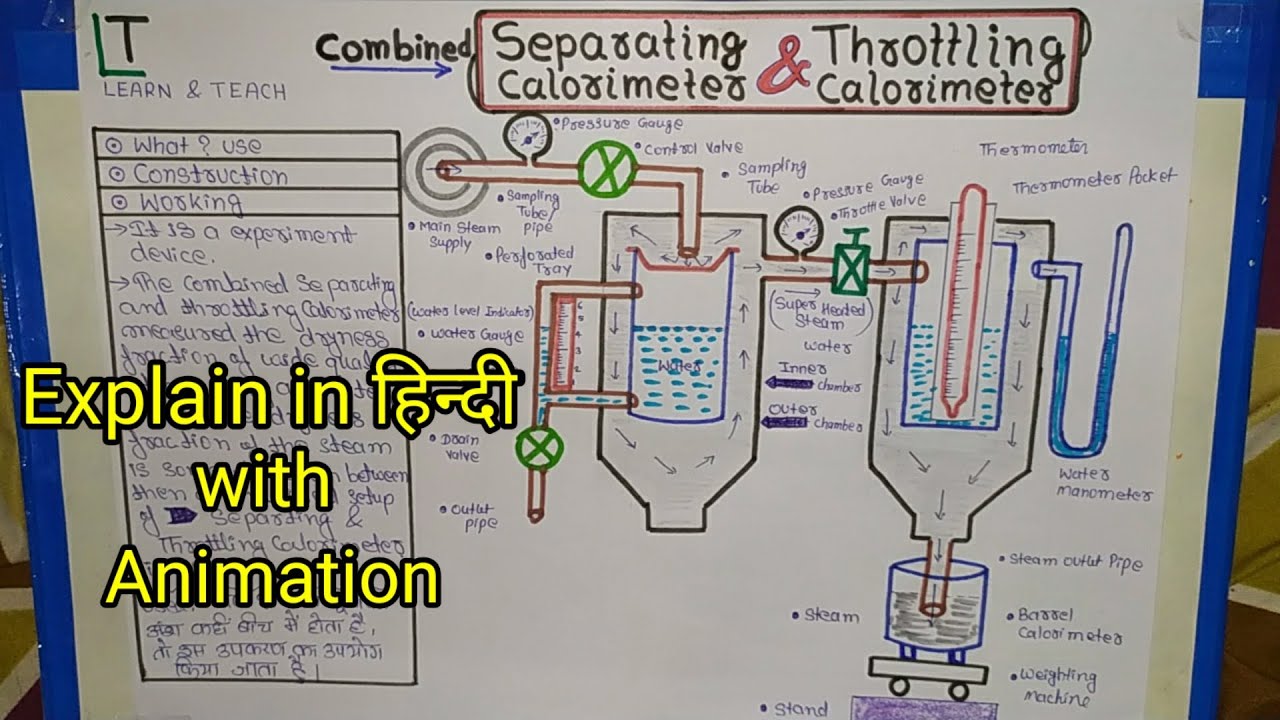

Combined SEPARATING CALORIMETER and THROTTLING CALORIMETER (हिन्दी

Throttling Calorimeter Application A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. Water particles from wet steam. This device takes a steam sample through a throttling orifice into a well. In this context, a modified throttling calorimeter was developed capable to determine low values of steam quality. The temperature change of a gas or liquid when it is forced through a valve or porous plug while kept insulated so that no heat is exchanged with the. This document describes an experiment conducted to determine the quality (dryness fraction) of steam passing through a steam main using a. If the steam is sufficiently dry to enable it to reach a. The most commonly used method in determining steam quality is throttling calorimeter. Historically, measuring steam quality was only feasible through the use of a throttling calorimeter. A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. Throttling and separating calorimeters are used to measure the dryness fraction of steam. In this device, electric heaters.

From www.everyeng.com

Throttling calorimeter Throttling Calorimeter Application If the steam is sufficiently dry to enable it to reach a. Historically, measuring steam quality was only feasible through the use of a throttling calorimeter. In this device, electric heaters. This document describes an experiment conducted to determine the quality (dryness fraction) of steam passing through a steam main using a. A combined separating and throttling calorimeter is used. Throttling Calorimeter Application.

From www.facebook.com

Combined Separating Calorimeter and Throttling calorimeter, Explain in Throttling Calorimeter Application If the steam is sufficiently dry to enable it to reach a. This document describes an experiment conducted to determine the quality (dryness fraction) of steam passing through a steam main using a. A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. Historically, measuring steam quality was only feasible through the use of. Throttling Calorimeter Application.

From khazna.ku.ac.ae

Saturation Pressure and throttling calorimeter TH3 — Khalifa University Throttling Calorimeter Application A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. The most commonly used method in determining steam quality is throttling calorimeter. This document describes an experiment conducted to determine the quality (dryness fraction) of steam passing through a steam main using a. In this context, a modified throttling calorimeter was developed capable to. Throttling Calorimeter Application.

From www.indiamart.com

TECHED Separating Throttling Calorimeter, For Laboratory Model at Rs Throttling Calorimeter Application Water particles from wet steam. A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. This device takes a steam sample through a throttling orifice into a well. In this context, a modified throttling calorimeter was developed capable to determine low values of steam quality. This document describes an experiment conducted to determine the. Throttling Calorimeter Application.

From www.youtube.com

Throttling Calorimeter YouTube Throttling Calorimeter Application In this device, electric heaters. In this context, a modified throttling calorimeter was developed capable to determine low values of steam quality. This device takes a steam sample through a throttling orifice into a well. Throttling and separating calorimeters are used to measure the dryness fraction of steam. The most commonly used method in determining steam quality is throttling calorimeter.. Throttling Calorimeter Application.

From www.laboratoryinstrumentindia.com

Separating and Throttling Calorimeter Bench Manufacturers, Suppliers Throttling Calorimeter Application The temperature change of a gas or liquid when it is forced through a valve or porous plug while kept insulated so that no heat is exchanged with the. Throttling and separating calorimeters are used to measure the dryness fraction of steam. A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. This document. Throttling Calorimeter Application.

From www.indiamart.com

Electric Mild Steel Separating And Throttling Calorimeter at Rs 66000 Throttling Calorimeter Application Historically, measuring steam quality was only feasible through the use of a throttling calorimeter. The temperature change of a gas or liquid when it is forced through a valve or porous plug while kept insulated so that no heat is exchanged with the. If the steam is sufficiently dry to enable it to reach a. Water particles from wet steam.. Throttling Calorimeter Application.

From www.youtube.com

Throttling Calorimeter YouTube Throttling Calorimeter Application In this device, electric heaters. A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. In this context, a modified throttling calorimeter was developed capable to determine low values of steam quality. Throttling and separating calorimeters are used to measure the dryness fraction of steam. Water particles from wet steam. The temperature change of. Throttling Calorimeter Application.

From www.indiamart.com

SEPARATING AND THROTTLING CALORIMETER, For College Laboratory at best Throttling Calorimeter Application Throttling and separating calorimeters are used to measure the dryness fraction of steam. This document describes an experiment conducted to determine the quality (dryness fraction) of steam passing through a steam main using a. If the steam is sufficiently dry to enable it to reach a. In this context, a modified throttling calorimeter was developed capable to determine low values. Throttling Calorimeter Application.

From www.youtube.com

Combined Seperating and throttling Calorimeter II Thermal Engineering Throttling Calorimeter Application If the steam is sufficiently dry to enable it to reach a. A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. The temperature change of a gas or liquid when it is forced through a valve or porous plug while kept insulated so that no heat is exchanged with the. The most commonly. Throttling Calorimeter Application.

From www.youtube.com

Throttling calorimeter YouTube Throttling Calorimeter Application In this device, electric heaters. Throttling and separating calorimeters are used to measure the dryness fraction of steam. If the steam is sufficiently dry to enable it to reach a. Water particles from wet steam. In this context, a modified throttling calorimeter was developed capable to determine low values of steam quality. A combined separating and throttling calorimeter is used. Throttling Calorimeter Application.

From www.indiamart.com

SUPERB TECHNOLOGIES Separating & Throttling Calorimeter, For Laboratory Throttling Calorimeter Application In this context, a modified throttling calorimeter was developed capable to determine low values of steam quality. Historically, measuring steam quality was only feasible through the use of a throttling calorimeter. This document describes an experiment conducted to determine the quality (dryness fraction) of steam passing through a steam main using a. If the steam is sufficiently dry to enable. Throttling Calorimeter Application.

From www.indiamart.com

Reliant Lab Separating And Throttling Calorimeter at Rs 45000/piece in Throttling Calorimeter Application This device takes a steam sample through a throttling orifice into a well. This document describes an experiment conducted to determine the quality (dryness fraction) of steam passing through a steam main using a. If the steam is sufficiently dry to enable it to reach a. The most commonly used method in determining steam quality is throttling calorimeter. Throttling and. Throttling Calorimeter Application.

From www.indiamart.com

Separating And Throttling Calorimeter, For Laboratory, Automation Grade Throttling Calorimeter Application The most commonly used method in determining steam quality is throttling calorimeter. Water particles from wet steam. The temperature change of a gas or liquid when it is forced through a valve or porous plug while kept insulated so that no heat is exchanged with the. This document describes an experiment conducted to determine the quality (dryness fraction) of steam. Throttling Calorimeter Application.

From www.youtube.com

Throttling calorimeter in Basic Mechanical Engineering, Throttling Calorimeter Application Throttling and separating calorimeters are used to measure the dryness fraction of steam. In this device, electric heaters. The temperature change of a gas or liquid when it is forced through a valve or porous plug while kept insulated so that no heat is exchanged with the. This device takes a steam sample through a throttling orifice into a well.. Throttling Calorimeter Application.

From systemfirefighting.blogspot.com

Fire fighting system for building Throttling valve thermodynamics Throttling Calorimeter Application The temperature change of a gas or liquid when it is forced through a valve or porous plug while kept insulated so that no heat is exchanged with the. In this device, electric heaters. In this context, a modified throttling calorimeter was developed capable to determine low values of steam quality. The most commonly used method in determining steam quality. Throttling Calorimeter Application.

From www.indiamart.com

XEEPL Separating and Throttling Calorimeter, Laboratory at Rs 95000 in Pune Throttling Calorimeter Application Water particles from wet steam. In this device, electric heaters. The temperature change of a gas or liquid when it is forced through a valve or porous plug while kept insulated so that no heat is exchanged with the. A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. This device takes a steam. Throttling Calorimeter Application.

From spectross.co.nz

SEPARATING AND THROTTLING CALORIMETER Spectro STEM Solutions Ltd Throttling Calorimeter Application The temperature change of a gas or liquid when it is forced through a valve or porous plug while kept insulated so that no heat is exchanged with the. The most commonly used method in determining steam quality is throttling calorimeter. In this context, a modified throttling calorimeter was developed capable to determine low values of steam quality. A combined. Throttling Calorimeter Application.

From www.tescaglobal.com

Separating & Throttling Calorimeter With Boiler Throttling Calorimeter Application The temperature change of a gas or liquid when it is forced through a valve or porous plug while kept insulated so that no heat is exchanged with the. Water particles from wet steam. This document describes an experiment conducted to determine the quality (dryness fraction) of steam passing through a steam main using a. A combined separating and throttling. Throttling Calorimeter Application.

From www.studypool.com

SOLUTION Separating and throttling calorimeter Studypool Throttling Calorimeter Application A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. Historically, measuring steam quality was only feasible through the use of a throttling calorimeter. In this device, electric heaters. If the steam is sufficiently dry to enable it to reach a. The most commonly used method in determining steam quality is throttling calorimeter. This. Throttling Calorimeter Application.

From www.indiamart.com

Separating & Throttling Calorimeter, for Laboratory at best price in Ambala Throttling Calorimeter Application The temperature change of a gas or liquid when it is forced through a valve or porous plug while kept insulated so that no heat is exchanged with the. The most commonly used method in determining steam quality is throttling calorimeter. In this context, a modified throttling calorimeter was developed capable to determine low values of steam quality. Throttling and. Throttling Calorimeter Application.

From www.indiamart.com

Trend Innovations Separating Throttling Calorimeter Test Rig Throttling Calorimeter Application The temperature change of a gas or liquid when it is forced through a valve or porous plug while kept insulated so that no heat is exchanged with the. Historically, measuring steam quality was only feasible through the use of a throttling calorimeter. This document describes an experiment conducted to determine the quality (dryness fraction) of steam passing through a. Throttling Calorimeter Application.

From www.chegg.com

Solved Derive the Equation for x1 (quality) for the Throttling Calorimeter Application A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. Historically, measuring steam quality was only feasible through the use of a throttling calorimeter. This document describes an experiment conducted to determine the quality (dryness fraction) of steam passing through a steam main using a. Water particles from wet steam. The most commonly used. Throttling Calorimeter Application.

From www.youtube.com

Throttling Calorimeter & Combined Separating and Throttling Calorimeter Throttling Calorimeter Application If the steam is sufficiently dry to enable it to reach a. In this device, electric heaters. Throttling and separating calorimeters are used to measure the dryness fraction of steam. Historically, measuring steam quality was only feasible through the use of a throttling calorimeter. This device takes a steam sample through a throttling orifice into a well. The temperature change. Throttling Calorimeter Application.

From www.youtube.com

Separating and throttling calorimeter YouTube Throttling Calorimeter Application This document describes an experiment conducted to determine the quality (dryness fraction) of steam passing through a steam main using a. The most commonly used method in determining steam quality is throttling calorimeter. In this context, a modified throttling calorimeter was developed capable to determine low values of steam quality. Water particles from wet steam. In this device, electric heaters.. Throttling Calorimeter Application.

From www.indiamart.com

Separating & Throttling Calorimeter, For Industrial at best price in Ambala Throttling Calorimeter Application Throttling and separating calorimeters are used to measure the dryness fraction of steam. A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. In this device, electric heaters. The most commonly used method in determining steam quality is throttling calorimeter. In this context, a modified throttling calorimeter was developed capable to determine low values. Throttling Calorimeter Application.

From www.youtube.com

Separating And Throttling Calorimeter YouTube Throttling Calorimeter Application The most commonly used method in determining steam quality is throttling calorimeter. In this device, electric heaters. Water particles from wet steam. A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. Historically, measuring steam quality was only feasible through the use of a throttling calorimeter. Throttling and separating calorimeters are used to measure. Throttling Calorimeter Application.

From www.indiamart.com

TECHED Separating Throttling Calorimeter, For Laboratory Model at Rs Throttling Calorimeter Application In this device, electric heaters. Historically, measuring steam quality was only feasible through the use of a throttling calorimeter. If the steam is sufficiently dry to enable it to reach a. The temperature change of a gas or liquid when it is forced through a valve or porous plug while kept insulated so that no heat is exchanged with the.. Throttling Calorimeter Application.

From www.indiamart.com

TECHED Separating Throttling Calorimeter, For Laboratory Model at Rs Throttling Calorimeter Application A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. In this device, electric heaters. This document describes an experiment conducted to determine the quality (dryness fraction) of steam passing through a steam main using a. If the steam is sufficiently dry to enable it to reach a. In this context, a modified throttling. Throttling Calorimeter Application.

From www.indiamart.com

SEPARATING & THROTTLING CALORIMETER, For Lab Experiment, Model Name Throttling Calorimeter Application The most commonly used method in determining steam quality is throttling calorimeter. Water particles from wet steam. A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. Throttling and separating calorimeters are used to measure the dryness fraction of steam. This document describes an experiment conducted to determine the quality (dryness fraction) of steam. Throttling Calorimeter Application.

From www.indiamart.com

Separating Throttling Calorimeter at best price in Sangli Throttling Calorimeter Application In this context, a modified throttling calorimeter was developed capable to determine low values of steam quality. In this device, electric heaters. A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. This document describes an experiment conducted to determine the quality (dryness fraction) of steam passing through a steam main using a. The. Throttling Calorimeter Application.

From www.youtube.com

Throttling Calorimeter YouTube Throttling Calorimeter Application This device takes a steam sample through a throttling orifice into a well. A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. The temperature change of a gas or liquid when it is forced through a valve or porous plug while kept insulated so that no heat is exchanged with the. The most. Throttling Calorimeter Application.

From www.youtube.com

Combined SEPARATING CALORIMETER and THROTTLING CALORIMETER (हिन्दी Throttling Calorimeter Application Historically, measuring steam quality was only feasible through the use of a throttling calorimeter. If the steam is sufficiently dry to enable it to reach a. Throttling and separating calorimeters are used to measure the dryness fraction of steam. This document describes an experiment conducted to determine the quality (dryness fraction) of steam passing through a steam main using a.. Throttling Calorimeter Application.

From www.indiamart.com

Separating & throttling calorimeter apparatus at Rs 204000.00 Throttling Calorimeter Application In this device, electric heaters. This document describes an experiment conducted to determine the quality (dryness fraction) of steam passing through a steam main using a. Throttling and separating calorimeters are used to measure the dryness fraction of steam. This device takes a steam sample through a throttling orifice into a well. If the steam is sufficiently dry to enable. Throttling Calorimeter Application.

From www.indiamart.com

TECHED Separating Throttling Calorimeter, For Laboratory Model at Rs Throttling Calorimeter Application A combined separating and throttling calorimeter is used to remove the drawback of separating calorimeter (i.e. In this device, electric heaters. The most commonly used method in determining steam quality is throttling calorimeter. If the steam is sufficiently dry to enable it to reach a. The temperature change of a gas or liquid when it is forced through a valve. Throttling Calorimeter Application.