Press Brake Flange Length . This applies to holes in the part too; Compare mechanical, hydraulic, and electric press brakes, and discover their. Wila recommends a flange length that is at least 6 times the material thickness using regular press brake tools. The minimum flange that can bend comfortably in any given die width is equal to 70 percent of that die. The parameters that can be. That is, holes should be located. A press brake bending calculator is a tool used to calculate the necessary parameters for bending a sheet metal part on a press brake machine. Keep flange lengths in mind when choosing your v dies. The flange length should be at least six times the metal thickness. The minimum flange a given v die can form is. A smaller v results in creating a. Learn everything about press brakes, the machines that bend and shape metal with incredible precision. The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on a press brake.

from shop.adhmt.com

Wila recommends a flange length that is at least 6 times the material thickness using regular press brake tools. The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on a press brake. This applies to holes in the part too; The minimum flange a given v die can form is. Learn everything about press brakes, the machines that bend and shape metal with incredible precision. The minimum flange that can bend comfortably in any given die width is equal to 70 percent of that die. The flange length should be at least six times the metal thickness. A press brake bending calculator is a tool used to calculate the necessary parameters for bending a sheet metal part on a press brake machine. The parameters that can be. A smaller v results in creating a.

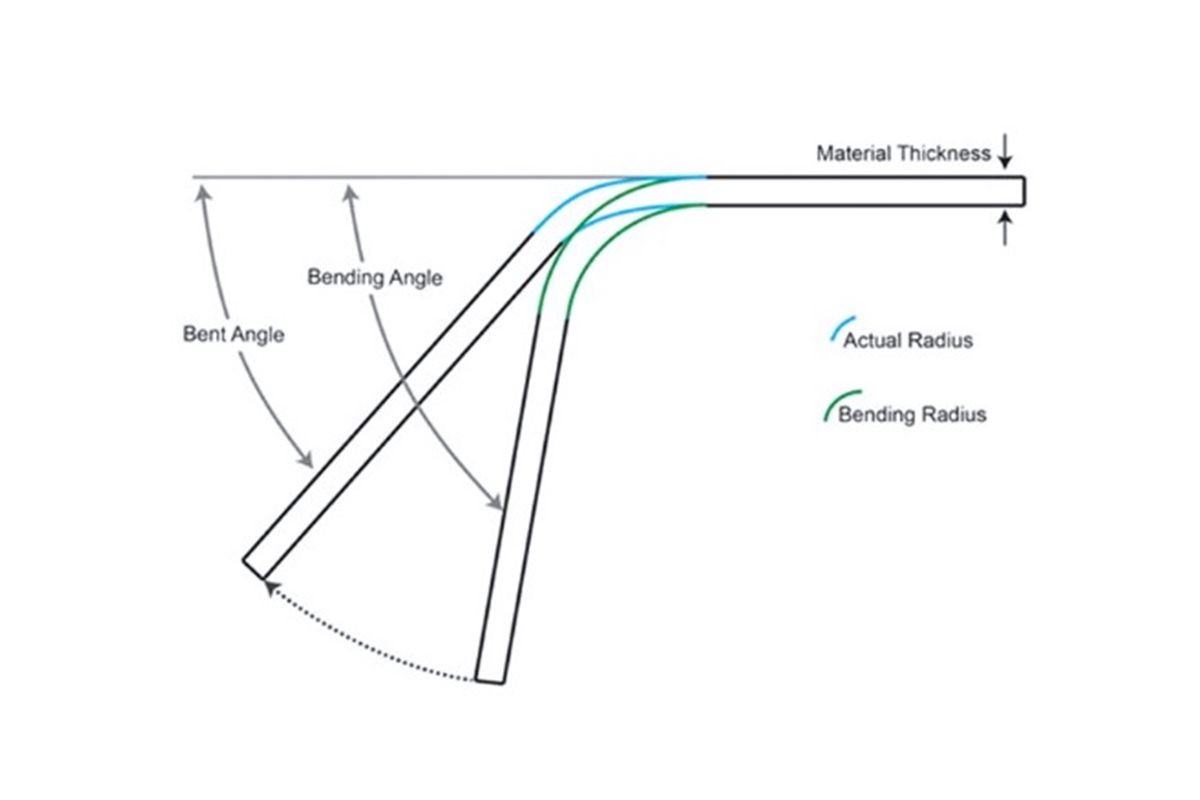

Minimizing springback in press brake bending with the right formulas

Press Brake Flange Length The minimum flange that can bend comfortably in any given die width is equal to 70 percent of that die. The minimum flange that can bend comfortably in any given die width is equal to 70 percent of that die. Keep flange lengths in mind when choosing your v dies. A smaller v results in creating a. The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on a press brake. Learn everything about press brakes, the machines that bend and shape metal with incredible precision. Compare mechanical, hydraulic, and electric press brakes, and discover their. That is, holes should be located. The minimum flange a given v die can form is. The flange length should be at least six times the metal thickness. A press brake bending calculator is a tool used to calculate the necessary parameters for bending a sheet metal part on a press brake machine. Wila recommends a flange length that is at least 6 times the material thickness using regular press brake tools. This applies to holes in the part too; The parameters that can be.

From www.pipingmaterial.ae

Din 2576 pn40 flange Din 2576 pn40 slip on/ plate flanges dimension Press Brake Flange Length The minimum flange a given v die can form is. That is, holes should be located. The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on a press brake. A press brake bending calculator is a tool used to calculate the necessary parameters for bending a. Press Brake Flange Length.

From shop.adhmt.com

Minimizing springback in press brake bending with the right formulas Press Brake Flange Length Learn everything about press brakes, the machines that bend and shape metal with incredible precision. The flange length should be at least six times the metal thickness. The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on a press brake. The minimum flange that can bend. Press Brake Flange Length.

From www.conic.co.jp

vol.3 PREPARATION FOR BENDING 1 TECHNICAL GUIDE CONIC Press Brake Flange Length That is, holes should be located. The minimum flange a given v die can form is. The parameters that can be. Wila recommends a flange length that is at least 6 times the material thickness using regular press brake tools. The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size. Press Brake Flange Length.

From www.amada.com

HM 2204 — HighPrecision Hydraulic Press Brake AMADA AMERICA Press Brake Flange Length A smaller v results in creating a. The minimum flange that can bend comfortably in any given die width is equal to 70 percent of that die. Keep flange lengths in mind when choosing your v dies. This applies to holes in the part too; Learn everything about press brakes, the machines that bend and shape metal with incredible precision.. Press Brake Flange Length.

From www.pinterest.ca

Baileigh HPB20 220V 3 Phase 20 Ton Horizontal Bending Press in 2023 Press Brake Flange Length A press brake bending calculator is a tool used to calculate the necessary parameters for bending a sheet metal part on a press brake machine. Wila recommends a flange length that is at least 6 times the material thickness using regular press brake tools. The minimum flange that can bend comfortably in any given die width is equal to 70. Press Brake Flange Length.

From www.thefabricator.com

The rules of press brake tool selection Press Brake Flange Length The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on a press brake. Learn everything about press brakes, the machines that bend and shape metal with incredible precision. The minimum flange that can bend comfortably in any given die width is equal to 70 percent of. Press Brake Flange Length.

From hacopress.en.made-in-china.com

Accurl Wc67K Nc Hydraulic Press Brake Flange Bending Machine China Press Brake Flange Length The minimum flange a given v die can form is. A press brake bending calculator is a tool used to calculate the necessary parameters for bending a sheet metal part on a press brake machine. A smaller v results in creating a. Wila recommends a flange length that is at least 6 times the material thickness using regular press brake. Press Brake Flange Length.

From www.harsle.com

PRESS BRAKE MACHINE FORMING HARSLE Press Brake Flange Length Keep flange lengths in mind when choosing your v dies. The minimum flange that can bend comfortably in any given die width is equal to 70 percent of that die. Compare mechanical, hydraulic, and electric press brakes, and discover their. A press brake bending calculator is a tool used to calculate the necessary parameters for bending a sheet metal part. Press Brake Flange Length.

From learningzonexisaaaaacx0o.z14.web.core.windows.net

Metric Flange Size Chart Press Brake Flange Length That is, holes should be located. Learn everything about press brakes, the machines that bend and shape metal with incredible precision. Compare mechanical, hydraulic, and electric press brakes, and discover their. A press brake bending calculator is a tool used to calculate the necessary parameters for bending a sheet metal part on a press brake machine. The parameters that can. Press Brake Flange Length.

From www.thefabricator.com

Press brake basics Bending across the hem Press Brake Flange Length The flange length should be at least six times the metal thickness. The minimum flange that can bend comfortably in any given die width is equal to 70 percent of that die. That is, holes should be located. The parameters that can be. Keep flange lengths in mind when choosing your v dies. Wila recommends a flange length that is. Press Brake Flange Length.

From www.thefabricator.com

Press brake bending basics Proper measurement of formed parts The Press Brake Flange Length The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on a press brake. The flange length should be at least six times the metal thickness. Wila recommends a flange length that is at least 6 times the material thickness using regular press brake tools. Compare mechanical,. Press Brake Flange Length.

From knowledge.autodesk.com

Avoiding collisions and pullup when forming sheet metal on a press Press Brake Flange Length The minimum flange a given v die can form is. The minimum flange that can bend comfortably in any given die width is equal to 70 percent of that die. Learn everything about press brakes, the machines that bend and shape metal with incredible precision. Wila recommends a flange length that is at least 6 times the material thickness using. Press Brake Flange Length.

From www.thefabricator.com

Press brake forming insights The return flange goes deep Press Brake Flange Length The minimum flange that can bend comfortably in any given die width is equal to 70 percent of that die. The minimum flange a given v die can form is. That is, holes should be located. Compare mechanical, hydraulic, and electric press brakes, and discover their. Learn everything about press brakes, the machines that bend and shape metal with incredible. Press Brake Flange Length.

From midwestpressbrake.com

Gooseneck Midwest Press Brake Dies Inc. Press Brake Flange Length The minimum flange that can bend comfortably in any given die width is equal to 70 percent of that die. This applies to holes in the part too; That is, holes should be located. A press brake bending calculator is a tool used to calculate the necessary parameters for bending a sheet metal part on a press brake machine. The. Press Brake Flange Length.

From www.wholesaletrailerb2b.com

Flange Brake 2.25in RD Press Brake Flange Length That is, holes should be located. The parameters that can be. The minimum flange that can bend comfortably in any given die width is equal to 70 percent of that die. This applies to holes in the part too; Wila recommends a flange length that is at least 6 times the material thickness using regular press brake tools. A press. Press Brake Flange Length.

From midwestpressbrake.com

Standing Seam Double Flange Midwest Press Brake Dies Inc. Press Brake Flange Length The minimum flange that can bend comfortably in any given die width is equal to 70 percent of that die. A press brake bending calculator is a tool used to calculate the necessary parameters for bending a sheet metal part on a press brake machine. The flange length should be at least six times the metal thickness. That is, holes. Press Brake Flange Length.

From www.wilatooling.com

Bottom bending (bottoming) WILA Press Brake Flange Length Keep flange lengths in mind when choosing your v dies. The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on a press brake. A press brake bending calculator is a tool used to calculate the necessary parameters for bending a sheet metal part on a press. Press Brake Flange Length.

From www.wilatooling.com

Bending short flanges WILA Press Brake Flange Length The minimum flange that can bend comfortably in any given die width is equal to 70 percent of that die. Keep flange lengths in mind when choosing your v dies. Wila recommends a flange length that is at least 6 times the material thickness using regular press brake tools. A smaller v results in creating a. That is, holes should. Press Brake Flange Length.

From mavink.com

Api Flange Dimension Chart Press Brake Flange Length Learn everything about press brakes, the machines that bend and shape metal with incredible precision. A smaller v results in creating a. Compare mechanical, hydraulic, and electric press brakes, and discover their. Keep flange lengths in mind when choosing your v dies. The minimum flange a given v die can form is. The upper tool splits that in half, and. Press Brake Flange Length.

From www.thefabricator.com

What happens when you don’t design for the press brake? Press Brake Flange Length This applies to holes in the part too; The parameters that can be. Wila recommends a flange length that is at least 6 times the material thickness using regular press brake tools. Keep flange lengths in mind when choosing your v dies. A press brake bending calculator is a tool used to calculate the necessary parameters for bending a sheet. Press Brake Flange Length.

From cepvezuu.blob.core.windows.net

Sheet Metal Brake Bend Radius at Roseline Speight blog Press Brake Flange Length Wila recommends a flange length that is at least 6 times the material thickness using regular press brake tools. The minimum flange a given v die can form is. A smaller v results in creating a. The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on. Press Brake Flange Length.

From www.youtube.com

Step bending with Bystronic Brake Press full automatic YouTube Press Brake Flange Length The flange length should be at least six times the metal thickness. Wila recommends a flange length that is at least 6 times the material thickness using regular press brake tools. The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on a press brake. Keep flange. Press Brake Flange Length.

From selmach.com

Press Brake Toolings, A Guide to Punches and Dies Selmach™ Press Brake Flange Length A smaller v results in creating a. Wila recommends a flange length that is at least 6 times the material thickness using regular press brake tools. The minimum flange a given v die can form is. The parameters that can be. The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange. Press Brake Flange Length.

From exyzhulwf.blob.core.windows.net

How To Use Flange Measuring Tool at Ray Perales blog Press Brake Flange Length The parameters that can be. Keep flange lengths in mind when choosing your v dies. Wila recommends a flange length that is at least 6 times the material thickness using regular press brake tools. Learn everything about press brakes, the machines that bend and shape metal with incredible precision. A smaller v results in creating a. Compare mechanical, hydraulic, and. Press Brake Flange Length.

From www.thefabricator.com

Press brake forming insights The return flange goes deep Press Brake Flange Length That is, holes should be located. The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on a press brake. Wila recommends a flange length that is at least 6 times the material thickness using regular press brake tools. A smaller v results in creating a. Learn. Press Brake Flange Length.

From www.youtube.com

Small Flanges on a Press Brake Tool YouTube Press Brake Flange Length The minimum flange that can bend comfortably in any given die width is equal to 70 percent of that die. This applies to holes in the part too; Keep flange lengths in mind when choosing your v dies. Compare mechanical, hydraulic, and electric press brakes, and discover their. The minimum flange a given v die can form is. The parameters. Press Brake Flange Length.

From www.thefabricator.com

Press brake bending tips for forming tapered bends and determining Press Brake Flange Length This applies to holes in the part too; That is, holes should be located. Compare mechanical, hydraulic, and electric press brakes, and discover their. Wila recommends a flange length that is at least 6 times the material thickness using regular press brake tools. A press brake bending calculator is a tool used to calculate the necessary parameters for bending a. Press Brake Flange Length.

From www.thefabricator.com

Press brakeformed tub girders accelerate U.S infrastructure rebuilding Press Brake Flange Length This applies to holes in the part too; The minimum flange a given v die can form is. Compare mechanical, hydraulic, and electric press brakes, and discover their. A press brake bending calculator is a tool used to calculate the necessary parameters for bending a sheet metal part on a press brake machine. Learn everything about press brakes, the machines. Press Brake Flange Length.

From www.thefabricator.com

Press brake forming insights The return flange goes deep Press Brake Flange Length The minimum flange a given v die can form is. Learn everything about press brakes, the machines that bend and shape metal with incredible precision. A press brake bending calculator is a tool used to calculate the necessary parameters for bending a sheet metal part on a press brake machine. That is, holes should be located. The parameters that can. Press Brake Flange Length.

From www.thefabricator.com

Press brake bending tips for forming tapered bends and determining Press Brake Flange Length Learn everything about press brakes, the machines that bend and shape metal with incredible precision. A smaller v results in creating a. The minimum flange a given v die can form is. Wila recommends a flange length that is at least 6 times the material thickness using regular press brake tools. The flange length should be at least six times. Press Brake Flange Length.

From www.approvedsheetmetal.com

The Perfect Fit Flange Formula (Updated for 2024) ASM Press Brake Flange Length Keep flange lengths in mind when choosing your v dies. A smaller v results in creating a. Learn everything about press brakes, the machines that bend and shape metal with incredible precision. That is, holes should be located. A press brake bending calculator is a tool used to calculate the necessary parameters for bending a sheet metal part on a. Press Brake Flange Length.

From www.thefabricator.com

How to bend cosmetically critical parts on the press brake Press Brake Flange Length Compare mechanical, hydraulic, and electric press brakes, and discover their. A press brake bending calculator is a tool used to calculate the necessary parameters for bending a sheet metal part on a press brake machine. That is, holes should be located. The minimum flange that can bend comfortably in any given die width is equal to 70 percent of that. Press Brake Flange Length.

From www.thefabricator.com

Horizontal bending on the press brake The Fabricator Press Brake Flange Length A smaller v results in creating a. Learn everything about press brakes, the machines that bend and shape metal with incredible precision. That is, holes should be located. The flange length should be at least six times the metal thickness. A press brake bending calculator is a tool used to calculate the necessary parameters for bending a sheet metal part. Press Brake Flange Length.

From aoxuancnc.en.made-in-china.com

Manual Press Brake Pneumatic Tdf Flange Bending Folding Machine for Press Brake Flange Length That is, holes should be located. The parameters that can be. Keep flange lengths in mind when choosing your v dies. A smaller v results in creating a. The upper tool splits that in half, and as a result, 3x material thickness is the recommended minimum flange size for air bending on a press brake. The flange length should be. Press Brake Flange Length.

From www.thefabricator.com

Press brake bending tips for forming tapered bends and determining Press Brake Flange Length This applies to holes in the part too; Wila recommends a flange length that is at least 6 times the material thickness using regular press brake tools. That is, holes should be located. A smaller v results in creating a. A press brake bending calculator is a tool used to calculate the necessary parameters for bending a sheet metal part. Press Brake Flange Length.