Plastic Snap Fit . The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and easiness to. Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly and reversibly joined. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. The solution to this apparent paradox is using snap fits to assemble parts. This manual will guide you through the. Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a recession or behind an obstruction in the mating component.

from facfox.com

The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and easiness to. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly and reversibly joined. This manual will guide you through the. Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a recession or behind an obstruction in the mating component. The solution to this apparent paradox is using snap fits to assemble parts.

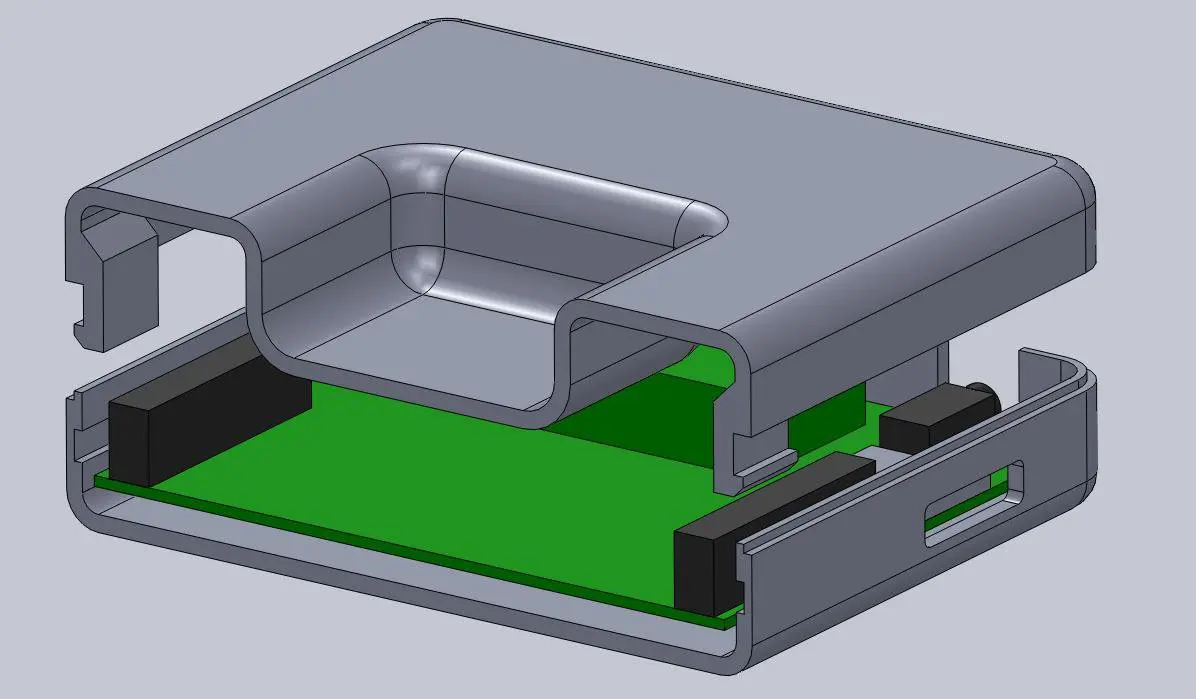

How to Design and 3D Print SnapFit Enclosures FacFox Docs

Plastic Snap Fit The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and easiness to. This manual will guide you through the. Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly and reversibly joined. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and easiness to. The solution to this apparent paradox is using snap fits to assemble parts. Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a recession or behind an obstruction in the mating component.

From facfox.com

How to Design and 3D Print SnapFit Enclosures FacFox Docs Plastic Snap Fit Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a recession or behind an obstruction in the mating component. Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly and reversibly joined. This manual will guide you through the. The solution to. Plastic Snap Fit.

From www.engineersrule.com

Snap Hook Design in CAD Engineers Rule Plastic Snap Fit This manual will guide you through the. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. The solution to this apparent paradox is using snap fits to assemble parts. Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a. Plastic Snap Fit.

From www.pinterest.com

Snap fit joints design guide Plastic design, Useful 3d prints, 3d Plastic Snap Fit The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and easiness to. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it. Plastic Snap Fit.

From unitymanufacture.com

Annular Snap Joints Applications And Design Considerations Unity Plastic Snap Fit Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a recession or behind an obstruction in the mating component. The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and easiness to. The solution to this apparent paradox is. Plastic Snap Fit.

From www.3dhubs.com

How to design snapfit joints for 3D printing 3D Hubs Plastic Snap Fit Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly and reversibly joined. The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and easiness to. Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until. Plastic Snap Fit.

From facfox.com

How to Design and 3D Print SnapFit Enclosures FacFox Docs Plastic Snap Fit This manual will guide you through the. Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly and reversibly joined. The solution to this apparent paradox is using snap fits to assemble parts. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. The. Plastic Snap Fit.

From www.indiamart.com

Plastic Snap Fit Section at best price in Ahmedabad by Devnidhi Plastic Snap Fit The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and easiness to. This manual will guide you through the. Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a recession or behind an obstruction in the mating component.. Plastic Snap Fit.

From www.rutlandplastics.co.uk

Design For Assembly 1 Rutland Plastics Plastic Snap Fit Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly and reversibly joined. The solution to this apparent paradox is using snap fits to assemble parts. This manual will guide you through the. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. Essentially,. Plastic Snap Fit.

From www.youtube.com

Plastic Parts Design What Is Snap Fit? YouTube Plastic Snap Fit This manual will guide you through the. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a recession or behind an obstruction in the mating component. Snap fits are integral. Plastic Snap Fit.

From studylib.net

Plastic Snap fit design Plastic Snap Fit Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a recession or behind an obstruction in the mating component. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. The most common material for snap fit joints are plastics like. Plastic Snap Fit.

From www.smlease.com

How to Design Snap Fit Joints in Plastic Parts SMLease Design Plastic Snap Fit The solution to this apparent paradox is using snap fits to assemble parts. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. This manual will guide you through the. Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a. Plastic Snap Fit.

From www.pinterest.com

Snap Fits Best Practices in 2021 Plastic design, Mechanical design Plastic Snap Fit The solution to this apparent paradox is using snap fits to assemble parts. Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly and reversibly joined. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. Essentially, they function by permitting a protruding part. Plastic Snap Fit.

From www.fictiv.com

How to Design Snap Fit Components Fictiv Plastic Snap Fit The solution to this apparent paradox is using snap fits to assemble parts. Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a recession or behind an obstruction in the mating component. Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly. Plastic Snap Fit.

From www.madearia.com

Snap Fit Design Types of Snap fits and Best Practices Plastic Snap Fit Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly and reversibly joined. Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a recession or behind an obstruction in the mating component. This manual will guide you through the. The solution to. Plastic Snap Fit.

From www.youtube.com

How to Design a Snap Fit Joint 3D Printing Fusion 360 Tutorial Plastic Snap Fit The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and easiness to. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it. Plastic Snap Fit.

From www.pinterest.com

snap fit Plastic design, Industrial design sketch, 3d printing Plastic Snap Fit The solution to this apparent paradox is using snap fits to assemble parts. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a recession or behind an obstruction in the. Plastic Snap Fit.

From at-machining.com

A Comprehensive Guide to Effective Snap Fit Design ATMachining Plastic Snap Fit This manual will guide you through the. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly and reversibly joined. Essentially, they function by permitting a protruding part of one component to elastically deform. Plastic Snap Fit.

From www.madearia.com

Snap Fit Design Types of Snap fits and Best Practices Plastic Snap Fit Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. This manual will guide you through the. Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly and reversibly joined. Essentially, they function by permitting a protruding part of one component to elastically deform. Plastic Snap Fit.

From www.hubs.com

CAD modeling 3 Snap fits Protolabs Network Plastic Snap Fit The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and easiness to. Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly and reversibly joined. This manual will guide you through the. Snap fits are an assembly method used to attach flexible. Plastic Snap Fit.

From sybridge.com

A Brief History of Plastic Injection Molding Plastic Snap Fit This manual will guide you through the. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and easiness to. Snap fits are integral fastening features that are molded into plastic. Plastic Snap Fit.

From www.3dhubs.com

CAD Modeling 3 Snap Fits Plastic Snap Fit The solution to this apparent paradox is using snap fits to assemble parts. This manual will guide you through the. The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and easiness to. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking. Plastic Snap Fit.

From www.3dhubs.com

CAD Modeling 3 Snap Fits Plastic Snap Fit The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and easiness to. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. The solution to this apparent paradox is using snap fits to assemble parts. Essentially, they function by permitting. Plastic Snap Fit.

From www.madearia.com

Snap Fit Design Types of Snap fits and Best Practices Plastic Snap Fit The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and easiness to. Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a recession or behind an obstruction in the mating component. The solution to this apparent paradox is. Plastic Snap Fit.

From www.kemalmfg.com

The Ultimate Guide to Snap Fit Designs Types and Best Practices Kemal Plastic Snap Fit This manual will guide you through the. Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a recession or behind an obstruction in the mating component. The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and easiness to.. Plastic Snap Fit.

From www.flickr.com

SnapFit Pivot Closeup 3Dprinted snapfit pivot design. R… Flickr Plastic Snap Fit This manual will guide you through the. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. The solution to this apparent paradox is using snap fits to assemble parts. Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly and reversibly joined. The. Plastic Snap Fit.

From www.hubs.com

CAD modeling 3 Snap fits Hubs Plastic Snap Fit Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a recession or behind an obstruction in the mating component. The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and easiness to. Snap fits are integral fastening features that. Plastic Snap Fit.

From www.3dhubs.com

How to design snapfit joints for 3D printing 3D Hubs Plastic Snap Fit Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly and reversibly joined. The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and easiness to. This manual will guide you through the. Snap fits are an assembly method used to attach flexible. Plastic Snap Fit.

From ajile.biz

Plastic Snap Fit Hose Clamp for Cables, Pipes, Hoses and Tubes Diameter Plastic Snap Fit Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly and reversibly joined. The solution to this apparent paradox is using snap fits to assemble parts. Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a recession or behind an obstruction in. Plastic Snap Fit.

From www.slideshare.net

Snap Fit Design by Neeraj Kumar Jha Plastic Snap Fit Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly and reversibly joined. The solution to this apparent paradox is using snap fits to assemble parts. This manual will guide you through the. Essentially,. Plastic Snap Fit.

From www.pingood.com.tw

Snap Fit Plastic Push Latch (DL2) Mechanical Components Supply Plastic Snap Fit Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly and reversibly joined. The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and. Plastic Snap Fit.

From www.china-machining.com

Snapfit Design 101 Basics, Types, and Best Practices Plastic Snap Fit This manual will guide you through the. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a recession or behind an obstruction in the mating component. Snap fits are integral. Plastic Snap Fit.

From www.madearia.com

Snap Fit Design Types of Snap fits and Best Practices Plastic Snap Fit This manual will guide you through the. The solution to this apparent paradox is using snap fits to assemble parts. Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly and reversibly joined. The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility. Plastic Snap Fit.

From proleantech.com

Comprehensive Guide to Snap Fits Design, Types, and Applications Plastic Snap Fit The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and easiness to. Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a recession or behind an obstruction in the mating component. The solution to this apparent paradox is. Plastic Snap Fit.

From br.pinterest.com

Snap Fits_ Emerald visual 3d printing, Useful 3d prints, Mechanical Plastic Snap Fit The most common material for snap fit joints are plastics like abs, petg, nylon, and pla due to their flexibility and easiness to. This manual will guide you through the. Snap fits are integral fastening features that are molded into plastic components, allowing them to be quickly and reversibly joined. The solution to this apparent paradox is using snap fits. Plastic Snap Fit.

From www.cgtrader.com

3D model Snap Fit Plastic Box VR / AR / lowpoly CGTrader Plastic Snap Fit The solution to this apparent paradox is using snap fits to assemble parts. Snap fits are an assembly method used to attach flexible plastic parts together by pushing their interlocking components together. Essentially, they function by permitting a protruding part of one component to elastically deform during assembly until it settles into a recession or behind an obstruction in the. Plastic Snap Fit.