Ball Screw Lead Calculation . A ball screw transforms rotational motion into transitional motion. The critical speed is the lowest rational speed that a shaft is in resonance. The ball screw force calculator is designed to determine the force applied to a ball screw assembly based on specific input parameters. 1 · 1000· 60 3000 = 20 mm therefore, it is necessary to select a type with a lead of 20 mm or longer. Ball screw lead is obtained as follows: In addition, the ball screw and the motor can be. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. Critical speed ball screw and lead screws formulas and calculator: As a result, the shaft is subject to loads: N c = f c ( d r / l c2) 10 7.

from www.youtube.com

The critical speed is the lowest rational speed that a shaft is in resonance. In addition, the ball screw and the motor can be. Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. N c = f c ( d r / l c2) 10 7. Ball screw lead is obtained as follows: As a result, the shaft is subject to loads: Critical speed ball screw and lead screws formulas and calculator: Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. The ball screw force calculator is designed to determine the force applied to a ball screw assembly based on specific input parameters. 1 · 1000· 60 3000 = 20 mm therefore, it is necessary to select a type with a lead of 20 mm or longer.

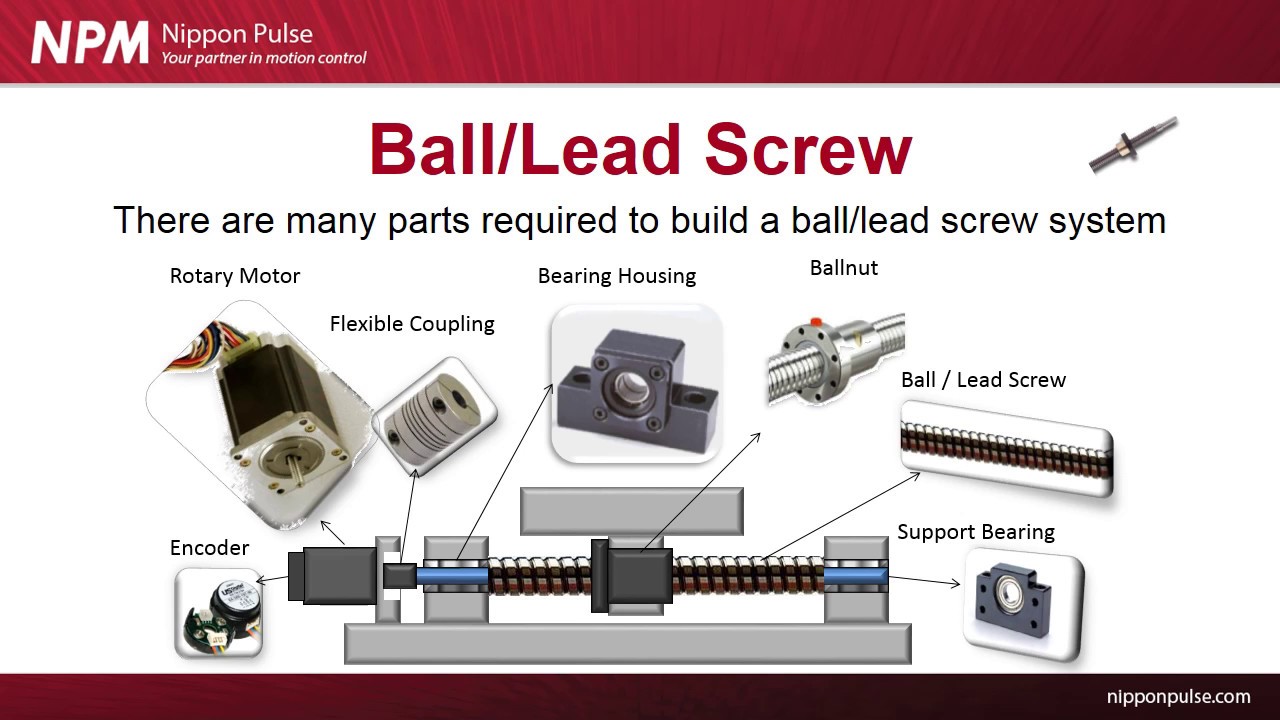

Overview of Ball Screw/Lead Screw Systems for Linear Movement YouTube

Ball Screw Lead Calculation Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. A ball screw transforms rotational motion into transitional motion. In addition, the ball screw and the motor can be. Critical speed ball screw and lead screws formulas and calculator: 1 · 1000· 60 3000 = 20 mm therefore, it is necessary to select a type with a lead of 20 mm or longer. Ball screw lead is obtained as follows: The critical speed is the lowest rational speed that a shaft is in resonance. The ball screw force calculator is designed to determine the force applied to a ball screw assembly based on specific input parameters. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. N c = f c ( d r / l c2) 10 7. As a result, the shaft is subject to loads: Quickly calculate the torque required to lift a load with a ballscrew or leadscrew.

From www.researchgate.net

Design of the drive system by ball screw of a lumped model Download Ball Screw Lead Calculation Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. 1 · 1000· 60 3000 = 20 mm therefore, it is necessary to select a type with a lead of 20 mm or longer. As a result, the shaft is subject to loads: N. Ball Screw Lead Calculation.

From www.mitcalc.com

MITcalc Ball screws, design, calculation and check Ball Screw Lead Calculation As a result, the shaft is subject to loads: N c = f c ( d r / l c2) 10 7. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. The critical speed is the lowest rational speed that a shaft is. Ball Screw Lead Calculation.

From www.youtube.com

Ball Screw Selection Calculation Made Easy Ultimate Guide 🔥 YouTube Ball Screw Lead Calculation Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. The critical speed is the lowest rational speed that a shaft is in resonance. Critical speed ball screw and lead screws formulas and calculator: As a result, the shaft is subject to loads: 1. Ball Screw Lead Calculation.

From www.iqsdirectory.com

Ball Screw What Is It? How Does It Work? Ball Screw Lead Calculation Critical speed ball screw and lead screws formulas and calculator: Ball screw lead is obtained as follows: Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. N c = f c ( d r / l c2) 10 7. The critical speed is. Ball Screw Lead Calculation.

From www.mitcalc.cz

MITcalc Ball screws, design, calculation and check Ball Screw Lead Calculation N c = f c ( d r / l c2) 10 7. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. As a result, the shaft is subject to loads: Critical speed ball screw and lead screws formulas and calculator: The ball. Ball Screw Lead Calculation.

From www.iqsdirectory.com

Ball Screw What Is It? How Does It Work? Ball Screw Lead Calculation A ball screw transforms rotational motion into transitional motion. Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. 1 · 1000· 60 3000 = 20 mm therefore, it is. Ball Screw Lead Calculation.

From www.researchgate.net

Schematic diagram of a vertical ball screw feed system. Download Ball Screw Lead Calculation In addition, the ball screw and the motor can be. A ball screw transforms rotational motion into transitional motion. The critical speed is the lowest rational speed that a shaft is in resonance. Critical speed ball screw and lead screws formulas and calculator: Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia. Ball Screw Lead Calculation.

From www.pinnaxis.com

Ball Screws The Basics Making Motion Work, 51 OFF Ball Screw Lead Calculation The ball screw force calculator is designed to determine the force applied to a ball screw assembly based on specific input parameters. As a result, the shaft is subject to loads: Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and. Ball Screw Lead Calculation.

From mechextreme.blogspot.com

How to select and calculate the ball screw Ball Screw Lead Calculation The ball screw force calculator is designed to determine the force applied to a ball screw assembly based on specific input parameters. Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. In addition, the ball screw and the motor can be. Ball screw lead is obtained as follows: The critical speed is the lowest rational. Ball Screw Lead Calculation.

From www.youtube.com

How to calculate back driving torque for ball screws and lead screws Ball Screw Lead Calculation N c = f c ( d r / l c2) 10 7. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. As a result, the shaft is subject to loads: A ball screw transforms rotational motion into transitional motion. The ball screw. Ball Screw Lead Calculation.

From www.linearmotiontips.com

How to account for ball and lead screw inertia during system design Ball Screw Lead Calculation The critical speed is the lowest rational speed that a shaft is in resonance. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. 1 · 1000· 60 3000 = 20 mm therefore, it is necessary to select a type with a lead of. Ball Screw Lead Calculation.

From www.gearservo.com

How to Calculate Ball Screw Ball Screw Lead Calculation The critical speed is the lowest rational speed that a shaft is in resonance. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. Critical speed ball screw and lead screws formulas and calculator: 1 · 1000· 60 3000 = 20 mm therefore, it. Ball Screw Lead Calculation.

From www.isel-us.com

Ball Screws and ball nuts Isel USA Ball Screw Lead Calculation Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. A ball screw transforms rotational motion into transitional motion. The ball screw force calculator is designed to determine the force applied to a ball screw assembly based on specific input parameters. In addition, the ball screw and the motor can be. Ball / lead screw motor. Ball Screw Lead Calculation.

From www.tolomatic.com

Selecting the Optimal Screw Technology Tolomatic Ball Screw Lead Calculation Critical speed ball screw and lead screws formulas and calculator: Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. The critical speed is the lowest rational speed that a shaft is in resonance. Ball screw lead is obtained as follows: The ball screw force calculator is designed to determine the force applied to a ball. Ball Screw Lead Calculation.

From www.iqsdirectory.com

Ball Screw What Is It? How Does It Work? Ball Screw Lead Calculation A ball screw transforms rotational motion into transitional motion. In addition, the ball screw and the motor can be. 1 · 1000· 60 3000 = 20 mm therefore, it is necessary to select a type with a lead of 20 mm or longer. The ball screw force calculator is designed to determine the force applied to a ball screw assembly. Ball Screw Lead Calculation.

From www.youtube.com

How to calculate the rigidity of a ball screw assembly A Motion Ball Screw Lead Calculation Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. 1 · 1000· 60 3000 = 20 mm therefore, it is necessary to select a type with a lead of 20 mm or longer. N c = f c ( d r / l. Ball Screw Lead Calculation.

From www.mdpi.com

Applied Sciences Free FullText Dynamic Analysis of Ball Screw Feed Ball Screw Lead Calculation Ball screw lead is obtained as follows: The critical speed is the lowest rational speed that a shaft is in resonance. As a result, the shaft is subject to loads: The ball screw force calculator is designed to determine the force applied to a ball screw assembly based on specific input parameters. A ball screw transforms rotational motion into transitional. Ball Screw Lead Calculation.

From www.chegg.com

Solved Q2. A Ball Screw mechanism is driven by stepping Ball Screw Lead Calculation Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. In addition, the ball screw and the motor can be. 1 · 1000· 60 3000 = 20 mm therefore, it is necessary to select a type with a lead of 20 mm or longer.. Ball Screw Lead Calculation.

From eng-resources.uncc.edu

Ball Screw Selection Guide UNC Charlotte Engineering Tool Kit Ball Screw Lead Calculation A ball screw transforms rotational motion into transitional motion. In addition, the ball screw and the motor can be. The ball screw force calculator is designed to determine the force applied to a ball screw assembly based on specific input parameters. 1 · 1000· 60 3000 = 20 mm therefore, it is necessary to select a type with a lead. Ball Screw Lead Calculation.

From www.mitcalc.com

MITcalc Ball screws, design, calculation and check Ball Screw Lead Calculation A ball screw transforms rotational motion into transitional motion. As a result, the shaft is subject to loads: The ball screw force calculator is designed to determine the force applied to a ball screw assembly based on specific input parameters. Ball screw lead is obtained as follows: Critical speed ball screw and lead screws formulas and calculator: In addition, the. Ball Screw Lead Calculation.

From www.youtube.com

Overview of Ball Screw/Lead Screw Systems for Linear Movement YouTube Ball Screw Lead Calculation 1 · 1000· 60 3000 = 20 mm therefore, it is necessary to select a type with a lead of 20 mm or longer. In addition, the ball screw and the motor can be. As a result, the shaft is subject to loads: Critical speed ball screw and lead screws formulas and calculator: Ball / lead screw motor sizing forms. Ball Screw Lead Calculation.

From www.youtube.com

Calculating Lead Screw Efficiency and Required Lifting Torque YouTube Ball Screw Lead Calculation Ball screw lead is obtained as follows: N c = f c ( d r / l c2) 10 7. A ball screw transforms rotational motion into transitional motion. The ball screw force calculator is designed to determine the force applied to a ball screw assembly based on specific input parameters. As a result, the shaft is subject to loads:. Ball Screw Lead Calculation.

From www.youtube.com

Ball Screw Drive Torque Calculation Motor Selection Calculation YouTube Ball Screw Lead Calculation In addition, the ball screw and the motor can be. The critical speed is the lowest rational speed that a shaft is in resonance. As a result, the shaft is subject to loads: N c = f c ( d r / l c2) 10 7. The ball screw force calculator is designed to determine the force applied to a. Ball Screw Lead Calculation.

From www.pinterest.com

Ball / lead screw motor sizing forms calculate the necessary Torque Ball Screw Lead Calculation In addition, the ball screw and the motor can be. As a result, the shaft is subject to loads: 1 · 1000· 60 3000 = 20 mm therefore, it is necessary to select a type with a lead of 20 mm or longer. Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. Ball screw lead. Ball Screw Lead Calculation.

From us.misumi-ec.com

Ball Screws Steel Ball Recirculation MISUMI Mech Lab Blog Ball Screw Lead Calculation A ball screw transforms rotational motion into transitional motion. N c = f c ( d r / l c2) 10 7. The ball screw force calculator is designed to determine the force applied to a ball screw assembly based on specific input parameters. The critical speed is the lowest rational speed that a shaft is in resonance. Quickly calculate. Ball Screw Lead Calculation.

From www.motioncontroltips.com

How to Size and Select Ball Screws An Engineer's Guide Ball Screw Lead Calculation The critical speed is the lowest rational speed that a shaft is in resonance. N c = f c ( d r / l c2) 10 7. The ball screw force calculator is designed to determine the force applied to a ball screw assembly based on specific input parameters. Critical speed ball screw and lead screws formulas and calculator: Quickly. Ball Screw Lead Calculation.

From www.e-motionsupply.com

Ball Screw Ball Screw Lead Calculation Critical speed ball screw and lead screws formulas and calculator: The critical speed is the lowest rational speed that a shaft is in resonance. Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. Ball screw lead is obtained as follows: 1 · 1000· 60 3000 = 20 mm therefore, it is necessary to select a. Ball Screw Lead Calculation.

From mitcalc.com

MITcalc Ball screws, design, calculation and check Ball Screw Lead Calculation In addition, the ball screw and the motor can be. 1 · 1000· 60 3000 = 20 mm therefore, it is necessary to select a type with a lead of 20 mm or longer. The ball screw force calculator is designed to determine the force applied to a ball screw assembly based on specific input parameters. The critical speed is. Ball Screw Lead Calculation.

From www.youtube.com

How to Calculate Critical Speed for Ball Screws and Lead Screws A Ball Screw Lead Calculation Ball screw lead is obtained as follows: Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. A ball screw transforms rotational motion into transitional motion. In addition, the ball. Ball Screw Lead Calculation.

From rockfordballscrew.com

Ball Screws and Ball Screw Assemblies Rockford Ball Screw Ball Screw Lead Calculation In addition, the ball screw and the motor can be. The ball screw force calculator is designed to determine the force applied to a ball screw assembly based on specific input parameters. Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. The critical speed is the lowest rational speed that a shaft is in resonance.. Ball Screw Lead Calculation.

From www.youtube.com

Ball Screw Calculation and Design (MITCalc24) YouTube Ball Screw Lead Calculation A ball screw transforms rotational motion into transitional motion. N c = f c ( d r / l c2) 10 7. As a result, the shaft is subject to loads: Critical speed ball screw and lead screws formulas and calculator: Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. In addition, the ball screw. Ball Screw Lead Calculation.

From www.researchgate.net

Schematic diagram of ball screw driven CNC axis Download Scientific Ball Screw Lead Calculation Ball screw lead is obtained as follows: Quickly calculate the torque required to lift a load with a ballscrew or leadscrew. N c = f c ( d r / l c2) 10 7. As a result, the shaft is subject to loads: Critical speed ball screw and lead screws formulas and calculator: Ball / lead screw motor sizing forms. Ball Screw Lead Calculation.

From www.youtube.com

Ball Lead Screw Properties YouTube Ball Screw Lead Calculation The critical speed is the lowest rational speed that a shaft is in resonance. The ball screw force calculator is designed to determine the force applied to a ball screw assembly based on specific input parameters. N c = f c ( d r / l c2) 10 7. Quickly calculate the torque required to lift a load with a. Ball Screw Lead Calculation.

From www.semanticscholar.org

Table 1 from An efficiency calculation model for ball screws by Ball Screw Lead Calculation The critical speed is the lowest rational speed that a shaft is in resonance. In addition, the ball screw and the motor can be. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. The ball screw force calculator is designed to determine the. Ball Screw Lead Calculation.

From www.industry-asia-pacific.com

SIMPLIFIED SIZING AND SELECTION WITH THOMSON BALL SCREW CONFIGURATION Ball Screw Lead Calculation In addition, the ball screw and the motor can be. Ball / lead screw motor sizing forms calculate the necessary torque, speed, stopping accuracy and system inertia important when selecting a proper motor for the application. N c = f c ( d r / l c2) 10 7. The critical speed is the lowest rational speed that a shaft. Ball Screw Lead Calculation.