Vacuum Bag Lamination Process . This section discusses the components of this system. Understanding the theory of vacuum systems and the advantages of vacuum bag laminating. the vacuum bag schedule is made up of a series of materials that provide a variety of services: Evaluating the equipment and materials used in vacuum bagging. Understand the theory of vacuum systems and the advantages of vacuum. this guide shows the principles and practical application of vacuum bagging for laminating composite materials with west system® epoxy. We’ll start with what vacuum is and then. Bagside release from the laminate, resin bleed, resin filtering or blocking, breathing (allowing gas to. the breather layer is used to maintain a “breather” path throughout the bag to the vacuum source, so that air and volatile can escape, and so continuous pressure can be applied to the laminate. This article is about how to make vacuum bags for use with composites.

from www.simtech.biz

Understanding the theory of vacuum systems and the advantages of vacuum bag laminating. Evaluating the equipment and materials used in vacuum bagging. the vacuum bag schedule is made up of a series of materials that provide a variety of services: the breather layer is used to maintain a “breather” path throughout the bag to the vacuum source, so that air and volatile can escape, and so continuous pressure can be applied to the laminate. This section discusses the components of this system. This article is about how to make vacuum bags for use with composites. Bagside release from the laminate, resin bleed, resin filtering or blocking, breathing (allowing gas to. We’ll start with what vacuum is and then. Understand the theory of vacuum systems and the advantages of vacuum. this guide shows the principles and practical application of vacuum bagging for laminating composite materials with west system® epoxy.

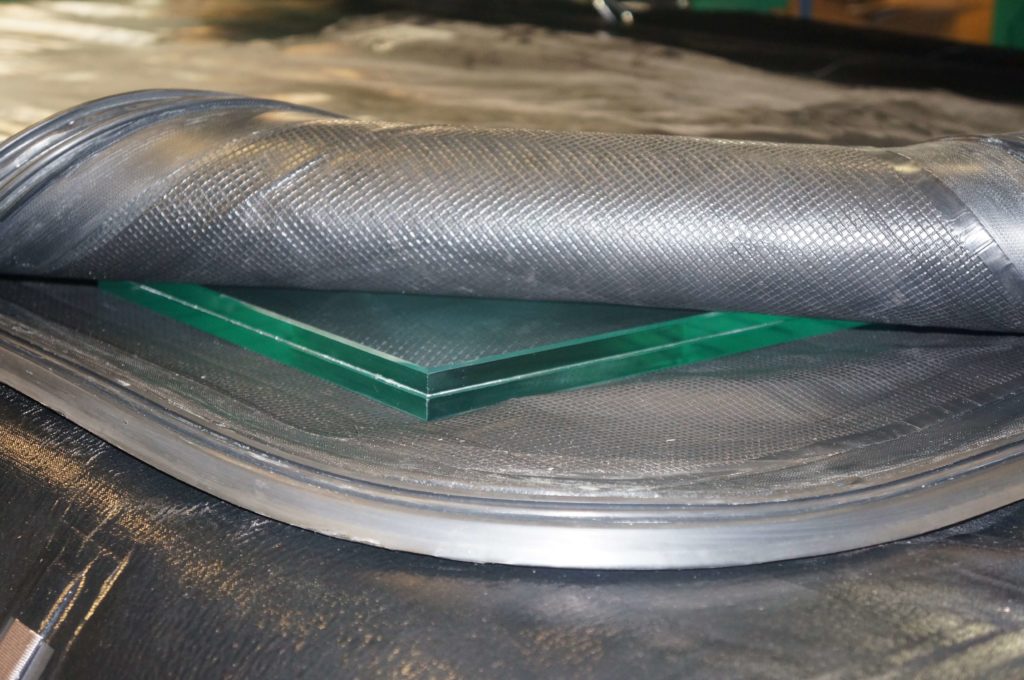

Laminating vacuum bag for furnace OBR Simtech

Vacuum Bag Lamination Process We’ll start with what vacuum is and then. the vacuum bag schedule is made up of a series of materials that provide a variety of services: Understanding the theory of vacuum systems and the advantages of vacuum bag laminating. the breather layer is used to maintain a “breather” path throughout the bag to the vacuum source, so that air and volatile can escape, and so continuous pressure can be applied to the laminate. This section discusses the components of this system. Bagside release from the laminate, resin bleed, resin filtering or blocking, breathing (allowing gas to. Understand the theory of vacuum systems and the advantages of vacuum. this guide shows the principles and practical application of vacuum bagging for laminating composite materials with west system® epoxy. This article is about how to make vacuum bags for use with composites. We’ll start with what vacuum is and then. Evaluating the equipment and materials used in vacuum bagging.

From www.youtube.com

Floor Vacuum Bond Lamination process YouTube Vacuum Bag Lamination Process We’ll start with what vacuum is and then. Understand the theory of vacuum systems and the advantages of vacuum. this guide shows the principles and practical application of vacuum bagging for laminating composite materials with west system® epoxy. This section discusses the components of this system. Bagside release from the laminate, resin bleed, resin filtering or blocking, breathing (allowing. Vacuum Bag Lamination Process.

From www.xinology.com

Glass Laminating Vacuum Bagging Films Introduction Vacuum Bag Lamination Process We’ll start with what vacuum is and then. the breather layer is used to maintain a “breather” path throughout the bag to the vacuum source, so that air and volatile can escape, and so continuous pressure can be applied to the laminate. Evaluating the equipment and materials used in vacuum bagging. This article is about how to make vacuum. Vacuum Bag Lamination Process.

From www.foxpak.com

Behind The Flexible Packaging Process Lamination Foxpak Vacuum Bag Lamination Process this guide shows the principles and practical application of vacuum bagging for laminating composite materials with west system® epoxy. the vacuum bag schedule is made up of a series of materials that provide a variety of services: Evaluating the equipment and materials used in vacuum bagging. Understanding the theory of vacuum systems and the advantages of vacuum bag. Vacuum Bag Lamination Process.

From www.semanticscholar.org

[PDF] Evaluation of DoubleVacuumBag Process For Composite Fabrication Vacuum Bag Lamination Process the breather layer is used to maintain a “breather” path throughout the bag to the vacuum source, so that air and volatile can escape, and so continuous pressure can be applied to the laminate. the vacuum bag schedule is made up of a series of materials that provide a variety of services: This section discusses the components of. Vacuum Bag Lamination Process.

From www.compositesone.com

Aerovac Process Materials are Designed for Vacuum Infusion Success Vacuum Bag Lamination Process Bagside release from the laminate, resin bleed, resin filtering or blocking, breathing (allowing gas to. Understanding the theory of vacuum systems and the advantages of vacuum bag laminating. the vacuum bag schedule is made up of a series of materials that provide a variety of services: the breather layer is used to maintain a “breather” path throughout the. Vacuum Bag Lamination Process.

From www.recyclingproductnews.com

Understanding flexible packaging for recycling Vacuum Bag Lamination Process We’ll start with what vacuum is and then. the breather layer is used to maintain a “breather” path throughout the bag to the vacuum source, so that air and volatile can escape, and so continuous pressure can be applied to the laminate. This article is about how to make vacuum bags for use with composites. Evaluating the equipment and. Vacuum Bag Lamination Process.

From in.cdgdbentre.edu.vn

Details 68+ vacuum bagging polyester resin in.cdgdbentre Vacuum Bag Lamination Process this guide shows the principles and practical application of vacuum bagging for laminating composite materials with west system® epoxy. Understand the theory of vacuum systems and the advantages of vacuum. the breather layer is used to maintain a “breather” path throughout the bag to the vacuum source, so that air and volatile can escape, and so continuous pressure. Vacuum Bag Lamination Process.

From www.youtube.com

Vacuum bag clamping wood lamination YouTube Vacuum Bag Lamination Process Understanding the theory of vacuum systems and the advantages of vacuum bag laminating. the breather layer is used to maintain a “breather” path throughout the bag to the vacuum source, so that air and volatile can escape, and so continuous pressure can be applied to the laminate. this guide shows the principles and practical application of vacuum bagging. Vacuum Bag Lamination Process.

From www.dynachem.eu

Automatic Vacuum Lamination Line Dynachem Automatic Lamination Vacuum Bag Lamination Process This section discusses the components of this system. the vacuum bag schedule is made up of a series of materials that provide a variety of services: We’ll start with what vacuum is and then. This article is about how to make vacuum bags for use with composites. Evaluating the equipment and materials used in vacuum bagging. Understanding the theory. Vacuum Bag Lamination Process.

From www.ucolin.com

silicone vacuum bag for laminated glass Green Tape, Silicone bag and Vacuum Bag Lamination Process We’ll start with what vacuum is and then. the breather layer is used to maintain a “breather” path throughout the bag to the vacuum source, so that air and volatile can escape, and so continuous pressure can be applied to the laminate. Bagside release from the laminate, resin bleed, resin filtering or blocking, breathing (allowing gas to. This section. Vacuum Bag Lamination Process.

From in.duhocakina.edu.vn

Discover more than 53 composite vacuum bagging process in.duhocakina Vacuum Bag Lamination Process We’ll start with what vacuum is and then. Evaluating the equipment and materials used in vacuum bagging. Understanding the theory of vacuum systems and the advantages of vacuum bag laminating. This section discusses the components of this system. this guide shows the principles and practical application of vacuum bagging for laminating composite materials with west system® epoxy. Understand the. Vacuum Bag Lamination Process.

From www.simtech.biz

Laminating vacuum bag for high temperature Oven or Autoclave use OBSJ Vacuum Bag Lamination Process the vacuum bag schedule is made up of a series of materials that provide a variety of services: the breather layer is used to maintain a “breather” path throughout the bag to the vacuum source, so that air and volatile can escape, and so continuous pressure can be applied to the laminate. This article is about how to. Vacuum Bag Lamination Process.

From www.durneysilicone.com

2MM Vacuum Silicone Bag for EVA Glass Laminate Furnace Vacuum Bag Lamination Process This article is about how to make vacuum bags for use with composites. the vacuum bag schedule is made up of a series of materials that provide a variety of services: this guide shows the principles and practical application of vacuum bagging for laminating composite materials with west system® epoxy. We’ll start with what vacuum is and then.. Vacuum Bag Lamination Process.

From in.duhocakina.edu.vn

Details more than 72 vacuum lamination bags super hot in.duhocakina Vacuum Bag Lamination Process Evaluating the equipment and materials used in vacuum bagging. the breather layer is used to maintain a “breather” path throughout the bag to the vacuum source, so that air and volatile can escape, and so continuous pressure can be applied to the laminate. Bagside release from the laminate, resin bleed, resin filtering or blocking, breathing (allowing gas to. . Vacuum Bag Lamination Process.

From www.researchgate.net

Laminated fitting specimen during deairing in vacuum bag lamination Vacuum Bag Lamination Process We’ll start with what vacuum is and then. Understand the theory of vacuum systems and the advantages of vacuum. the vacuum bag schedule is made up of a series of materials that provide a variety of services: this guide shows the principles and practical application of vacuum bagging for laminating composite materials with west system® epoxy. This article. Vacuum Bag Lamination Process.

From www.stylesgurus.com

vacuum bag fiberglass process Style Guru Fashion, Glitz, Glamour Vacuum Bag Lamination Process the vacuum bag schedule is made up of a series of materials that provide a variety of services: Evaluating the equipment and materials used in vacuum bagging. This section discusses the components of this system. This article is about how to make vacuum bags for use with composites. Understand the theory of vacuum systems and the advantages of vacuum.. Vacuum Bag Lamination Process.

From www.durney.net

Reusable Vacuum Bag for Glass Lamination Vacuum Bag Lamination Process This section discusses the components of this system. Understand the theory of vacuum systems and the advantages of vacuum. We’ll start with what vacuum is and then. the vacuum bag schedule is made up of a series of materials that provide a variety of services: Understanding the theory of vacuum systems and the advantages of vacuum bag laminating. . Vacuum Bag Lamination Process.

From www.uwplast.com

LDPE Pp Woven Bag Lamination Machine Film Lamination Process 236m Min Vacuum Bag Lamination Process Understanding the theory of vacuum systems and the advantages of vacuum bag laminating. the vacuum bag schedule is made up of a series of materials that provide a variety of services: We’ll start with what vacuum is and then. this guide shows the principles and practical application of vacuum bagging for laminating composite materials with west system® epoxy.. Vacuum Bag Lamination Process.

From zitpro.ru

Vacuum bagging Eckventil waschmaschine Vacuum Bag Lamination Process the breather layer is used to maintain a “breather” path throughout the bag to the vacuum source, so that air and volatile can escape, and so continuous pressure can be applied to the laminate. This article is about how to make vacuum bags for use with composites. This section discusses the components of this system. the vacuum bag. Vacuum Bag Lamination Process.

From www.simtech.biz

Laminating vacuum bag for high temperature Oven or Autoclave use OBSJ Vacuum Bag Lamination Process Understand the theory of vacuum systems and the advantages of vacuum. Bagside release from the laminate, resin bleed, resin filtering or blocking, breathing (allowing gas to. this guide shows the principles and practical application of vacuum bagging for laminating composite materials with west system® epoxy. This section discusses the components of this system. Understanding the theory of vacuum systems. Vacuum Bag Lamination Process.

From www.youtube.com

PP Woven Bag Laminating Machine YouTube Vacuum Bag Lamination Process This section discusses the components of this system. Understanding the theory of vacuum systems and the advantages of vacuum bag laminating. the breather layer is used to maintain a “breather” path throughout the bag to the vacuum source, so that air and volatile can escape, and so continuous pressure can be applied to the laminate. We’ll start with what. Vacuum Bag Lamination Process.

From www.youtube.com

Vacuum Press for veneering, laminating, bending wood, 3D foil / film Vacuum Bag Lamination Process Bagside release from the laminate, resin bleed, resin filtering or blocking, breathing (allowing gas to. This article is about how to make vacuum bags for use with composites. This section discusses the components of this system. Understand the theory of vacuum systems and the advantages of vacuum. Evaluating the equipment and materials used in vacuum bagging. Understanding the theory of. Vacuum Bag Lamination Process.

From www.researchgate.net

Vacuum bagging arrangement and the plot of temperature versus time and Vacuum Bag Lamination Process the breather layer is used to maintain a “breather” path throughout the bag to the vacuum source, so that air and volatile can escape, and so continuous pressure can be applied to the laminate. the vacuum bag schedule is made up of a series of materials that provide a variety of services: This article is about how to. Vacuum Bag Lamination Process.

From www.youtube.com

Wet Layup Vacuum Bagging Cored Carbon Fiber Panel YouTube Vacuum Bag Lamination Process Bagside release from the laminate, resin bleed, resin filtering or blocking, breathing (allowing gas to. the breather layer is used to maintain a “breather” path throughout the bag to the vacuum source, so that air and volatile can escape, and so continuous pressure can be applied to the laminate. Evaluating the equipment and materials used in vacuum bagging. We’ll. Vacuum Bag Lamination Process.

From in.duhocakina.edu.vn

Aggregate 67+ vacuum bagging process best in.duhocakina Vacuum Bag Lamination Process Evaluating the equipment and materials used in vacuum bagging. Understand the theory of vacuum systems and the advantages of vacuum. We’ll start with what vacuum is and then. this guide shows the principles and practical application of vacuum bagging for laminating composite materials with west system® epoxy. This article is about how to make vacuum bags for use with. Vacuum Bag Lamination Process.

From www.epoxyworks.com

Vacuum Bagging Basics Epoxyworks Vacuum Bag Lamination Process This article is about how to make vacuum bags for use with composites. the vacuum bag schedule is made up of a series of materials that provide a variety of services: this guide shows the principles and practical application of vacuum bagging for laminating composite materials with west system® epoxy. This section discusses the components of this system.. Vacuum Bag Lamination Process.

From explorecomposites.com

Laminating with Prepregs Explore Composites! Vacuum Bag Lamination Process Bagside release from the laminate, resin bleed, resin filtering or blocking, breathing (allowing gas to. This article is about how to make vacuum bags for use with composites. Understanding the theory of vacuum systems and the advantages of vacuum bag laminating. the breather layer is used to maintain a “breather” path throughout the bag to the vacuum source, so. Vacuum Bag Lamination Process.

From in.duhocakina.edu.vn

Discover more than 53 composite vacuum bagging process in.duhocakina Vacuum Bag Lamination Process Understanding the theory of vacuum systems and the advantages of vacuum bag laminating. Bagside release from the laminate, resin bleed, resin filtering or blocking, breathing (allowing gas to. the vacuum bag schedule is made up of a series of materials that provide a variety of services: We’ll start with what vacuum is and then. This article is about how. Vacuum Bag Lamination Process.

From www.simtech.biz

Laminating vacuum bag for furnace OBR Simtech Vacuum Bag Lamination Process Understand the theory of vacuum systems and the advantages of vacuum. This article is about how to make vacuum bags for use with composites. We’ll start with what vacuum is and then. the breather layer is used to maintain a “breather” path throughout the bag to the vacuum source, so that air and volatile can escape, and so continuous. Vacuum Bag Lamination Process.

From www.ebay.com

VACUUM BAGGING KIT BAG & VACUUM SEALANT TAPE & POLYESTER PEEL Vacuum Bag Lamination Process This article is about how to make vacuum bags for use with composites. Understand the theory of vacuum systems and the advantages of vacuum. Bagside release from the laminate, resin bleed, resin filtering or blocking, breathing (allowing gas to. This section discusses the components of this system. Understanding the theory of vacuum systems and the advantages of vacuum bag laminating.. Vacuum Bag Lamination Process.

From compositeslab.com

Vacuum Bag Molding Closed Molding CompositesLab Vacuum Bag Lamination Process Bagside release from the laminate, resin bleed, resin filtering or blocking, breathing (allowing gas to. Understanding the theory of vacuum systems and the advantages of vacuum bag laminating. Evaluating the equipment and materials used in vacuum bagging. the vacuum bag schedule is made up of a series of materials that provide a variety of services: Understand the theory of. Vacuum Bag Lamination Process.

From www.woodweb.com

Vacuum Bagging Outside the Form Vacuum Bag Lamination Process Bagside release from the laminate, resin bleed, resin filtering or blocking, breathing (allowing gas to. the vacuum bag schedule is made up of a series of materials that provide a variety of services: This article is about how to make vacuum bags for use with composites. This section discusses the components of this system. the breather layer is. Vacuum Bag Lamination Process.

From www.easycomposites.co.uk

How to Hand Laminate & Vacuum Bag a Simple Carbon Fibre Part Easy Vacuum Bag Lamination Process this guide shows the principles and practical application of vacuum bagging for laminating composite materials with west system® epoxy. Evaluating the equipment and materials used in vacuum bagging. We’ll start with what vacuum is and then. Understanding the theory of vacuum systems and the advantages of vacuum bag laminating. This section discusses the components of this system. This article. Vacuum Bag Lamination Process.

From www.leverglass.com

Vacuum Bagging film for Laminated Glass Vacuum Bag Lamination Process Bagside release from the laminate, resin bleed, resin filtering or blocking, breathing (allowing gas to. Understanding the theory of vacuum systems and the advantages of vacuum bag laminating. the vacuum bag schedule is made up of a series of materials that provide a variety of services: this guide shows the principles and practical application of vacuum bagging for. Vacuum Bag Lamination Process.

From www.macnaughtongroup.com

Vacuum Bagging Techniques Vacuum Bag Lamination Process Bagside release from the laminate, resin bleed, resin filtering or blocking, breathing (allowing gas to. the breather layer is used to maintain a “breather” path throughout the bag to the vacuum source, so that air and volatile can escape, and so continuous pressure can be applied to the laminate. Understand the theory of vacuum systems and the advantages of. Vacuum Bag Lamination Process.