Pull In System Meaning . If you have an explicit wip limit in your production, you have a pull system and hence have access to all the benefits of a lean pull. What is a pull supply chain system? The pull system is a technique used in lean manufacturing to minimize waste in production. A pull system is a lean manufacturing strategy that relies on customer demand to facilitate the production of goods. Ingredients or components used in the manufacturing process. By implementing a pull system,. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. What is a pull system? A pull system is a lean manufacturing process used in the production process to reduce waste. A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction.

from www.slideshare.net

What is a pull system? In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. A pull system is a lean manufacturing strategy that relies on customer demand to facilitate the production of goods. By implementing a pull system,. Ingredients or components used in the manufacturing process. What is a pull supply chain system? A pull system is a lean manufacturing process used in the production process to reduce waste. A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction. If you have an explicit wip limit in your production, you have a pull system and hence have access to all the benefits of a lean pull. The pull system is a technique used in lean manufacturing to minimize waste in production.

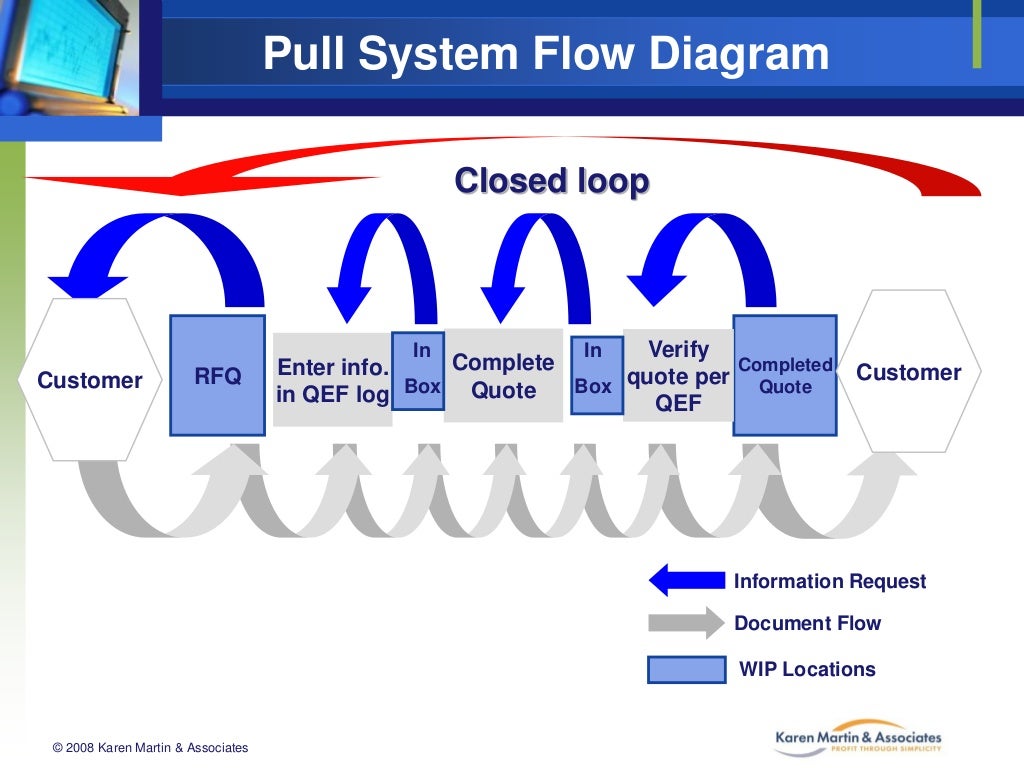

Pull System Flow Diagram Closed

Pull In System Meaning A pull system is a lean manufacturing strategy that relies on customer demand to facilitate the production of goods. What is a pull supply chain system? Ingredients or components used in the manufacturing process. A pull system is a lean manufacturing strategy that relies on customer demand to facilitate the production of goods. What is a pull system? The pull system is a technique used in lean manufacturing to minimize waste in production. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. A pull system is a lean manufacturing process used in the production process to reduce waste. A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction. By implementing a pull system,. If you have an explicit wip limit in your production, you have a pull system and hence have access to all the benefits of a lean pull.

From elsmar.com

Pull System Pull In System Meaning In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. What is a pull system? If you have an explicit wip limit in your production, you have a pull system and hence have access to all the benefits of a lean pull. By implementing a pull system,. The pull system is a. Pull In System Meaning.

From www.slideshare.net

Pull Systems Pull In System Meaning By implementing a pull system,. What is a pull system? A pull system is a lean manufacturing strategy that relies on customer demand to facilitate the production of goods. What is a pull supply chain system? The pull system is a technique used in lean manufacturing to minimize waste in production. A pull system is a lean manufacturing process used. Pull In System Meaning.

From elsmar.com

Synchronous / Lean Manufacturing Pull System Pull In System Meaning What is a pull supply chain system? A pull system is a lean manufacturing strategy that relies on customer demand to facilitate the production of goods. A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction. What is a pull system? Ingredients or components used in. Pull In System Meaning.

From www.youtube.com

What is a Pull System? YouTube Pull In System Meaning The pull system is a technique used in lean manufacturing to minimize waste in production. A pull system is a lean manufacturing strategy that relies on customer demand to facilitate the production of goods. If you have an explicit wip limit in your production, you have a pull system and hence have access to all the benefits of a lean. Pull In System Meaning.

From meksmart.com

WHAT IS PULL SYSTEM? PULL STRATEGY IN INVENTORY MANAGEMENT Pull In System Meaning A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction. What is a pull system? By implementing a pull system,. If you have an explicit wip limit in your production, you have a pull system and hence have access to all the benefits of a lean. Pull In System Meaning.

From www.yash.com

Digital Pull System Material flow Operations SAP Pull In System Meaning The pull system is a technique used in lean manufacturing to minimize waste in production. What is a pull supply chain system? If you have an explicit wip limit in your production, you have a pull system and hence have access to all the benefits of a lean pull. Ingredients or components used in the manufacturing process. A pull system. Pull In System Meaning.

From www.lean.org

Pull Production Lean Enterprise Institute Pull In System Meaning What is a pull system? If you have an explicit wip limit in your production, you have a pull system and hence have access to all the benefits of a lean pull. What is a pull supply chain system? A pull system is a lean manufacturing process used in the production process to reduce waste. In lean manufacturing, push system. Pull In System Meaning.

From teamhood.com

Kanban Pull System Definition and Practical Examples Pull In System Meaning By implementing a pull system,. A pull system is a lean manufacturing process used in the production process to reduce waste. What is a pull system? If you have an explicit wip limit in your production, you have a pull system and hence have access to all the benefits of a lean pull. In lean manufacturing, push system vs pull. Pull In System Meaning.

From www.deprettoindustrie.com

Riser pull in system De Pretto Industrie Pull In System Meaning In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. A pull system is a lean manufacturing strategy that relies on customer demand to facilitate the production of goods. A pull system is a lean manufacturing process used in the production process to reduce waste. What is a pull supply chain system?. Pull In System Meaning.

From www.inflowinventory.com

An InDepth Look Into Push vs Pull System Manufacturing Pull In System Meaning What is a pull supply chain system? If you have an explicit wip limit in your production, you have a pull system and hence have access to all the benefits of a lean pull. By implementing a pull system,. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. A pull system. Pull In System Meaning.

From www.slideshare.net

Pull System Flow Diagram Closed Pull In System Meaning A pull system is a lean manufacturing strategy that relies on customer demand to facilitate the production of goods. What is a pull system? By implementing a pull system,. A pull system is a lean manufacturing process used in the production process to reduce waste. If you have an explicit wip limit in your production, you have a pull system. Pull In System Meaning.

From www.inflowinventory.com

Push vs Pull System Manufacturing An InDepth Analysis Pull In System Meaning A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction. What is a pull supply chain system? What is a pull system? If you have an explicit wip limit in your production, you have a pull system and hence have access to all the benefits of. Pull In System Meaning.

From alexsibaja.blogspot.com

Lean Manufacturing & Six Sigma Pull Production Systems 生産システムを引いて Pull In System Meaning Ingredients or components used in the manufacturing process. A pull system is a lean manufacturing process used in the production process to reduce waste. A pull system is a lean manufacturing strategy that relies on customer demand to facilitate the production of goods. By implementing a pull system,. A pull system is an essential lean management technique that can help. Pull In System Meaning.

From elsmar.com

Benefits of Pull Systems Pull In System Meaning The pull system is a technique used in lean manufacturing to minimize waste in production. A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction. A pull system is a lean manufacturing process used in the production process to reduce waste. By implementing a pull system,.. Pull In System Meaning.

From gioempyes.blob.core.windows.net

Pull Meaning In Engineering at Donald Salazar blog Pull In System Meaning The pull system is a technique used in lean manufacturing to minimize waste in production. What is a pull system? What is a pull supply chain system? By implementing a pull system,. If you have an explicit wip limit in your production, you have a pull system and hence have access to all the benefits of a lean pull. A. Pull In System Meaning.

From www.slideserve.com

PPT Chapter 7 JustinTime and Lean Systems PowerPoint Presentation Pull In System Meaning What is a pull system? In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction. A pull system is a lean manufacturing strategy that relies on customer demand. Pull In System Meaning.

From www.blockchain-council.org

What is Push and Pull Strategy in Supply Chain Management? Pull In System Meaning What is a pull supply chain system? If you have an explicit wip limit in your production, you have a pull system and hence have access to all the benefits of a lean pull. The pull system is a technique used in lean manufacturing to minimize waste in production. A pull system is an essential lean management technique that can. Pull In System Meaning.

From elsmar.com

Pull System Example Pull In System Meaning What is a pull supply chain system? By implementing a pull system,. What is a pull system? Ingredients or components used in the manufacturing process. A pull system is a lean manufacturing strategy that relies on customer demand to facilitate the production of goods. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact. Pull In System Meaning.

From meaningkosh.com

Pull System MeaningKosh Pull In System Meaning In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. A pull system is a lean manufacturing process used in the production process to reduce waste. A pull system is a lean manufacturing strategy that relies on customer demand to facilitate the production of goods. A pull system is an essential lean. Pull In System Meaning.

From www.youtube.com

Pull in meaning of Pull in YouTube Pull In System Meaning A pull system is a lean manufacturing process used in the production process to reduce waste. If you have an explicit wip limit in your production, you have a pull system and hence have access to all the benefits of a lean pull. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a. Pull In System Meaning.

From www.kaizenworld.com

Pull System Kaizenworld Pull In System Meaning What is a pull system? The pull system is a technique used in lean manufacturing to minimize waste in production. A pull system is a lean manufacturing strategy that relies on customer demand to facilitate the production of goods. What is a pull supply chain system? A pull system is an essential lean management technique that can help you reduce. Pull In System Meaning.

From www.slideserve.com

PPT Chapter 21 PowerPoint Presentation, free download ID5415364 Pull In System Meaning In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. What is a pull system? Ingredients or components used in the manufacturing process. The pull system is a technique used in lean manufacturing to minimize waste in production. A pull system is an essential lean management technique that can help you reduce. Pull In System Meaning.

From meksmart.com

WHAT IS PULL SYSTEM? PULL STRATEGY IN INVENTORY MANAGEMENT Pull In System Meaning Ingredients or components used in the manufacturing process. A pull system is a lean manufacturing process used in the production process to reduce waste. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. What is a pull supply chain system? What is a pull system? By implementing a pull system,. A. Pull In System Meaning.

From www.nov.com

Riser PullIn Systems NOV Pull In System Meaning By implementing a pull system,. If you have an explicit wip limit in your production, you have a pull system and hence have access to all the benefits of a lean pull. A pull system is a lean manufacturing process used in the production process to reduce waste. The pull system is a technique used in lean manufacturing to minimize. Pull In System Meaning.

From www.deprettoindustrie.com

Riser pull in system De Pretto Industrie Pull In System Meaning The pull system is a technique used in lean manufacturing to minimize waste in production. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. Ingredients or components used in the manufacturing process. By implementing a pull system,. A pull system is a lean manufacturing process used in the production process to. Pull In System Meaning.

From www.youtube.com

Pull System YouTube Pull In System Meaning What is a pull system? If you have an explicit wip limit in your production, you have a pull system and hence have access to all the benefits of a lean pull. A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction. The pull system is. Pull In System Meaning.

From www.deskera.com

Push System vs. Pull System in Manufacturing Management Pull In System Meaning What is a pull supply chain system? The pull system is a technique used in lean manufacturing to minimize waste in production. Ingredients or components used in the manufacturing process. A pull system is an essential lean management technique that can help you reduce waste and production costs, increase efficiency and improve customer satisfaction. If you have an explicit wip. Pull In System Meaning.

From alexsibaja.blogspot.com

Lean Manufacturing & Six Sigma Pull Production Systems 生産システムを引いて Pull In System Meaning In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. What is a pull system? Ingredients or components used in the manufacturing process. What is a pull supply chain system? The pull system is a technique used in lean manufacturing to minimize waste in production. A pull system is a lean manufacturing. Pull In System Meaning.

From waxemi.com

Push System vs. Pull System in Manufacturing Management (2023) Pull In System Meaning What is a pull system? What is a pull supply chain system? If you have an explicit wip limit in your production, you have a pull system and hence have access to all the benefits of a lean pull. In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. Ingredients or components. Pull In System Meaning.

From www.allaboutlean.com

What Are the Criteria to Decide on a Pull System? Pull In System Meaning In lean manufacturing, push system vs pull system represent the contrasting philosophies that can significantly impact a company’s. What is a pull supply chain system? A pull system is a lean manufacturing process used in the production process to reduce waste. What is a pull system? By implementing a pull system,. A pull system is a lean manufacturing strategy that. Pull In System Meaning.

From businessmap.io

What Is a Pull System? A Practical Guide to Increasing Process Efficiency Pull In System Meaning What is a pull supply chain system? By implementing a pull system,. Ingredients or components used in the manufacturing process. A pull system is a lean manufacturing strategy that relies on customer demand to facilitate the production of goods. If you have an explicit wip limit in your production, you have a pull system and hence have access to all. Pull In System Meaning.

From www.impactfirst.co

Pull System Definition, Its 3 Types & Differences with Push Pull In System Meaning What is a pull supply chain system? If you have an explicit wip limit in your production, you have a pull system and hence have access to all the benefits of a lean pull. By implementing a pull system,. What is a pull system? A pull system is a lean manufacturing process used in the production process to reduce waste.. Pull In System Meaning.

From www.slideshare.net

Pull Systems A method of Pull In System Meaning Ingredients or components used in the manufacturing process. By implementing a pull system,. A pull system is a lean manufacturing process used in the production process to reduce waste. The pull system is a technique used in lean manufacturing to minimize waste in production. What is a pull system? If you have an explicit wip limit in your production, you. Pull In System Meaning.

From www.slideshare.net

Pull Systems Pull In System Meaning What is a pull supply chain system? What is a pull system? A pull system is a lean manufacturing strategy that relies on customer demand to facilitate the production of goods. Ingredients or components used in the manufacturing process. The pull system is a technique used in lean manufacturing to minimize waste in production. If you have an explicit wip. Pull In System Meaning.

From phe.com.sg

FPSO RiserPull In System Ph Hydraulics & Engineering Pte Ltd Pull In System Meaning The pull system is a technique used in lean manufacturing to minimize waste in production. A pull system is a lean manufacturing process used in the production process to reduce waste. A pull system is a lean manufacturing strategy that relies on customer demand to facilitate the production of goods. A pull system is an essential lean management technique that. Pull In System Meaning.