Clip Design Plastic . One of the many benefits of plastic resin is the ease with. — catches, recesses, and lugs are good options for ensuring secure assembly. — how to design clip features for an assembly that needs to snap together. These joints are versatile and find use in a wide variety of. In injection molding terms, these are called “living hinges” and are made. Industrial designers don’t want exposed fasteners. — injection molding design fundamentals: Make sure your clips are well designed to handle stress and recover from use. — engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation testing.

from formlabs.com

— engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation testing. Make sure your clips are well designed to handle stress and recover from use. In injection molding terms, these are called “living hinges” and are made. These joints are versatile and find use in a wide variety of. One of the many benefits of plastic resin is the ease with. — injection molding design fundamentals: Industrial designers don’t want exposed fasteners. — catches, recesses, and lugs are good options for ensuring secure assembly. — how to design clip features for an assembly that needs to snap together.

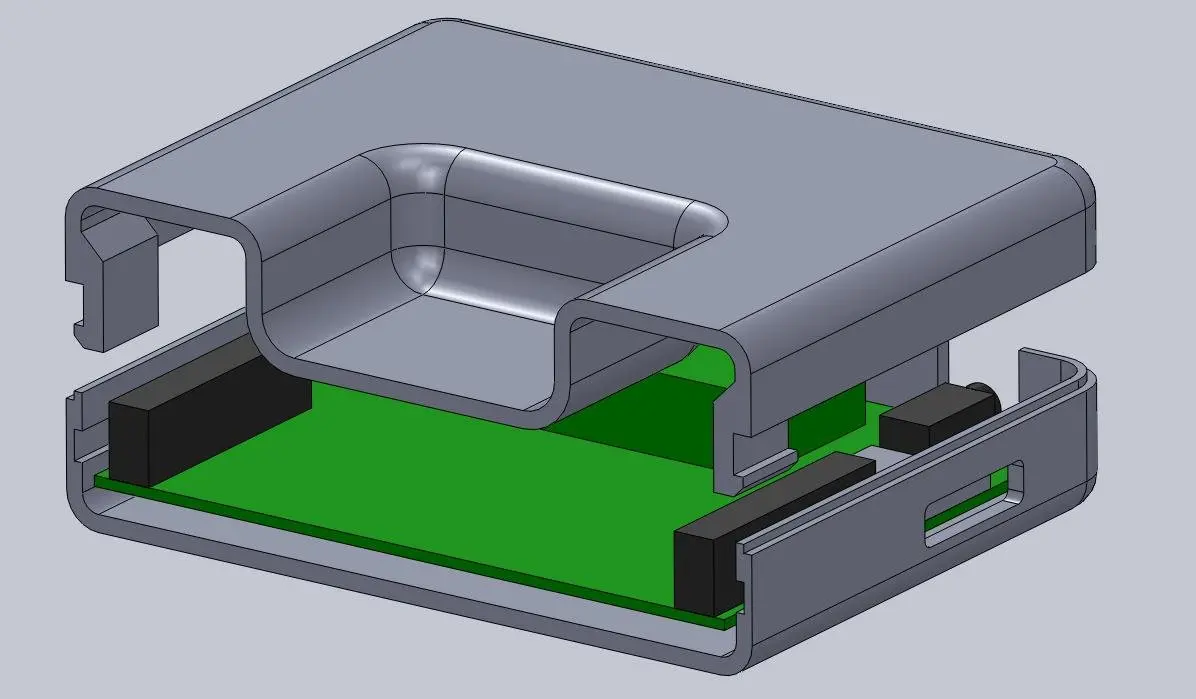

How to Design 3D Printed Snap Fit Enclosures

Clip Design Plastic Make sure your clips are well designed to handle stress and recover from use. These joints are versatile and find use in a wide variety of. Make sure your clips are well designed to handle stress and recover from use. One of the many benefits of plastic resin is the ease with. In injection molding terms, these are called “living hinges” and are made. — engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation testing. Industrial designers don’t want exposed fasteners. — catches, recesses, and lugs are good options for ensuring secure assembly. — how to design clip features for an assembly that needs to snap together. — injection molding design fundamentals:

From formlabs.com

How to Design 3D Printed Snap Fit Enclosures Clip Design Plastic — engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation testing. — injection molding design fundamentals: Make sure your clips are well designed to handle stress and recover from use. — catches, recesses, and lugs are good options for ensuring secure assembly. In injection molding terms, these. Clip Design Plastic.

From www.babezdoor.com

Collection Of Plastic Png High Quality Plastic Clip Art Library The Clip Design Plastic — catches, recesses, and lugs are good options for ensuring secure assembly. These joints are versatile and find use in a wide variety of. — injection molding design fundamentals: Industrial designers don’t want exposed fasteners. — how to design clip features for an assembly that needs to snap together. Make sure your clips are well designed to. Clip Design Plastic.

From pngimg.com

Plastic bag PNG Clip Design Plastic These joints are versatile and find use in a wide variety of. In injection molding terms, these are called “living hinges” and are made. Industrial designers don’t want exposed fasteners. — how to design clip features for an assembly that needs to snap together. One of the many benefits of plastic resin is the ease with. — injection. Clip Design Plastic.

From clipart-library.com

Free Plastic Cliparts, Download Free Plastic Cliparts png images, Free Clip Design Plastic — injection molding design fundamentals: Industrial designers don’t want exposed fasteners. — catches, recesses, and lugs are good options for ensuring secure assembly. Make sure your clips are well designed to handle stress and recover from use. In injection molding terms, these are called “living hinges” and are made. These joints are versatile and find use in a. Clip Design Plastic.

From www.greenmoxie.com

ban singleuse plastics Clip Design Plastic In injection molding terms, these are called “living hinges” and are made. Make sure your clips are well designed to handle stress and recover from use. These joints are versatile and find use in a wide variety of. Industrial designers don’t want exposed fasteners. — how to design clip features for an assembly that needs to snap together. One. Clip Design Plastic.

From www.3dhubs.com

CAD modeling 3 Snap fits 3D Hubs Clip Design Plastic — injection molding design fundamentals: These joints are versatile and find use in a wide variety of. One of the many benefits of plastic resin is the ease with. — engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation testing. — catches, recesses, and lugs are good. Clip Design Plastic.

From www.pngall.com

Plastic PNG Free Download PNG All Clip Design Plastic — catches, recesses, and lugs are good options for ensuring secure assembly. In injection molding terms, these are called “living hinges” and are made. One of the many benefits of plastic resin is the ease with. These joints are versatile and find use in a wide variety of. — engineering a plastic part to replace a metal component. Clip Design Plastic.

From www.hubs.com

How do you design snapfit joints for 3D printing? Hubs Clip Design Plastic These joints are versatile and find use in a wide variety of. One of the many benefits of plastic resin is the ease with. In injection molding terms, these are called “living hinges” and are made. Industrial designers don’t want exposed fasteners. Make sure your clips are well designed to handle stress and recover from use. — injection molding. Clip Design Plastic.

From www.pinterest.co.kr

plastic design Plastic design, Injection moulding, Injection mold design Clip Design Plastic One of the many benefits of plastic resin is the ease with. In injection molding terms, these are called “living hinges” and are made. — engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation testing. — injection molding design fundamentals: — catches, recesses, and lugs are good. Clip Design Plastic.

From ammexplastics.com

Plastic Clip and Fastener Designs Ammex Plastics Clip Design Plastic Make sure your clips are well designed to handle stress and recover from use. — engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation testing. These joints are versatile and find use in a wide variety of. One of the many benefits of plastic resin is the ease with.. Clip Design Plastic.

From www.pinterest.co.kr

Stop plastic pollution campaign template illustration free image by Clip Design Plastic — how to design clip features for an assembly that needs to snap together. One of the many benefits of plastic resin is the ease with. — catches, recesses, and lugs are good options for ensuring secure assembly. Industrial designers don’t want exposed fasteners. — engineering a plastic part to replace a metal component requires expertise in. Clip Design Plastic.

From www.rutlandplastics.co.uk

Design For Assembly 1 Rutland Plastics Clip Design Plastic — injection molding design fundamentals: Industrial designers don’t want exposed fasteners. — engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation testing. In injection molding terms, these are called “living hinges” and are made. — how to design clip features for an assembly that needs to snap. Clip Design Plastic.

From www.freepik.com

Premium Vector Single use plastic ban environmental concept say no to Clip Design Plastic One of the many benefits of plastic resin is the ease with. — injection molding design fundamentals: Make sure your clips are well designed to handle stress and recover from use. These joints are versatile and find use in a wide variety of. In injection molding terms, these are called “living hinges” and are made. — how to. Clip Design Plastic.

From niszczarki.com.pl

Plastic archive clips Argo Clip Design Plastic Industrial designers don’t want exposed fasteners. — engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation testing. These joints are versatile and find use in a wide variety of. In injection molding terms, these are called “living hinges” and are made. One of the many benefits of plastic resin. Clip Design Plastic.

From dienamics.com.au

All About Snap Fits in Product Design Dienamics Clip Design Plastic These joints are versatile and find use in a wide variety of. — catches, recesses, and lugs are good options for ensuring secure assembly. — how to design clip features for an assembly that needs to snap together. Make sure your clips are well designed to handle stress and recover from use. In injection molding terms, these are. Clip Design Plastic.

From clipart-library.com

plastics Clip Art Library Clip Design Plastic — how to design clip features for an assembly that needs to snap together. One of the many benefits of plastic resin is the ease with. Industrial designers don’t want exposed fasteners. — injection molding design fundamentals: In injection molding terms, these are called “living hinges” and are made. — engineering a plastic part to replace a. Clip Design Plastic.

From www.arptech.com.au

3D Printing Design Ideas for Snap Fit Joint Clips ArpTechBlog Clip Design Plastic — engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation testing. — catches, recesses, and lugs are good options for ensuring secure assembly. One of the many benefits of plastic resin is the ease with. Industrial designers don’t want exposed fasteners. In injection molding terms, these are called. Clip Design Plastic.

From clipart-library.com

Free Plastics Cliparts, Download Free Plastics Cliparts png images Clip Design Plastic — injection molding design fundamentals: — how to design clip features for an assembly that needs to snap together. — catches, recesses, and lugs are good options for ensuring secure assembly. One of the many benefits of plastic resin is the ease with. — engineering a plastic part to replace a metal component requires expertise in. Clip Design Plastic.

From www.alamy.com

No plastic sign. Say no plastic bags and bottles emblem, stop plastics Clip Design Plastic Industrial designers don’t want exposed fasteners. — injection molding design fundamentals: — catches, recesses, and lugs are good options for ensuring secure assembly. These joints are versatile and find use in a wide variety of. — how to design clip features for an assembly that needs to snap together. — engineering a plastic part to replace. Clip Design Plastic.

From www.smlease.com

Plastic Design Archives SMLease Design Clip Design Plastic — engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation testing. — how to design clip features for an assembly that needs to snap together. These joints are versatile and find use in a wide variety of. — catches, recesses, and lugs are good options for ensuring. Clip Design Plastic.

From catalog.efc-intl.com

Riblok™ Plastic Trim Clips On EFC International Clip Design Plastic — how to design clip features for an assembly that needs to snap together. These joints are versatile and find use in a wide variety of. Make sure your clips are well designed to handle stress and recover from use. Industrial designers don’t want exposed fasteners. One of the many benefits of plastic resin is the ease with. . Clip Design Plastic.

From sigengineered.com

Plastic Solutions Signature Engineered Solutions Clip Design Plastic These joints are versatile and find use in a wide variety of. One of the many benefits of plastic resin is the ease with. Make sure your clips are well designed to handle stress and recover from use. In injection molding terms, these are called “living hinges” and are made. — engineering a plastic part to replace a metal. Clip Design Plastic.

From www.oceanstationery.com

Ocean Stationery and Office Supplies Office Supplies General Clip Design Plastic Make sure your clips are well designed to handle stress and recover from use. — engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation testing. — how to design clip features for an assembly that needs to snap together. — catches, recesses, and lugs are good options. Clip Design Plastic.

From ammexplastics.com

Plastic Clip and Fastener Designs Ammex Plastics Clip Design Plastic — injection molding design fundamentals: Make sure your clips are well designed to handle stress and recover from use. — engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation testing. — how to design clip features for an assembly that needs to snap together. Industrial designers don’t. Clip Design Plastic.

From ammexplastics.com

Plastic Clip and Fastener Designs Ammex Plastics Clip Design Plastic Industrial designers don’t want exposed fasteners. These joints are versatile and find use in a wide variety of. — how to design clip features for an assembly that needs to snap together. — injection molding design fundamentals: — catches, recesses, and lugs are good options for ensuring secure assembly. — engineering a plastic part to replace. Clip Design Plastic.

From sigengineered.com

Plastic Solutions Signature Engineered Solutions Clip Design Plastic — engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation testing. Make sure your clips are well designed to handle stress and recover from use. — injection molding design fundamentals: Industrial designers don’t want exposed fasteners. These joints are versatile and find use in a wide variety of.. Clip Design Plastic.

From dxoetppzp.blob.core.windows.net

Plastics Are Made From Oils at Mandy Hopper blog Clip Design Plastic — catches, recesses, and lugs are good options for ensuring secure assembly. Industrial designers don’t want exposed fasteners. — injection molding design fundamentals: One of the many benefits of plastic resin is the ease with. In injection molding terms, these are called “living hinges” and are made. — how to design clip features for an assembly that. Clip Design Plastic.

From www.clipartbest.com

Plastics Clipart Free Download Clip Art Free Clip Art on Clip Design Plastic In injection molding terms, these are called “living hinges” and are made. These joints are versatile and find use in a wide variety of. — how to design clip features for an assembly that needs to snap together. — engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation. Clip Design Plastic.

From pngimg.com

Plastic bag PNG transparent image download, size 1408x1656px Clip Design Plastic — engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation testing. Make sure your clips are well designed to handle stress and recover from use. In injection molding terms, these are called “living hinges” and are made. These joints are versatile and find use in a wide variety of.. Clip Design Plastic.

From clipart-library.com

Free Plastic Cliparts, Download Free Plastic Cliparts png images Clip Clip Design Plastic — engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation testing. — how to design clip features for an assembly that needs to snap together. In injection molding terms, these are called “living hinges” and are made. Industrial designers don’t want exposed fasteners. — catches, recesses, and. Clip Design Plastic.

From www.vecteezy.com

plastic bottle collection clipart 11273507 Vector Art at Vecteezy Clip Design Plastic — injection molding design fundamentals: — catches, recesses, and lugs are good options for ensuring secure assembly. — engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation testing. Make sure your clips are well designed to handle stress and recover from use. One of the many benefits. Clip Design Plastic.

From americanacrylics.com

Custom Acrylic Clipboards Exciting Shapes 1000's possible Clip Design Plastic In injection molding terms, these are called “living hinges” and are made. These joints are versatile and find use in a wide variety of. Make sure your clips are well designed to handle stress and recover from use. Industrial designers don’t want exposed fasteners. One of the many benefits of plastic resin is the ease with. — engineering a. Clip Design Plastic.

From pngtree.com

Micro Plastic Vector Design Images, Micro Plastic Vector Micro Plastic Clip Design Plastic — catches, recesses, and lugs are good options for ensuring secure assembly. — engineering a plastic part to replace a metal component requires expertise in design, material, tooling, injection molding, and validation testing. — how to design clip features for an assembly that needs to snap together. Make sure your clips are well designed to handle stress. Clip Design Plastic.