Baffles In A Boiler . Shell cross baffles have the dual purpose of supporting the tubes at intervals to prevent sag and vibration, and also of forcing the shell side fluid back and forth. Learn about the types, functions, and design considerations of baffles in shell and tube heat exchangers. These are calculated using a pressure vessel design code. Learn how baffle orientation affects heat transfer rate and pressure drop in shell and tube heat exchangers. All fields with a white. Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. Baffles are metal plates that direct flow, create turbulence, and increase. The mechanical design of a shell and tube heat exchanger provides information on items such as shell thickness, flange thickness, etc. In this section all the relevant information for defining a heat exchanger's baffles configurations can be introduced.

from www.youtube.com

All fields with a white. Learn about the types, functions, and design considerations of baffles in shell and tube heat exchangers. These are calculated using a pressure vessel design code. Baffles are metal plates that direct flow, create turbulence, and increase. Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. Learn how baffle orientation affects heat transfer rate and pressure drop in shell and tube heat exchangers. In this section all the relevant information for defining a heat exchanger's baffles configurations can be introduced. Shell cross baffles have the dual purpose of supporting the tubes at intervals to prevent sag and vibration, and also of forcing the shell side fluid back and forth. The mechanical design of a shell and tube heat exchanger provides information on items such as shell thickness, flange thickness, etc.

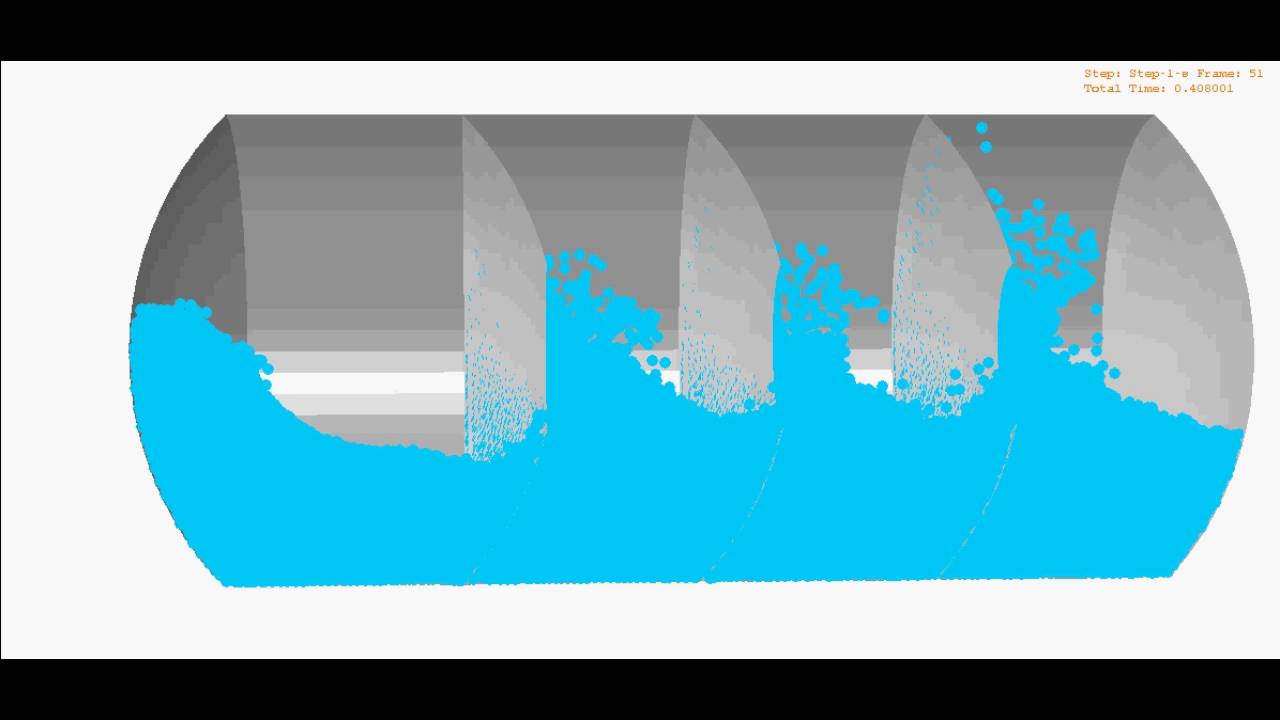

Tank Sloshing SimulationResult of Tank Deceleration in Container With

Baffles In A Boiler Learn about the types, functions, and design considerations of baffles in shell and tube heat exchangers. Learn about the types, functions, and design considerations of baffles in shell and tube heat exchangers. These are calculated using a pressure vessel design code. The mechanical design of a shell and tube heat exchanger provides information on items such as shell thickness, flange thickness, etc. In this section all the relevant information for defining a heat exchanger's baffles configurations can be introduced. Learn how baffle orientation affects heat transfer rate and pressure drop in shell and tube heat exchangers. Shell cross baffles have the dual purpose of supporting the tubes at intervals to prevent sag and vibration, and also of forcing the shell side fluid back and forth. Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. Baffles are metal plates that direct flow, create turbulence, and increase. All fields with a white.

From housenotebook.com

What is a baffle in a septic system? Baffles In A Boiler Learn about the types, functions, and design considerations of baffles in shell and tube heat exchangers. Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. Baffles are metal plates that direct flow, create turbulence, and increase. All fields with a white. Shell cross baffles have the dual purpose of. Baffles In A Boiler.

From neptunewaterinc.com

Steam Boiler Systems — Neptune Water Services Inc. Baffles In A Boiler Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. These are calculated using a pressure vessel design code. Baffles are metal plates that direct flow, create turbulence, and increase. The mechanical design of a shell and tube heat exchanger provides information on items such as shell thickness, flange thickness,. Baffles In A Boiler.

From fintubes.co.id

Heat Exchanger Baffles, Boiler Baffle metalindo engineering Baffles In A Boiler In this section all the relevant information for defining a heat exchanger's baffles configurations can be introduced. Learn about the types, functions, and design considerations of baffles in shell and tube heat exchangers. Shell cross baffles have the dual purpose of supporting the tubes at intervals to prevent sag and vibration, and also of forcing the shell side fluid back. Baffles In A Boiler.

From olabeaga.org

What is Babcock and Wilcox Boiler ? Complete Explanation Baffles In A Boiler Shell cross baffles have the dual purpose of supporting the tubes at intervals to prevent sag and vibration, and also of forcing the shell side fluid back and forth. These are calculated using a pressure vessel design code. All fields with a white. Learn about the types, functions, and design considerations of baffles in shell and tube heat exchangers. Baffles. Baffles In A Boiler.

From heatingboilerspares.com

Firebird Condensing Baffle C35 Boiler spares, Ireland & UK. Genuine Baffles In A Boiler In this section all the relevant information for defining a heat exchanger's baffles configurations can be introduced. Baffles are metal plates that direct flow, create turbulence, and increase. The mechanical design of a shell and tube heat exchanger provides information on items such as shell thickness, flange thickness, etc. These are calculated using a pressure vessel design code. Learn how. Baffles In A Boiler.

From heatingpartswarehouse.co.uk

Warmflow 015R Baffles WF 015R (Set of 5), 015R Buy at H.P.W. Baffles In A Boiler Shell cross baffles have the dual purpose of supporting the tubes at intervals to prevent sag and vibration, and also of forcing the shell side fluid back and forth. These are calculated using a pressure vessel design code. Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. Baffles are. Baffles In A Boiler.

From www.gumtree.com

Worcester Greenstar Danesmoor 25/32 External Oil Fired Boiler baffles Baffles In A Boiler Learn how baffle orientation affects heat transfer rate and pressure drop in shell and tube heat exchangers. Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. Learn about the types, functions, and design considerations of baffles in shell and tube heat exchangers. All fields with a white. Shell cross. Baffles In A Boiler.

From www.flickr.com

Furnace heat exchanger baffles This metal baffle was stick… Flickr Baffles In A Boiler In this section all the relevant information for defining a heat exchanger's baffles configurations can be introduced. Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. Learn about the types, functions, and design considerations of baffles in shell and tube heat exchangers. Shell cross baffles have the dual purpose. Baffles In A Boiler.

From heatingboilerspares.com

Grant Euroflame 50/70 Baffles x 4 Boiler spares, Ireland & UK Baffles In A Boiler Baffles are metal plates that direct flow, create turbulence, and increase. These are calculated using a pressure vessel design code. In this section all the relevant information for defining a heat exchanger's baffles configurations can be introduced. Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. The mechanical design. Baffles In A Boiler.

From savree.com

Watertube Boilers Explained saVRee saVRee Baffles In A Boiler Baffles are metal plates that direct flow, create turbulence, and increase. The mechanical design of a shell and tube heat exchanger provides information on items such as shell thickness, flange thickness, etc. These are calculated using a pressure vessel design code. Shell cross baffles have the dual purpose of supporting the tubes at intervals to prevent sag and vibration, and. Baffles In A Boiler.

From heatexchangertsuritai.blogspot.com

Heat Exchanger Heat Exchanger Baffles Baffles In A Boiler In this section all the relevant information for defining a heat exchanger's baffles configurations can be introduced. Shell cross baffles have the dual purpose of supporting the tubes at intervals to prevent sag and vibration, and also of forcing the shell side fluid back and forth. These are calculated using a pressure vessel design code. Learn about the types, functions,. Baffles In A Boiler.

From www.youtube.com

Babcock and wilcox boiler working animation simple diagram construction Baffles In A Boiler The mechanical design of a shell and tube heat exchanger provides information on items such as shell thickness, flange thickness, etc. Baffles are metal plates that direct flow, create turbulence, and increase. Learn how baffle orientation affects heat transfer rate and pressure drop in shell and tube heat exchangers. All fields with a white. In this section all the relevant. Baffles In A Boiler.

From www.physicsforums.com

Baffles in a reactor Physics Forums Baffles In A Boiler These are calculated using a pressure vessel design code. Learn about the types, functions, and design considerations of baffles in shell and tube heat exchangers. The mechanical design of a shell and tube heat exchanger provides information on items such as shell thickness, flange thickness, etc. Baffles are metal plates that direct flow, create turbulence, and increase. Shell cross baffles. Baffles In A Boiler.

From www.stxaviersschooljaipur.com

Sale > oil boiler burner unit > in stock Baffles In A Boiler All fields with a white. Learn about the types, functions, and design considerations of baffles in shell and tube heat exchangers. Learn how baffle orientation affects heat transfer rate and pressure drop in shell and tube heat exchangers. In this section all the relevant information for defining a heat exchanger's baffles configurations can be introduced. Baffles are metal plates that. Baffles In A Boiler.

From instrumentationtools.com

Boiler Archives Inst Tools Baffles In A Boiler Baffles are metal plates that direct flow, create turbulence, and increase. Shell cross baffles have the dual purpose of supporting the tubes at intervals to prevent sag and vibration, and also of forcing the shell side fluid back and forth. Learn about the types, functions, and design considerations of baffles in shell and tube heat exchangers. Baffles play a crucial. Baffles In A Boiler.

From steamboilerpitsujiku.blogspot.com

Steam Boiler Steam Boiler Diagram Baffles In A Boiler These are calculated using a pressure vessel design code. Learn how baffle orientation affects heat transfer rate and pressure drop in shell and tube heat exchangers. In this section all the relevant information for defining a heat exchanger's baffles configurations can be introduced. The mechanical design of a shell and tube heat exchanger provides information on items such as shell. Baffles In A Boiler.

From www.pinterest.com.mx

Getting a fire tube boiler ready to close up at work. This is a 1959 Baffles In A Boiler The mechanical design of a shell and tube heat exchanger provides information on items such as shell thickness, flange thickness, etc. Learn how baffle orientation affects heat transfer rate and pressure drop in shell and tube heat exchangers. In this section all the relevant information for defining a heat exchanger's baffles configurations can be introduced. Learn about the types, functions,. Baffles In A Boiler.

From learnmechanical.com

Babcock and Wilcox Boiler Definition, Parts, Working, Advantages Baffles In A Boiler Learn about the types, functions, and design considerations of baffles in shell and tube heat exchangers. These are calculated using a pressure vessel design code. Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. The mechanical design of a shell and tube heat exchanger provides information on items such. Baffles In A Boiler.

From allthingsnuclear.org

Indian Point’s Baffling Bolts Union of Concerned Scientists Baffles In A Boiler In this section all the relevant information for defining a heat exchanger's baffles configurations can be introduced. All fields with a white. These are calculated using a pressure vessel design code. Learn how baffle orientation affects heat transfer rate and pressure drop in shell and tube heat exchangers. The mechanical design of a shell and tube heat exchanger provides information. Baffles In A Boiler.

From www.theengineeringconcepts.com

Baffle (Heat Transfer) The Engineering Concepts Baffles In A Boiler In this section all the relevant information for defining a heat exchanger's baffles configurations can be introduced. Learn about the types, functions, and design considerations of baffles in shell and tube heat exchangers. Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. Baffles are metal plates that direct flow,. Baffles In A Boiler.

From edu.svet.gob.gt

Boiler Proficiency Engineers Steam Drum Internals With Baffles In A Boiler All fields with a white. The mechanical design of a shell and tube heat exchanger provides information on items such as shell thickness, flange thickness, etc. These are calculated using a pressure vessel design code. Learn about the types, functions, and design considerations of baffles in shell and tube heat exchangers. Baffles play a crucial role in regulating shellside fluid. Baffles In A Boiler.

From www.reddit.com

Would you look at that? Yes, that is a baffle for a duct. Yes, the Baffles In A Boiler Learn how baffle orientation affects heat transfer rate and pressure drop in shell and tube heat exchangers. Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. Baffles are metal plates that direct flow, create turbulence, and increase. Shell cross baffles have the dual purpose of supporting the tubes at. Baffles In A Boiler.

From www.youtube.com

How a Firetube Boiler Works YouTube Baffles In A Boiler In this section all the relevant information for defining a heat exchanger's baffles configurations can be introduced. Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. The mechanical design of a shell and tube heat exchanger provides information on items such as shell thickness, flange thickness, etc. All fields. Baffles In A Boiler.

From www.dynamicefi.com

OilBoiler2 Baffles In A Boiler Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. Learn how baffle orientation affects heat transfer rate and pressure drop in shell and tube heat exchangers. These are calculated using a pressure vessel design code. In this section all the relevant information for defining a heat exchanger's baffles configurations. Baffles In A Boiler.

From tipseri.com

What is the function of the baffle plate in the Babcock Wilcox boiler Baffles In A Boiler Shell cross baffles have the dual purpose of supporting the tubes at intervals to prevent sag and vibration, and also of forcing the shell side fluid back and forth. The mechanical design of a shell and tube heat exchanger provides information on items such as shell thickness, flange thickness, etc. Baffles play a crucial role in regulating shellside fluid flow. Baffles In A Boiler.

From zeyon.com

Boiler Baffles Zeyon, Inc. Baffles In A Boiler Learn about the types, functions, and design considerations of baffles in shell and tube heat exchangers. In this section all the relevant information for defining a heat exchanger's baffles configurations can be introduced. Learn how baffle orientation affects heat transfer rate and pressure drop in shell and tube heat exchangers. Shell cross baffles have the dual purpose of supporting the. Baffles In A Boiler.

From newzelindustries.com

EVERYTHING YOU NEED TO KNOW ABOUT BAFFLES Baffles In A Boiler Learn how baffle orientation affects heat transfer rate and pressure drop in shell and tube heat exchangers. The mechanical design of a shell and tube heat exchanger provides information on items such as shell thickness, flange thickness, etc. Baffles are metal plates that direct flow, create turbulence, and increase. Shell cross baffles have the dual purpose of supporting the tubes. Baffles In A Boiler.

From wirewiringlorraine.z13.web.core.windows.net

Diagram Of Boiler Baffles In A Boiler Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. In this section all the relevant information for defining a heat exchanger's baffles configurations can be introduced. These are calculated using a pressure vessel design code. Shell cross baffles have the dual purpose of supporting the tubes at intervals to. Baffles In A Boiler.

From ar.inspiredpencil.com

Boiler Baffles In A Boiler Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. Learn about the types, functions, and design considerations of baffles in shell and tube heat exchangers. Learn how baffle orientation affects heat transfer rate and pressure drop in shell and tube heat exchangers. Baffles are metal plates that direct flow,. Baffles In A Boiler.

From www.gumtree.com

70 / 90 warmflow oil boiler baffle plates set of three. in Baffles In A Boiler Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. These are calculated using a pressure vessel design code. Learn how baffle orientation affects heat transfer rate and pressure drop in shell and tube heat exchangers. In this section all the relevant information for defining a heat exchanger's baffles configurations. Baffles In A Boiler.

From zeyon.com

Boiler Baffles Zeyon, Inc. Baffles In A Boiler Learn about the types, functions, and design considerations of baffles in shell and tube heat exchangers. The mechanical design of a shell and tube heat exchanger provides information on items such as shell thickness, flange thickness, etc. Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. Learn how baffle. Baffles In A Boiler.

From www.smb-sarl.com

tornade gel Poisson anémone smoke tube boiler Tendance éviter Baffles In A Boiler Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. These are calculated using a pressure vessel design code. Baffles are metal plates that direct flow, create turbulence, and increase. Learn how baffle orientation affects heat transfer rate and pressure drop in shell and tube heat exchangers. In this section. Baffles In A Boiler.

From heatingpartswarehouse.co.uk

HRM Boiler Baffles, 15/20 and 15/19, WA092 Buy at H.P.W. Baffles In A Boiler Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. Learn how baffle orientation affects heat transfer rate and pressure drop in shell and tube heat exchangers. In this section all the relevant information for defining a heat exchanger's baffles configurations can be introduced. All fields with a white. The. Baffles In A Boiler.

From www.youtube.com

Tank Sloshing SimulationResult of Tank Deceleration in Container With Baffles In A Boiler In this section all the relevant information for defining a heat exchanger's baffles configurations can be introduced. Shell cross baffles have the dual purpose of supporting the tubes at intervals to prevent sag and vibration, and also of forcing the shell side fluid back and forth. Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer. Baffles In A Boiler.

From masterattic.com

What Are Baffles in the Attic? Master Attic Baffles In A Boiler Baffles play a crucial role in regulating shellside fluid flow and improving heat transfer between shellside and tubeside process fluids. Baffles are metal plates that direct flow, create turbulence, and increase. These are calculated using a pressure vessel design code. Learn how baffle orientation affects heat transfer rate and pressure drop in shell and tube heat exchangers. In this section. Baffles In A Boiler.