Brazing Cleaning . Remove all flux residue before submitting the part for inspection and pressure testing. When you’re brazing, cleaning your materials thoroughly is very important. — improper plate cleaning. Improper cleaning can also lead to oxidation, which you always want to avoid when working with metals. The first step is to remove all flux residues. Second, pickle the joint to remove any oxide scale formed during the. Brazing will trap impurities on the surface. — when using flux for brazing, you may need to remove residual flux with an appropriate method for your materials and process. Torch or manual brazing, induction brazing, resistance brazing, and vacuum brazing. cleaning a braze joint is a two step process. Immediately after the brazing alloy has set, quench with water or apply a wet cloth to crack and remove. — proper cleaning of components to be brazed is essential prior to their being assembled together for brazing, because once the parts. — clean the parts after brazing, which is a quick but critical step because flux is a corrosive alkaline that could corrode the base material. If debris is caught on the edges, the bond will be corrupted. there are four main types of brazing heating methods:

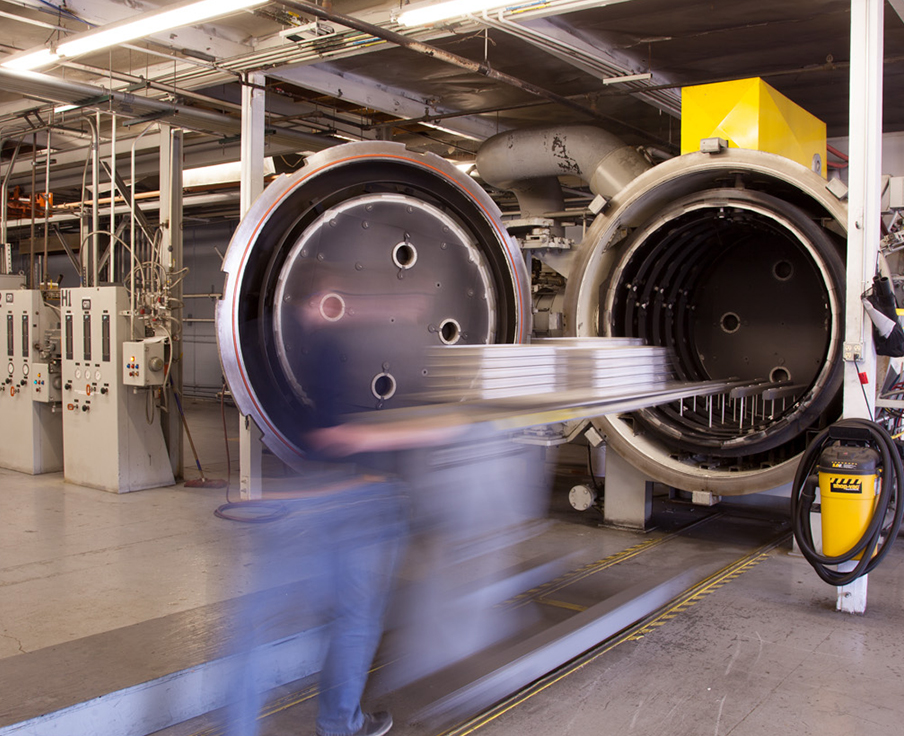

from www.thermalvac.com

— improper plate cleaning. The first step is to remove all flux residues. Second, pickle the joint to remove any oxide scale formed during the. Torch or manual brazing, induction brazing, resistance brazing, and vacuum brazing. Immediately after the brazing alloy has set, quench with water or apply a wet cloth to crack and remove. If debris is caught on the edges, the bond will be corrupted. — clean the parts after brazing, which is a quick but critical step because flux is a corrosive alkaline that could corrode the base material. — when using flux for brazing, you may need to remove residual flux with an appropriate method for your materials and process. there are four main types of brazing heating methods: When you’re brazing, cleaning your materials thoroughly is very important.

Vacuum Brazing ThermalVac Technology

Brazing Cleaning Second, pickle the joint to remove any oxide scale formed during the. — when using flux for brazing, you may need to remove residual flux with an appropriate method for your materials and process. Torch or manual brazing, induction brazing, resistance brazing, and vacuum brazing. Brazing will trap impurities on the surface. cleaning a braze joint is a two step process. there are four main types of brazing heating methods: Immediately after the brazing alloy has set, quench with water or apply a wet cloth to crack and remove. Improper cleaning can also lead to oxidation, which you always want to avoid when working with metals. Second, pickle the joint to remove any oxide scale formed during the. When you’re brazing, cleaning your materials thoroughly is very important. If debris is caught on the edges, the bond will be corrupted. — improper plate cleaning. — proper cleaning of components to be brazed is essential prior to their being assembled together for brazing, because once the parts. The first step is to remove all flux residues. Remove all flux residue before submitting the part for inspection and pressure testing. — clean the parts after brazing, which is a quick but critical step because flux is a corrosive alkaline that could corrode the base material.

From www.intran.mx

The Benefits of Controlled Atmosphere Brazing Intran Blog Brazing Cleaning — improper plate cleaning. Remove all flux residue before submitting the part for inspection and pressure testing. — clean the parts after brazing, which is a quick but critical step because flux is a corrosive alkaline that could corrode the base material. there are four main types of brazing heating methods: If debris is caught on the. Brazing Cleaning.

From www.youtube.com

How to Braze steel cleaning YouTube Brazing Cleaning When you’re brazing, cleaning your materials thoroughly is very important. cleaning a braze joint is a two step process. Improper cleaning can also lead to oxidation, which you always want to avoid when working with metals. there are four main types of brazing heating methods: The first step is to remove all flux residues. — clean the. Brazing Cleaning.

From blog.thepipingmart.com

How to Braze Mild Steel A Complete Guide Brazing Cleaning The first step is to remove all flux residues. cleaning a braze joint is a two step process. — when using flux for brazing, you may need to remove residual flux with an appropriate method for your materials and process. — clean the parts after brazing, which is a quick but critical step because flux is a. Brazing Cleaning.

From georgeindustries.com

Aluminum Brazing Dip Brazing & Vacuum Brazing Industries Brazing Cleaning Torch or manual brazing, induction brazing, resistance brazing, and vacuum brazing. When you’re brazing, cleaning your materials thoroughly is very important. The first step is to remove all flux residues. — clean the parts after brazing, which is a quick but critical step because flux is a corrosive alkaline that could corrode the base material. Immediately after the brazing. Brazing Cleaning.

From www.youtube.com

Brazing 06 Brazing Step 3 Pre Cleaning YouTube Brazing Cleaning — proper cleaning of components to be brazed is essential prior to their being assembled together for brazing, because once the parts. If debris is caught on the edges, the bond will be corrupted. The first step is to remove all flux residues. Remove all flux residue before submitting the part for inspection and pressure testing. — improper. Brazing Cleaning.

From kaybrazing.com

Essential Criteria for Brazing Item 2 Proper CleaningRole of Grit Brazing Cleaning cleaning a braze joint is a two step process. — proper cleaning of components to be brazed is essential prior to their being assembled together for brazing, because once the parts. — clean the parts after brazing, which is a quick but critical step because flux is a corrosive alkaline that could corrode the base material. Torch. Brazing Cleaning.

From www.vacubraze.net

Vacuum Brazing Vacu Braze Brazing Cleaning If debris is caught on the edges, the bond will be corrupted. cleaning a braze joint is a two step process. Improper cleaning can also lead to oxidation, which you always want to avoid when working with metals. Remove all flux residue before submitting the part for inspection and pressure testing. — clean the parts after brazing, which. Brazing Cleaning.

From www.thermalvac.com

Vacuum Brazing ThermalVac Technology Brazing Cleaning — clean the parts after brazing, which is a quick but critical step because flux is a corrosive alkaline that could corrode the base material. The first step is to remove all flux residues. Immediately after the brazing alloy has set, quench with water or apply a wet cloth to crack and remove. Remove all flux residue before submitting. Brazing Cleaning.

From www.thefabricator.com

How to braze in a sixstep process Brazing Cleaning — proper cleaning of components to be brazed is essential prior to their being assembled together for brazing, because once the parts. Second, pickle the joint to remove any oxide scale formed during the. Improper cleaning can also lead to oxidation, which you always want to avoid when working with metals. When you’re brazing, cleaning your materials thoroughly is. Brazing Cleaning.

From www.youtube.com

Fundamentals of Brazing 6 Cleaning the Joint YouTube Brazing Cleaning Improper cleaning can also lead to oxidation, which you always want to avoid when working with metals. — when using flux for brazing, you may need to remove residual flux with an appropriate method for your materials and process. Brazing will trap impurities on the surface. — improper plate cleaning. there are four main types of brazing. Brazing Cleaning.

From www.wallworkht.co.uk

Vacuum Brazing, Reducing Residual Stress via Heat Treatment Brazing Cleaning Remove all flux residue before submitting the part for inspection and pressure testing. — when using flux for brazing, you may need to remove residual flux with an appropriate method for your materials and process. The first step is to remove all flux residues. there are four main types of brazing heating methods: When you’re brazing, cleaning your. Brazing Cleaning.

From www.vpei.com

Vacuum Brazing Services Vacuum Process Engineering Brazing Cleaning The first step is to remove all flux residues. When you’re brazing, cleaning your materials thoroughly is very important. Improper cleaning can also lead to oxidation, which you always want to avoid when working with metals. Remove all flux residue before submitting the part for inspection and pressure testing. Torch or manual brazing, induction brazing, resistance brazing, and vacuum brazing.. Brazing Cleaning.

From www.contractormag.com

Common Brazing Mistakes and How to Avoid Them Contractor Brazing Cleaning Improper cleaning can also lead to oxidation, which you always want to avoid when working with metals. The first step is to remove all flux residues. — when using flux for brazing, you may need to remove residual flux with an appropriate method for your materials and process. Remove all flux residue before submitting the part for inspection and. Brazing Cleaning.

From www.youtube.com

How to braze copper with silphos brazing rod YouTube Brazing Cleaning Brazing will trap impurities on the surface. Torch or manual brazing, induction brazing, resistance brazing, and vacuum brazing. — when using flux for brazing, you may need to remove residual flux with an appropriate method for your materials and process. If debris is caught on the edges, the bond will be corrupted. — improper plate cleaning. The first. Brazing Cleaning.

From kaybrazing.com

Essential Criteria for Brazing Item 2 — Proper Cleaning/handling means Brazing Cleaning Torch or manual brazing, induction brazing, resistance brazing, and vacuum brazing. Remove all flux residue before submitting the part for inspection and pressure testing. Second, pickle the joint to remove any oxide scale formed during the. — when using flux for brazing, you may need to remove residual flux with an appropriate method for your materials and process. When. Brazing Cleaning.

From www.youtube.com

Silver Brazing Demo Stainless Steel, Brass, & Copper YouTube Brazing Cleaning When you’re brazing, cleaning your materials thoroughly is very important. — when using flux for brazing, you may need to remove residual flux with an appropriate method for your materials and process. The first step is to remove all flux residues. there are four main types of brazing heating methods: Second, pickle the joint to remove any oxide. Brazing Cleaning.

From www.youtube.com

116 Vibratory cleaning in preparation for brazing YouTube Brazing Cleaning The first step is to remove all flux residues. there are four main types of brazing heating methods: — proper cleaning of components to be brazed is essential prior to their being assembled together for brazing, because once the parts. Second, pickle the joint to remove any oxide scale formed during the. — when using flux for. Brazing Cleaning.

From www.kaybrazing.com

Essential Criteria for Brazing Item 1 — Proper Cleaning (Part A) Brazing Cleaning Second, pickle the joint to remove any oxide scale formed during the. Immediately after the brazing alloy has set, quench with water or apply a wet cloth to crack and remove. cleaning a braze joint is a two step process. The first step is to remove all flux residues. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. Brazing Cleaning.

From www.youtube.com

Brazing Tutorial!! YouTube Brazing Cleaning Torch or manual brazing, induction brazing, resistance brazing, and vacuum brazing. cleaning a braze joint is a two step process. — clean the parts after brazing, which is a quick but critical step because flux is a corrosive alkaline that could corrode the base material. When you’re brazing, cleaning your materials thoroughly is very important. — proper. Brazing Cleaning.

From georgeindustries.com

Aluminum Brazing Dip Brazing & Vacuum Brazing Industries Brazing Cleaning Brazing will trap impurities on the surface. Torch or manual brazing, induction brazing, resistance brazing, and vacuum brazing. there are four main types of brazing heating methods: Second, pickle the joint to remove any oxide scale formed during the. — improper plate cleaning. — clean the parts after brazing, which is a quick but critical step because. Brazing Cleaning.

From www.youtube.com

Brazing 09 Brazing Step 6 Removing Residue YouTube Brazing Cleaning When you’re brazing, cleaning your materials thoroughly is very important. Immediately after the brazing alloy has set, quench with water or apply a wet cloth to crack and remove. The first step is to remove all flux residues. Torch or manual brazing, induction brazing, resistance brazing, and vacuum brazing. Remove all flux residue before submitting the part for inspection and. Brazing Cleaning.

From www.saldobrase.com

Copper brazing guide Saldobrase srl Brazing Cleaning Brazing will trap impurities on the surface. The first step is to remove all flux residues. When you’re brazing, cleaning your materials thoroughly is very important. If debris is caught on the edges, the bond will be corrupted. — when using flux for brazing, you may need to remove residual flux with an appropriate method for your materials and. Brazing Cleaning.

From blog.lucasmilhaupt.com

Brazing Surface Preparation How to Clean Base Materials Brazing Cleaning Remove all flux residue before submitting the part for inspection and pressure testing. — improper plate cleaning. Brazing will trap impurities on the surface. Immediately after the brazing alloy has set, quench with water or apply a wet cloth to crack and remove. Second, pickle the joint to remove any oxide scale formed during the. — clean the. Brazing Cleaning.

From weldingpros.net

Brazing Filler Metals And Fluxes Explained In Detail Brazing Cleaning Improper cleaning can also lead to oxidation, which you always want to avoid when working with metals. Immediately after the brazing alloy has set, quench with water or apply a wet cloth to crack and remove. Remove all flux residue before submitting the part for inspection and pressure testing. When you’re brazing, cleaning your materials thoroughly is very important. . Brazing Cleaning.

From www.flickr.com

Brazing complete, just needs cleaning up Trev Smedley Flickr Brazing Cleaning — proper cleaning of components to be brazed is essential prior to their being assembled together for brazing, because once the parts. When you’re brazing, cleaning your materials thoroughly is very important. Improper cleaning can also lead to oxidation, which you always want to avoid when working with metals. there are four main types of brazing heating methods:. Brazing Cleaning.

From engineeringlearner.com

Types of Brazing Definition, Principle, Applications, Advantages Brazing Cleaning Brazing will trap impurities on the surface. When you’re brazing, cleaning your materials thoroughly is very important. If debris is caught on the edges, the bond will be corrupted. The first step is to remove all flux residues. Torch or manual brazing, induction brazing, resistance brazing, and vacuum brazing. — when using flux for brazing, you may need to. Brazing Cleaning.

From www.youtube.com

brazing flux removal YouTube Brazing Cleaning cleaning a braze joint is a two step process. If debris is caught on the edges, the bond will be corrupted. Immediately after the brazing alloy has set, quench with water or apply a wet cloth to crack and remove. Brazing will trap impurities on the surface. When you’re brazing, cleaning your materials thoroughly is very important. The first. Brazing Cleaning.

From blog.lucasmilhaupt.com

How to Clean a Braze Joint in Two Steps Brazing Cleaning cleaning a braze joint is a two step process. — improper plate cleaning. Remove all flux residue before submitting the part for inspection and pressure testing. Torch or manual brazing, induction brazing, resistance brazing, and vacuum brazing. When you’re brazing, cleaning your materials thoroughly is very important. — when using flux for brazing, you may need to. Brazing Cleaning.

From www.mechero.my

What is Brazing Process? Brazing Types & Applications Brazing Cleaning The first step is to remove all flux residues. Brazing will trap impurities on the surface. cleaning a braze joint is a two step process. If debris is caught on the edges, the bond will be corrupted. Remove all flux residue before submitting the part for inspection and pressure testing. there are four main types of brazing heating. Brazing Cleaning.

From www.tav-vacuumfurnaces.com

Vacuum brazing the guide to perfect brazed joints Brazing Cleaning — clean the parts after brazing, which is a quick but critical step because flux is a corrosive alkaline that could corrode the base material. If debris is caught on the edges, the bond will be corrupted. — improper plate cleaning. cleaning a braze joint is a two step process. Immediately after the brazing alloy has set,. Brazing Cleaning.

From tmpn.com

Brazing Brush Taurus Maintenance Products Brazing Cleaning When you’re brazing, cleaning your materials thoroughly is very important. — clean the parts after brazing, which is a quick but critical step because flux is a corrosive alkaline that could corrode the base material. Immediately after the brazing alloy has set, quench with water or apply a wet cloth to crack and remove. If debris is caught on. Brazing Cleaning.

From blog.lucasmilhaupt.com

How To Clean Brazing Metals Brazing Cleaning The first step is to remove all flux residues. — improper plate cleaning. Improper cleaning can also lead to oxidation, which you always want to avoid when working with metals. cleaning a braze joint is a two step process. Second, pickle the joint to remove any oxide scale formed during the. If debris is caught on the edges,. Brazing Cleaning.

From www.youtube.com

Brazing Copper to Brass with SilFos® YouTube Brazing Cleaning Remove all flux residue before submitting the part for inspection and pressure testing. Torch or manual brazing, induction brazing, resistance brazing, and vacuum brazing. Second, pickle the joint to remove any oxide scale formed during the. — when using flux for brazing, you may need to remove residual flux with an appropriate method for your materials and process. Immediately. Brazing Cleaning.

From kaybrazing.com

Essential Criteria for Brazing Item 2 Proper cleaning—role of tumble Brazing Cleaning Improper cleaning can also lead to oxidation, which you always want to avoid when working with metals. — proper cleaning of components to be brazed is essential prior to their being assembled together for brazing, because once the parts. — when using flux for brazing, you may need to remove residual flux with an appropriate method for your. Brazing Cleaning.

From fractory.com

Brazing Explained Definition, Process, Types Fractory Brazing Cleaning — proper cleaning of components to be brazed is essential prior to their being assembled together for brazing, because once the parts. Torch or manual brazing, induction brazing, resistance brazing, and vacuum brazing. Immediately after the brazing alloy has set, quench with water or apply a wet cloth to crack and remove. — improper plate cleaning. Remove all. Brazing Cleaning.