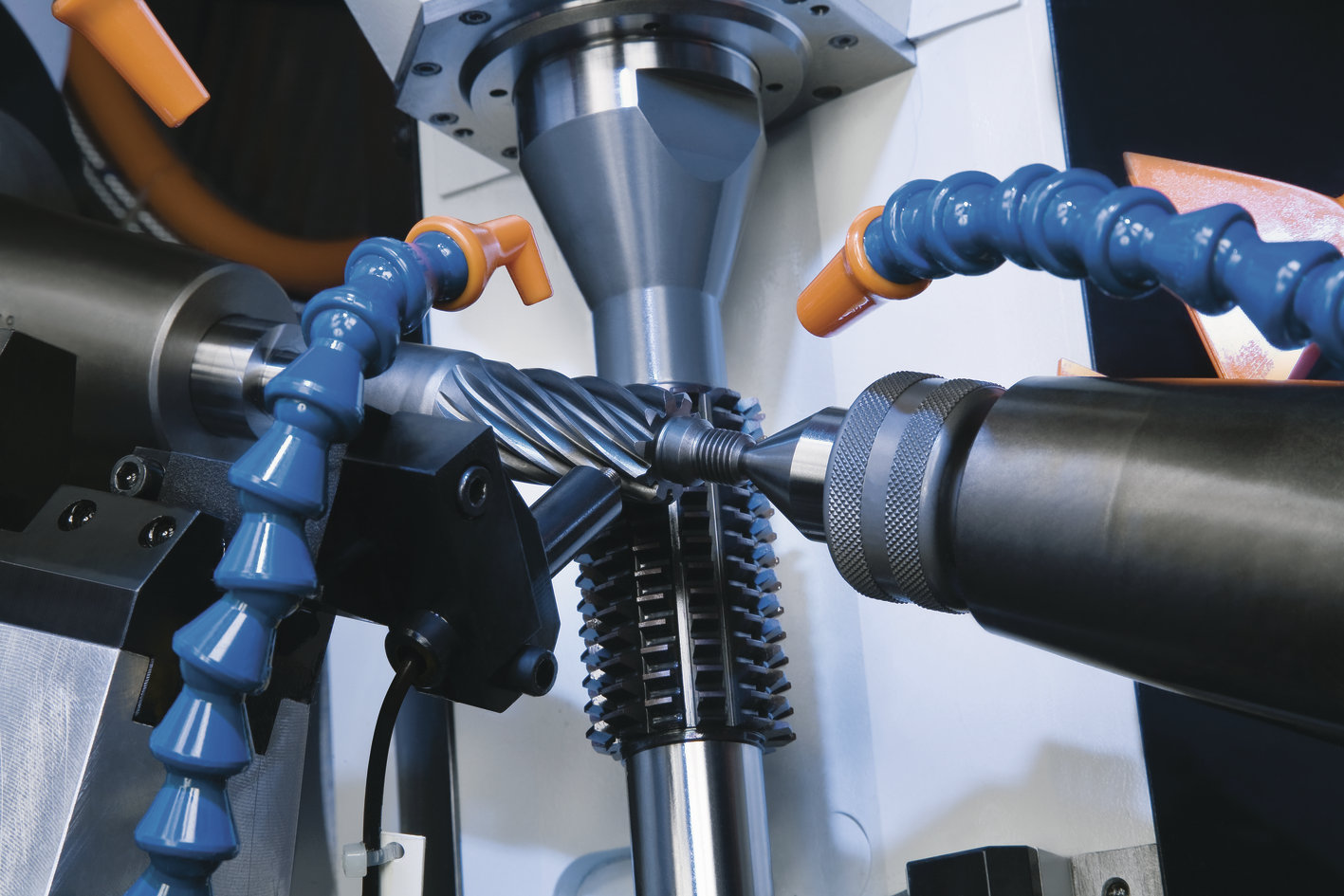

Hobbing Machine Concept . Gear hobbing is a commonly used manufacturing process for producing gears. Gear hobbing is not a form cutting process, such as gashing or milling where the cutter is a conjugate form of the gear tooth. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. This is because of the generating nature of this particular cutting process. Hobbing machines provide gear manufacturers a fast and accurate method for cutting parts. It involves the creation of gear teeth by cutting. This is achieved by a hobbing machine that ensures exact rotational synchrony. The cutter profile on a. Each successive rack is shifted axially to create a. The hob is a series of racks positioned around the circumference of a cylindrical tool. Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its.

from www.emag.com

It involves the creation of gear teeth by cutting. Gear hobbing is not a form cutting process, such as gashing or milling where the cutter is a conjugate form of the gear tooth. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its. Gear hobbing is a commonly used manufacturing process for producing gears. This is because of the generating nature of this particular cutting process. This is achieved by a hobbing machine that ensures exact rotational synchrony. Each successive rack is shifted axially to create a. The hob is a series of racks positioned around the circumference of a cylindrical tool. The cutter profile on a.

Gear Hobbing Machine K 160 Gear Hobbing at the Highest Level

Hobbing Machine Concept This is because of the generating nature of this particular cutting process. The hob is a series of racks positioned around the circumference of a cylindrical tool. It involves the creation of gear teeth by cutting. This is because of the generating nature of this particular cutting process. Each successive rack is shifted axially to create a. The cutter profile on a. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. Gear hobbing is not a form cutting process, such as gashing or milling where the cutter is a conjugate form of the gear tooth. Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its. Hobbing machines provide gear manufacturers a fast and accurate method for cutting parts. This is achieved by a hobbing machine that ensures exact rotational synchrony. Gear hobbing is a commonly used manufacturing process for producing gears.

From www.youtube.com

Liebherr Gear Hobbing and profile Hobbing Machine LC 4000 YouTube Hobbing Machine Concept Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its. This is achieved by a hobbing machine that ensures exact rotational synchrony. The cutter profile on a. The hob is a series of racks positioned around the circumference of a cylindrical tool. It involves. Hobbing Machine Concept.

From www.indiamart.com

TOS FO 6 Gear Hobbing Machine at Rs 8500/piece Gear Hobbing Machine Hobbing Machine Concept The cutter profile on a. It involves the creation of gear teeth by cutting. Gear hobbing is a commonly used manufacturing process for producing gears. The hob is a series of racks positioned around the circumference of a cylindrical tool. Gear hobbing is not a form cutting process, such as gashing or milling where the cutter is a conjugate form. Hobbing Machine Concept.

From www.liebherr.com

LC 600 2000 Gear hobbing machines Liebherr Liebherr Hobbing Machine Concept Gear hobbing is a commonly used manufacturing process for producing gears. Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its. This is achieved by a hobbing machine that ensures exact rotational synchrony. Gear hobbing is not a form cutting process, such as gashing. Hobbing Machine Concept.

From www.liebherr.com

LC 180 280 Gear hobbing machines Liebherr Liebherr Hobbing Machine Concept Gear hobbing is a commonly used manufacturing process for producing gears. Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its. This is because of the generating nature of this particular cutting process. Gear hobbing is not a form cutting process, such as gashing. Hobbing Machine Concept.

From geepro.en.made-in-china.com

G400 6 Axis CNC Gear Hobbing Machine with Automation Ring Loader Hobbing Machine Concept Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. This is because of the generating nature of this particular cutting process.. Hobbing Machine Concept.

From engineeringlearn.com

Gear Hobbing Machine Definition, Types, Uses, Working & Construction Hobbing Machine Concept The hob is a series of racks positioned around the circumference of a cylindrical tool. This is achieved by a hobbing machine that ensures exact rotational synchrony. Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its. The cutter profile on a. Each successive. Hobbing Machine Concept.

From www.liebherr.com

LC 180 280 Gear hobbing machines Liebherr Liebherr Hobbing Machine Concept The cutter profile on a. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. The hob is a series of racks positioned around the circumference of a cylindrical tool. Gear hobbing is a commonly used manufacturing process for producing gears. It involves the creation of gear teeth. Hobbing Machine Concept.

From www.liebherr.com

LC 2000 12000 Gear hobbing machines Liebherr Liebherr Hobbing Machine Concept This is because of the generating nature of this particular cutting process. It involves the creation of gear teeth by cutting. Gear hobbing is not a form cutting process, such as gashing or milling where the cutter is a conjugate form of the gear tooth. Gear hobbing is a machining process that involves cutting teeth into a gear blank using. Hobbing Machine Concept.

From www.liebherr.com

Gear hobbing machines Liebherr Liebherr Hobbing Machine Concept Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its. The cutter profile on a. This is achieved by a hobbing machine. Hobbing Machine Concept.

From www.machineryoffers.com

Y3150 gear hobbing machine large module hobbing machine for sale Hobbing Machine Concept It involves the creation of gear teeth by cutting. This is because of the generating nature of this particular cutting process. Hobbing machines provide gear manufacturers a fast and accurate method for cutting parts. Gear hobbing is a commonly used manufacturing process for producing gears. Each successive rack is shifted axially to create a. Hobbing is a fast and efficient. Hobbing Machine Concept.

From www.liebherr.com

LC 180 280 Gear hobbing machines Liebherr Liebherr Hobbing Machine Concept Hobbing machines provide gear manufacturers a fast and accurate method for cutting parts. Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its. This is achieved by a hobbing machine that ensures exact rotational synchrony. Each successive rack is shifted axially to create a.. Hobbing Machine Concept.

From www.indiamart.com

Universal Gear Hobbing Machine Model V1000, 1000 Mm X 10 Module at Hobbing Machine Concept The hob is a series of racks positioned around the circumference of a cylindrical tool. The cutter profile on a. Gear hobbing is not a form cutting process, such as gashing or milling where the cutter is a conjugate form of the gear tooth. It involves the creation of gear teeth by cutting. Each successive rack is shifted axially to. Hobbing Machine Concept.

From www.liebherr.com

LC 600 2000 Gear hobbing machines Liebherr Liebherr Hobbing Machine Concept Hobbing machines provide gear manufacturers a fast and accurate method for cutting parts. This is achieved by a hobbing machine that ensures exact rotational synchrony. Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its. This is because of the generating nature of this. Hobbing Machine Concept.

From www.liebherr.com

LC 60 130 Gear hobbing machines Liebherr Liebherr Hobbing Machine Concept Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its. It involves the creation of gear teeth by cutting. This is achieved by a hobbing machine that ensures exact rotational synchrony. This is because of the generating nature of this particular cutting process. Hobbing. Hobbing Machine Concept.

From www.emag.com

Gear Hobbing Machine K 160 Gear Hobbing at the Highest Level Hobbing Machine Concept It involves the creation of gear teeth by cutting. This is because of the generating nature of this particular cutting process. The cutter profile on a. Hobbing machines provide gear manufacturers a fast and accurate method for cutting parts. Each successive rack is shifted axially to create a. Hobbing is a fast and efficient way to produce gears of all. Hobbing Machine Concept.

From www.emag.com

VL 4 H Gear Hobbing Machine for Fast Gear Cutting Hobbing Machine Concept The cutter profile on a. It involves the creation of gear teeth by cutting. This is achieved by a hobbing machine that ensures exact rotational synchrony. Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its. Hobbing machines provide gear manufacturers a fast and. Hobbing Machine Concept.

From www.liebherr.com

LC 180 280 Gear hobbing machines Liebherr Liebherr Hobbing Machine Concept Gear hobbing is not a form cutting process, such as gashing or milling where the cutter is a conjugate form of the gear tooth. Each successive rack is shifted axially to create a. Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its. Gear. Hobbing Machine Concept.

From www.liebherr.com

LC 60 130 Gear hobbing machines Liebherr Liebherr Hobbing Machine Concept The cutter profile on a. Each successive rack is shifted axially to create a. This is achieved by a hobbing machine that ensures exact rotational synchrony. It involves the creation of gear teeth by cutting. Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from. Hobbing Machine Concept.

From www.dreamstime.com

Gear hobbing machine stock photo. Image of concepts 248639168 Hobbing Machine Concept This is because of the generating nature of this particular cutting process. Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its. Gear hobbing is not a form cutting process, such as gashing or milling where the cutter is a conjugate form of the. Hobbing Machine Concept.

From www.star-su.com

H 250400 Vertical Gear Hobbing Machine StarSU Hobbing Machine Concept Gear hobbing is not a form cutting process, such as gashing or milling where the cutter is a conjugate form of the gear tooth. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. This is achieved by a hobbing machine that ensures exact rotational synchrony. Each successive. Hobbing Machine Concept.

From thors.com

Gear Hobbing Video Series 2 Hobbing Machine Concept It involves the creation of gear teeth by cutting. This is because of the generating nature of this particular cutting process. Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its. Gear hobbing is a commonly used manufacturing process for producing gears. Gear hobbing. Hobbing Machine Concept.

From www.pinterest.com

The Model 160 hobbing machine combines current technological Hobbing Machine Concept Hobbing machines provide gear manufacturers a fast and accurate method for cutting parts. This is achieved by a hobbing machine that ensures exact rotational synchrony. The cutter profile on a. Each successive rack is shifted axially to create a. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a. Hobbing Machine Concept.

From www.liebherr.com

Gear hobbing machines Liebherr Liebherr Hobbing Machine Concept Gear hobbing is not a form cutting process, such as gashing or milling where the cutter is a conjugate form of the gear tooth. Gear hobbing is a commonly used manufacturing process for producing gears. The cutter profile on a. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called. Hobbing Machine Concept.

From www.liebherr.com

LC 60 130 Gear hobbing machines Liebherr Liebherr Hobbing Machine Concept The hob is a series of racks positioned around the circumference of a cylindrical tool. Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its. Each successive rack is shifted axially to create a. It involves the creation of gear teeth by cutting. The. Hobbing Machine Concept.

From www.pli-international.com

CNC Gear Hobbing Machine LIEBHERR LC802 PLI International Hobbing Machine Concept Gear hobbing is a commonly used manufacturing process for producing gears. It involves the creation of gear teeth by cutting. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the. Hobbing Machine Concept.

From www.liebherr.com

LC 180 280 Gear hobbing machines Liebherr Liebherr Hobbing Machine Concept It involves the creation of gear teeth by cutting. Gear hobbing is a commonly used manufacturing process for producing gears. Hobbing machines provide gear manufacturers a fast and accurate method for cutting parts. This is achieved by a hobbing machine that ensures exact rotational synchrony. Gear hobbing is a machining process that involves cutting teeth into a gear blank using. Hobbing Machine Concept.

From asthegearturns.com

The Hobbing Process, Part 1 As the Gear Turns Hobbing Machine Concept Each successive rack is shifted axially to create a. Hobbing machines provide gear manufacturers a fast and accurate method for cutting parts. This is because of the generating nature of this particular cutting process. Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its.. Hobbing Machine Concept.

From www.emag.com

Gear Hobbing Machines for Precise Gear Hobbing Hobbing Machine Concept The cutter profile on a. Gear hobbing is a commonly used manufacturing process for producing gears. Each successive rack is shifted axially to create a. This is because of the generating nature of this particular cutting process. This is achieved by a hobbing machine that ensures exact rotational synchrony. Gear hobbing is a machining process that involves cutting teeth into. Hobbing Machine Concept.

From www.mhd-maschinen.de

GEAR HOBBING MACHINES MHD Maschinen Hobbing Machine Concept Hobbing machines provide gear manufacturers a fast and accurate method for cutting parts. This is achieved by a hobbing machine that ensures exact rotational synchrony. Each successive rack is shifted axially to create a. Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its.. Hobbing Machine Concept.

From www.liebherr.com

LC 2000 12000 Gear hobbing machines Liebherr Liebherr Hobbing Machine Concept Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its. The hob is a series of racks positioned around the circumference of a cylindrical tool. Gear hobbing is a commonly used manufacturing process for producing gears. The cutter profile on a. Gear hobbing is. Hobbing Machine Concept.

From www.youtube.com

CNC Gear Hobbing Machine EIFCO YouTube Hobbing Machine Concept The cutter profile on a. Gear hobbing is not a form cutting process, such as gashing or milling where the cutter is a conjugate form of the gear tooth. Hobbing machines provide gear manufacturers a fast and accurate method for cutting parts. The hob is a series of racks positioned around the circumference of a cylindrical tool. Gear hobbing is. Hobbing Machine Concept.

From www.youtube.com

Liebherr Gear Hobbing Machine LC 380500 YouTube Hobbing Machine Concept Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. The hob is a series of racks positioned around the circumference of a cylindrical tool. The cutter profile on a. This is because of the generating nature of this particular cutting process. Hobbing is a fast and efficient. Hobbing Machine Concept.

From www.liebherr.com

LC 2000 12000 Gear hobbing machines Liebherr Liebherr Hobbing Machine Concept Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. Gear hobbing is not a form cutting process, such as gashing or milling where the cutter is a conjugate form of the gear tooth. Each successive rack is shifted axially to create a. Gear hobbing is a commonly. Hobbing Machine Concept.

From www.liebherr.com

LC 300 500 Gear hobbing machines Liebherr Liebherr Hobbing Machine Concept Hobbing is a fast and efficient way to produce gears of all sorts and sizes, especially with the leaps and bounds it has made from its. The cutter profile on a. Each successive rack is shifted axially to create a. Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called. Hobbing Machine Concept.

From thors.com

Gear Hobbing Video Series 1 Hobbing Machine Concept Gear hobbing is a machining process that involves cutting teeth into a gear blank using a specialized cutting tool called a hob. Hobbing machines provide gear manufacturers a fast and accurate method for cutting parts. Each successive rack is shifted axially to create a. The hob is a series of racks positioned around the circumference of a cylindrical tool. Gear. Hobbing Machine Concept.