How To Lubricate A Drill Press . some signs that indicate a drill press spindle needs lubrication include increased friction or resistance when. additionally, it’s important to lubricate the drill press to prevent rust and improve the smoothness of its operation. to properly lubricate your drill press with oil, start by cleaning the surfaces to be lubricated with a rag or brush to. Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth operation and preventing damage. Find woodworking video tutorials, tips, techniques and more. by keeping all components clean, lubricated, and adjusted, you reduce wear and tear, preventing premature. your woodworking adventure starts here! discover how to extend the life and improve the performance of your drill press with essential maintenance tips. essentially, you need to apply a lubricant like oil or grease to the spindle and its bearings to reduce friction and prevent damage.

from drillay.com

some signs that indicate a drill press spindle needs lubrication include increased friction or resistance when. Find woodworking video tutorials, tips, techniques and more. discover how to extend the life and improve the performance of your drill press with essential maintenance tips. additionally, it’s important to lubricate the drill press to prevent rust and improve the smoothness of its operation. to properly lubricate your drill press with oil, start by cleaning the surfaces to be lubricated with a rag or brush to. Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth operation and preventing damage. essentially, you need to apply a lubricant like oil or grease to the spindle and its bearings to reduce friction and prevent damage. by keeping all components clean, lubricated, and adjusted, you reduce wear and tear, preventing premature. your woodworking adventure starts here!

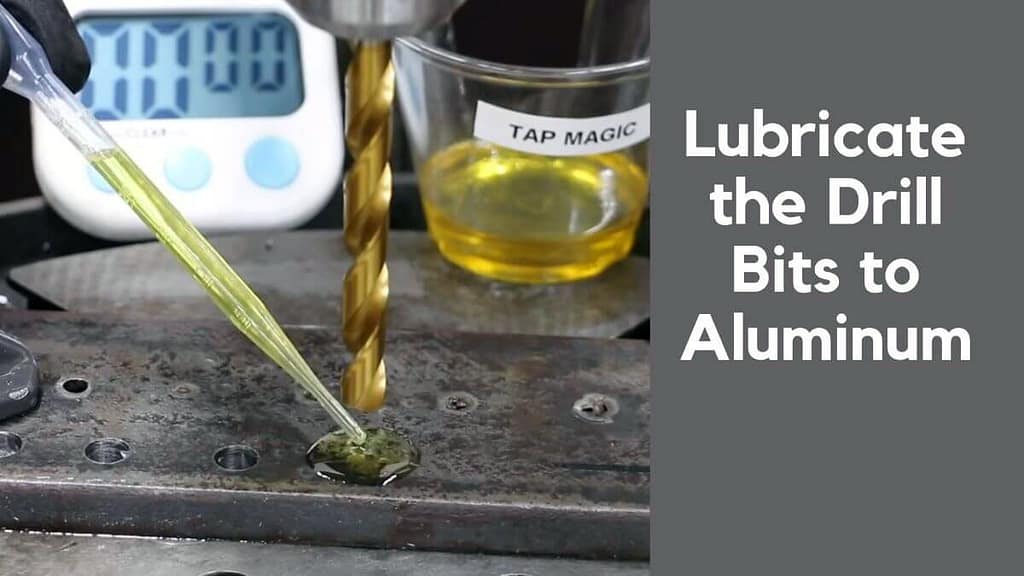

The Ultimate Guide of How to Drill Aluminum? Drillay

How To Lubricate A Drill Press essentially, you need to apply a lubricant like oil or grease to the spindle and its bearings to reduce friction and prevent damage. by keeping all components clean, lubricated, and adjusted, you reduce wear and tear, preventing premature. Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth operation and preventing damage. essentially, you need to apply a lubricant like oil or grease to the spindle and its bearings to reduce friction and prevent damage. discover how to extend the life and improve the performance of your drill press with essential maintenance tips. some signs that indicate a drill press spindle needs lubrication include increased friction or resistance when. to properly lubricate your drill press with oil, start by cleaning the surfaces to be lubricated with a rag or brush to. your woodworking adventure starts here! additionally, it’s important to lubricate the drill press to prevent rust and improve the smoothness of its operation. Find woodworking video tutorials, tips, techniques and more.

From www.pinterest.jp

12" VariableSpeed Benchtop Drill Press with Laser Grizzly Industrial Drill press, Drill How To Lubricate A Drill Press Find woodworking video tutorials, tips, techniques and more. to properly lubricate your drill press with oil, start by cleaning the surfaces to be lubricated with a rag or brush to. additionally, it’s important to lubricate the drill press to prevent rust and improve the smoothness of its operation. Always clean your drill press thoroughly before applying any lubricant. How To Lubricate A Drill Press.

From www.youtube.com

Drill press (bit lube) total completion YouTube How To Lubricate A Drill Press Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth operation and preventing damage. additionally, it’s important to lubricate the drill press to prevent rust and improve the smoothness of its operation. your woodworking adventure starts here! Find woodworking video tutorials, tips, techniques and more. by keeping all components clean,. How To Lubricate A Drill Press.

From drillvalley.com

How to Drill Holes in Rocks Using a Drill Press (6 steps) How To Lubricate A Drill Press your woodworking adventure starts here! Find woodworking video tutorials, tips, techniques and more. Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth operation and preventing damage. to properly lubricate your drill press with oil, start by cleaning the surfaces to be lubricated with a rag or brush to. by. How To Lubricate A Drill Press.

From www.youtube.com

VEVOR DRILL PRESS pt 1 876 tubalcain YouTube How To Lubricate A Drill Press essentially, you need to apply a lubricant like oil or grease to the spindle and its bearings to reduce friction and prevent damage. discover how to extend the life and improve the performance of your drill press with essential maintenance tips. Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth. How To Lubricate A Drill Press.

From www.youtube.com

How to Maintain Lubricating Treadmills YouTube How To Lubricate A Drill Press Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth operation and preventing damage. additionally, it’s important to lubricate the drill press to prevent rust and improve the smoothness of its operation. your woodworking adventure starts here! Find woodworking video tutorials, tips, techniques and more. by keeping all components clean,. How To Lubricate A Drill Press.

From www.youtube.com

How to Change The Drill Chuck Replace Drill Chuck YouTube How To Lubricate A Drill Press Find woodworking video tutorials, tips, techniques and more. additionally, it’s important to lubricate the drill press to prevent rust and improve the smoothness of its operation. essentially, you need to apply a lubricant like oil or grease to the spindle and its bearings to reduce friction and prevent damage. your woodworking adventure starts here! some signs. How To Lubricate A Drill Press.

From www.youtube.com

Where To Lubricate Power Press YouTube How To Lubricate A Drill Press discover how to extend the life and improve the performance of your drill press with essential maintenance tips. to properly lubricate your drill press with oil, start by cleaning the surfaces to be lubricated with a rag or brush to. Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth operation. How To Lubricate A Drill Press.

From gooddrillpress.com

How to Make a Drill Press Variable Speed? DIY Good Drill Press How To Lubricate A Drill Press some signs that indicate a drill press spindle needs lubrication include increased friction or resistance when. additionally, it’s important to lubricate the drill press to prevent rust and improve the smoothness of its operation. Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth operation and preventing damage. your woodworking. How To Lubricate A Drill Press.

From www.polytechforum.com

Cutting oil or coolant for drill press How To Lubricate A Drill Press to properly lubricate your drill press with oil, start by cleaning the surfaces to be lubricated with a rag or brush to. additionally, it’s important to lubricate the drill press to prevent rust and improve the smoothness of its operation. essentially, you need to apply a lubricant like oil or grease to the spindle and its bearings. How To Lubricate A Drill Press.

From www.youtube.com

Best Drill Presses of 2023 [TOP 5 ] Best Drill Presses of 2023 YouTube How To Lubricate A Drill Press some signs that indicate a drill press spindle needs lubrication include increased friction or resistance when. Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth operation and preventing damage. discover how to extend the life and improve the performance of your drill press with essential maintenance tips. essentially, you. How To Lubricate A Drill Press.

From www.youtube.com

How to properly lube and testfit a clutch disc prior to installation. YouTube How To Lubricate A Drill Press essentially, you need to apply a lubricant like oil or grease to the spindle and its bearings to reduce friction and prevent damage. to properly lubricate your drill press with oil, start by cleaning the surfaces to be lubricated with a rag or brush to. your woodworking adventure starts here! by keeping all components clean, lubricated,. How To Lubricate A Drill Press.

From www.youtube.com

How to Lubricate Air Tools Super Easy! YouTube How To Lubricate A Drill Press some signs that indicate a drill press spindle needs lubrication include increased friction or resistance when. by keeping all components clean, lubricated, and adjusted, you reduce wear and tear, preventing premature. essentially, you need to apply a lubricant like oil or grease to the spindle and its bearings to reduce friction and prevent damage. your woodworking. How To Lubricate A Drill Press.

From www.familyhandyman.com

Drill Press What It Is and When Do You Use it? The Family Handyman How To Lubricate A Drill Press Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth operation and preventing damage. some signs that indicate a drill press spindle needs lubrication include increased friction or resistance when. essentially, you need to apply a lubricant like oil or grease to the spindle and its bearings to reduce friction and. How To Lubricate A Drill Press.

From www.practicalmachinist.com

Gear lube for old drill press... How To Lubricate A Drill Press Find woodworking video tutorials, tips, techniques and more. by keeping all components clean, lubricated, and adjusted, you reduce wear and tear, preventing premature. Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth operation and preventing damage. your woodworking adventure starts here! discover how to extend the life and improve. How To Lubricate A Drill Press.

From www.youtube.com

Rotary hammer .Clean and Lubrication .DRILL YouTube How To Lubricate A Drill Press discover how to extend the life and improve the performance of your drill press with essential maintenance tips. Find woodworking video tutorials, tips, techniques and more. by keeping all components clean, lubricated, and adjusted, you reduce wear and tear, preventing premature. to properly lubricate your drill press with oil, start by cleaning the surfaces to be lubricated. How To Lubricate A Drill Press.

From 100workfromhome.com

Best delta drill press motor The Best Home How To Lubricate A Drill Press by keeping all components clean, lubricated, and adjusted, you reduce wear and tear, preventing premature. essentially, you need to apply a lubricant like oil or grease to the spindle and its bearings to reduce friction and prevent damage. Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth operation and preventing. How To Lubricate A Drill Press.

From toolsterritory.com

How To Lubricate An Electric Drill? Tools Territory How To Lubricate A Drill Press essentially, you need to apply a lubricant like oil or grease to the spindle and its bearings to reduce friction and prevent damage. discover how to extend the life and improve the performance of your drill press with essential maintenance tips. Find woodworking video tutorials, tips, techniques and more. some signs that indicate a drill press spindle. How To Lubricate A Drill Press.

From handymansworld.net

Drill Press Parts and Their Functions Handyman's World How To Lubricate A Drill Press by keeping all components clean, lubricated, and adjusted, you reduce wear and tear, preventing premature. Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth operation and preventing damage. additionally, it’s important to lubricate the drill press to prevent rust and improve the smoothness of its operation. essentially, you need. How To Lubricate A Drill Press.

From www.youtube.com

How To Lube A Bike Chain GCN Tech's Guide To Oiling Your Bicycle Chain YouTube How To Lubricate A Drill Press your woodworking adventure starts here! additionally, it’s important to lubricate the drill press to prevent rust and improve the smoothness of its operation. discover how to extend the life and improve the performance of your drill press with essential maintenance tips. essentially, you need to apply a lubricant like oil or grease to the spindle and. How To Lubricate A Drill Press.

From www.onallcylinders.com

Video How (and Why) To Lubricate Your Garage Air Tools—and How Often You Should Do It How To Lubricate A Drill Press your woodworking adventure starts here! Find woodworking video tutorials, tips, techniques and more. essentially, you need to apply a lubricant like oil or grease to the spindle and its bearings to reduce friction and prevent damage. additionally, it’s important to lubricate the drill press to prevent rust and improve the smoothness of its operation. to properly. How To Lubricate A Drill Press.

From drillay.com

The Ultimate Guide of How to Drill Aluminum? Drillay How To Lubricate A Drill Press additionally, it’s important to lubricate the drill press to prevent rust and improve the smoothness of its operation. your woodworking adventure starts here! discover how to extend the life and improve the performance of your drill press with essential maintenance tips. Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring. How To Lubricate A Drill Press.

From civilmint.com

Parts Of A Drill Press And Their Functions [Explained With Diagram] How To Lubricate A Drill Press by keeping all components clean, lubricated, and adjusted, you reduce wear and tear, preventing premature. some signs that indicate a drill press spindle needs lubrication include increased friction or resistance when. discover how to extend the life and improve the performance of your drill press with essential maintenance tips. Find woodworking video tutorials, tips, techniques and more.. How To Lubricate A Drill Press.

From gooddrillpress.com

Bilt Hard 12inch drill press Your Ultimate Tool Guide Good Drill Press How To Lubricate A Drill Press additionally, it’s important to lubricate the drill press to prevent rust and improve the smoothness of its operation. by keeping all components clean, lubricated, and adjusted, you reduce wear and tear, preventing premature. Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth operation and preventing damage. some signs that. How To Lubricate A Drill Press.

From nevonprojects.com

Drill Press Project How to Make a Mini Drill Press How To Lubricate A Drill Press Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth operation and preventing damage. to properly lubricate your drill press with oil, start by cleaning the surfaces to be lubricated with a rag or brush to. your woodworking adventure starts here! by keeping all components clean, lubricated, and adjusted, you. How To Lubricate A Drill Press.

From www.zoro.com

How to Measure a Drill Press How To Lubricate A Drill Press some signs that indicate a drill press spindle needs lubrication include increased friction or resistance when. essentially, you need to apply a lubricant like oil or grease to the spindle and its bearings to reduce friction and prevent damage. to properly lubricate your drill press with oil, start by cleaning the surfaces to be lubricated with a. How To Lubricate A Drill Press.

From hookedontool.com

What To Look For In A Drill Press? A Brief Guide HookedOnTool How To Lubricate A Drill Press Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth operation and preventing damage. discover how to extend the life and improve the performance of your drill press with essential maintenance tips. to properly lubricate your drill press with oil, start by cleaning the surfaces to be lubricated with a rag. How To Lubricate A Drill Press.

From drillay.com

How to Use Drill Press? Drillay How To Lubricate A Drill Press discover how to extend the life and improve the performance of your drill press with essential maintenance tips. some signs that indicate a drill press spindle needs lubrication include increased friction or resistance when. additionally, it’s important to lubricate the drill press to prevent rust and improve the smoothness of its operation. by keeping all components. How To Lubricate A Drill Press.

From www.youtube.com

How to Lubricate Your CNC Router Parts Bearing Blocks (Profile Linear Railbased Machines) YouTube How To Lubricate A Drill Press additionally, it’s important to lubricate the drill press to prevent rust and improve the smoothness of its operation. some signs that indicate a drill press spindle needs lubrication include increased friction or resistance when. by keeping all components clean, lubricated, and adjusted, you reduce wear and tear, preventing premature. essentially, you need to apply a lubricant. How To Lubricate A Drill Press.

From www.youtube.com

Repairing a rechargeable drill, how to lubricate it and restore it like new YouTube How To Lubricate A Drill Press some signs that indicate a drill press spindle needs lubrication include increased friction or resistance when. Find woodworking video tutorials, tips, techniques and more. additionally, it’s important to lubricate the drill press to prevent rust and improve the smoothness of its operation. your woodworking adventure starts here! essentially, you need to apply a lubricant like oil. How To Lubricate A Drill Press.

From www.wrenchandscrewdriver.com

How to lubricate an electric drill? Tool Box! How To Lubricate A Drill Press your woodworking adventure starts here! additionally, it’s important to lubricate the drill press to prevent rust and improve the smoothness of its operation. Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth operation and preventing damage. Find woodworking video tutorials, tips, techniques and more. discover how to extend the. How To Lubricate A Drill Press.

From gooddrillpress.com

How To Use A Drill Press As A Lathe? Mastering DIY Good Drill Press How To Lubricate A Drill Press discover how to extend the life and improve the performance of your drill press with essential maintenance tips. to properly lubricate your drill press with oil, start by cleaning the surfaces to be lubricated with a rag or brush to. by keeping all components clean, lubricated, and adjusted, you reduce wear and tear, preventing premature. Find woodworking. How To Lubricate A Drill Press.

From www.youtube.com

How to lubricate cordless drill? YouTube How To Lubricate A Drill Press to properly lubricate your drill press with oil, start by cleaning the surfaces to be lubricated with a rag or brush to. essentially, you need to apply a lubricant like oil or grease to the spindle and its bearings to reduce friction and prevent damage. your woodworking adventure starts here! additionally, it’s important to lubricate the. How To Lubricate A Drill Press.

From www.pinterest.com

How to Drill Straight Without a Drill Press? Easiest Ways Explained! Drillay Drill press How To Lubricate A Drill Press to properly lubricate your drill press with oil, start by cleaning the surfaces to be lubricated with a rag or brush to. by keeping all components clean, lubricated, and adjusted, you reduce wear and tear, preventing premature. essentially, you need to apply a lubricant like oil or grease to the spindle and its bearings to reduce friction. How To Lubricate A Drill Press.

From toolsprofy.com

How to Drill a Straight Hole Without a Drill Press? ToolsProfy How To Lubricate A Drill Press your woodworking adventure starts here! essentially, you need to apply a lubricant like oil or grease to the spindle and its bearings to reduce friction and prevent damage. Find woodworking video tutorials, tips, techniques and more. Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth operation and preventing damage. . How To Lubricate A Drill Press.

From www.youtube.com

How to RUIN Your Drill Press leatherwork YouTube How To Lubricate A Drill Press discover how to extend the life and improve the performance of your drill press with essential maintenance tips. essentially, you need to apply a lubricant like oil or grease to the spindle and its bearings to reduce friction and prevent damage. Always clean your drill press thoroughly before applying any lubricant to remove dust and debris, ensuring smooth. How To Lubricate A Drill Press.