Gear Grinding Basics . Gear grinding and honing are hard finishing methods for gears, using tools with a specific geometrical profile and geometrically. The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. Gear grinding is basically the process of creating the teeth or splines on a gear. There are two processes utilized and each has its own costs. In gear manufacturing, gear grinding is a finishing method which utilizes abrasive wheels to exclude small variations on gear. Gear tooth profile grinding, also known as form grinding, is a finishing method used in gear manufacturing. It is an intricate process used to remove surface materials on. The process of gear grinding is one of the final steps of producing gears. It involves the use of vitrified bonded grinding wheels to.

from www.samputensili.com

There are two processes utilized and each has its own costs. In gear manufacturing, gear grinding is a finishing method which utilizes abrasive wheels to exclude small variations on gear. Gear grinding and honing are hard finishing methods for gears, using tools with a specific geometrical profile and geometrically. Gear tooth profile grinding, also known as form grinding, is a finishing method used in gear manufacturing. The process of gear grinding is one of the final steps of producing gears. Gear grinding is basically the process of creating the teeth or splines on a gear. It involves the use of vitrified bonded grinding wheels to. The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. It is an intricate process used to remove surface materials on.

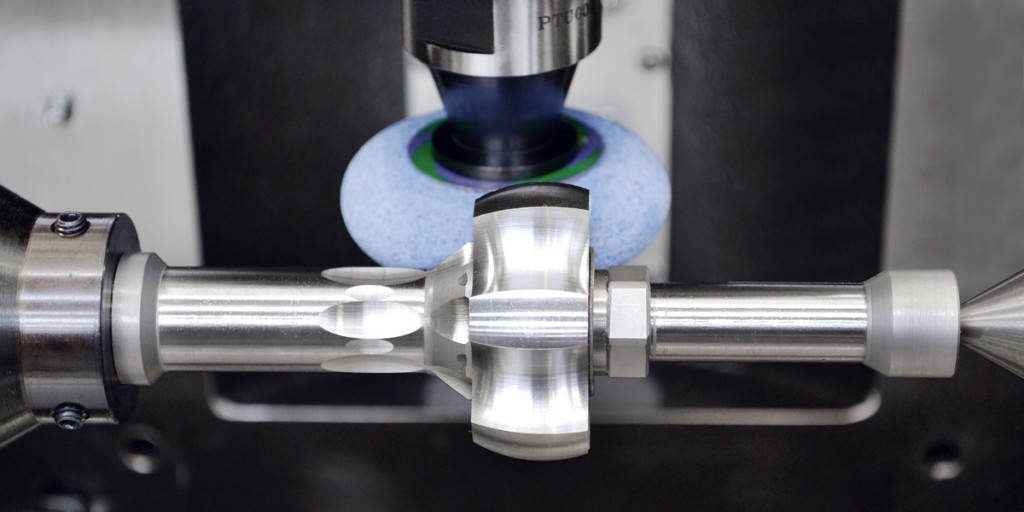

Gear Profile Grinding GP 500 H Samputensili

Gear Grinding Basics In gear manufacturing, gear grinding is a finishing method which utilizes abrasive wheels to exclude small variations on gear. Gear grinding is basically the process of creating the teeth or splines on a gear. The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. In gear manufacturing, gear grinding is a finishing method which utilizes abrasive wheels to exclude small variations on gear. Gear tooth profile grinding, also known as form grinding, is a finishing method used in gear manufacturing. Gear grinding and honing are hard finishing methods for gears, using tools with a specific geometrical profile and geometrically. It is an intricate process used to remove surface materials on. There are two processes utilized and each has its own costs. The process of gear grinding is one of the final steps of producing gears. It involves the use of vitrified bonded grinding wheels to.

From www.geartechnology.com

Force Modeling in Generating Gear Grinding Considering the Grinding Worm Topography Gear Gear Grinding Basics There are two processes utilized and each has its own costs. It involves the use of vitrified bonded grinding wheels to. The process of gear grinding is one of the final steps of producing gears. Gear grinding and honing are hard finishing methods for gears, using tools with a specific geometrical profile and geometrically. In gear manufacturing, gear grinding is. Gear Grinding Basics.

From klingelnberg.com

Klingelnberg Group Cylindrical Gear Grinding Machines Gear Grinding Basics It is an intricate process used to remove surface materials on. Gear tooth profile grinding, also known as form grinding, is a finishing method used in gear manufacturing. The process of gear grinding is one of the final steps of producing gears. In gear manufacturing, gear grinding is a finishing method which utilizes abrasive wheels to exclude small variations on. Gear Grinding Basics.

From www.reddit.com

Gear Grinding r/Machinists Gear Grinding Basics Gear grinding and honing are hard finishing methods for gears, using tools with a specific geometrical profile and geometrically. Gear grinding is basically the process of creating the teeth or splines on a gear. Gear tooth profile grinding, also known as form grinding, is a finishing method used in gear manufacturing. It involves the use of vitrified bonded grinding wheels. Gear Grinding Basics.

From www.researchgate.net

Kinematics of gear grinding Download Scientific Diagram Gear Grinding Basics It is an intricate process used to remove surface materials on. Gear grinding and honing are hard finishing methods for gears, using tools with a specific geometrical profile and geometrically. Gear grinding is basically the process of creating the teeth or splines on a gear. The process of gear grinding is one of the final steps of producing gears. Gear. Gear Grinding Basics.

From www.xometry.com

Everything You Need to Know About Gear Cutting Gear Grinding Basics Gear grinding is basically the process of creating the teeth or splines on a gear. The process of gear grinding is one of the final steps of producing gears. In gear manufacturing, gear grinding is a finishing method which utilizes abrasive wheels to exclude small variations on gear. Gear tooth profile grinding, also known as form grinding, is a finishing. Gear Grinding Basics.

From www.samputensili.com

Gear Profile Grinding GP 500 H Samputensili Gear Grinding Basics The process of gear grinding is one of the final steps of producing gears. Gear grinding and honing are hard finishing methods for gears, using tools with a specific geometrical profile and geometrically. It is an intricate process used to remove surface materials on. There are two processes utilized and each has its own costs. Gear tooth profile grinding, also. Gear Grinding Basics.

From www.geartechnology.com

Large Gear Grinding Gear Technology Magazine Gear Grinding Basics In gear manufacturing, gear grinding is a finishing method which utilizes abrasive wheels to exclude small variations on gear. It involves the use of vitrified bonded grinding wheels to. The process of gear grinding is one of the final steps of producing gears. Gear grinding and honing are hard finishing methods for gears, using tools with a specific geometrical profile. Gear Grinding Basics.

From skandaaerospace.com

Gear Cutting & Grinding kanda Gear Grinding Basics Gear grinding is basically the process of creating the teeth or splines on a gear. Gear grinding and honing are hard finishing methods for gears, using tools with a specific geometrical profile and geometrically. The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. Gear tooth profile grinding, also known as form grinding, is a finishing method. Gear Grinding Basics.

From minigears.co.uk

Gear Grinding Services High Precision Gear Finishing Gear Grinding Basics It involves the use of vitrified bonded grinding wheels to. It is an intricate process used to remove surface materials on. The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. Gear grinding is basically the process of creating the teeth or splines on a gear. Gear tooth profile grinding, also known as form grinding, is a. Gear Grinding Basics.

From gearmotions.com

Benefits of Precision Gear Grinding Gear Motions Gear Grinding Basics Gear tooth profile grinding, also known as form grinding, is a finishing method used in gear manufacturing. Gear grinding and honing are hard finishing methods for gears, using tools with a specific geometrical profile and geometrically. The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. There are two processes utilized and each has its own costs.. Gear Grinding Basics.

From www.holroyd.com

Holroyd HG350G gear grinding centre is first to use Siemens’ Sinumerik ONE CNC PTG Friction Gear Grinding Basics There are two processes utilized and each has its own costs. The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. Gear tooth profile grinding, also known as form grinding, is a finishing method used in gear manufacturing. The process of gear grinding is one of the final steps of producing gears. Gear grinding is basically the. Gear Grinding Basics.

From link.springer.com

Gear Grinding SpringerLink Gear Grinding Basics There are two processes utilized and each has its own costs. Gear grinding is basically the process of creating the teeth or splines on a gear. In gear manufacturing, gear grinding is a finishing method which utilizes abrasive wheels to exclude small variations on gear. It involves the use of vitrified bonded grinding wheels to. Gear grinding and honing are. Gear Grinding Basics.

From www.grindtech.com

Precision Grinding Archives Grinding Techniques Gear Grinding Basics Gear grinding is basically the process of creating the teeth or splines on a gear. It involves the use of vitrified bonded grinding wheels to. Gear tooth profile grinding, also known as form grinding, is a finishing method used in gear manufacturing. The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. In gear manufacturing, gear grinding. Gear Grinding Basics.

From gearmotions.com

Gear Grinding Precision Gear Manufacturing at Gear Motions Gear Grinding Basics The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. In gear manufacturing, gear grinding is a finishing method which utilizes abrasive wheels to exclude small variations on gear. There are two processes utilized and each has its own costs. The process of gear grinding is one of the final steps of producing gears. Gear grinding and. Gear Grinding Basics.

From www.tasowheel.fi

Which are the main benefits of gear grinding? Tasowheel Gear Grinding Basics It is an intricate process used to remove surface materials on. It involves the use of vitrified bonded grinding wheels to. In gear manufacturing, gear grinding is a finishing method which utilizes abrasive wheels to exclude small variations on gear. Gear tooth profile grinding, also known as form grinding, is a finishing method used in gear manufacturing. The most common. Gear Grinding Basics.

From www.mactool.com

Gear Grinding Machine Tools (India) Limited Gear Grinding Basics It is an intricate process used to remove surface materials on. In gear manufacturing, gear grinding is a finishing method which utilizes abrasive wheels to exclude small variations on gear. The process of gear grinding is one of the final steps of producing gears. Gear tooth profile grinding, also known as form grinding, is a finishing method used in gear. Gear Grinding Basics.

From gearmotions.com

Gear Grinding Precision Gear Manufacturing at Gear Motions Gear Grinding Basics The process of gear grinding is one of the final steps of producing gears. There are two processes utilized and each has its own costs. Gear tooth profile grinding, also known as form grinding, is a finishing method used in gear manufacturing. Gear grinding is basically the process of creating the teeth or splines on a gear. The most common. Gear Grinding Basics.

From www.factoriaeng.co.za

Gear Manufacturing & Cutting In Gauteng Gear Suppliers Factoria Engineering Works Gear Grinding Basics There are two processes utilized and each has its own costs. The process of gear grinding is one of the final steps of producing gears. In gear manufacturing, gear grinding is a finishing method which utilizes abrasive wheels to exclude small variations on gear. The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. It involves the. Gear Grinding Basics.

From www.researchgate.net

Basic gear grinding motion diagram with worm grinding wheel (Zhou, 2016) Download Scientific Gear Grinding Basics The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. In gear manufacturing, gear grinding is a finishing method which utilizes abrasive wheels to exclude small variations on gear. There are two processes utilized and each has its own costs. Gear grinding is basically the process of creating the teeth or splines on a gear. Gear grinding. Gear Grinding Basics.

From avion-tech.com

Gear & Spline Grinding Avion Technologies Inc. Gear Grinding Basics The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. It involves the use of vitrified bonded grinding wheels to. Gear grinding is basically the process of creating the teeth or splines on a gear. There are two processes utilized and each has its own costs. The process of gear grinding is one of the final steps. Gear Grinding Basics.

From www.researchgate.net

Gear form grinding with form wheel Download Scientific Diagram Gear Grinding Basics In gear manufacturing, gear grinding is a finishing method which utilizes abrasive wheels to exclude small variations on gear. Gear grinding is basically the process of creating the teeth or splines on a gear. It is an intricate process used to remove surface materials on. The process of gear grinding is one of the final steps of producing gears. It. Gear Grinding Basics.

From seibushoko.com

Profile Gear Grinding|MACHINES|Products|SEIBU SHOKO CO., LTD. Gear Grinding Basics It is an intricate process used to remove surface materials on. The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. Gear tooth profile grinding, also known as form grinding, is a finishing method used in gear manufacturing. In gear manufacturing, gear grinding is a finishing method which utilizes abrasive wheels to exclude small variations on gear.. Gear Grinding Basics.

From www.researchgate.net

Grains and wheel grinding surface of gear grinding Download Scientific Diagram Gear Grinding Basics There are two processes utilized and each has its own costs. The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. Gear grinding is basically the process of creating the teeth or splines on a gear. It is an intricate process used to remove surface materials on. The process of gear grinding is one of the final. Gear Grinding Basics.

From learndriving.tips

Why Do Car Gears Grind? » Learn Driving Tips Gear Grinding Basics Gear tooth profile grinding, also known as form grinding, is a finishing method used in gear manufacturing. The process of gear grinding is one of the final steps of producing gears. The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. In gear manufacturing, gear grinding is a finishing method which utilizes abrasive wheels to exclude small. Gear Grinding Basics.

From www.slideserve.com

PPT GEARS MACHINING PowerPoint Presentation, free download ID1414221 Gear Grinding Basics Gear grinding is basically the process of creating the teeth or splines on a gear. Gear tooth profile grinding, also known as form grinding, is a finishing method used in gear manufacturing. It is an intricate process used to remove surface materials on. The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. The process of gear. Gear Grinding Basics.

From true-gear.com

All You Should Know About Gear Grinding Gear Grinding Basics Gear grinding is basically the process of creating the teeth or splines on a gear. Gear tooth profile grinding, also known as form grinding, is a finishing method used in gear manufacturing. There are two processes utilized and each has its own costs. It is an intricate process used to remove surface materials on. In gear manufacturing, gear grinding is. Gear Grinding Basics.

From ronsongears.com.au

Gear Cutting CNC Gear Cutting CNC Gear Grinding Ronson Gears Gear Grinding Basics The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. There are two processes utilized and each has its own costs. It is an intricate process used to remove surface materials on. In gear manufacturing, gear grinding is a finishing method which utilizes abrasive wheels to exclude small variations on gear. Gear grinding and honing are hard. Gear Grinding Basics.

From www.manufacturingguide.com

Gear profile grinding Find suppliers, processes & material Gear Grinding Basics The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. It is an intricate process used to remove surface materials on. There are two processes utilized and each has its own costs. Gear grinding is basically the process of creating the teeth or splines on a gear. The process of gear grinding is one of the final. Gear Grinding Basics.

From www.franklingear.com

Gear Grinding Franklin Machine & Gear Corporation Gear Grinding Basics In gear manufacturing, gear grinding is a finishing method which utilizes abrasive wheels to exclude small variations on gear. It is an intricate process used to remove surface materials on. It involves the use of vitrified bonded grinding wheels to. Gear grinding is basically the process of creating the teeth or splines on a gear. The most common gear machining. Gear Grinding Basics.

From www.researchgate.net

Gear machining on the HOFLER RAPID 1250 gear grinding machine Download Scientific Diagram Gear Grinding Basics It is an intricate process used to remove surface materials on. Gear grinding and honing are hard finishing methods for gears, using tools with a specific geometrical profile and geometrically. The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. It involves the use of vitrified bonded grinding wheels to. The process of gear grinding is one. Gear Grinding Basics.

From www.linkedin.com

What is the advantages of gear grinding and gear lapping method Gear Grinding Basics The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. It is an intricate process used to remove surface materials on. The process of gear grinding is one of the final steps of producing gears. There are two processes utilized and each has its own costs. Gear grinding is basically the process of creating the teeth or. Gear Grinding Basics.

From beningtongears.com

Services Benington Gears Gear Grinding Basics Gear grinding is basically the process of creating the teeth or splines on a gear. Gear tooth profile grinding, also known as form grinding, is a finishing method used in gear manufacturing. Gear grinding and honing are hard finishing methods for gears, using tools with a specific geometrical profile and geometrically. In gear manufacturing, gear grinding is a finishing method. Gear Grinding Basics.

From extrudergearbox.net

Gear Grinding The Process and Its Benefits Gear Grinding Basics It involves the use of vitrified bonded grinding wheels to. It is an intricate process used to remove surface materials on. The most common gear machining methods include hobbing, broaching, milling, grinding, and skiving. Gear grinding and honing are hard finishing methods for gears, using tools with a specific geometrical profile and geometrically. Gear tooth profile grinding, also known as. Gear Grinding Basics.

From www.machinemfg.com

11 Steps of Gear Processing You Must Know MachineMFG Gear Grinding Basics Gear grinding and honing are hard finishing methods for gears, using tools with a specific geometrical profile and geometrically. Gear grinding is basically the process of creating the teeth or splines on a gear. The process of gear grinding is one of the final steps of producing gears. It involves the use of vitrified bonded grinding wheels to. In gear. Gear Grinding Basics.

From www.thefabricator.com

Grinding tool basics Finish it right Gear Grinding Basics It involves the use of vitrified bonded grinding wheels to. Gear tooth profile grinding, also known as form grinding, is a finishing method used in gear manufacturing. Gear grinding is basically the process of creating the teeth or splines on a gear. It is an intricate process used to remove surface materials on. Gear grinding and honing are hard finishing. Gear Grinding Basics.