Sheet Metal Center Hole . Recommended center distance between holes in sheet metal part. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision cnc bending. Some features such as countersinks are doable but counter bores and other. In real practice, the process of hole punching differs depending on the materials, thickness, and the. For bearing area (a), use product of the bolt. The recommended minimum distance between two hole centers in sheet. Sheet metal hole punching is a common method to create a hole in a metal sheet. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Manufacturing sheet metal parts up to ¼” (6.35mm) in thickness, but this tolerance mainly depends on the geometry of the part.

from www.hlhprototypes.com

Recommended center distance between holes in sheet metal part. In real practice, the process of hole punching differs depending on the materials, thickness, and the. Manufacturing sheet metal parts up to ¼” (6.35mm) in thickness, but this tolerance mainly depends on the geometry of the part. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision cnc bending. For bearing area (a), use product of the bolt. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Some features such as countersinks are doable but counter bores and other. The recommended minimum distance between two hole centers in sheet. Sheet metal hole punching is a common method to create a hole in a metal sheet.

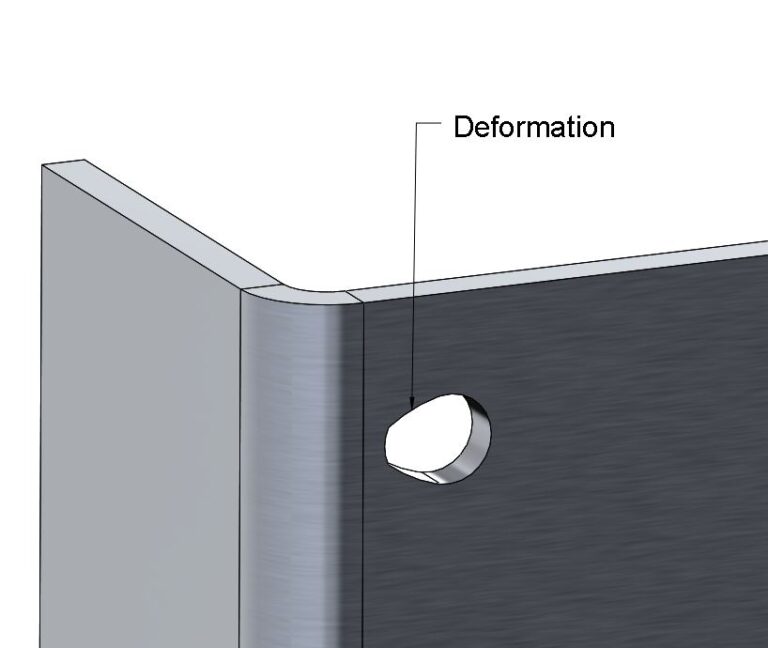

Mastering the Art of Bending Sheet Metal Design Tips for Success

Sheet Metal Center Hole For bearing area (a), use product of the bolt. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Sheet metal hole punching is a common method to create a hole in a metal sheet. Manufacturing sheet metal parts up to ¼” (6.35mm) in thickness, but this tolerance mainly depends on the geometry of the part. For bearing area (a), use product of the bolt. Some features such as countersinks are doable but counter bores and other. The recommended minimum distance between two hole centers in sheet. In real practice, the process of hole punching differs depending on the materials, thickness, and the. Recommended center distance between holes in sheet metal part. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision cnc bending.

From www.walmart.com

BCLONG Pneumatic Straight Type Punch Air Flange Tool Auto Body Sheet Sheet Metal Center Hole When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision cnc bending. Manufacturing sheet metal parts up to ¼” (6.35mm) in thickness, but this tolerance mainly depends on the geometry of. Sheet Metal Center Hole.

From www.giangrandi.org

How to drill large holes in sheet metal Sheet Metal Center Hole When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Sheet metal hole punching is a common method to create a hole in a metal sheet. For bearing area (a), use product of the bolt. In real practice, the process of hole punching differs depending on the materials, thickness, and the. The recommended. Sheet Metal Center Hole.

From perforatedmetalsheet.com

Slotted Hole Perforated Metal Sheet Metal Center Hole When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision cnc bending. Sheet metal hole punching is a common method to create a hole in a metal sheet. Recommended center distance. Sheet Metal Center Hole.

From www.snowrobin.jp

18 Gauge Finish Staggered 0.125 Holes 12 Width 304 Stainless Steel Sheet Metal Center Hole Some features such as countersinks are doable but counter bores and other. Manufacturing sheet metal parts up to ¼” (6.35mm) in thickness, but this tolerance mainly depends on the geometry of the part. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Sheet metal hole punching is a common method to create. Sheet Metal Center Hole.

From www.snowrobin.jp

18 Gauge Finish Staggered 0.125 Holes 12 Width 304 Stainless Steel Sheet Metal Center Hole In real practice, the process of hole punching differs depending on the materials, thickness, and the. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision cnc bending. For bearing area (a), use product of the bolt. When considering sheet metal thickness, a single sheet with punches (holes). Sheet Metal Center Hole.

From www.walmart.com

Carbide Tipped 11/8Inch Hole Cutter1/8Inch Sheet Metal Sheet Metal Center Hole In real practice, the process of hole punching differs depending on the materials, thickness, and the. Some features such as countersinks are doable but counter bores and other. For bearing area (a), use product of the bolt. The recommended minimum distance between two hole centers in sheet. Sheet metal fabrication design guide with tips and best practices on designing sheet. Sheet Metal Center Hole.

From www.walmart.com

10Pcs Insert Bit Set Tool Screwdriver Insert Bits Sheet Metal Hole Saw Sheet Metal Center Hole When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. The recommended minimum distance between two hole centers in sheet. Recommended center distance between holes in sheet metal part. Manufacturing sheet metal parts up to ¼” (6.35mm) in thickness, but this tolerance mainly depends on the geometry of the part. Sheet metal fabrication. Sheet Metal Center Hole.

From price.com

304 Stainless Steel Perforated Sheet Perforated Metal Sheet Steel Sheet Metal Center Hole For bearing area (a), use product of the bolt. Recommended center distance between holes in sheet metal part. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision cnc bending. Manufacturing sheet metal parts up to ¼” (6.35mm) in thickness, but this tolerance mainly depends on the geometry. Sheet Metal Center Hole.

From ftplatinum.ae

BPF Flush Mount Black PLASTIC Sheet Metal Hole Plug for 1/4" to 2" Hole Sheet Metal Center Hole Recommended center distance between holes in sheet metal part. Sheet metal hole punching is a common method to create a hole in a metal sheet. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision cnc bending. Manufacturing sheet metal parts up to ¼” (6.35mm) in thickness, but. Sheet Metal Center Hole.

From www.csfabs.co.uk

Countersunk Holes in Sheet Metal C&S Fabrications Sheet Metal Center Hole Recommended center distance between holes in sheet metal part. Some features such as countersinks are doable but counter bores and other. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision cnc bending. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule. Sheet Metal Center Hole.

From www.walmart.com

BCLONG Pneumatic Straight Type Punch Air Flange Tool Auto Body Sheet Sheet Metal Center Hole When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Some features such as countersinks are doable but counter bores and other. The recommended minimum distance between two hole centers in sheet. In real practice, the process of hole punching differs depending on the materials, thickness, and the. For bearing area (a), use. Sheet Metal Center Hole.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Center Hole When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Manufacturing sheet metal parts up to ¼” (6.35mm) in thickness, but this tolerance mainly depends on the geometry of the part. Some features such as countersinks are doable but counter bores and other. The recommended minimum distance between two hole centers in sheet.. Sheet Metal Center Hole.

From ftplatinum.ae

3/4" Sheet Metal Hole Plugs Snap in Auto Body Hole Cover Black 1" Top Sheet Metal Center Hole Manufacturing sheet metal parts up to ¼” (6.35mm) in thickness, but this tolerance mainly depends on the geometry of the part. In real practice, the process of hole punching differs depending on the materials, thickness, and the. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision cnc. Sheet Metal Center Hole.

From www.familyhandyman.com

12 Tips for Drilling Holes in Metal — The Family Handyman Sheet Metal Center Hole The recommended minimum distance between two hole centers in sheet. Recommended center distance between holes in sheet metal part. Some features such as countersinks are doable but counter bores and other. Sheet metal hole punching is a common method to create a hole in a metal sheet. Manufacturing sheet metal parts up to ¼” (6.35mm) in thickness, but this tolerance. Sheet Metal Center Hole.

From www.aliexpress.com

155x38mmStainlessSteel2HolesFlatCornerBracePlateConnector Sheet Metal Center Hole Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision cnc bending. Manufacturing sheet metal parts up to ¼” (6.35mm) in thickness, but this tolerance mainly depends on the geometry of the part. Sheet metal hole punching is a common method to create a hole in a metal. Sheet Metal Center Hole.

From www.youtube.com

How to Cut a Round Hole in Sheet Metal with Tin Snips or avaiation Sheet Metal Center Hole Recommended center distance between holes in sheet metal part. Sheet metal hole punching is a common method to create a hole in a metal sheet. The recommended minimum distance between two hole centers in sheet. Some features such as countersinks are doable but counter bores and other. For bearing area (a), use product of the bolt. Sheet metal fabrication design. Sheet Metal Center Hole.

From www.giangrandi.org

How to drill large holes in sheet metal Sheet Metal Center Hole Sheet metal hole punching is a common method to create a hole in a metal sheet. Some features such as countersinks are doable but counter bores and other. For bearing area (a), use product of the bolt. The recommended minimum distance between two hole centers in sheet. Recommended center distance between holes in sheet metal part. When considering sheet metal. Sheet Metal Center Hole.

From www.scrapmonster.com

C1008/1010 Perforated Steel Sheet, Steel Finished Product Sheet Metal Center Hole Some features such as countersinks are doable but counter bores and other. For bearing area (a), use product of the bolt. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. In real practice, the process of hole punching differs depending on the materials, thickness, and the. Sheet metal hole punching is a. Sheet Metal Center Hole.

From themeshcompany.com

4mm Round Hole Mild Steel Perforated Metal Sheet With Holes 6mm Pitch Sheet Metal Center Hole Manufacturing sheet metal parts up to ¼” (6.35mm) in thickness, but this tolerance mainly depends on the geometry of the part. In real practice, the process of hole punching differs depending on the materials, thickness, and the. Recommended center distance between holes in sheet metal part. Some features such as countersinks are doable but counter bores and other. The recommended. Sheet Metal Center Hole.

From dogboxparts.com

Aluminum Perforated Sheet 1/8″ Thick,1/4″ Hole, 3/8″ Stagger, Various Sheet Metal Center Hole Some features such as countersinks are doable but counter bores and other. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. In real practice, the process of hole punching differs depending on the materials, thickness, and the. The recommended minimum distance between two hole centers in sheet. For bearing area (a), use. Sheet Metal Center Hole.

From www.shineyondmetal.com

Round Hole Expanded Metal Supply Sheet Metal Center Hole Sheet metal hole punching is a common method to create a hole in a metal sheet. Recommended center distance between holes in sheet metal part. Manufacturing sheet metal parts up to ¼” (6.35mm) in thickness, but this tolerance mainly depends on the geometry of the part. In real practice, the process of hole punching differs depending on the materials, thickness,. Sheet Metal Center Hole.

From www.youtube.com

How To EASILY Repair Holes In Aluminum YouTube Sheet Metal Center Hole Sheet metal hole punching is a common method to create a hole in a metal sheet. For bearing area (a), use product of the bolt. Recommended center distance between holes in sheet metal part. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision cnc bending. Manufacturing sheet. Sheet Metal Center Hole.

From www.bigstockphoto.com

Metal Plate Holes On Image & Photo (Free Trial) Bigstock Sheet Metal Center Hole Some features such as countersinks are doable but counter bores and other. In real practice, the process of hole punching differs depending on the materials, thickness, and the. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. The recommended minimum distance between two hole centers in sheet. Manufacturing sheet metal parts up. Sheet Metal Center Hole.

From www.jsmetalmesh.com

Slotted Hole Perforated Metal Sheet Metal Center Hole When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Recommended center distance between holes in sheet metal part. Some features such as countersinks are doable but counter bores and other. The recommended minimum distance between two hole centers in sheet. In real practice, the process of hole punching differs depending on the. Sheet Metal Center Hole.

From ftplatinum.ae

BPF Flush Mount Black PLASTIC Sheet Metal Hole Plug for 1/4" to 2" Hole Sheet Metal Center Hole Manufacturing sheet metal parts up to ¼” (6.35mm) in thickness, but this tolerance mainly depends on the geometry of the part. In real practice, the process of hole punching differs depending on the materials, thickness, and the. Recommended center distance between holes in sheet metal part. Some features such as countersinks are doable but counter bores and other. Sheet metal. Sheet Metal Center Hole.

From cocos.com.ar

Click now to browse 1/4 Holes on 3/8 Centers 11.8x11.8 304 Stainless Sheet Metal Center Hole In real practice, the process of hole punching differs depending on the materials, thickness, and the. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision cnc bending. Some features such. Sheet Metal Center Hole.

From www.youtube.com

How to Use a Center Punch (PreDrilling Operation) YouTube Sheet Metal Center Hole Sheet metal hole punching is a common method to create a hole in a metal sheet. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision cnc bending. Some features such as countersinks are doable but counter bores and other. Recommended center distance between holes in sheet metal. Sheet Metal Center Hole.

From www.walmart.com

(Pack of 25) BPF1 Flush Mount Black Plastic Body and Sheet Metal Hole Sheet Metal Center Hole Sheet metal hole punching is a common method to create a hole in a metal sheet. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. The recommended minimum distance between two hole centers in sheet. Some features such as countersinks are doable but counter bores and other. Recommended center distance between holes. Sheet Metal Center Hole.

From www.smlease.com

Sheet Metal Design Guidelines Design for Manufacturing Sheet Metal Center Hole Some features such as countersinks are doable but counter bores and other. The recommended minimum distance between two hole centers in sheet. Sheet metal hole punching is a common method to create a hole in a metal sheet. In real practice, the process of hole punching differs depending on the materials, thickness, and the. Recommended center distance between holes in. Sheet Metal Center Hole.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Center Hole Manufacturing sheet metal parts up to ¼” (6.35mm) in thickness, but this tolerance mainly depends on the geometry of the part. For bearing area (a), use product of the bolt. The recommended minimum distance between two hole centers in sheet. Sheet metal hole punching is a common method to create a hole in a metal sheet. Sheet metal fabrication design. Sheet Metal Center Hole.

From ftplatinum.ae

3/4" Sheet Metal Hole Plugs Snap in Auto Body Hole Cover Black 1" Top Sheet Metal Center Hole In real practice, the process of hole punching differs depending on the materials, thickness, and the. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Sheet metal hole punching is a common method to create a hole in a metal sheet. Manufacturing sheet metal parts up to ¼” (6.35mm) in thickness, but. Sheet Metal Center Hole.

From ftplatinum.ae

3/4" Sheet Metal Hole Plugs Snap in Auto Body Hole Cover Black 1" Top Sheet Metal Center Hole Recommended center distance between holes in sheet metal part. The recommended minimum distance between two hole centers in sheet. In real practice, the process of hole punching differs depending on the materials, thickness, and the. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision cnc bending. When. Sheet Metal Center Hole.

From www.walmart.com

(Pack of 25) BPF1 Flush Mount Black Plastic Body and Sheet Metal Hole Sheet Metal Center Hole The recommended minimum distance between two hole centers in sheet. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision cnc bending. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. Sheet metal hole punching is a common method to. Sheet Metal Center Hole.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success Sheet Metal Center Hole For bearing area (a), use product of the bolt. The recommended minimum distance between two hole centers in sheet. Some features such as countersinks are doable but counter bores and other. Sheet metal hole punching is a common method to create a hole in a metal sheet. Manufacturing sheet metal parts up to ¼” (6.35mm) in thickness, but this tolerance. Sheet Metal Center Hole.

From www.familyhandyman.com

12 Tips for Drilling Holes in Metal The Family Handyman Sheet Metal Center Hole Recommended center distance between holes in sheet metal part. When considering sheet metal thickness, a single sheet with punches (holes) is a good rule of thumb. In real practice, the process of hole punching differs depending on the materials, thickness, and the. Some features such as countersinks are doable but counter bores and other. Sheet metal fabrication design guide with. Sheet Metal Center Hole.