Countersunk The Hole . Turn your screw upside down and press the head against the countersink hole. Take the countersink cutter out from the hole and clear away any sawdust that built up around it. If the hole is the same diameter as the screw’s head, then you’re ready to screw it in. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. A countersunk hole is an integral feature in various engineering and manufacturing processes. A countersink consists of a conical hole that is coaxial to a. A countersink is a simple hole with a conical hole above it. The 3d model below shows a countersink with the same countersink next to it cut in half: It is a conical hole cut into a material, allowing the screw head of a flathead screw. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk.

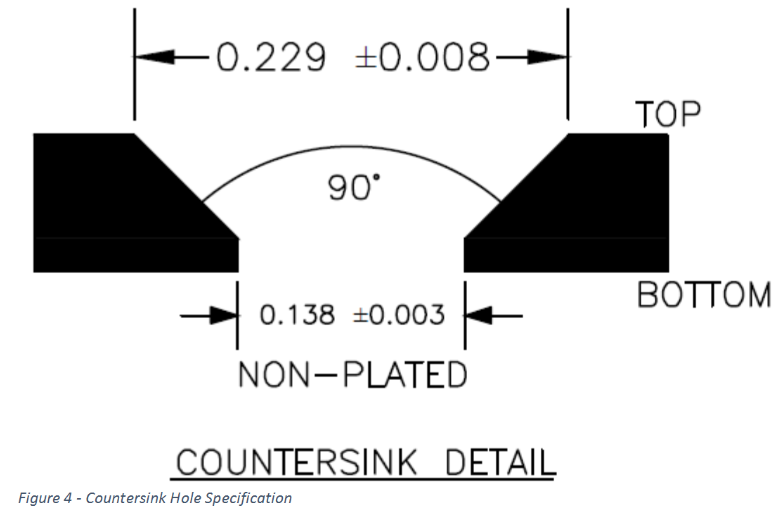

from www.7pcb.com

Turn your screw upside down and press the head against the countersink hole. Take the countersink cutter out from the hole and clear away any sawdust that built up around it. A countersunk hole is an integral feature in various engineering and manufacturing processes. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. A countersink is a simple hole with a conical hole above it. It is a conical hole cut into a material, allowing the screw head of a flathead screw. If the hole is the same diameter as the screw’s head, then you’re ready to screw it in. A countersink consists of a conical hole that is coaxial to a. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. The 3d model below shows a countersink with the same countersink next to it cut in half:

The Difference Between Counterbore and Countersink Holes

Countersunk The Hole If the hole is the same diameter as the screw’s head, then you’re ready to screw it in. The 3d model below shows a countersink with the same countersink next to it cut in half: The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. A countersink consists of a conical hole that is coaxial to a. A countersunk hole is an integral feature in various engineering and manufacturing processes. Take the countersink cutter out from the hole and clear away any sawdust that built up around it. Turn your screw upside down and press the head against the countersink hole. It is a conical hole cut into a material, allowing the screw head of a flathead screw. A countersink is a simple hole with a conical hole above it. If the hole is the same diameter as the screw’s head, then you’re ready to screw it in.

From mechheart.com

What is a Countersunk Screw? MECHHEART Countersunk The Hole Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. It is a. Countersunk The Hole.

From www.spex1.com

Countersink vs. Counterbore Holes in Machining Precision Machine Countersunk The Hole If the hole is the same diameter as the screw’s head, then you’re ready to screw it in. Turn your screw upside down and press the head against the countersink hole. A countersink consists of a conical hole that is coaxial to a. A countersunk hole is an integral feature in various engineering and manufacturing processes. It is a conical. Countersunk The Hole.

From www.pinterest.jp

The best way to get a nice, smooth countersunk hole in your workpiece Countersunk The Hole Take the countersink cutter out from the hole and clear away any sawdust that built up around it. It is a conical hole cut into a material, allowing the screw head of a flathead screw. Turn your screw upside down and press the head against the countersink hole. Countersunk holes are a type of engineering hole most commonly used for. Countersunk The Hole.

From www.csfabs.co.uk

Countersunk Holes in Sheet Metal C&S Fabrications Countersunk The Hole It is a conical hole cut into a material, allowing the screw head of a flathead screw. A countersunk hole is an integral feature in various engineering and manufacturing processes. If the hole is the same diameter as the screw’s head, then you’re ready to screw it in. Turn your screw upside down and press the head against the countersink. Countersunk The Hole.

From www.gdandtbasics.com

Applying Position Tolerances to Countersunk Fixed Fastener Assembly Countersunk The Hole A countersunk hole is an integral feature in various engineering and manufacturing processes. Turn your screw upside down and press the head against the countersink hole. A countersink consists of a conical hole that is coaxial to a. A countersink is a simple hole with a conical hole above it. The purpose of a countersink is to allow a fastener,. Countersunk The Hole.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersunk The Hole A countersink is a simple hole with a conical hole above it. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. The purpose of a countersink is to allow a fastener, typically a flathead screw, to. Countersunk The Hole.

From en.wikipedia.org

Countersink Wikipedia Countersunk The Hole A countersink consists of a conical hole that is coaxial to a. Take the countersink cutter out from the hole and clear away any sawdust that built up around it. A countersunk hole is an integral feature in various engineering and manufacturing processes. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of. Countersunk The Hole.

From www.youtube.com

Punching Countersunk Holes YouTube Countersunk The Hole The 3d model below shows a countersink with the same countersink next to it cut in half: Take the countersink cutter out from the hole and clear away any sawdust that built up around it. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. The. Countersunk The Hole.

From forums.autodesk.com

Add hole type counterbored+countersunk Autodesk Community Countersunk The Hole If the hole is the same diameter as the screw’s head, then you’re ready to screw it in. A countersink consists of a conical hole that is coaxial to a. A countersunk hole is an integral feature in various engineering and manufacturing processes. A countersink is a simple hole with a conical hole above it. Take the countersink cutter out. Countersunk The Hole.

From www.thehandymansdaughter.com

How to Countersink Screws The Handyman's Daughter Countersunk The Hole Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. A countersink is an angled taper applied to a hole that allows a. Countersunk The Hole.

From www.gdandtbasics.com

Applying Position Tolerances to Countersunk Fixed Fastener Assembly Countersunk The Hole The 3d model below shows a countersink with the same countersink next to it cut in half: A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. Turn your screw upside down and press the head against. Countersunk The Hole.

From engineersbible.com

Countersunk Hole Size for Socket Flat Head (ANSI Metric) Countersunk The Hole Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. If the hole is the same diameter as the screw’s head, then you’re ready to screw it in. A countersink is a simple hole with a conical hole above it. Turn your screw upside down and. Countersunk The Hole.

From be-cu.com

Countersink Holes An Essential Guide To Precision And Functionality Countersunk The Hole Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. The 3d model below shows a countersink with the same countersink next to it cut in half: A countersink is a simple hole with a conical hole above it. It is a conical hole cut into. Countersunk The Hole.

From sawsonskates.com

pilotholevscountersinkhole1 Saws on Skates Countersunk The Hole It is a conical hole cut into a material, allowing the screw head of a flathead screw. The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. If the hole is the same diameter as the screw’s head, then you’re ready to screw it in. A countersunk. Countersunk The Hole.

From carbidenz.co.nz

CROSS HOLE COUNTERSINK 1638mm (Magafor) Countersunk The Hole If the hole is the same diameter as the screw’s head, then you’re ready to screw it in. The 3d model below shows a countersink with the same countersink next to it cut in half: A countersink consists of a conical hole that is coaxial to a. The purpose of a countersink is to allow a fastener, typically a flathead. Countersunk The Hole.

From www.madearia.com

What are the different types of holes in engineering? Countersunk The Hole If the hole is the same diameter as the screw’s head, then you’re ready to screw it in. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. Take the countersink cutter out from the hole and. Countersunk The Hole.

From www.youtube.com

How to make Countersink Holes in SolidWorks by Hole Wizard Command Countersunk The Hole Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Turn your screw upside down and press the head against the countersink hole. If the hole is the same diameter as the screw’s head, then you’re ready to screw it in. A countersunk hole is an. Countersunk The Hole.

From www.theengineeringknowledge.com

What is Countersink vs. Counterbore Holes in Machining The Countersunk The Hole If the hole is the same diameter as the screw’s head, then you’re ready to screw it in. A countersink is a simple hole with a conical hole above it. The 3d model below shows a countersink with the same countersink next to it cut in half: Countersunk holes are a type of engineering hole most commonly used for the. Countersunk The Hole.

From ar.inspiredpencil.com

Standard Countersink Hole Countersunk The Hole Take the countersink cutter out from the hole and clear away any sawdust that built up around it. It is a conical hole cut into a material, allowing the screw head of a flathead screw. A countersunk hole is an integral feature in various engineering and manufacturing processes. Countersunk holes are a type of engineering hole most commonly used for. Countersunk The Hole.

From www.7pcb.com

The Difference Between Counterbore and Countersink Holes Countersunk The Hole It is a conical hole cut into a material, allowing the screw head of a flathead screw. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. Countersunk holes are a type of engineering hole most commonly. Countersunk The Hole.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersunk The Hole The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. Turn your screw upside down and press the head against the countersink hole. Take the countersink cutter out from the hole and clear away any sawdust that built up around it. The 3d model below shows a. Countersunk The Hole.

From engineersbible.com

Countersunk Hole Size for Machine Screw (ANSI Metric) Countersunk The Hole A countersink consists of a conical hole that is coaxial to a. Turn your screw upside down and press the head against the countersink hole. The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. Take the countersink cutter out from the hole and clear away any. Countersunk The Hole.

From www.researchgate.net

Configuration of the double countersunk hole. Download Scientific Diagram Countersunk The Hole Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. A countersunk hole is an integral feature in various engineering and manufacturing processes. Take the countersink cutter out from the hole and clear away any sawdust that built up around it. The purpose of a countersink. Countersunk The Hole.

From www.youtube.com

🔩 How To Make Countersink And Counterbore Holes FreeCAD Hole Tutorial Countersunk The Hole Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. A countersunk hole is an integral feature in various engineering and manufacturing processes. Turn your screw upside down and press the head against the countersink hole. The 3d model below shows a countersink with the same. Countersunk The Hole.

From www.youtube.com

How to Make Countersink Holes in SolidWorks using Hole Wizard Command Countersunk The Hole The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. Turn your screw upside down and press the head against the countersink hole. A countersunk hole is an integral feature in various engineering and manufacturing processes. If the hole is the same diameter as the screw’s head,. Countersunk The Hole.

From www.slideserve.com

PPT Holes PowerPoint Presentation, free download ID2107959 Countersunk The Hole The 3d model below shows a countersink with the same countersink next to it cut in half: If the hole is the same diameter as the screw’s head, then you’re ready to screw it in. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. A. Countersunk The Hole.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersunk The Hole A countersink is a simple hole with a conical hole above it. The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. A. Countersunk The Hole.

From www.protoexpress.com

Countersink Holes in PCBs Sierra Circuits Countersunk The Hole A countersink consists of a conical hole that is coaxial to a. If the hole is the same diameter as the screw’s head, then you’re ready to screw it in. The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. The 3d model below shows a countersink. Countersunk The Hole.

From ar.inspiredpencil.com

Standard Countersink Hole Countersunk The Hole If the hole is the same diameter as the screw’s head, then you’re ready to screw it in. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. The 3d model below shows a countersink with the. Countersunk The Hole.

From www.theengineeringknowledge.com

What is Countersink vs. Counterbore Holes in Machining The Countersunk The Hole Take the countersink cutter out from the hole and clear away any sawdust that built up around it. If the hole is the same diameter as the screw’s head, then you’re ready to screw it in. A countersink is a simple hole with a conical hole above it. Turn your screw upside down and press the head against the countersink. Countersunk The Hole.

From www.theengineeringknowledge.com

What are Countersink Holes in Engineering? The Engineering Knowledge Countersunk The Hole The 3d model below shows a countersink with the same countersink next to it cut in half: A countersunk hole is an integral feature in various engineering and manufacturing processes. Turn your screw upside down and press the head against the countersink hole. If the hole is the same diameter as the screw’s head, then you’re ready to screw it. Countersunk The Hole.

From dobemy.com

Countersunk Holes vs. Counterbore Holes What's the Difference?DOBEMY Countersunk The Hole It is a conical hole cut into a material, allowing the screw head of a flathead screw. A countersunk hole is an integral feature in various engineering and manufacturing processes. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which. Countersunk The Hole.

From www.theengineeringknowledge.com

What are Countersink Holes in Engineering? The Engineering Knowledge Countersunk The Hole A countersink consists of a conical hole that is coaxial to a. A countersunk hole is an integral feature in various engineering and manufacturing processes. A countersink is a simple hole with a conical hole above it. Take the countersink cutter out from the hole and clear away any sawdust that built up around it. The 3d model below shows. Countersunk The Hole.

From informacionpublica.svet.gob.gt

Countersunk Hole Size For Machine Screw (ANSI Metric) Countersunk The Hole The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. Turn your screw upside down and press the head against the countersink hole. A countersunk hole is an integral feature in various engineering and manufacturing processes. If the hole is the same diameter as the screw’s head,. Countersunk The Hole.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersunk The Hole The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. If the hole is the same diameter as the screw’s head, then you’re ready to screw it in. Turn your screw upside down and press the head against the countersink hole. Take the countersink cutter out from. Countersunk The Hole.