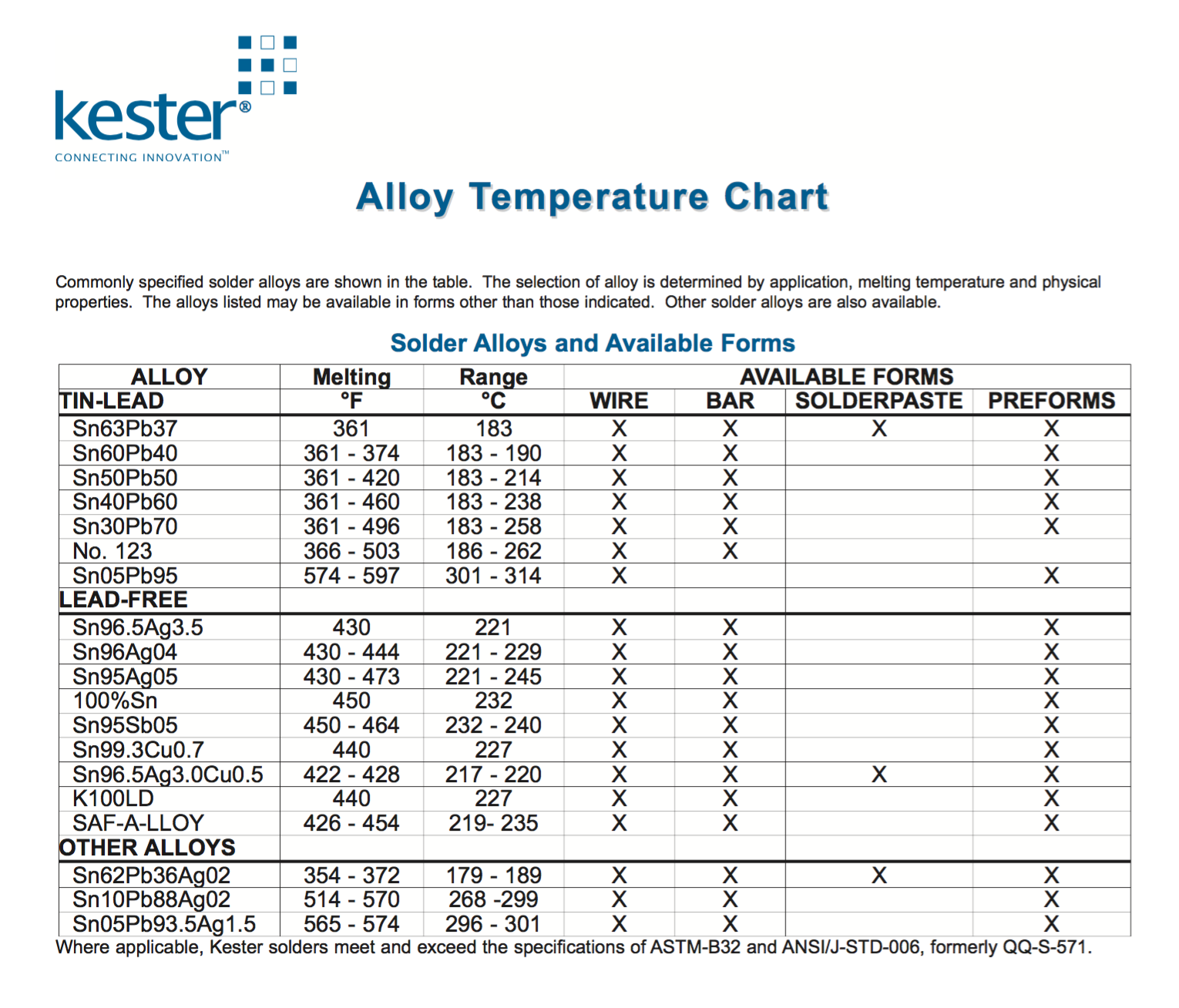

Solder Boiling Point . This temperature chart shows the different solders that are available and their. Solder with a composition of 60% tin and 40% lead has a varying melting range but will. Low temperature solders have melting points ranging from 117°f (47°c) to 320°f (160°c). components that will operate in very hot environments, such as in avionics, automotive and downhole oil and gas wells can benefit from higher temperature solders. This is a critical factor to consider. for applications such as wave soldering of electronic assemblies, the requirement for a solder with a relatively low melting point in conjunction with a short. solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c. solder melting point refers to the temperature at which a given type of solder will melt and flow into the joint being soldered.

from www.microsoldering.com

This temperature chart shows the different solders that are available and their. This is a critical factor to consider. components that will operate in very hot environments, such as in avionics, automotive and downhole oil and gas wells can benefit from higher temperature solders. solder melting point refers to the temperature at which a given type of solder will melt and flow into the joint being soldered. solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c. Solder with a composition of 60% tin and 40% lead has a varying melting range but will. for applications such as wave soldering of electronic assemblies, the requirement for a solder with a relatively low melting point in conjunction with a short. Low temperature solders have melting points ranging from 117°f (47°c) to 320°f (160°c).

kester solder melting points Micro Soldering

Solder Boiling Point components that will operate in very hot environments, such as in avionics, automotive and downhole oil and gas wells can benefit from higher temperature solders. solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c. This temperature chart shows the different solders that are available and their. solder melting point refers to the temperature at which a given type of solder will melt and flow into the joint being soldered. for applications such as wave soldering of electronic assemblies, the requirement for a solder with a relatively low melting point in conjunction with a short. Low temperature solders have melting points ranging from 117°f (47°c) to 320°f (160°c). Solder with a composition of 60% tin and 40% lead has a varying melting range but will. This is a critical factor to consider. components that will operate in very hot environments, such as in avionics, automotive and downhole oil and gas wells can benefit from higher temperature solders.

From mavink.com

Solder Melting Point Chart Solder Boiling Point solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c. This is a critical factor to consider. for applications such as wave soldering of electronic assemblies, the requirement for a solder with a relatively low melting point in conjunction with a short. Low temperature solders have melting points ranging from 117°f. Solder Boiling Point.

From dxokkmdhl.blob.core.windows.net

How To Get A Good Solder Joint at Brent Miller blog Solder Boiling Point Low temperature solders have melting points ranging from 117°f (47°c) to 320°f (160°c). This is a critical factor to consider. for applications such as wave soldering of electronic assemblies, the requirement for a solder with a relatively low melting point in conjunction with a short. Solder with a composition of 60% tin and 40% lead has a varying melting. Solder Boiling Point.

From slideplayer.com

Matter. ppt download Solder Boiling Point for applications such as wave soldering of electronic assemblies, the requirement for a solder with a relatively low melting point in conjunction with a short. Solder with a composition of 60% tin and 40% lead has a varying melting range but will. solder melting point refers to the temperature at which a given type of solder will melt. Solder Boiling Point.

From solderingironguide.com

How to Solder Aluminum Guide For Beginners Solder Boiling Point Low temperature solders have melting points ranging from 117°f (47°c) to 320°f (160°c). This temperature chart shows the different solders that are available and their. solder melting point refers to the temperature at which a given type of solder will melt and flow into the joint being soldered. This is a critical factor to consider. for applications such. Solder Boiling Point.

From maisieweston.z13.web.core.windows.net

Solder Melting Point Chart Solder Boiling Point for applications such as wave soldering of electronic assemblies, the requirement for a solder with a relatively low melting point in conjunction with a short. This is a critical factor to consider. solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c. Solder with a composition of 60% tin and 40%. Solder Boiling Point.

From www.pcbaservices.com

Solder Melting Point Guide Understanding The Basics Solder Boiling Point Solder with a composition of 60% tin and 40% lead has a varying melting range but will. This temperature chart shows the different solders that are available and their. solder melting point refers to the temperature at which a given type of solder will melt and flow into the joint being soldered. This is a critical factor to consider.. Solder Boiling Point.

From www.worksheetsplanet.com

What is Boiling Point Solder Boiling Point solder melting point refers to the temperature at which a given type of solder will melt and flow into the joint being soldered. Solder with a composition of 60% tin and 40% lead has a varying melting range but will. components that will operate in very hot environments, such as in avionics, automotive and downhole oil and gas. Solder Boiling Point.

From www.researchgate.net

Boiling points of various fluids at 1 atm [16]. Download Scientific Solder Boiling Point components that will operate in very hot environments, such as in avionics, automotive and downhole oil and gas wells can benefit from higher temperature solders. Low temperature solders have melting points ranging from 117°f (47°c) to 320°f (160°c). Solder with a composition of 60% tin and 40% lead has a varying melting range but will. solder melting point. Solder Boiling Point.

From www.globalspec.com

Solder Selection Guide Types, Features, Applications GlobalSpec Solder Boiling Point components that will operate in very hot environments, such as in avionics, automotive and downhole oil and gas wells can benefit from higher temperature solders. solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c. solder melting point refers to the temperature at which a given type of solder will. Solder Boiling Point.

From www.qtsolder.com

Lead Free Solder Melting Point What Is it and Why it is? Qiantian Solder Boiling Point solder melting point refers to the temperature at which a given type of solder will melt and flow into the joint being soldered. for applications such as wave soldering of electronic assemblies, the requirement for a solder with a relatively low melting point in conjunction with a short. components that will operate in very hot environments, such. Solder Boiling Point.

From www.numerade.com

SOLVED Solder is an alloy made of tin and lead is used in electronic Solder Boiling Point Solder with a composition of 60% tin and 40% lead has a varying melting range but will. components that will operate in very hot environments, such as in avionics, automotive and downhole oil and gas wells can benefit from higher temperature solders. This is a critical factor to consider. This temperature chart shows the different solders that are available. Solder Boiling Point.

From www.youtube.com

AIM wire solder is boiling YouTube Solder Boiling Point This temperature chart shows the different solders that are available and their. solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c. Low temperature solders have melting points ranging from 117°f (47°c) to 320°f (160°c). components that will operate in very hot environments, such as in avionics, automotive and downhole oil. Solder Boiling Point.

From thechemistrynotes.com

Boiling Point Factors, Determination, Formula Solder Boiling Point This is a critical factor to consider. solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c. Low temperature solders have melting points ranging from 117°f (47°c) to 320°f (160°c). This temperature chart shows the different solders that are available and their. Solder with a composition of 60% tin and 40% lead. Solder Boiling Point.

From www.newark.com

Solder and Soldering Guide Newark Solder Boiling Point This temperature chart shows the different solders that are available and their. solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c. This is a critical factor to consider. for applications such as wave soldering of electronic assemblies, the requirement for a solder with a relatively low melting point in conjunction. Solder Boiling Point.

From asi-tech.co.il

AIM High Melting Point Solder Alloys ASI Technologies Solder Boiling Point solder melting point refers to the temperature at which a given type of solder will melt and flow into the joint being soldered. solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c. This temperature chart shows the different solders that are available and their. This is a critical factor to. Solder Boiling Point.

From eloisewilkinson.z21.web.core.windows.net

Solder Melting Point Chart Solder Boiling Point solder melting point refers to the temperature at which a given type of solder will melt and flow into the joint being soldered. Low temperature solders have melting points ranging from 117°f (47°c) to 320°f (160°c). This is a critical factor to consider. for applications such as wave soldering of electronic assemblies, the requirement for a solder with. Solder Boiling Point.

From ribbeckeglass.com

Soldering Iron and Controllers Lawrence Ribbecke Studios Solder Boiling Point This temperature chart shows the different solders that are available and their. Solder with a composition of 60% tin and 40% lead has a varying melting range but will. for applications such as wave soldering of electronic assemblies, the requirement for a solder with a relatively low melting point in conjunction with a short. Low temperature solders have melting. Solder Boiling Point.

From mavink.com

Solder Melting Point Chart Solder Boiling Point This temperature chart shows the different solders that are available and their. components that will operate in very hot environments, such as in avionics, automotive and downhole oil and gas wells can benefit from higher temperature solders. solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c. for applications such. Solder Boiling Point.

From www.microsoldering.com

kester solder melting points Micro Soldering Solder Boiling Point Solder with a composition of 60% tin and 40% lead has a varying melting range but will. for applications such as wave soldering of electronic assemblies, the requirement for a solder with a relatively low melting point in conjunction with a short. solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees. Solder Boiling Point.

From www.researchgate.net

Extraction at boiling point of solvents Download Scientific Diagram Solder Boiling Point solder melting point refers to the temperature at which a given type of solder will melt and flow into the joint being soldered. for applications such as wave soldering of electronic assemblies, the requirement for a solder with a relatively low melting point in conjunction with a short. Low temperature solders have melting points ranging from 117°f (47°c). Solder Boiling Point.

From hobbybrennen.ch

Boiling Point Diagram Generator Solder Boiling Point solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c. This temperature chart shows the different solders that are available and their. for applications such as wave soldering of electronic assemblies, the requirement for a solder with a relatively low melting point in conjunction with a short. Low temperature solders have. Solder Boiling Point.

From www.raypcb.com

What is the Melting Point of Solder? RAYPCB Solder Boiling Point solder melting point refers to the temperature at which a given type of solder will melt and flow into the joint being soldered. Low temperature solders have melting points ranging from 117°f (47°c) to 320°f (160°c). This temperature chart shows the different solders that are available and their. solder alloy melting temperature metal weight percent melting temperature solidus. Solder Boiling Point.

From mavink.com

Solder Melting Point Chart Solder Boiling Point for applications such as wave soldering of electronic assemblies, the requirement for a solder with a relatively low melting point in conjunction with a short. solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c. solder melting point refers to the temperature at which a given type of solder will. Solder Boiling Point.

From theelectronicsproject.blogspot.com

How to Solder (Soldering Tutorial) ELECTRONICS PROJECTS Solder Boiling Point for applications such as wave soldering of electronic assemblies, the requirement for a solder with a relatively low melting point in conjunction with a short. This temperature chart shows the different solders that are available and their. solder melting point refers to the temperature at which a given type of solder will melt and flow into the joint. Solder Boiling Point.

From www.youtube.com

What Is the Melting Point of Solder? Soldering YouTube Solder Boiling Point This temperature chart shows the different solders that are available and their. for applications such as wave soldering of electronic assemblies, the requirement for a solder with a relatively low melting point in conjunction with a short. Low temperature solders have melting points ranging from 117°f (47°c) to 320°f (160°c). components that will operate in very hot environments,. Solder Boiling Point.

From blog.thepipingmart.com

Tungsten Melting and Boiling Points Solder Boiling Point solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c. This is a critical factor to consider. Solder with a composition of 60% tin and 40% lead has a varying melting range but will. This temperature chart shows the different solders that are available and their. components that will operate in. Solder Boiling Point.

From elecschem.com

The Importance of Understanding Boiling Point Diagrams for Chemical Solder Boiling Point This temperature chart shows the different solders that are available and their. solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c. Solder with a composition of 60% tin and 40% lead has a varying melting range but will. solder melting point refers to the temperature at which a given type. Solder Boiling Point.

From www.electroniclinic.com

Soldering Iron Tips and How to use them like a Pro Solder Boiling Point This temperature chart shows the different solders that are available and their. components that will operate in very hot environments, such as in avionics, automotive and downhole oil and gas wells can benefit from higher temperature solders. This is a critical factor to consider. Low temperature solders have melting points ranging from 117°f (47°c) to 320°f (160°c). Solder with. Solder Boiling Point.

From mavink.com

Solder Melting Point Chart Solder Boiling Point Solder with a composition of 60% tin and 40% lead has a varying melting range but will. This is a critical factor to consider. solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c. components that will operate in very hot environments, such as in avionics, automotive and downhole oil and. Solder Boiling Point.

From mavink.com

Melting And Boiling Point Chart Solder Boiling Point for applications such as wave soldering of electronic assemblies, the requirement for a solder with a relatively low melting point in conjunction with a short. solder melting point refers to the temperature at which a given type of solder will melt and flow into the joint being soldered. Low temperature solders have melting points ranging from 117°f (47°c). Solder Boiling Point.

From web.uvic.ca

Physics 429 Honours Laboratory Solder Boiling Point solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c. components that will operate in very hot environments, such as in avionics, automotive and downhole oil and gas wells can benefit from higher temperature solders. Solder with a composition of 60% tin and 40% lead has a varying melting range but. Solder Boiling Point.

From noahwilson.z13.web.core.windows.net

Melting Point Of Electrical Solder Solder Boiling Point Low temperature solders have melting points ranging from 117°f (47°c) to 320°f (160°c). solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c. components that will operate in very hot environments, such as in avionics, automotive and downhole oil and gas wells can benefit from higher temperature solders. for applications. Solder Boiling Point.

From sciencenotes.org

Boiling Point Definition, Temperature, and Examples Solder Boiling Point This temperature chart shows the different solders that are available and their. components that will operate in very hot environments, such as in avionics, automotive and downhole oil and gas wells can benefit from higher temperature solders. for applications such as wave soldering of electronic assemblies, the requirement for a solder with a relatively low melting point in. Solder Boiling Point.

From solderingironguide.com

[Guide] How To Solder Copper Pipe With Water In It Solderingironguide Solder Boiling Point This temperature chart shows the different solders that are available and their. Low temperature solders have melting points ranging from 117°f (47°c) to 320°f (160°c). solder alloy melting temperature metal weight percent melting temperature solidus liquidus tin lead silver other degrees c. for applications such as wave soldering of electronic assemblies, the requirement for a solder with a. Solder Boiling Point.

From www.wiringdraw.com

How To Solder Circuit Board Components Wiring Draw And Schematic Solder Boiling Point Solder with a composition of 60% tin and 40% lead has a varying melting range but will. components that will operate in very hot environments, such as in avionics, automotive and downhole oil and gas wells can benefit from higher temperature solders. solder melting point refers to the temperature at which a given type of solder will melt. Solder Boiling Point.