What Flux Do You Use For Brazing . Here's a crash course that explores the types of silver brazing flux we manufacture: This ensures a stronger bond between the two metals and prevents oxidation from occurring. Fluxes are either a white or black paste or white powder. The basics you should know; There are fluxes formulated for practically every need; Ever wonder about the different flux types and where each is used? For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. We use brazing flux to prevent air from entering the joint when brazing. Ferrous and nickel alloys can use two types of fluxes: The basics you should know;

from www.cruxweld.com

Fluxes are either a white or black paste or white powder. Ever wonder about the different flux types and where each is used? For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. Here's a crash course that explores the types of silver brazing flux we manufacture: This ensures a stronger bond between the two metals and prevents oxidation from occurring. There are fluxes formulated for practically every need; We use brazing flux to prevent air from entering the joint when brazing. Ferrous and nickel alloys can use two types of fluxes: The basics you should know; The basics you should know;

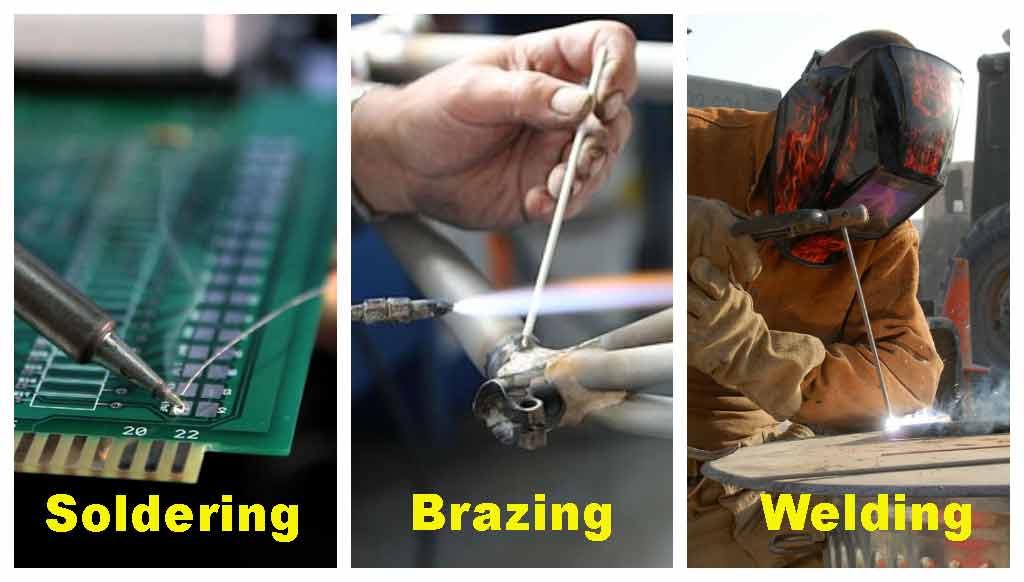

The Difference between Soldering and Brazing with Welding [The

What Flux Do You Use For Brazing This ensures a stronger bond between the two metals and prevents oxidation from occurring. For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. Here's a crash course that explores the types of silver brazing flux we manufacture: There are fluxes formulated for practically every need; The basics you should know; Fluxes are either a white or black paste or white powder. The basics you should know; Ever wonder about the different flux types and where each is used? This ensures a stronger bond between the two metals and prevents oxidation from occurring. We use brazing flux to prevent air from entering the joint when brazing. Ferrous and nickel alloys can use two types of fluxes:

From bridgwaterweldingsupplies.co.uk

Brazing Flux What Flux Do You Use For Brazing The basics you should know; Here's a crash course that explores the types of silver brazing flux we manufacture: We use brazing flux to prevent air from entering the joint when brazing. Fluxes are either a white or black paste or white powder. Ever wonder about the different flux types and where each is used? Ferrous and nickel alloys can. What Flux Do You Use For Brazing.

From dokumen.tips

(PDF) How to Select a Brazing Flux · 2020. 1. 3. · per AWS Brazing What Flux Do You Use For Brazing Here's a crash course that explores the types of silver brazing flux we manufacture: Ever wonder about the different flux types and where each is used? Ferrous and nickel alloys can use two types of fluxes: There are fluxes formulated for practically every need; Fluxes are either a white or black paste or white powder. This ensures a stronger bond. What Flux Do You Use For Brazing.

From www.castolin.com

Paste flux for braze welding with Brazing Alloy 18. Brass/ Bronze flux What Flux Do You Use For Brazing For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. The basics you should know; Ever wonder about the different flux types and where each is used? Here's a crash course that explores the types of silver brazing flux we manufacture: Fluxes are either a white or black paste or. What Flux Do You Use For Brazing.

From www.cashbuildonline.co.za

Brazing Flux Cashbuild What Flux Do You Use For Brazing Ever wonder about the different flux types and where each is used? Ferrous and nickel alloys can use two types of fluxes: There are fluxes formulated for practically every need; The basics you should know; The basics you should know; This ensures a stronger bond between the two metals and prevents oxidation from occurring. For manual torch brazing applications, welding. What Flux Do You Use For Brazing.

From breakthroughblacksmithing.wordpress.com

The Strength of Paste Brazing A Modern Solution for Stronger Joints What Flux Do You Use For Brazing Ferrous and nickel alloys can use two types of fluxes: Here's a crash course that explores the types of silver brazing flux we manufacture: Ever wonder about the different flux types and where each is used? For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. We use brazing flux. What Flux Do You Use For Brazing.

From weldingpros.net

Brazing Filler Metals And Fluxes Explained In Detail What Flux Do You Use For Brazing This ensures a stronger bond between the two metals and prevents oxidation from occurring. The basics you should know; We use brazing flux to prevent air from entering the joint when brazing. For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. Ever wonder about the different flux types and. What Flux Do You Use For Brazing.

From www.thewelderswarehouse.com

500g Brazing Flux for most Grades of Brazing Alloys What Flux Do You Use For Brazing Ever wonder about the different flux types and where each is used? We use brazing flux to prevent air from entering the joint when brazing. The basics you should know; For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. Fluxes are either a white or black paste or white. What Flux Do You Use For Brazing.

From www.hobbyistgeek.com

What Is Brazing Flux And How To Use It? What Flux Do You Use For Brazing We use brazing flux to prevent air from entering the joint when brazing. There are fluxes formulated for practically every need; Ferrous and nickel alloys can use two types of fluxes: Ever wonder about the different flux types and where each is used? For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three. What Flux Do You Use For Brazing.

From shahab-co.com

What is Induction brazing Brazing uses heat and a filler metal (alloy What Flux Do You Use For Brazing The basics you should know; The basics you should know; This ensures a stronger bond between the two metals and prevents oxidation from occurring. We use brazing flux to prevent air from entering the joint when brazing. For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. Ferrous and nickel. What Flux Do You Use For Brazing.

From rosipinkqq.blogspot.com

Brazing Copper To Brass / Copper Nickel Brazing Unified Engineering What Flux Do You Use For Brazing Here's a crash course that explores the types of silver brazing flux we manufacture: Ever wonder about the different flux types and where each is used? Ferrous and nickel alloys can use two types of fluxes: For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. The basics you should. What Flux Do You Use For Brazing.

From www.cruxweld.com

The Difference between Soldering and Brazing with Welding [The What Flux Do You Use For Brazing Ever wonder about the different flux types and where each is used? For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. Ferrous and nickel alloys can use two types of fluxes: There are fluxes formulated for practically every need; The basics you should know; We use brazing flux to. What Flux Do You Use For Brazing.

From www.hobbyistgeek.com

How Do You Remove Flux After Brazing? “A Time Saver’’ What Flux Do You Use For Brazing The basics you should know; This ensures a stronger bond between the two metals and prevents oxidation from occurring. For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. The basics you should know; Fluxes are either a white or black paste or white powder. Here's a crash course that. What Flux Do You Use For Brazing.

From www.youtube.com

Brazing 101. How to braze copper to steel. Heating and air school What Flux Do You Use For Brazing For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. Fluxes are either a white or black paste or white powder. The basics you should know; There are fluxes formulated for practically every need; Here's a crash course that explores the types of silver brazing flux we manufacture: Ferrous and. What Flux Do You Use For Brazing.

From www.youtube.com

Brazing Process Animation YouTube What Flux Do You Use For Brazing The basics you should know; There are fluxes formulated for practically every need; For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. We use brazing flux to prevent air from entering the joint when brazing. Ever wonder about the different flux types and where each is used? The basics. What Flux Do You Use For Brazing.

From www.hobbyistgeek.com

What Is Brazing Flux And How To Use It? What Flux Do You Use For Brazing The basics you should know; There are fluxes formulated for practically every need; For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. Ever wonder about the different flux types and where each is used? The basics you should know; Ferrous and nickel alloys can use two types of fluxes:. What Flux Do You Use For Brazing.

From blog.thepipingmart.com

What is Brazing Fluxes? Uses and Working What Flux Do You Use For Brazing This ensures a stronger bond between the two metals and prevents oxidation from occurring. Ferrous and nickel alloys can use two types of fluxes: The basics you should know; Here's a crash course that explores the types of silver brazing flux we manufacture: Fluxes are either a white or black paste or white powder. The basics you should know; We. What Flux Do You Use For Brazing.

From engineeringlearner.com

Types of Brazing Definition, Principle, Applications, Advantages What Flux Do You Use For Brazing For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. Fluxes are either a white or black paste or white powder. Ever wonder about the different flux types and where each is used? This ensures a stronger bond between the two metals and prevents oxidation from occurring. The basics you. What Flux Do You Use For Brazing.

From www.youtube.com

How to Braze Copper to Steel with Handy One® YouTube What Flux Do You Use For Brazing Ever wonder about the different flux types and where each is used? The basics you should know; Ferrous and nickel alloys can use two types of fluxes: Here's a crash course that explores the types of silver brazing flux we manufacture: This ensures a stronger bond between the two metals and prevents oxidation from occurring. There are fluxes formulated for. What Flux Do You Use For Brazing.

From www.youtube.com

Brazing Copper to Brass with SilFos® YouTube What Flux Do You Use For Brazing Ever wonder about the different flux types and where each is used? Here's a crash course that explores the types of silver brazing flux we manufacture: For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. The basics you should know; Fluxes are either a white or black paste or. What Flux Do You Use For Brazing.

From www.youtube.com

Brazing Copper to Copper with SilFos® YouTube What Flux Do You Use For Brazing There are fluxes formulated for practically every need; This ensures a stronger bond between the two metals and prevents oxidation from occurring. The basics you should know; The basics you should know; Fluxes are either a white or black paste or white powder. Ever wonder about the different flux types and where each is used? Here's a crash course that. What Flux Do You Use For Brazing.

From dir.indiamart.com

Brass Brazing Fluxes at Best Price in India What Flux Do You Use For Brazing The basics you should know; This ensures a stronger bond between the two metals and prevents oxidation from occurring. Ever wonder about the different flux types and where each is used? For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. There are fluxes formulated for practically every need; Here's. What Flux Do You Use For Brazing.

From www.youtube.com

SOLDERING ,BRAZING AND BRAZE WELDING YouTube What Flux Do You Use For Brazing The basics you should know; Ever wonder about the different flux types and where each is used? There are fluxes formulated for practically every need; We use brazing flux to prevent air from entering the joint when brazing. Fluxes are either a white or black paste or white powder. Ferrous and nickel alloys can use two types of fluxes: The. What Flux Do You Use For Brazing.

From dir.indiamart.com

Brass Brazing Fluxes at Best Price in India What Flux Do You Use For Brazing Ever wonder about the different flux types and where each is used? The basics you should know; There are fluxes formulated for practically every need; The basics you should know; We use brazing flux to prevent air from entering the joint when brazing. Here's a crash course that explores the types of silver brazing flux we manufacture: For manual torch. What Flux Do You Use For Brazing.

From ar.inspiredpencil.com

Soldering What Flux Do You Use For Brazing We use brazing flux to prevent air from entering the joint when brazing. There are fluxes formulated for practically every need; For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. Here's a crash course that explores the types of silver brazing flux we manufacture: Fluxes are either a white. What Flux Do You Use For Brazing.

From yamaha-ls3.blogspot.com

Restoration Yamaha LS3 1972 Brazing fuel tank and fork ears What Flux Do You Use For Brazing This ensures a stronger bond between the two metals and prevents oxidation from occurring. Ferrous and nickel alloys can use two types of fluxes: The basics you should know; Fluxes are either a white or black paste or white powder. The basics you should know; For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys. What Flux Do You Use For Brazing.

From blog.thepipingmart.com

Brazing Flux vs Soldering Flux What's the Difference What Flux Do You Use For Brazing Ferrous and nickel alloys can use two types of fluxes: The basics you should know; There are fluxes formulated for practically every need; For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. We use brazing flux to prevent air from entering the joint when brazing. This ensures a stronger. What Flux Do You Use For Brazing.

From dynaweld.com.au

Bossweld Universal Copper and Brass Flux What Flux Do You Use For Brazing Fluxes are either a white or black paste or white powder. There are fluxes formulated for practically every need; Ferrous and nickel alloys can use two types of fluxes: Here's a crash course that explores the types of silver brazing flux we manufacture: Ever wonder about the different flux types and where each is used? We use brazing flux to. What Flux Do You Use For Brazing.

From weldcote.com

brazing flux white anti borax fluxes Weldcote Welding For WellBeing What Flux Do You Use For Brazing We use brazing flux to prevent air from entering the joint when brazing. Here's a crash course that explores the types of silver brazing flux we manufacture: The basics you should know; Fluxes are either a white or black paste or white powder. Ferrous and nickel alloys can use two types of fluxes: There are fluxes formulated for practically every. What Flux Do You Use For Brazing.

From www.walmart.com

Brazing Flux Powder, 8Ounce What Flux Do You Use For Brazing Fluxes are either a white or black paste or white powder. The basics you should know; This ensures a stronger bond between the two metals and prevents oxidation from occurring. For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. Ever wonder about the different flux types and where each. What Flux Do You Use For Brazing.

From www.hobbyistgeek.com

What Is Brazing Flux And How To Use It? What Flux Do You Use For Brazing Fluxes are either a white or black paste or white powder. There are fluxes formulated for practically every need; Here's a crash course that explores the types of silver brazing flux we manufacture: The basics you should know; For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. The basics. What Flux Do You Use For Brazing.

From shopee.ph

Borax Brazing Flux 450g Shopee Philippines What Flux Do You Use For Brazing Fluxes are either a white or black paste or white powder. Ferrous and nickel alloys can use two types of fluxes: This ensures a stronger bond between the two metals and prevents oxidation from occurring. Here's a crash course that explores the types of silver brazing flux we manufacture: The basics you should know; The basics you should know; There. What Flux Do You Use For Brazing.

From www.youtube.com

When to use Flux ? YouTube What Flux Do You Use For Brazing Ferrous and nickel alloys can use two types of fluxes: For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. The basics you should know; There are fluxes formulated for practically every need; We use brazing flux to prevent air from entering the joint when brazing. Here's a crash course. What Flux Do You Use For Brazing.

From www.youtube.com

What is Solder Flux and How to Use It YouTube What Flux Do You Use For Brazing Fluxes are either a white or black paste or white powder. The basics you should know; For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. There are fluxes formulated for practically every need; Here's a crash course that explores the types of silver brazing flux we manufacture: The basics. What Flux Do You Use For Brazing.

From www.itagas.eu

Brazing Flux 150gr ITAGAS Condizionamento e Refrigerazione Made in What Flux Do You Use For Brazing This ensures a stronger bond between the two metals and prevents oxidation from occurring. The basics you should know; Ferrous and nickel alloys can use two types of fluxes: For manual torch brazing applications, welding distributors typically handle four families of filler metal alloys and three types of flux. The basics you should know; Fluxes are either a white or. What Flux Do You Use For Brazing.

From exouthzlp.blob.core.windows.net

Copper Brazing Wire at Salvador Lane blog What Flux Do You Use For Brazing Ferrous and nickel alloys can use two types of fluxes: This ensures a stronger bond between the two metals and prevents oxidation from occurring. The basics you should know; The basics you should know; We use brazing flux to prevent air from entering the joint when brazing. Fluxes are either a white or black paste or white powder. There are. What Flux Do You Use For Brazing.