How To Measure Tool Life . Actual cutting time to failure. Active tool life monitoring can allow you to gain more value from your tool and cnc machine. Tool life monitoring (cutting edge durability) the tool life can be expressed in different ways: But there’s a way to switch to a new tool while your cnc machine is running, and this is true tool life management. There are several ways to measure, quantify, and track your tool health. The formula for tool life typically takes the form of: Discover how spindle runout affects your cnc tool life and how to measure and fix it. Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of cut (d)) with variations depending on specific applications and tool wear models. Get expert tips and techniques to optimize your machining process. To help with this, i offer a custom macro that monitors the amount of time or number of parts a cutting tool machines before it gets.

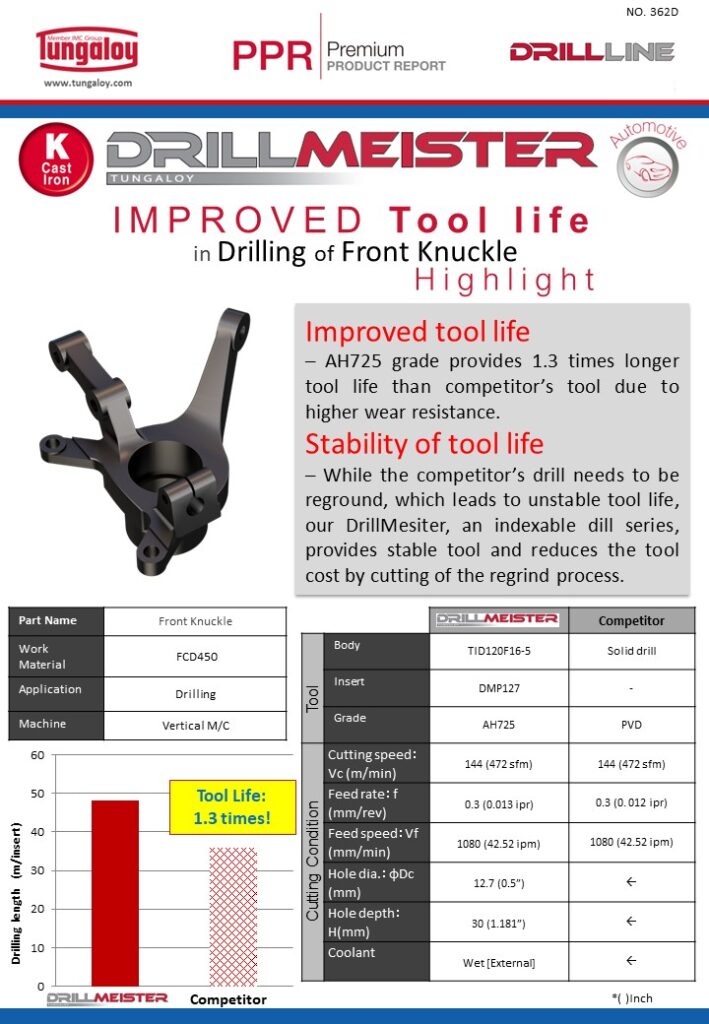

from tungaloy.com

But there’s a way to switch to a new tool while your cnc machine is running, and this is true tool life management. Discover how spindle runout affects your cnc tool life and how to measure and fix it. Actual cutting time to failure. Active tool life monitoring can allow you to gain more value from your tool and cnc machine. The formula for tool life typically takes the form of: Tool life monitoring (cutting edge durability) the tool life can be expressed in different ways: Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of cut (d)) with variations depending on specific applications and tool wear models. There are several ways to measure, quantify, and track your tool health. To help with this, i offer a custom macro that monitors the amount of time or number of parts a cutting tool machines before it gets. Get expert tips and techniques to optimize your machining process.

Examples of extended tool life with DrillMeister Hole making

How To Measure Tool Life Active tool life monitoring can allow you to gain more value from your tool and cnc machine. The formula for tool life typically takes the form of: To help with this, i offer a custom macro that monitors the amount of time or number of parts a cutting tool machines before it gets. There are several ways to measure, quantify, and track your tool health. But there’s a way to switch to a new tool while your cnc machine is running, and this is true tool life management. Get expert tips and techniques to optimize your machining process. Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of cut (d)) with variations depending on specific applications and tool wear models. Active tool life monitoring can allow you to gain more value from your tool and cnc machine. Discover how spindle runout affects your cnc tool life and how to measure and fix it. Tool life monitoring (cutting edge durability) the tool life can be expressed in different ways: Actual cutting time to failure.

From www.studocu.com

Tool Wear, Tool Life and Machinability Ways of measuring tool life No How To Measure Tool Life The formula for tool life typically takes the form of: To help with this, i offer a custom macro that monitors the amount of time or number of parts a cutting tool machines before it gets. Tool life monitoring (cutting edge durability) the tool life can be expressed in different ways: Tool life (t) = constant (c) / (cutting speed. How To Measure Tool Life.

From www.electrician-1.com

25 Types of Measuring Instruments and Their Uses electrical and How To Measure Tool Life Discover how spindle runout affects your cnc tool life and how to measure and fix it. Active tool life monitoring can allow you to gain more value from your tool and cnc machine. Actual cutting time to failure. Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of cut (d)) with variations depending. How To Measure Tool Life.

From www.researchgate.net

Tool life data for eight inserts Download Table How To Measure Tool Life Get expert tips and techniques to optimize your machining process. But there’s a way to switch to a new tool while your cnc machine is running, and this is true tool life management. Tool life monitoring (cutting edge durability) the tool life can be expressed in different ways: There are several ways to measure, quantify, and track your tool health.. How To Measure Tool Life.

From www.youtube.com

TAYLOR'S TOOL LIFE EQUATION TOOL LIFE EFFECT ON TOOL LIFE YouTube How To Measure Tool Life There are several ways to measure, quantify, and track your tool health. The formula for tool life typically takes the form of: Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of cut (d)) with variations depending on specific applications and tool wear models. Discover how spindle runout affects your cnc tool life. How To Measure Tool Life.

From encyclopedia.pub

Remaining Tool Life Prediction Encyclopedia MDPI How To Measure Tool Life The formula for tool life typically takes the form of: There are several ways to measure, quantify, and track your tool health. To help with this, i offer a custom macro that monitors the amount of time or number of parts a cutting tool machines before it gets. Actual cutting time to failure. Tool life monitoring (cutting edge durability) the. How To Measure Tool Life.

From tungaloy.com

Examples of extended tool life with DrillMeister Hole making How To Measure Tool Life Discover how spindle runout affects your cnc tool life and how to measure and fix it. The formula for tool life typically takes the form of: Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of cut (d)) with variations depending on specific applications and tool wear models. To help with this, i. How To Measure Tool Life.

From www.numerical.minaprem.com

Taylor’s Tool Life Formula for Machining How To Measure Tool Life To help with this, i offer a custom macro that monitors the amount of time or number of parts a cutting tool machines before it gets. But there’s a way to switch to a new tool while your cnc machine is running, and this is true tool life management. The formula for tool life typically takes the form of: Get. How To Measure Tool Life.

From canadianwoodworking.com

Measuring Tools Canadian Woodworking How To Measure Tool Life Actual cutting time to failure. But there’s a way to switch to a new tool while your cnc machine is running, and this is true tool life management. To help with this, i offer a custom macro that monitors the amount of time or number of parts a cutting tool machines before it gets. Active tool life monitoring can allow. How To Measure Tool Life.

From www.researchgate.net

Tool life depends upon various factors. Download Scientific Diagram How To Measure Tool Life But there’s a way to switch to a new tool while your cnc machine is running, and this is true tool life management. Actual cutting time to failure. The formula for tool life typically takes the form of: To help with this, i offer a custom macro that monitors the amount of time or number of parts a cutting tool. How To Measure Tool Life.

From www.researchgate.net

Feed and depth of cut effects on toollife in machining with grooved How To Measure Tool Life To help with this, i offer a custom macro that monitors the amount of time or number of parts a cutting tool machines before it gets. But there’s a way to switch to a new tool while your cnc machine is running, and this is true tool life management. Actual cutting time to failure. Tool life (t) = constant (c). How To Measure Tool Life.

From www.researchgate.net

Turning tool life tests parameters. Download Table How To Measure Tool Life Actual cutting time to failure. Get expert tips and techniques to optimize your machining process. Tool life monitoring (cutting edge durability) the tool life can be expressed in different ways: To help with this, i offer a custom macro that monitors the amount of time or number of parts a cutting tool machines before it gets. Active tool life monitoring. How To Measure Tool Life.

From honsaaerospace.com

How to Maximize Tool Life Honsa Aerospace How To Measure Tool Life Actual cutting time to failure. Active tool life monitoring can allow you to gain more value from your tool and cnc machine. Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of cut (d)) with variations depending on specific applications and tool wear models. There are several ways to measure, quantify, and track. How To Measure Tool Life.

From www.theengineerspost.com

16 Different Types of Measuring Tools and Their Uses [PDF] How To Measure Tool Life To help with this, i offer a custom macro that monitors the amount of time or number of parts a cutting tool machines before it gets. Active tool life monitoring can allow you to gain more value from your tool and cnc machine. There are several ways to measure, quantify, and track your tool health. But there’s a way to. How To Measure Tool Life.

From www.slideshare.net

TOOL LIFE TEST How To Measure Tool Life Tool life monitoring (cutting edge durability) the tool life can be expressed in different ways: To help with this, i offer a custom macro that monitors the amount of time or number of parts a cutting tool machines before it gets. There are several ways to measure, quantify, and track your tool health. But there’s a way to switch to. How To Measure Tool Life.

From www.chegg.com

Solved Example 2 Taylor Tool Life equation is given by How To Measure Tool Life Get expert tips and techniques to optimize your machining process. Active tool life monitoring can allow you to gain more value from your tool and cnc machine. There are several ways to measure, quantify, and track your tool health. To help with this, i offer a custom macro that monitors the amount of time or number of parts a cutting. How To Measure Tool Life.

From www.rigpl.com

Rohit Cutting Tools Machinability & Machinability Rating How To Measure Tool Life Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of cut (d)) with variations depending on specific applications and tool wear models. Tool life monitoring (cutting edge durability) the tool life can be expressed in different ways: Get expert tips and techniques to optimize your machining process. Actual cutting time to failure. There. How To Measure Tool Life.

From www.researchgate.net

Typical tool life curves Download Scientific Diagram How To Measure Tool Life The formula for tool life typically takes the form of: There are several ways to measure, quantify, and track your tool health. Get expert tips and techniques to optimize your machining process. Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of cut (d)) with variations depending on specific applications and tool wear. How To Measure Tool Life.

From www.slideserve.com

PPT Application of measurements in daily life PowerPoint Presentation How To Measure Tool Life Get expert tips and techniques to optimize your machining process. Discover how spindle runout affects your cnc tool life and how to measure and fix it. Actual cutting time to failure. There are several ways to measure, quantify, and track your tool health. Tool life monitoring (cutting edge durability) the tool life can be expressed in different ways: Tool life. How To Measure Tool Life.

From www.slideserve.com

PPT Application of measurements in daily life PowerPoint Presentation How To Measure Tool Life To help with this, i offer a custom macro that monitors the amount of time or number of parts a cutting tool machines before it gets. Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of cut (d)) with variations depending on specific applications and tool wear models. Get expert tips and techniques. How To Measure Tool Life.

From slideplayer.com

Tool Wear, Tool life & Machinability ppt download How To Measure Tool Life Active tool life monitoring can allow you to gain more value from your tool and cnc machine. The formula for tool life typically takes the form of: Actual cutting time to failure. Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of cut (d)) with variations depending on specific applications and tool wear. How To Measure Tool Life.

From www.youtube.com

Tool life and factor affecting tool life in hindi YouTube How To Measure Tool Life There are several ways to measure, quantify, and track your tool health. Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of cut (d)) with variations depending on specific applications and tool wear models. The formula for tool life typically takes the form of: Get expert tips and techniques to optimize your machining. How To Measure Tool Life.

From entagalex.blogspot.com

Production Engineering TOOL LIFE How To Measure Tool Life Active tool life monitoring can allow you to gain more value from your tool and cnc machine. Discover how spindle runout affects your cnc tool life and how to measure and fix it. Get expert tips and techniques to optimize your machining process. Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of. How To Measure Tool Life.

From www.scribd.com

Tool Wear and Tool Life PDF Wear Machining How To Measure Tool Life Tool life monitoring (cutting edge durability) the tool life can be expressed in different ways: Get expert tips and techniques to optimize your machining process. Discover how spindle runout affects your cnc tool life and how to measure and fix it. Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of cut (d)). How To Measure Tool Life.

From www.researchgate.net

Feed and depth of cut effects on toollife in machining with grooved How To Measure Tool Life The formula for tool life typically takes the form of: To help with this, i offer a custom macro that monitors the amount of time or number of parts a cutting tool machines before it gets. Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of cut (d)) with variations depending on specific. How To Measure Tool Life.

From www.youtube.com

TOOL LIFE Taylor's Tool Life Equation Factor Affecting Tool Life How To Measure Tool Life The formula for tool life typically takes the form of: But there’s a way to switch to a new tool while your cnc machine is running, and this is true tool life management. Tool life monitoring (cutting edge durability) the tool life can be expressed in different ways: There are several ways to measure, quantify, and track your tool health.. How To Measure Tool Life.

From present5.com

Lecture 7 Machining Tool Life Wear and Failure How To Measure Tool Life Actual cutting time to failure. Get expert tips and techniques to optimize your machining process. The formula for tool life typically takes the form of: Active tool life monitoring can allow you to gain more value from your tool and cnc machine. But there’s a way to switch to a new tool while your cnc machine is running, and this. How To Measure Tool Life.

From engineeringlearn.com

25 Types of Measuring Instruments and Their Uses [with Pictures & Names How To Measure Tool Life Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of cut (d)) with variations depending on specific applications and tool wear models. The formula for tool life typically takes the form of: Tool life monitoring (cutting edge durability) the tool life can be expressed in different ways: There are several ways to measure,. How To Measure Tool Life.

From www.numerical.minaprem.com

Calculate value of index in Taylor’s Tool Life equation in machining How To Measure Tool Life To help with this, i offer a custom macro that monitors the amount of time or number of parts a cutting tool machines before it gets. Discover how spindle runout affects your cnc tool life and how to measure and fix it. Tool life monitoring (cutting edge durability) the tool life can be expressed in different ways: The formula for. How To Measure Tool Life.

From study.com

Measurement Lesson for Kids Lesson How To Measure Tool Life Tool life monitoring (cutting edge durability) the tool life can be expressed in different ways: Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of cut (d)) with variations depending on specific applications and tool wear models. To help with this, i offer a custom macro that monitors the amount of time or. How To Measure Tool Life.

From entagalex.blogspot.com

TOOL LIFE Mechanical engineering How To Measure Tool Life Active tool life monitoring can allow you to gain more value from your tool and cnc machine. To help with this, i offer a custom macro that monitors the amount of time or number of parts a cutting tool machines before it gets. Tool life monitoring (cutting edge durability) the tool life can be expressed in different ways: The formula. How To Measure Tool Life.

From www.researchgate.net

Setup for tool life test Download Scientific Diagram How To Measure Tool Life Active tool life monitoring can allow you to gain more value from your tool and cnc machine. Discover how spindle runout affects your cnc tool life and how to measure and fix it. Get expert tips and techniques to optimize your machining process. There are several ways to measure, quantify, and track your tool health. Tool life (t) = constant. How To Measure Tool Life.

From tungaloy.com

Examples of extended tool life with DrillMeister Hole making How To Measure Tool Life But there’s a way to switch to a new tool while your cnc machine is running, and this is true tool life management. Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of cut (d)) with variations depending on specific applications and tool wear models. Active tool life monitoring can allow you to. How To Measure Tool Life.

From www.pinterest.com

Measuring devices.pdf Google Drive Life skills classroom, Life How To Measure Tool Life But there’s a way to switch to a new tool while your cnc machine is running, and this is true tool life management. Actual cutting time to failure. Discover how spindle runout affects your cnc tool life and how to measure and fix it. Tool life monitoring (cutting edge durability) the tool life can be expressed in different ways: There. How To Measure Tool Life.

From www.machinemetrics.com

What is Tool Life? How to Optimize Tooling with Machine Data How To Measure Tool Life To help with this, i offer a custom macro that monitors the amount of time or number of parts a cutting tool machines before it gets. Actual cutting time to failure. Tool life (t) = constant (c) / (cutting speed (v) * feed rate (f) * depth of cut (d)) with variations depending on specific applications and tool wear models.. How To Measure Tool Life.

From www.researchgate.net

Typical tool life curves Download Scientific Diagram How To Measure Tool Life Discover how spindle runout affects your cnc tool life and how to measure and fix it. Tool life monitoring (cutting edge durability) the tool life can be expressed in different ways: There are several ways to measure, quantify, and track your tool health. The formula for tool life typically takes the form of: Tool life (t) = constant (c) /. How To Measure Tool Life.