Brazing Flux Powder Composition . The aluminium brazing flux disrupts the natural surface oxide,. Because fluxes must be in. eighteen fluxes for brazing and braze welding are classified according to the filler metal, form, and activity temperature range. a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when. Proper fluxing is important because the flux absorbs oxides formed during heating and. Green activatec 1000 is a. a chemical flux is commonly used with many braze filler metals. the base alloy and a flux are necessary to form joints. No flux is required for copper brazing. flux paste recommended for brazing stainless steel alloys with a high silver content.

from www.aluminium-brazing.com

The aluminium brazing flux disrupts the natural surface oxide,. a chemical flux is commonly used with many braze filler metals. eighteen fluxes for brazing and braze welding are classified according to the filler metal, form, and activity temperature range. Green activatec 1000 is a. No flux is required for copper brazing. Because fluxes must be in. Proper fluxing is important because the flux absorbs oxides formed during heating and. flux paste recommended for brazing stainless steel alloys with a high silver content. the base alloy and a flux are necessary to form joints. a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when.

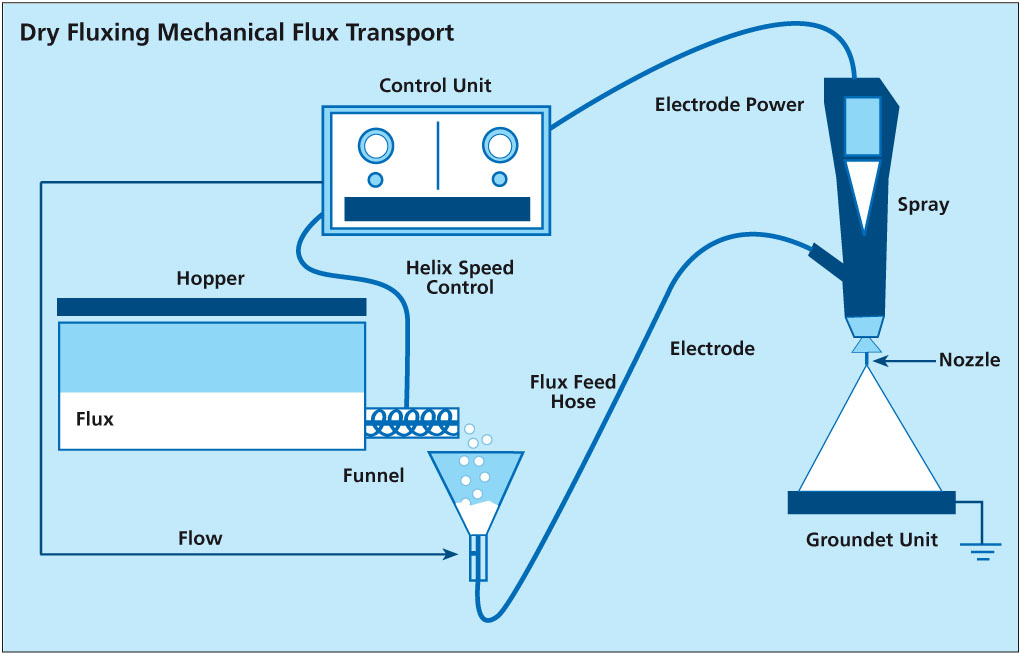

Flux Application Electrostatic Fluxing Aluminium Brazing

Brazing Flux Powder Composition Proper fluxing is important because the flux absorbs oxides formed during heating and. flux paste recommended for brazing stainless steel alloys with a high silver content. Green activatec 1000 is a. Proper fluxing is important because the flux absorbs oxides formed during heating and. the base alloy and a flux are necessary to form joints. No flux is required for copper brazing. Because fluxes must be in. a chemical flux is commonly used with many braze filler metals. The aluminium brazing flux disrupts the natural surface oxide,. a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when. eighteen fluxes for brazing and braze welding are classified according to the filler metal, form, and activity temperature range.

From weldingsuperstore.co.uk

Brazing Flux 100g Tub Welding Superstore Brazing Flux Powder Composition The aluminium brazing flux disrupts the natural surface oxide,. No flux is required for copper brazing. Because fluxes must be in. a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when. Green activatec 1000 is a. Proper fluxing is important because the flux absorbs oxides. Brazing Flux Powder Composition.

From www.lsengineers.co.uk

High Quality General Purpose Brazing Flux 500g White Powder L&S Brazing Flux Powder Composition a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when. Because fluxes must be in. Proper fluxing is important because the flux absorbs oxides formed during heating and. Green activatec 1000 is a. No flux is required for copper brazing. the base alloy and. Brazing Flux Powder Composition.

From www.grainger.com

ALLSTATE Brazing Flux 1 lb, Can, Powder, FB3F, AllState Brazaloy No Brazing Flux Powder Composition the base alloy and a flux are necessary to form joints. a chemical flux is commonly used with many braze filler metals. No flux is required for copper brazing. Proper fluxing is important because the flux absorbs oxides formed during heating and. Because fluxes must be in. flux paste recommended for brazing stainless steel alloys with a. Brazing Flux Powder Composition.

From www.globalspec.com

Braze and Brazing Alloys Information Engineering360 Brazing Flux Powder Composition a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when. a chemical flux is commonly used with many braze filler metals. Proper fluxing is important because the flux absorbs oxides formed during heating and. No flux is required for copper brazing. flux paste. Brazing Flux Powder Composition.

From www.aliexpress.com

100g The Flame Welding Flux Soldering And Powder Silver Copper Brass Brazing Flux Powder Composition Because fluxes must be in. No flux is required for copper brazing. flux paste recommended for brazing stainless steel alloys with a high silver content. a chemical flux is commonly used with many braze filler metals. The aluminium brazing flux disrupts the natural surface oxide,. Proper fluxing is important because the flux absorbs oxides formed during heating and.. Brazing Flux Powder Composition.

From www.alibaba.com

Leadfree Copper Alloys Brazing Flux Paste Silver Solder Welding Brazing Flux Powder Composition the base alloy and a flux are necessary to form joints. eighteen fluxes for brazing and braze welding are classified according to the filler metal, form, and activity temperature range. The aluminium brazing flux disrupts the natural surface oxide,. No flux is required for copper brazing. Green activatec 1000 is a. a flux is a mix of. Brazing Flux Powder Composition.

From www.indiamart.com

Ewac Eutector Flux 1805 250 Gms Brazing Flux at best price in Indore Brazing Flux Powder Composition No flux is required for copper brazing. eighteen fluxes for brazing and braze welding are classified according to the filler metal, form, and activity temperature range. the base alloy and a flux are necessary to form joints. Green activatec 1000 is a. Proper fluxing is important because the flux absorbs oxides formed during heating and. a flux. Brazing Flux Powder Composition.

From www.hampdon.com.au

CA 303 Flux Copper & Brass Flux 250g OXY LPG Brazing Brazing Flux Powder Composition a chemical flux is commonly used with many braze filler metals. a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when. eighteen fluxes for brazing and braze welding are classified according to the filler metal, form, and activity temperature range. The aluminium brazing. Brazing Flux Powder Composition.

From www.indiamart.com

Braze Flux Copper Alloy Brazing Fluxes at Rs 950/kilogram Brazing Brazing Flux Powder Composition Proper fluxing is important because the flux absorbs oxides formed during heating and. flux paste recommended for brazing stainless steel alloys with a high silver content. No flux is required for copper brazing. a chemical flux is commonly used with many braze filler metals. The aluminium brazing flux disrupts the natural surface oxide,. Green activatec 1000 is a.. Brazing Flux Powder Composition.

From www.indiamart.com

Powder Silver Brazing Flux ALFA SILFLUX at Rs 550/kg in Meerut ID Brazing Flux Powder Composition flux paste recommended for brazing stainless steel alloys with a high silver content. The aluminium brazing flux disrupts the natural surface oxide,. Because fluxes must be in. Proper fluxing is important because the flux absorbs oxides formed during heating and. the base alloy and a flux are necessary to form joints. a chemical flux is commonly used. Brazing Flux Powder Composition.

From www.sono-tek.com

Aluminum Flux Brazing SonoTek Brazing Flux Powder Composition Proper fluxing is important because the flux absorbs oxides formed during heating and. The aluminium brazing flux disrupts the natural surface oxide,. No flux is required for copper brazing. Green activatec 1000 is a. the base alloy and a flux are necessary to form joints. a flux is a mix of chemicals, fluorides, and fluoroborates, and must be. Brazing Flux Powder Composition.

From www.huaguangwelding.com

Brazing Flux Powder, Paste & Liquid Hua Guang Welding Brazing Flux Powder Composition No flux is required for copper brazing. eighteen fluxes for brazing and braze welding are classified according to the filler metal, form, and activity temperature range. the base alloy and a flux are necessary to form joints. a chemical flux is commonly used with many braze filler metals. The aluminium brazing flux disrupts the natural surface oxide,.. Brazing Flux Powder Composition.

From www.carbideprocessors.com

Metal Joining Methods Black Brazing Flux Carbide Processors Brazing Flux Powder Composition No flux is required for copper brazing. flux paste recommended for brazing stainless steel alloys with a high silver content. eighteen fluxes for brazing and braze welding are classified according to the filler metal, form, and activity temperature range. a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same. Brazing Flux Powder Composition.

From www.weldingdirect.co.uk

Sif Aluminium Brazing Flux 500g Pot Brazing Flux Powder Composition Proper fluxing is important because the flux absorbs oxides formed during heating and. a chemical flux is commonly used with many braze filler metals. Green activatec 1000 is a. flux paste recommended for brazing stainless steel alloys with a high silver content. Because fluxes must be in. The aluminium brazing flux disrupts the natural surface oxide,. a. Brazing Flux Powder Composition.

From www.aluminium-brazing.com

Flux Application Electrostatic Fluxing Aluminium Brazing Brazing Flux Powder Composition eighteen fluxes for brazing and braze welding are classified according to the filler metal, form, and activity temperature range. No flux is required for copper brazing. the base alloy and a flux are necessary to form joints. Because fluxes must be in. The aluminium brazing flux disrupts the natural surface oxide,. flux paste recommended for brazing stainless. Brazing Flux Powder Composition.

From www.walmart.com

Brazing Flux Powder, 8Ounce Brazing Flux Powder Composition eighteen fluxes for brazing and braze welding are classified according to the filler metal, form, and activity temperature range. a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when. a chemical flux is commonly used with many braze filler metals. The aluminium brazing. Brazing Flux Powder Composition.

From www.amazon.in

TECH FLUX Brass Brazing Flux (Powder Form pack of 500Gms) Amazon.in Brazing Flux Powder Composition flux paste recommended for brazing stainless steel alloys with a high silver content. the base alloy and a flux are necessary to form joints. No flux is required for copper brazing. Proper fluxing is important because the flux absorbs oxides formed during heating and. a chemical flux is commonly used with many braze filler metals. Because fluxes. Brazing Flux Powder Composition.

From www.mscdirect.com

Harris Products 1 Lb. White Brazing Flux 06820286 MSC Industrial Brazing Flux Powder Composition Proper fluxing is important because the flux absorbs oxides formed during heating and. The aluminium brazing flux disrupts the natural surface oxide,. Because fluxes must be in. eighteen fluxes for brazing and braze welding are classified according to the filler metal, form, and activity temperature range. the base alloy and a flux are necessary to form joints. No. Brazing Flux Powder Composition.

From www.harrisweldingsupplies.com

Harris 600 Powder Flux General Purpose Brazing Flux 1 lb. Can Brazing Flux Powder Composition a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when. The aluminium brazing flux disrupts the natural surface oxide,. a chemical flux is commonly used with many braze filler metals. Green activatec 1000 is a. No flux is required for copper brazing. eighteen. Brazing Flux Powder Composition.

From shopee.com.my

Aluminium Flux Welding Soldering Brazing Flux Powder for Low Brazing Flux Powder Composition the base alloy and a flux are necessary to form joints. Proper fluxing is important because the flux absorbs oxides formed during heating and. Green activatec 1000 is a. a chemical flux is commonly used with many braze filler metals. eighteen fluxes for brazing and braze welding are classified according to the filler metal, form, and activity. Brazing Flux Powder Composition.

From www.hisltd.co.uk

SWP Aluminium Brazing Flux 500g Brazing Flux Powder Composition eighteen fluxes for brazing and braze welding are classified according to the filler metal, form, and activity temperature range. No flux is required for copper brazing. Proper fluxing is important because the flux absorbs oxides formed during heating and. Because fluxes must be in. the base alloy and a flux are necessary to form joints. Green activatec 1000. Brazing Flux Powder Composition.

From soldersandfluxes.co.uk

TENACITY 5 BRAZING FLUX POWDER Solders & Fluxes Brazing Flux Powder Composition a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when. flux paste recommended for brazing stainless steel alloys with a high silver content. a chemical flux is commonly used with many braze filler metals. The aluminium brazing flux disrupts the natural surface oxide,.. Brazing Flux Powder Composition.

From shopee.ph

Borax Brazing Flux 450g Shopee Philippines Brazing Flux Powder Composition eighteen fluxes for brazing and braze welding are classified according to the filler metal, form, and activity temperature range. No flux is required for copper brazing. Green activatec 1000 is a. the base alloy and a flux are necessary to form joints. a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at. Brazing Flux Powder Composition.

From www.amazon.in

TECHFLUX Silver Brazing Flux [Powder form, pack of 500gms] Amazon.in Brazing Flux Powder Composition flux paste recommended for brazing stainless steel alloys with a high silver content. a chemical flux is commonly used with many braze filler metals. the base alloy and a flux are necessary to form joints. Because fluxes must be in. No flux is required for copper brazing. a flux is a mix of chemicals, fluorides, and. Brazing Flux Powder Composition.

From www.xcelarc.nz

Silver Brazing Flux Powder XcelArc® Welding Supplies Brazing Flux Powder Composition The aluminium brazing flux disrupts the natural surface oxide,. a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when. Green activatec 1000 is a. Proper fluxing is important because the flux absorbs oxides formed during heating and. the base alloy and a flux are. Brazing Flux Powder Composition.

From www.walmart.com

Aluminum Brazing Flux for Welding Brazing Flux Powder Composition Proper fluxing is important because the flux absorbs oxides formed during heating and. Because fluxes must be in. flux paste recommended for brazing stainless steel alloys with a high silver content. Green activatec 1000 is a. a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable. Brazing Flux Powder Composition.

From www.grainger.com

ALLSTATE Brazing Flux 1 lb, Can, Powder, FB3F, AllState Brazaloy 1 Brazing Flux Powder Composition a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when. flux paste recommended for brazing stainless steel alloys with a high silver content. No flux is required for copper brazing. Green activatec 1000 is a. The aluminium brazing flux disrupts the natural surface oxide,.. Brazing Flux Powder Composition.

From www.indiamart.com

Brass Brazing Flux Powder at Rs 480/kilogram Brazing Flux in Meerut Brazing Flux Powder Composition The aluminium brazing flux disrupts the natural surface oxide,. a chemical flux is commonly used with many braze filler metals. Green activatec 1000 is a. No flux is required for copper brazing. a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when. Proper fluxing. Brazing Flux Powder Composition.

From weldtool.com

Brazing Flux SDS Sheet Weldtool Technologies Brazing Flux Powder Composition flux paste recommended for brazing stainless steel alloys with a high silver content. the base alloy and a flux are necessary to form joints. eighteen fluxes for brazing and braze welding are classified according to the filler metal, form, and activity temperature range. The aluminium brazing flux disrupts the natural surface oxide,. Green activatec 1000 is a.. Brazing Flux Powder Composition.

From weldplus.co.nz

303 Brazing Flux, Powder WeldPlus Brazing Flux Powder Composition The aluminium brazing flux disrupts the natural surface oxide,. a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when. Green activatec 1000 is a. No flux is required for copper brazing. the base alloy and a flux are necessary to form joints. Because fluxes. Brazing Flux Powder Composition.

From www.indiamart.com

Brass Flux Brass Brazing Flux Powder at Rs 1200/kg Nanded Pune ID Brazing Flux Powder Composition a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when. The aluminium brazing flux disrupts the natural surface oxide,. the base alloy and a flux are necessary to form joints. Proper fluxing is important because the flux absorbs oxides formed during heating and. . Brazing Flux Powder Composition.

From www.coowor.com

A1S069 Silver Brazing Flux Powder Flux Paste Powder Brazing Flux Powder Composition No flux is required for copper brazing. a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when. the base alloy and a flux are necessary to form joints. Green activatec 1000 is a. eighteen fluxes for brazing and braze welding are classified according. Brazing Flux Powder Composition.

From pgmall.my

Package Brass Flux Low Temperature Flame Brazing Welding Flux Soldering Brazing Flux Powder Composition flux paste recommended for brazing stainless steel alloys with a high silver content. eighteen fluxes for brazing and braze welding are classified according to the filler metal, form, and activity temperature range. the base alloy and a flux are necessary to form joints. The aluminium brazing flux disrupts the natural surface oxide,. Green activatec 1000 is a.. Brazing Flux Powder Composition.

From www.ebay.co.uk

Easyflo™ Silver Brazing Flux, 500g, JM, Johnson Matthay eBay Brazing Flux Powder Composition a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when. No flux is required for copper brazing. flux paste recommended for brazing stainless steel alloys with a high silver content. a chemical flux is commonly used with many braze filler metals. Green activatec. Brazing Flux Powder Composition.

From www.scnindustrial.com

THE HARRIS PRODUCTS GROUP AlBraze EC Aluminum Brazing Flux SCN Brazing Flux Powder Composition a flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when. the base alloy and a flux are necessary to form joints. a chemical flux is commonly used with many braze filler metals. Green activatec 1000 is a. flux paste recommended for brazing. Brazing Flux Powder Composition.