Rockwell Scale A . The first is a small pressure application that determines metal hardness or resistance under a light, precisely controlled force. N and s = various scale factors that can be found in the chart below. The rockwell scale is one of the standard methods used to measure a material's hardness. The indentation tool, or indenter as it’s called in the rockwell. Rockwell standard hardness scales and applications. A widely used variant of the rockwell hardness test is the superficial. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: The equation for the rockwell hardness test for metals is below: The rockwell test measures the depth of. This table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. The scale has different numbers that. Hra, hrbw, hrc, hr30n, hr15tw), each. D=depth from zero load point.

from mungfali.com

The rockwell test measures the depth of. N and s = various scale factors that can be found in the chart below. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. Rockwell standard hardness scales and applications. D=depth from zero load point. The equation for the rockwell hardness test for metals is below: The scale has different numbers that. A widely used variant of the rockwell hardness test is the superficial. The indentation tool, or indenter as it’s called in the rockwell. This table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales.

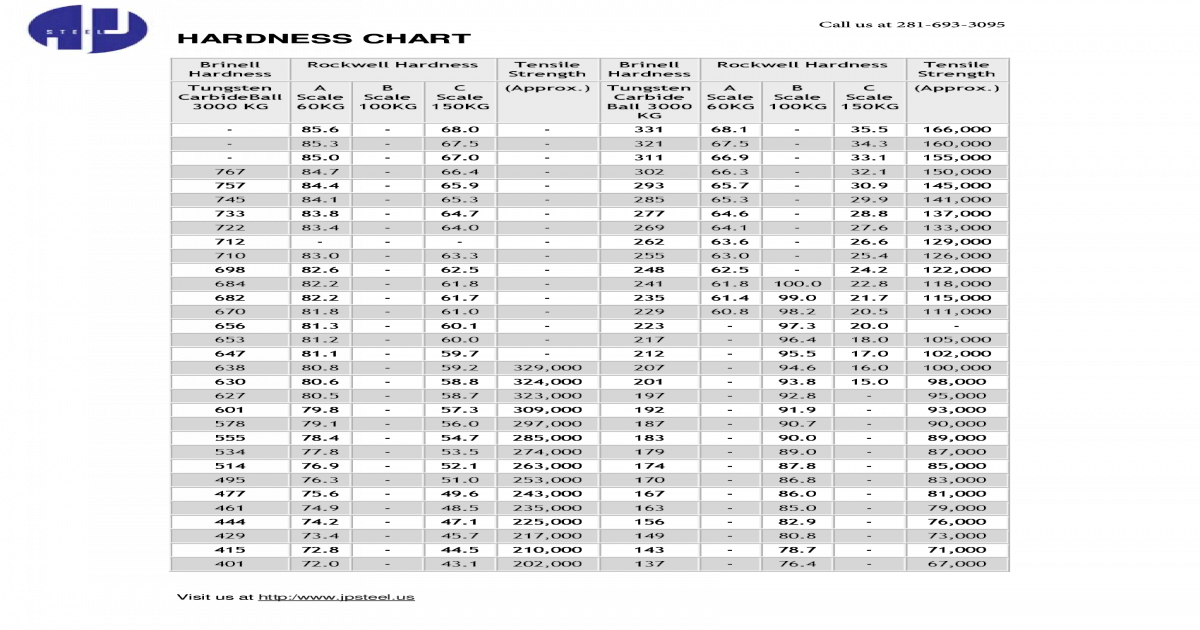

Rockwell Hardness Scale Chart

Rockwell Scale A Rockwell standard hardness scales and applications. D=depth from zero load point. The indentation tool, or indenter as it’s called in the rockwell. A widely used variant of the rockwell hardness test is the superficial. The scale has different numbers that. The rockwell scale is one of the standard methods used to measure a material's hardness. Hra, hrbw, hrc, hr30n, hr15tw), each. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The first is a small pressure application that determines metal hardness or resistance under a light, precisely controlled force. N and s = various scale factors that can be found in the chart below. Rockwell standard hardness scales and applications. The equation for the rockwell hardness test for metals is below: This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: This table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. The rockwell test measures the depth of.

From www.knivesfromjapan.co.uk

Rockwell Scale Rockwell Scale A D=depth from zero load point. The first is a small pressure application that determines metal hardness or resistance under a light, precisely controlled force. The rockwell test measures the depth of. A widely used variant of the rockwell hardness test is the superficial. The indentation tool, or indenter as it’s called in the rockwell. This results in 30 different rockwell. Rockwell Scale A.

From amesportablehardnesstesters.com

Hardness Testing in Rockwell Scales Rockwell Scale A Hra, hrbw, hrc, hr30n, hr15tw), each. The scale has different numbers that. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: The rockwell scale is one of the standard methods used to measure a material's hardness. Rockwell standard hardness scales and applications. The. Rockwell Scale A.

From mungfali.com

Rockwell Hardness Scale Chart Rockwell Scale A The rockwell test measures the depth of. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. A widely used variant of the rockwell hardness test is the superficial. The scale has different numbers that. Rockwell standard hardness scales and applications. The indentation tool, or indenter as it’s called in the rockwell. Hra, hrbw,. Rockwell Scale A.

From www.slideserve.com

PPT Bruce Mayer, PE Licensed Electrical & Mechanical Engineer BMayer Rockwell Scale A 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The rockwell scale is one of the standard methods used to measure a material's hardness. D=depth from zero load point. The rockwell test measures the depth of. Rockwell standard hardness scales and applications. This table shows approximate hardness of steel using brinell, rockwell b. Rockwell Scale A.

From www.hardnessgauge.com

What is the Rockwell Scale? Hardness Tester Rockwell Scale A The first is a small pressure application that determines metal hardness or resistance under a light, precisely controlled force. The rockwell test measures the depth of. A widely used variant of the rockwell hardness test is the superficial. The equation for the rockwell hardness test for metals is below: This table shows approximate hardness of steel using brinell, rockwell b. Rockwell Scale A.

From mungfali.com

Rockwell Hardness Scale Chart Rockwell Scale A This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: N and s = various scale factors that can be found in the chart below. The equation for the rockwell hardness test for metals is below: Rockwell standard hardness scales and applications. The rockwell. Rockwell Scale A.

From engistudies.blogspot.com

Rockwell Hardness Test Experiment & its Advantages Engistudies Rockwell Scale A 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The rockwell scale is one of the standard methods used to measure a material's hardness. Rockwell standard hardness scales and applications. The equation for the rockwell hardness test for metals is below: This results in 30 different rockwell scales standardized according to iso 6508. Rockwell Scale A.

From metallography-matters.buehler.com

Material Thickness When Choosing a Rockwell Scale Metallography Matters Rockwell Scale A N and s = various scale factors that can be found in the chart below. A widely used variant of the rockwell hardness test is the superficial. The first is a small pressure application that determines metal hardness or resistance under a light, precisely controlled force. 21 rows the rockwell scale is a hardness scale based on indentation hardness of. Rockwell Scale A.

From mungfali.com

Rockwell Hardness Scale Chart Rockwell Scale A The equation for the rockwell hardness test for metals is below: Rockwell standard hardness scales and applications. The scale has different numbers that. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. Hra, hrbw, hrc, hr30n, hr15tw), each. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18. Rockwell Scale A.

From payscalechart.z28.web.core.windows.net

rockwell scale conversion chart Rockwell hardness chart metals brinell Rockwell Scale A 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: The scale has different numbers that. The equation for the rockwell hardness test for metals is below: The. Rockwell Scale A.

From www.koiknives.com

Rockwell Hardness Scale What It Means for Knife Performance Koi Knives Rockwell Scale A The equation for the rockwell hardness test for metals is below: This table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. Rockwell standard hardness scales and applications. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The scale has different numbers that. A widely used variant of. Rockwell Scale A.

From mungfali.com

Rockwell Hardness Scale Chart Rockwell Scale A The rockwell test measures the depth of. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: The equation for the rockwell hardness test for metals is below: D=depth from zero load point. Rockwell standard hardness scales and applications. This table shows approximate hardness. Rockwell Scale A.

From blog.hdmdknives.com

What Does the Rockwell Hardness Scale Mean for Knives? HDMD Knives Blog Rockwell Scale A The scale has different numbers that. The rockwell test measures the depth of. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The indentation tool, or indenter as it’s called in the rockwell. Hra, hrbw, hrc, hr30n, hr15tw), each. This results in 30 different rockwell scales standardized according to iso 6508 and astm. Rockwell Scale A.

From www.jewelry-secrets.com

ROCKWELL SCALE VS THE MOH’S SCALE Jewelry Secrets Rockwell Scale A The rockwell scale is one of the standard methods used to measure a material's hardness. The indentation tool, or indenter as it’s called in the rockwell. This table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. N and s = various scale factors that can be found in the chart below. Rockwell standard hardness. Rockwell Scale A.

From www.slideserve.com

PPT Hardness test PowerPoint Presentation, free download ID2099201 Rockwell Scale A D=depth from zero load point. This table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. Rockwell standard hardness scales and applications. The equation for the rockwell hardness test for metals is below: N and s = various scale factors that can be found in the chart below. The rockwell scale is one of the. Rockwell Scale A.

From amesportablehardnesstesters.com

Raised Flat 1/8" Rockwell Scale A N and s = various scale factors that can be found in the chart below. The scale has different numbers that. The rockwell test measures the depth of. The first is a small pressure application that determines metal hardness or resistance under a light, precisely controlled force. The equation for the rockwell hardness test for metals is below: D=depth from. Rockwell Scale A.

From payscalechart.z28.web.core.windows.net

rockwell scale conversion chart Rockwell hardness chart metals brinell Rockwell Scale A Rockwell standard hardness scales and applications. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: This table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. The rockwell test measures the depth of. Hra, hrbw, hrc, hr30n, hr15tw),. Rockwell Scale A.

From einvoice.fpt.com.vn

The Rockwell Metal Hardness Scales Explained, 54 OFF Rockwell Scale A The rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: Hra, hrbw, hrc, hr30n, hr15tw), each. D=depth from zero load point. Rockwell standard. Rockwell Scale A.

From payscalechart.z28.web.core.windows.net

rockwell scale conversion chart Rockwell hardness chart metals brinell Rockwell Scale A N and s = various scale factors that can be found in the chart below. The indentation tool, or indenter as it’s called in the rockwell. A widely used variant of the rockwell hardness test is the superficial. The first is a small pressure application that determines metal hardness or resistance under a light, precisely controlled force. Rockwell standard hardness. Rockwell Scale A.

From www.vrogue.co

Rockwell Hardness Scale Conversion Chart vrogue.co Rockwell Scale A N and s = various scale factors that can be found in the chart below. This table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. Hra, hrbw, hrc, hr30n, hr15tw), each. A widely used variant of the rockwell hardness test is the superficial. 21 rows the rockwell scale is a hardness scale based on. Rockwell Scale A.

From amesportablehardnesstesters.com

The Rockwell Metal Hardness Scales Explained Rockwell Scale A The rockwell scale is one of the standard methods used to measure a material's hardness. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The first is a small pressure application that determines metal hardness or resistance under a light, precisely controlled force. The equation for the rockwell hardness test for metals is. Rockwell Scale A.

From alchetron.com

Rockwell scale Alchetron, The Free Social Encyclopedia Rockwell Scale A A widely used variant of the rockwell hardness test is the superficial. The indentation tool, or indenter as it’s called in the rockwell. The rockwell test measures the depth of. The rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that. The equation for the rockwell hardness test for metals. Rockwell Scale A.

From inksterspartoftherock.blogspot.com

20 Best Rockwell Hardness Chart Rockwell Scale A N and s = various scale factors that can be found in the chart below. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: The rockwell scale is one of the standard methods used to measure a material's hardness. D=depth from zero load. Rockwell Scale A.

From www.penntoolco.com

SPI Dial Rockwell Scale Hardness Tester, Rockwell & Superficial Rockwell Scale A The scale has different numbers that. The rockwell scale is one of the standard methods used to measure a material's hardness. Hra, hrbw, hrc, hr30n, hr15tw), each. A widely used variant of the rockwell hardness test is the superficial. The equation for the rockwell hardness test for metals is below: The rockwell test measures the depth of. Rockwell standard hardness. Rockwell Scale A.

From payscalechart.z28.web.core.windows.net

rockwell scale chart Metal hardness scale Rockwell Scale A N and s = various scale factors that can be found in the chart below. The first is a small pressure application that determines metal hardness or resistance under a light, precisely controlled force. Hra, hrbw, hrc, hr30n, hr15tw), each. The rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers. Rockwell Scale A.

From www.tec-science.com

Rockwell hardness test tecscience Rockwell Scale A The first is a small pressure application that determines metal hardness or resistance under a light, precisely controlled force. The indentation tool, or indenter as it’s called in the rockwell. The rockwell test measures the depth of. D=depth from zero load point. A widely used variant of the rockwell hardness test is the superficial. The scale has different numbers that.. Rockwell Scale A.

From mungfali.com

Rockwell Hardness Scale Chart Rockwell Scale A Hra, hrbw, hrc, hr30n, hr15tw), each. The equation for the rockwell hardness test for metals is below: The scale has different numbers that. N and s = various scale factors that can be found in the chart below. The rockwell test measures the depth of. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a. Rockwell Scale A.

From www.auto-met.com

Rockwell Hardness Scale Indentor Load Chart Rockwell Scale A The indentation tool, or indenter as it’s called in the rockwell. Rockwell standard hardness scales and applications. D=depth from zero load point. The rockwell scale is one of the standard methods used to measure a material's hardness. The rockwell test measures the depth of. N and s = various scale factors that can be found in the chart below. The. Rockwell Scale A.

From mavink.com

Rockwell Hardness Scale Conversion Chart Rockwell Scale A A widely used variant of the rockwell hardness test is the superficial. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The rockwell test measures the depth. Rockwell Scale A.

From www.tec-science.com

Rockwell hardness test tecscience Rockwell Scale A The scale has different numbers that. D=depth from zero load point. The equation for the rockwell hardness test for metals is below: Rockwell standard hardness scales and applications. The rockwell test measures the depth of. Hra, hrbw, hrc, hr30n, hr15tw), each. The indentation tool, or indenter as it’s called in the rockwell. This table shows approximate hardness of steel using. Rockwell Scale A.

From www.researchgate.net

Scale "A" Rockwell hardness values for both alloys after different Rockwell Scale A The equation for the rockwell hardness test for metals is below: Rockwell standard hardness scales and applications. Hra, hrbw, hrc, hr30n, hr15tw), each. N and s = various scale factors that can be found in the chart below. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or. Rockwell Scale A.

From www.penntoolco.com

SPI Dial Rockwell Scale Hardness Tester, Superficial Rockwell 21314 Rockwell Scale A This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a, b, c, 30n, 15t) or rockwell test methods (e.g.: This table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. The indentation tool, or indenter as it’s called in the rockwell. Hra, hrbw, hrc, hr30n, hr15tw), each. D=depth. Rockwell Scale A.

From www.yorksaw.com

Rockwell Hardness Guide What it is, How to Measure, & More Rockwell Scale A 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. N and s = various scale factors that can be found in the chart below. The indentation tool, or indenter as it’s called in the rockwell. The equation for the rockwell hardness test for metals is below: D=depth from zero load point. A widely. Rockwell Scale A.

From whatispiping.com

Rockwell Hardness Scale for Hardness Test What Is Piping Rockwell Scale A Hra, hrbw, hrc, hr30n, hr15tw), each. The scale has different numbers that. The rockwell scale is one of the standard methods used to measure a material's hardness. This table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. This results in 30 different rockwell scales standardized according to iso 6508 and astm e18 (e.g., a,. Rockwell Scale A.

From tillyclark.z13.web.core.windows.net

Rockwell Hardness Conversion Chart Rockwell Scale A Rockwell standard hardness scales and applications. Hra, hrbw, hrc, hr30n, hr15tw), each. N and s = various scale factors that can be found in the chart below. A widely used variant of the rockwell hardness test is the superficial. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. D=depth from zero load point.. Rockwell Scale A.