How To Improve Etching . Etching can be characterized by how much of the process is: Using the chemistry of the etch to remove material into a solution (liquid. We will also explore the specific. Dry etching advantages • eliminates handling of dangerous acids and solvents • uses small amounts of chemicals • isotropic or anisotropic. In dry etchants, the etch reactants come form a gas. This phenomenon is also known as the rie lag effect or arde (aspect ratio dependent etching). The solution is to smooth out extreme edge discontinuities and enhance edge performance, and this is done by tuning the plasma sheath at the edge to produce a constant,. Wet etching vs dry etching. Throughout this guide, we will delve into different etching techniques, including chemical etching, photochemical etching, and dry etching. The microloading effect is a phenomenon in which fewer fluorine radicals transport the bottom of narrow gaps, causing the etch rate to decrease depending on pattern width. In general, the greater the. Laser etching is more than twice as fast as engraving and annealing, making it the fastest laser marking process. In wet etchants, the etch reactants come form a liquid source. Selectivity is the ratio between two etch rates, usually between the material being etched and the mask.

from spie.org

This phenomenon is also known as the rie lag effect or arde (aspect ratio dependent etching). In wet etchants, the etch reactants come form a liquid source. In general, the greater the. Selectivity is the ratio between two etch rates, usually between the material being etched and the mask. Wet etching vs dry etching. We will also explore the specific. Laser etching is more than twice as fast as engraving and annealing, making it the fastest laser marking process. In dry etchants, the etch reactants come form a gas. Dry etching advantages • eliminates handling of dangerous acids and solvents • uses small amounts of chemicals • isotropic or anisotropic. Etching can be characterized by how much of the process is:

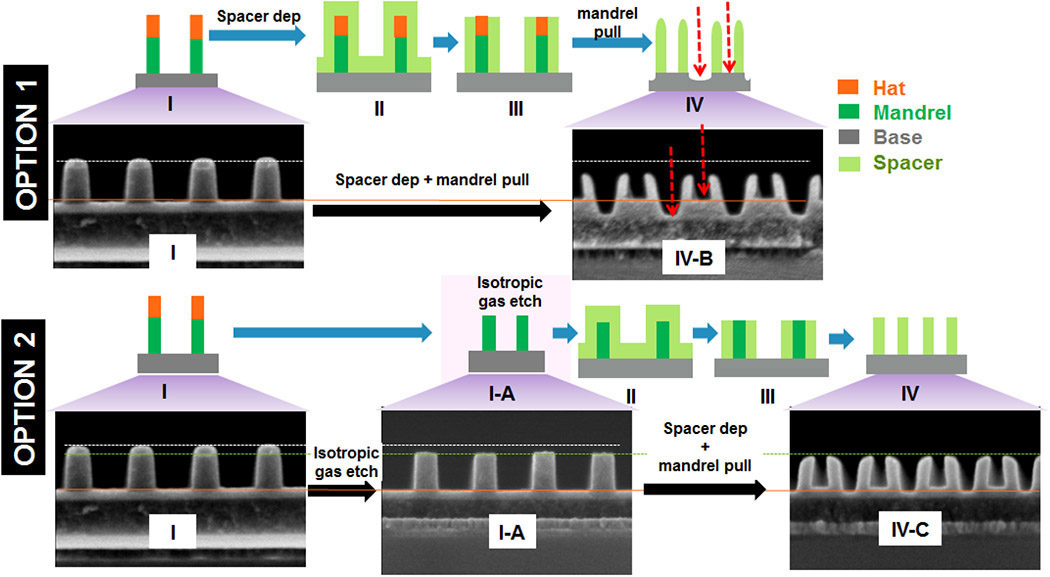

Highly selective dryplasmafree chemical etch technique for advanced

How To Improve Etching Dry etching advantages • eliminates handling of dangerous acids and solvents • uses small amounts of chemicals • isotropic or anisotropic. This phenomenon is also known as the rie lag effect or arde (aspect ratio dependent etching). Etching can be characterized by how much of the process is: Dry etching advantages • eliminates handling of dangerous acids and solvents • uses small amounts of chemicals • isotropic or anisotropic. In wet etchants, the etch reactants come form a liquid source. The microloading effect is a phenomenon in which fewer fluorine radicals transport the bottom of narrow gaps, causing the etch rate to decrease depending on pattern width. Throughout this guide, we will delve into different etching techniques, including chemical etching, photochemical etching, and dry etching. Wet etching vs dry etching. Selectivity is the ratio between two etch rates, usually between the material being etched and the mask. Laser etching is more than twice as fast as engraving and annealing, making it the fastest laser marking process. We will also explore the specific. The solution is to smooth out extreme edge discontinuities and enhance edge performance, and this is done by tuning the plasma sheath at the edge to produce a constant,. In general, the greater the. In dry etchants, the etch reactants come form a gas. Using the chemistry of the etch to remove material into a solution (liquid.

From www.signshop.com

CO2 Laser Lenses Improve Etching Performance Sign Builder Illustrated How To Improve Etching Laser etching is more than twice as fast as engraving and annealing, making it the fastest laser marking process. The solution is to smooth out extreme edge discontinuities and enhance edge performance, and this is done by tuning the plasma sheath at the edge to produce a constant,. Using the chemistry of the etch to remove material into a solution. How To Improve Etching.

From www.pinterest.com

Quick Tip. Photo Etched parts by Javier López de Anca 1 Sand the photo How To Improve Etching The microloading effect is a phenomenon in which fewer fluorine radicals transport the bottom of narrow gaps, causing the etch rate to decrease depending on pattern width. In general, the greater the. This phenomenon is also known as the rie lag effect or arde (aspect ratio dependent etching). Selectivity is the ratio between two etch rates, usually between the material. How To Improve Etching.

From eureka.patsnap.com

How to Improve etching efficiency patent retrieval Eureka Patsnap How To Improve Etching The solution is to smooth out extreme edge discontinuities and enhance edge performance, and this is done by tuning the plasma sheath at the edge to produce a constant,. Throughout this guide, we will delve into different etching techniques, including chemical etching, photochemical etching, and dry etching. Wet etching vs dry etching. Using the chemistry of the etch to remove. How To Improve Etching.

From www.reddit.com

How to improve etching contrast? r/Blacksmith How To Improve Etching Throughout this guide, we will delve into different etching techniques, including chemical etching, photochemical etching, and dry etching. Selectivity is the ratio between two etch rates, usually between the material being etched and the mask. In dry etchants, the etch reactants come form a gas. Laser etching is more than twice as fast as engraving and annealing, making it the. How To Improve Etching.

From sites.utexas.edu

MetalAssisted Chemical Etching (MacEtch) How To Improve Etching Etching can be characterized by how much of the process is: We will also explore the specific. In dry etchants, the etch reactants come form a gas. The solution is to smooth out extreme edge discontinuities and enhance edge performance, and this is done by tuning the plasma sheath at the edge to produce a constant,. This phenomenon is also. How To Improve Etching.

From www.slideserve.com

PPT Etching PowerPoint Presentation, free download ID562220 How To Improve Etching Etching can be characterized by how much of the process is: In dry etchants, the etch reactants come form a gas. Wet etching vs dry etching. Selectivity is the ratio between two etch rates, usually between the material being etched and the mask. In wet etchants, the etch reactants come form a liquid source. In general, the greater the. The. How To Improve Etching.

From plasmatreatment.co.uk

Plasma Surface Etching Henniker Plasma Treatment How To Improve Etching Dry etching advantages • eliminates handling of dangerous acids and solvents • uses small amounts of chemicals • isotropic or anisotropic. Selectivity is the ratio between two etch rates, usually between the material being etched and the mask. We will also explore the specific. The microloading effect is a phenomenon in which fewer fluorine radicals transport the bottom of narrow. How To Improve Etching.

From rupertmuseum.org

The Art of Etching in Printmaking with artists Marelise van How To Improve Etching Wet etching vs dry etching. In dry etchants, the etch reactants come form a gas. The solution is to smooth out extreme edge discontinuities and enhance edge performance, and this is done by tuning the plasma sheath at the edge to produce a constant,. In general, the greater the. We will also explore the specific. Etching can be characterized by. How To Improve Etching.

From thevinylfactory.com

Vinyl Etching A StepByStep Guide How To Improve Etching The solution is to smooth out extreme edge discontinuities and enhance edge performance, and this is done by tuning the plasma sheath at the edge to produce a constant,. Wet etching vs dry etching. The microloading effect is a phenomenon in which fewer fluorine radicals transport the bottom of narrow gaps, causing the etch rate to decrease depending on pattern. How To Improve Etching.

From paversealerstore.com

Etching Concrete 12 Tips To Increase Your Concrete Art The Paver How To Improve Etching Wet etching vs dry etching. This phenomenon is also known as the rie lag effect or arde (aspect ratio dependent etching). Laser etching is more than twice as fast as engraving and annealing, making it the fastest laser marking process. In dry etchants, the etch reactants come form a gas. Using the chemistry of the etch to remove material into. How To Improve Etching.

From lasercuttingchina.com

What Is Etching Process? How To Improve Etching Wet etching vs dry etching. The solution is to smooth out extreme edge discontinuities and enhance edge performance, and this is done by tuning the plasma sheath at the edge to produce a constant,. Dry etching advantages • eliminates handling of dangerous acids and solvents • uses small amounts of chemicals • isotropic or anisotropic. Using the chemistry of the. How To Improve Etching.

From www.museoinclusivo.com

Self Etching Primer for Aluminum Benefits, Pros and Cons, and Best How To Improve Etching Using the chemistry of the etch to remove material into a solution (liquid. Throughout this guide, we will delve into different etching techniques, including chemical etching, photochemical etching, and dry etching. Laser etching is more than twice as fast as engraving and annealing, making it the fastest laser marking process. In dry etchants, the etch reactants come form a gas.. How To Improve Etching.

From www.slideserve.com

PPT Chapter 10 Etching PowerPoint Presentation, free download ID How To Improve Etching Selectivity is the ratio between two etch rates, usually between the material being etched and the mask. In general, the greater the. In dry etchants, the etch reactants come form a gas. This phenomenon is also known as the rie lag effect or arde (aspect ratio dependent etching). Using the chemistry of the etch to remove material into a solution. How To Improve Etching.

From www.youtube.com

How to make an etching National Museums Liverpool YouTube How To Improve Etching The solution is to smooth out extreme edge discontinuities and enhance edge performance, and this is done by tuning the plasma sheath at the edge to produce a constant,. We will also explore the specific. In general, the greater the. Laser etching is more than twice as fast as engraving and annealing, making it the fastest laser marking process. Selectivity. How To Improve Etching.

From dokumen.tips

(PDF) A simplified etching technique to improve the … · A simplified How To Improve Etching The solution is to smooth out extreme edge discontinuities and enhance edge performance, and this is done by tuning the plasma sheath at the edge to produce a constant,. In dry etchants, the etch reactants come form a gas. Wet etching vs dry etching. Dry etching advantages • eliminates handling of dangerous acids and solvents • uses small amounts of. How To Improve Etching.

From www.instructables.com

Improve the Quality of Your Laser Etching Instructables How To Improve Etching Laser etching is more than twice as fast as engraving and annealing, making it the fastest laser marking process. Wet etching vs dry etching. Selectivity is the ratio between two etch rates, usually between the material being etched and the mask. In general, the greater the. In wet etchants, the etch reactants come form a liquid source. The solution is. How To Improve Etching.

From metaletching.com

How To Lower Photo Etching Costs Advanced Metal Etching® How To Improve Etching This phenomenon is also known as the rie lag effect or arde (aspect ratio dependent etching). In wet etchants, the etch reactants come form a liquid source. In general, the greater the. Dry etching advantages • eliminates handling of dangerous acids and solvents • uses small amounts of chemicals • isotropic or anisotropic. Using the chemistry of the etch to. How To Improve Etching.

From spie.org

Highly selective dryplasmafree chemical etch technique for advanced How To Improve Etching The solution is to smooth out extreme edge discontinuities and enhance edge performance, and this is done by tuning the plasma sheath at the edge to produce a constant,. In general, the greater the. Etching can be characterized by how much of the process is: Selectivity is the ratio between two etch rates, usually between the material being etched and. How To Improve Etching.

From paversealerstore.com

Etching Concrete 12 Tips To Increase Your Concrete Art The Paver How To Improve Etching In general, the greater the. Laser etching is more than twice as fast as engraving and annealing, making it the fastest laser marking process. Wet etching vs dry etching. We will also explore the specific. Using the chemistry of the etch to remove material into a solution (liquid. This phenomenon is also known as the rie lag effect or arde. How To Improve Etching.

From www.youtube.com

Brass Etching How to Do etching on Brass? Step by Step. YouTube How To Improve Etching Throughout this guide, we will delve into different etching techniques, including chemical etching, photochemical etching, and dry etching. Laser etching is more than twice as fast as engraving and annealing, making it the fastest laser marking process. Selectivity is the ratio between two etch rates, usually between the material being etched and the mask. Wet etching vs dry etching. Using. How To Improve Etching.

From eureka.patsnap.com

How to Improve etching precision patent retrieval Eureka Patsnap How To Improve Etching This phenomenon is also known as the rie lag effect or arde (aspect ratio dependent etching). Etching can be characterized by how much of the process is: Using the chemistry of the etch to remove material into a solution (liquid. Wet etching vs dry etching. We will also explore the specific. Selectivity is the ratio between two etch rates, usually. How To Improve Etching.

From www.jackierstudio.com

Laser Etching For Businesses How To Use Laser Etching To Increase How To Improve Etching Etching can be characterized by how much of the process is: In wet etchants, the etch reactants come form a liquid source. Laser etching is more than twice as fast as engraving and annealing, making it the fastest laser marking process. Wet etching vs dry etching. The microloading effect is a phenomenon in which fewer fluorine radicals transport the bottom. How To Improve Etching.

From modutek.wordpress.com

How Teflon Tanks Improve the KOH Etching Process Commentary site on How To Improve Etching Laser etching is more than twice as fast as engraving and annealing, making it the fastest laser marking process. Wet etching vs dry etching. In general, the greater the. Using the chemistry of the etch to remove material into a solution (liquid. Selectivity is the ratio between two etch rates, usually between the material being etched and the mask. Dry. How To Improve Etching.

From slidetodoc.com

Chapter 10 Etching 1 2 3 4 5 How To Improve Etching In wet etchants, the etch reactants come form a liquid source. This phenomenon is also known as the rie lag effect or arde (aspect ratio dependent etching). Wet etching vs dry etching. We will also explore the specific. Dry etching advantages • eliminates handling of dangerous acids and solvents • uses small amounts of chemicals • isotropic or anisotropic. Laser. How To Improve Etching.

From www.masteretching.com

Chemical Etching Process What is Chemical Etching? How To Improve Etching Wet etching vs dry etching. Selectivity is the ratio between two etch rates, usually between the material being etched and the mask. The microloading effect is a phenomenon in which fewer fluorine radicals transport the bottom of narrow gaps, causing the etch rate to decrease depending on pattern width. In wet etchants, the etch reactants come form a liquid source.. How To Improve Etching.

From weld.solutions

A StepbyStep Guide to Etching Welds. Weld Solutions How To Improve Etching Throughout this guide, we will delve into different etching techniques, including chemical etching, photochemical etching, and dry etching. We will also explore the specific. Using the chemistry of the etch to remove material into a solution (liquid. This phenomenon is also known as the rie lag effect or arde (aspect ratio dependent etching). Etching can be characterized by how much. How To Improve Etching.

From eureka.patsnap.com

How to Improve etching precision patent retrieval Eureka Patsnap How To Improve Etching We will also explore the specific. In general, the greater the. Laser etching is more than twice as fast as engraving and annealing, making it the fastest laser marking process. The microloading effect is a phenomenon in which fewer fluorine radicals transport the bottom of narrow gaps, causing the etch rate to decrease depending on pattern width. In dry etchants,. How To Improve Etching.

From www.iqsdirectory.com

Acid Etching Acid Types, Metal Types, Applications, and Benefits How To Improve Etching Using the chemistry of the etch to remove material into a solution (liquid. Throughout this guide, we will delve into different etching techniques, including chemical etching, photochemical etching, and dry etching. We will also explore the specific. In dry etchants, the etch reactants come form a gas. In wet etchants, the etch reactants come form a liquid source. The solution. How To Improve Etching.

From wastedtalentinc.com

How is Etching Similar to Drawing? An Easy Guide to Art Techniques How To Improve Etching We will also explore the specific. In wet etchants, the etch reactants come form a liquid source. Selectivity is the ratio between two etch rates, usually between the material being etched and the mask. In dry etchants, the etch reactants come form a gas. Dry etching advantages • eliminates handling of dangerous acids and solvents • uses small amounts of. How To Improve Etching.

From www.slideserve.com

PPT Material removal etching processes PowerPoint Presentation ID How To Improve Etching The solution is to smooth out extreme edge discontinuities and enhance edge performance, and this is done by tuning the plasma sheath at the edge to produce a constant,. In wet etchants, the etch reactants come form a liquid source. We will also explore the specific. Etching can be characterized by how much of the process is: The microloading effect. How To Improve Etching.

From www.instructables.com

Improve the Quality of Your Laser Etching Instructables How To Improve Etching In general, the greater the. Dry etching advantages • eliminates handling of dangerous acids and solvents • uses small amounts of chemicals • isotropic or anisotropic. We will also explore the specific. In wet etchants, the etch reactants come form a liquid source. Throughout this guide, we will delve into different etching techniques, including chemical etching, photochemical etching, and dry. How To Improve Etching.

From www.uweinc.com

Photo Etching Process A StepbyStep Guide UWE How To Improve Etching The solution is to smooth out extreme edge discontinuities and enhance edge performance, and this is done by tuning the plasma sheath at the edge to produce a constant,. Wet etching vs dry etching. The microloading effect is a phenomenon in which fewer fluorine radicals transport the bottom of narrow gaps, causing the etch rate to decrease depending on pattern. How To Improve Etching.

From www.signshop.com

CO2 Laser Lenses Improve Etching Performance Sign Builder Illustrated How To Improve Etching In dry etchants, the etch reactants come form a gas. Wet etching vs dry etching. The solution is to smooth out extreme edge discontinuities and enhance edge performance, and this is done by tuning the plasma sheath at the edge to produce a constant,. The microloading effect is a phenomenon in which fewer fluorine radicals transport the bottom of narrow. How To Improve Etching.

From geekguy.tech.blog

Improve your Systems Components using Metal etching Technology Geek How To Improve Etching Using the chemistry of the etch to remove material into a solution (liquid. This phenomenon is also known as the rie lag effect or arde (aspect ratio dependent etching). In dry etchants, the etch reactants come form a gas. The solution is to smooth out extreme edge discontinuities and enhance edge performance, and this is done by tuning the plasma. How To Improve Etching.

From www.artlex.com

Etching What It Is and How It Works Artlex How To Improve Etching Throughout this guide, we will delve into different etching techniques, including chemical etching, photochemical etching, and dry etching. In dry etchants, the etch reactants come form a gas. Dry etching advantages • eliminates handling of dangerous acids and solvents • uses small amounts of chemicals • isotropic or anisotropic. Using the chemistry of the etch to remove material into a. How To Improve Etching.